Biomass boiler for boiler front flue gas drying and continuous bale combustion

A biomass boiler and drying technology, applied in the direction of climate sustainability, combustion methods, combustion equipment, etc., to reduce grate corrosion, reduce moisture, and prevent coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

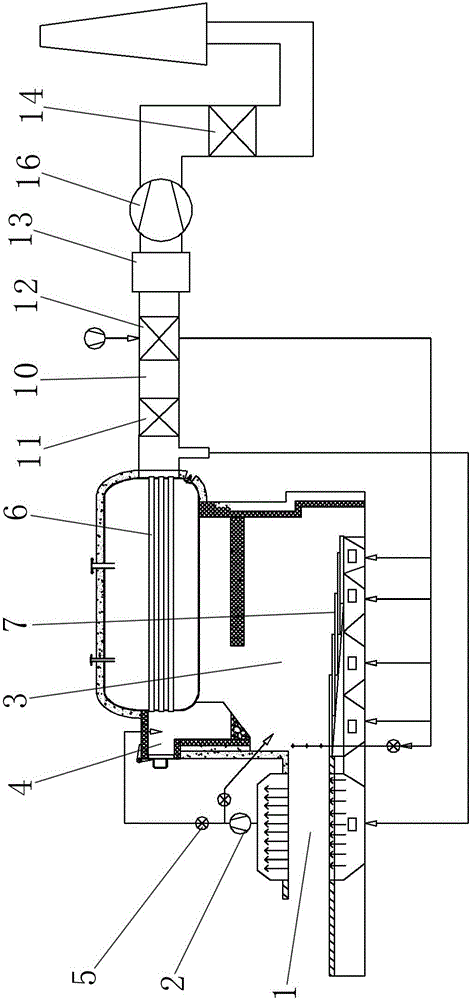

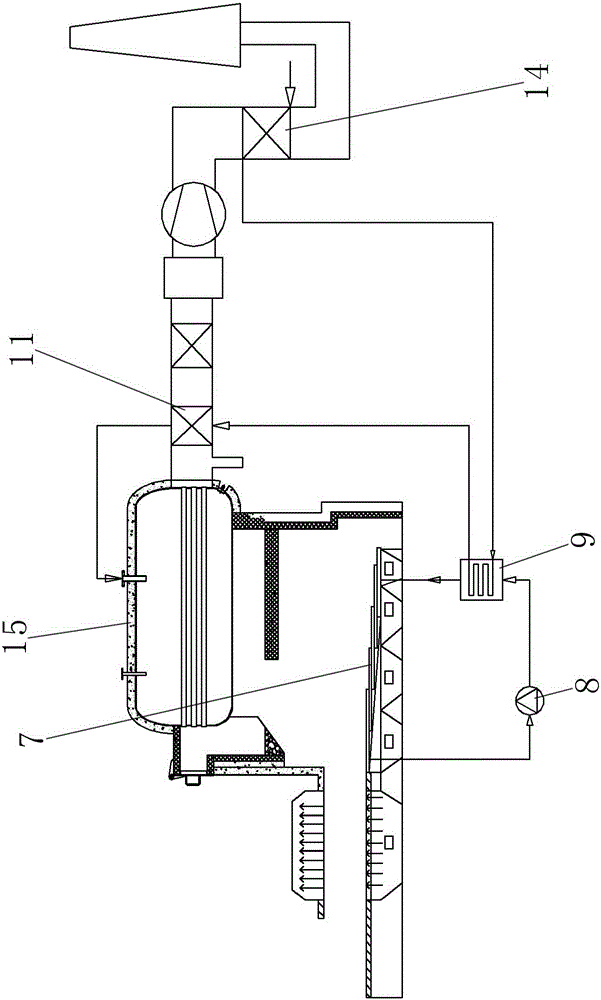

[0014] refer to figure 1 and figure 2 , a biomass boiler with flue gas drying in front of the furnace and continuous bundled firing, which includes a biomass boiler body, a drying area 1 is arranged before the feed port of the biomass boiler body, and a smoke inlet device is arranged at the bottom of the drying area 1, The hot flue gas at 350-400°C is sucked in from the smoke inlet device in the drying area 1, and the bundled biomass is dried. A smoke exhaust device and an induced draft fan 1 are installed above the drying area 1, and the smoke sent from the bottom is sucked. The hot flue gas sucks out the moisture in the bale, and at the same time, under the suction of the induced draft fan 1, a small part of the high-temperature flue gas in the furnace 3 is also sucked into the bale, drying and igniting the biomass like smoking. The smoke exhaust device and The air inlet of induced draft fan one 2 is connected, and the gas outlet of induced draft fan one 2 is respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com