Biomass-combustion-heat-driven absorption type Organic Rankine Cycle distributed combined cooling, heating and power system

A technology of cogeneration of cooling, heating and power and Rankine cycle, which is applied in the field of resources and environment, can solve the problem of low utilization rate of heat energy, achieve the effect of improving utilization rate, avoiding local pyrolysis, and strengthening the absorption process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

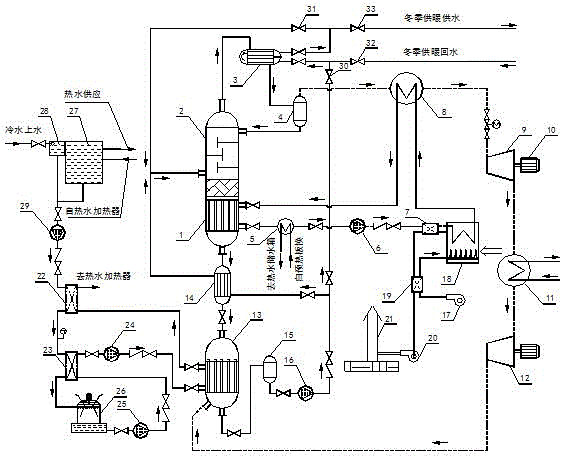

[0035] like figure 1 As shown, the biomass combustion heat energy drives the absorption organic Rankine cycle distributed cogeneration system, including biomass boiler equipment pipelines, heat transfer oil circulation loops, absorption organic Rankine cycle loops, domestic hot water pipelines , heating water supply pipeline, cooling closed-loop circulation loop and cooling water circulation loop;

[0036] The pipeline of the biomass boiler equipment is composed of a flue gas preheater 7, a blower 17, a biomass heat transfer oil boiler 18, an air preheater 19, an induced draft fan 20, a chimney 21 and the pipelines connecting them. The air outlet of the blower 17 is connected to the The cold air inlet of air preheater 1 is connected, the hot air outlet of air preheater 19 is connected with the air inlet of biomass heat transfer oil boiler 18, the flue gas outlet of biomass heat transfer oil boiler 18 is connected with the inlet of flue gas preheater 7, and the flue gas The fl...

Embodiment 2

[0047] like figure 1 As shown, the biomass combustion heat energy drives the absorption organic Rankine cycle distributed cogeneration system, including biomass boiler equipment pipelines, heat transfer oil circulation loops, absorption organic Rankine cycle loops, domestic hot water pipelines , heating water supply pipeline, cooling closed-loop circulation loop and cooling water circulation loop;

[0048] The pipeline of the biomass boiler equipment is composed of a flue gas preheater 7, a blower 17, a biomass heat transfer oil boiler 18, an air preheater 19, an induced draft fan 20, a chimney 21 and the pipelines connecting them. The air outlet of the blower 17 is connected to the The cold air inlet of air preheater 1 is connected, the hot air outlet of air preheater 19 is connected with the air inlet of biomass heat transfer oil boiler 18, the flue gas outlet of biomass heat transfer oil boiler 18 is connected with the inlet of flue gas preheater 7, and the flue gas The fl...

Embodiment 3

[0057] Such as figure 1 As shown, the biomass combustion heat energy drives the absorption organic Rankine cycle distributed cogeneration system, including biomass boiler equipment pipelines, heat transfer oil circulation loops, absorption organic Rankine cycle loops, domestic hot water pipelines , heating water supply pipeline, cooling closed-loop circulation loop and cooling water circulation loop;

[0058] The pipeline of the biomass boiler equipment is composed of a flue gas preheater 7, a blower 17, a biomass heat transfer oil boiler 18, an air preheater 19, an induced draft fan 20, a chimney 21 and the pipelines connecting them. The air outlet of the blower 17 is connected to the The cold air inlet of air preheater 1 is connected, the hot air outlet of air preheater 19 is connected with the air inlet of biomass heat transfer oil boiler 18, the flue gas outlet of biomass heat transfer oil boiler 18 is connected with the inlet of flue gas preheater 7, and the flue gas The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com