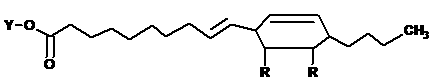

Method for preparing nonane diacid and biomass diesel from tung oil

A technology for biomass diesel and azelaic acid is applied in chemical instruments and methods, ozonation to prepare carboxylic acid, fatty acid production, etc., which can solve the problems of high condition requirements, complex process and high process cost, and achieves environmental protection in the form of oxidation. The effect of high product yield and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

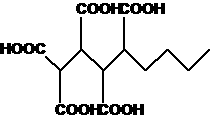

[0051] (1) Take 100g of tung oil and react with 33.3g of maleic anhydride Diels-Alder. The light yellow tung oil comes from the oil extracted from the three-year-old tung tree in Sichuan and Chongqing. The iodine value is 171, and the unsaturated acid content is 94.8. %, of which the content of α-tung acid is 80%, the content of oleic acid is 5.4%, the content of linoleic acid is 7.8%, the content of linolenic acid is 0.98%, and the content of arachidic acid is 0.62%; according to the content of α-tung acid in tung oil The molar ratio of tung oil to dienophilic monomer is determined to be 1:2.45, the reaction temperature is 60°C, the catalyst is 0.1%, the reaction time is 1h, and the dienophilic adduct of tung oil is obtained.

[0052] (2) Oxidation reaction: Dissolve tung oil and dienophilic monomer M through Diels-Alder reaction adduct raw material in 500 g of 15% acetic acid solvent, stir at high speed for 20 minutes in a reactor at 20°C, add 50 g of distilled water And con...

Embodiment 2

[0056] (1) Take 100g tung oil and 33.3g Diels-Alder reaction addition of acrylic acid. The light yellow tung oil comes from the oil extracted from the three-year-old tung tree in Southwest China. The iodine value is 175 and the unsaturated acid content is 95.2%. The content of α-tung acid is 80.2%, the content of oleic acid is 5.4%, the content of linoleic acid is 7.9%, the content of linolenic acid is 1.05%, and the content of arachidic acid is 0.65%; according to the content of α-tung acid and linolenic acid in tung oil Trienoic acid content determination The molar ratio of tung oil to dienophilic monomer is preferably 1:2.45, the reaction temperature is 120°C, the catalyst is 0.3%, and the polymerization inhibitor hydroquinone with a mass fraction of acrylic acid of 0.4% is added, and the reaction time is 2.5 h, to obtain tung oil dienophile adduct.

[0057] (2) Oxidation reaction: Dissolve tung oil and dienophilic monomer M through Diels-Alder reaction adduct raw material in...

Embodiment 3

[0061] (1) Take 100g of tung oil and react with 33.3g of maleic anhydride Diels-Alder. The raw material light yellow tung oil comes from the oil extracted from the three-year-old tung tree in central China. Its iodine value is 169 and its unsaturated acid content is 93.3%. α-The content of oleic acid is 75.4%, the content of oleic acid is 7.8%, the content of linoleic acid is 8.45%, the content of linolenic acid is 0.9%, and the content of arachidienoic acid is 0.75%; the reaction temperature is 180 ° C, the catalyst is 0.5%, and the reaction After 4 hours, tung oil dienophilic adducts were obtained.

[0062] (2) Oxidation reaction: Dissolve tung oil and dienophilic monomer M through Diels-Alder reaction adduct raw material in 500 g of 15% acetic acid solvent, stir at high speed in a reaction kettle at 20 °C for 20 minutes, add 50 g of distilled water and continue to stir at high speed, then add 0.5% of tung oil raw material weight 2,2,6,6-tetramethylpiperidine nitroxide radic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com