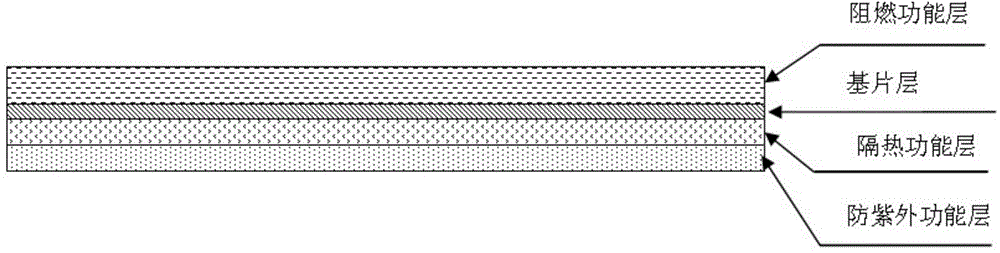

Transparent, flame-retardant, thermal-insulation and anti-ultraviolet polymer composite film as well as preparation method and application thereof

A high-molecular polymer and anti-ultraviolet technology, which can be used in other household appliances, chemical instruments and methods, applications, etc., can solve the problems of low transmittance of visible light, high processing and production costs, and no absorption in the infrared region.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] (1) Nano magnesium hydroxide (Mg(OH) 2 ) nanoparticles dispersed in toluene to form 2 transparent dispersion; the above containing Mg (OH) 2 Mix the transparent dispersion liquid with PDMS and additives or a solution of a certain concentration to obtain a film-forming stock solution. Mg(OH) in this step 2 The mass ratio with PDMS is about 30:70.

[0082] Disperse nano indium tin oxide (ITO) into an appropriate amount of ethanol to form a transparent dispersion containing ITO; fully stir the above transparent dispersion containing ITO with polyvinyl butyral (PVB) and additives to obtain heat insulation function layer of film-forming stock solution. The mass ratio of each main component in this step is ITO:PVB:auxiliary agent=5:75:20.

[0083] Disperse the ZnO nanoparticles into an appropriate amount of ethanol to form a transparent dispersion containing the ZnO nanoparticles. Fully mixing the transparent dispersion liquid containing ZnO nanoparticles and polyvinyl ...

Embodiment 2

[0088] (1) 30 parts of nano-aluminum hydroxide (Al(OH) 3 ) dispersed in toluene to form Al(OH) 3 transparent dispersion. The above containing Al(OH) 3 Mix the transparent dispersion liquid with PDMS and an appropriate amount of additives to obtain a film-forming stock solution. Al(OH) in this step 3 The mass ratio with PDMS is about 30:70.

[0089] LaB 6 Nanoparticles were dispersed into an appropriate amount of ethanol to form a LaB-containing 6 Transparent dispersion of nanoparticles. will contain LaB 6 The transparent dispersion liquid of nanoparticles, polyvinyl butyral (PVB) and additives are evenly mixed to obtain the film-forming stock solution of the heat-insulating functional layer. The mass ratio of each main component in this step is LaB 6 :PVB:auxiliary=5:75:20.

[0090] Disperse ZnO nanoparticles into a certain amount of ethanol to form a transparent dispersion containing ZnO nanoparticles. The transparent dispersion liquid containing ZnO nanoparticles ...

Embodiment 3

[0095] (1) Mg(OH) 2 Nanoparticles dispersed in toluene to form Mg(OH)-containing 2 transparent dispersion; will contain Mg(OH) 2 The transparent dispersion liquid, polytrimethylene terephthalate and additives are uniformly mixed to obtain the film-forming film-forming stock solution of the flame-retardant functional layer. Mg(OH) in this step 2 The mass ratio with PDMS is about 40:60.

[0096] A mixture of ITO and ATO (ITO:ATO=w1:w2=1:1) was dispersed into a certain amount of ethanol to form a transparent dispersion containing ITO and ATO nanoparticles. Mix the transparent dispersion containing ITO and ATO nanoparticles with PVB and an appropriate amount of additives to obtain the film-forming stock solution of the heat-insulating functional layer. The mass ratio of each main component in this step is (ITO and ATO):PVB:auxiliary agent=5:75:20.

[0097] Disperse ZnO nanoparticles into a certain amount of ethanol to form a transparent dispersion containing ZnO nanoparticles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com