Washing governing system and method for fermentation odor and combustion smoke

一种燃烧烟气、臭气的技术,应用在燃烧方法、化学仪器和方法、气体处理等方向,能够解决缩短发酵时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

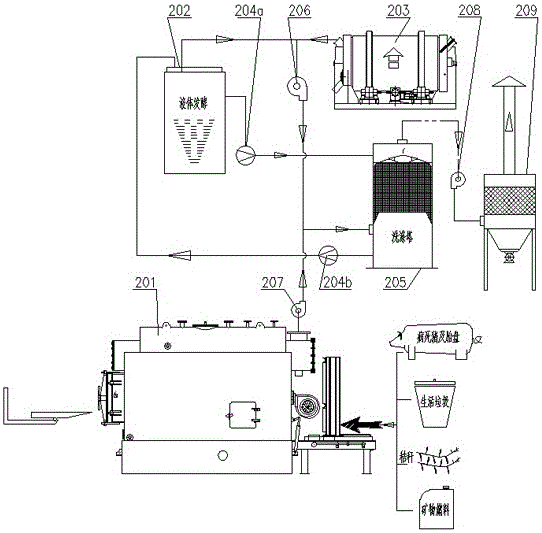

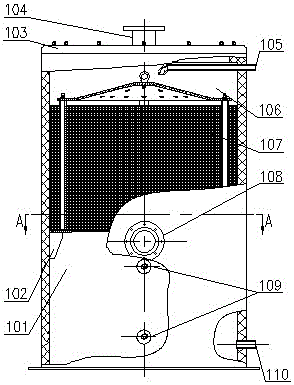

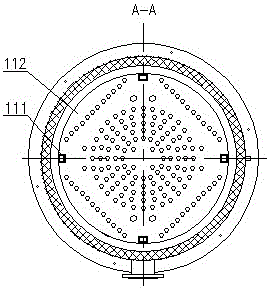

[0059] Start the induced draft fan 206, the foul gas discharged by the organic waste in the solid fermentation reactor 203 and the liquid fermentation reactor 202 during the fermentation process is introduced into the scrubber from the air inlet at the bottom of the scrubber 205 through the induced draft fan 206, and at the same time, start Circulating water pump 204a, the excrement liquid in the liquid fermentation reactor 202 is pumped in the washing tower 205 from the liquid inlet at the top of the washing tower 205 through the circulating water pump 204a, and the excrement and urine liquid is pumped into the washing tower 205 through the splitter plate 105 in the washing tower 205. Evenly sprayed on the packing layer on the hanging basket 107, the odor and the feces and urine liquid are fully exchanged in heat and mass in the packing layer, and the gas discharged from the liquid discharge port on the top of the washing tower 205 is introduced into the biological system throu...

Embodiment 2

[0063] Diesel is used as the combustion equipment of the multifunctional biomass combustion boiler 201. The flue gas generated by combustion is introduced into the scrubber 205 from the air inlet at the bottom of the scrubber 205 through the exhaust fan 207. At the same time, the circulation pump 204a is started, and the liquid fermentation reactor The excrement and urine liquid in 202 is pumped into the washing tower 205 from the liquid inlet at the top of the washing tower 205 through the circulating water pump 204a, and the excrement and urine liquid is evenly sprayed on the hanging basket 107 through the splitter plate 105 in the washing tower 205. On the packing layer, after the flue gas and feces and urine liquid are fully exchanged in heat and mass in the packing layer, the gas discharged from the liquid discharge port at the top of the washing tower 205 is introduced into the biological deodorization filter tower 210 through the induced draft fan 208, and passed through ...

Embodiment 3

[0067] Start the straw fuel automatic conveying equipment 304, send the straw into the multifunctional biomass burning boiler 201, use diesel oil as the ignition equipment of the multifunctional biomass burning boiler 201, and the flue gas generated by combustion passes through the exhaust fan 207 and is discharged from the washing tower 205 The air inlet at the bottom is introduced in the washing tower 205, and at the same time, the circulating pump 204a is started, and the excrement and urine liquid in the liquid fermentation reactor 202 is pumped into the washing tower 205 from the liquid inlet at the top of the washing tower 205 through the circulating water pump 204a. Through the distribution plate 105 in the washing tower 205, the excrement liquid is evenly sprayed on the packing layer on the hanging basket 107. The gas discharged from the liquid outlet at the top of 205 is introduced into the biological deodorization filter tower 210 through the induced draft fan 208, ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com