Carbon matrix fertilizer production resource comprehensive utilization method based on updraft carbon gas co-production furnace

A technology for producing resources and carbon-based fertilizers, applied in the direction of fertilizer mixture, application, nitrogen fertilizer, etc., can solve the problems of serious environmental pollution and low resource utilization rate, and achieve the effect of improving utilization efficiency and realizing energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

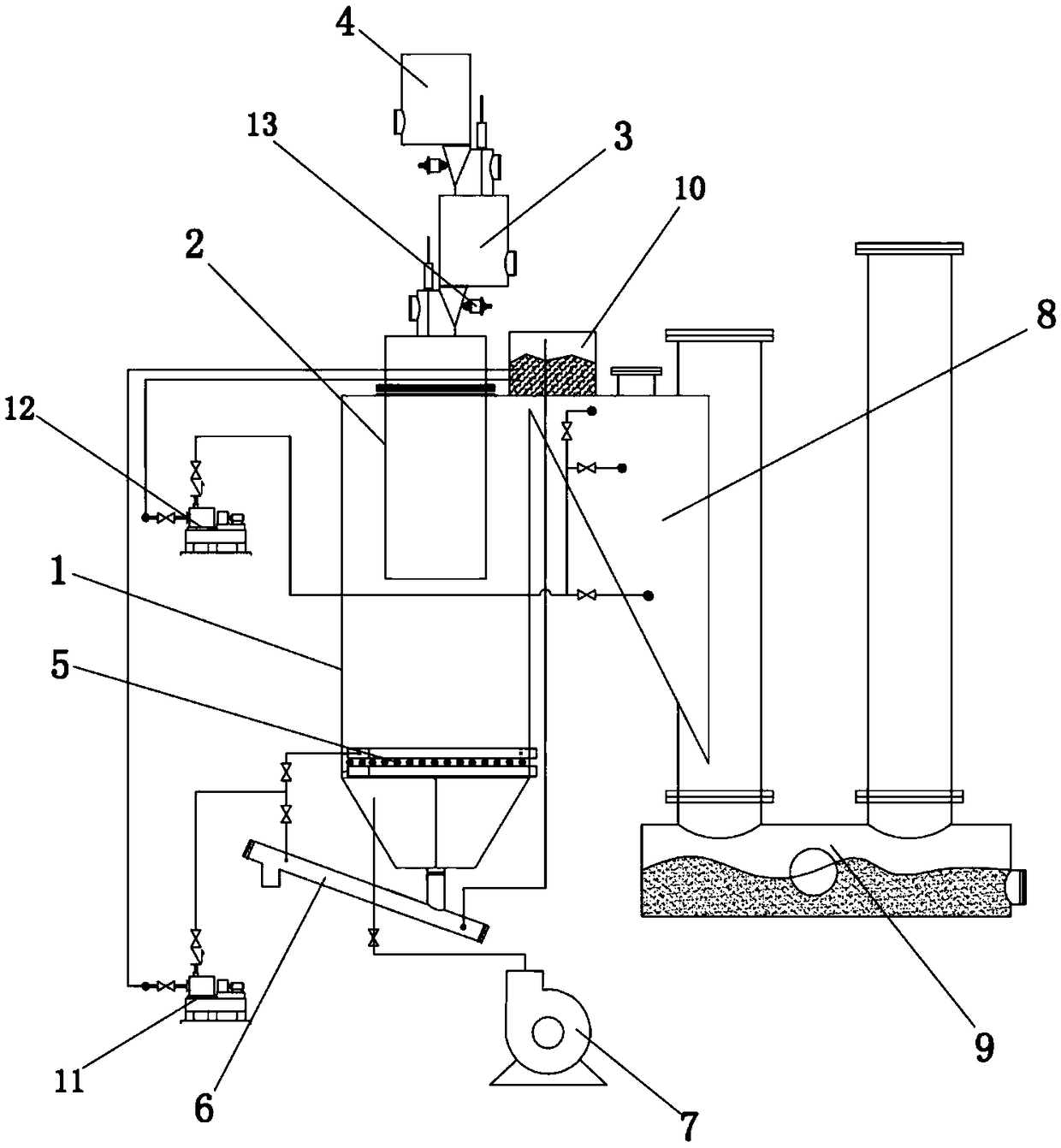

[0027] A method for comprehensive utilization of carbon-based fertilizer production resources based on an updraft carbon-gas cogeneration furnace, the specific steps are as follows:

[0028] a. Use a crusher to crush the agricultural and forestry wastes to a size of less than 12 cm, and send the crushed materials into the drum dryer for raw material drying pretreatment;

[0029] b. The dried material enters the updraft charcoal-gas cogeneration furnace for pyrolysis and gasification reaction to produce biomass charcoal and biomass combustible gas;

[0030] c. Grinding the generated biochar, the particle size of the charcoal powder is 60-80 mesh, spraying the ground biochar with wood vinegar; adding the sprayed biochar to inorganic fertilizer and binder to form charcoal Base fertilizer, the mass percentages of the biomass charcoal, inorganic fertilizer, and binder are respectively 10% to 40%, 40% to 70%, and 1% to 10%, wherein the inorganic fertilizer is one of the following: a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com