Household garbage low-temperature pyrolysis treatment system

A technology of low-temperature pyrolysis and treatment system, which is applied in the field of low-temperature pyrolysis treatment system for domestic waste, and can solve problems such as difficult operation, large amount of flue gas, and large investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

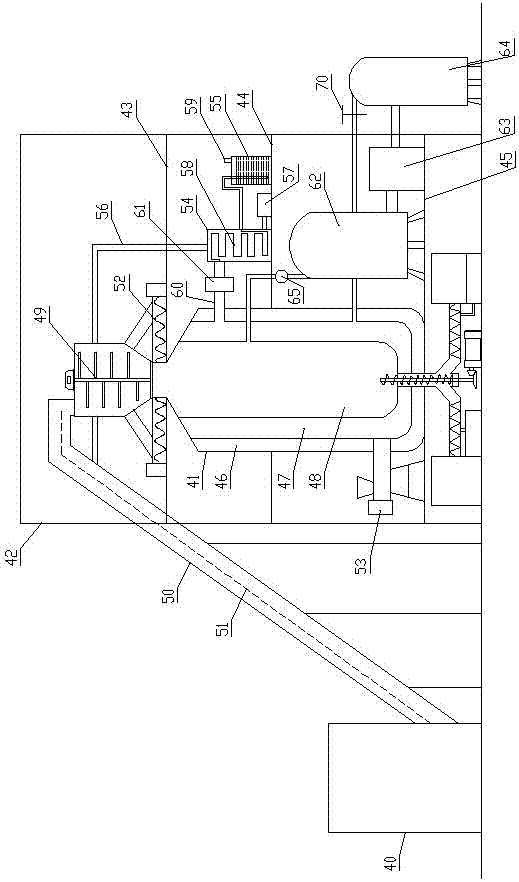

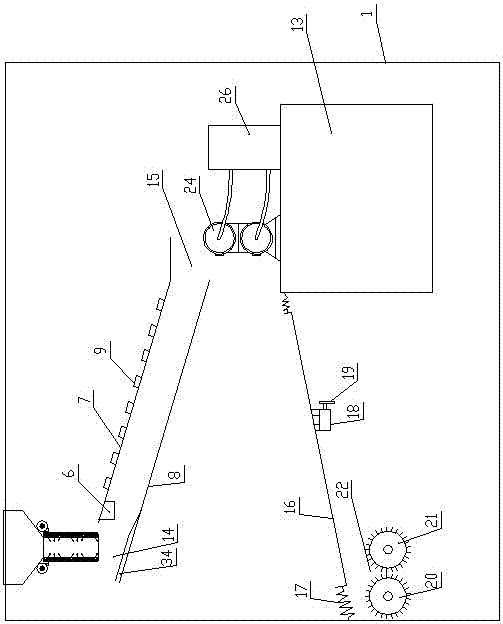

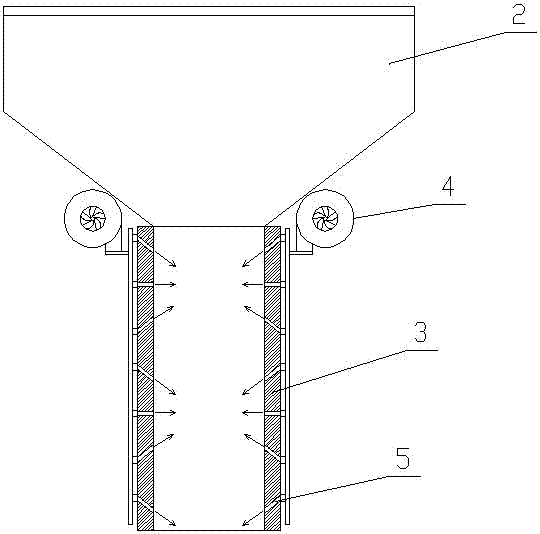

[0032] Such as Figure 1-7 As shown, the domestic waste low-temperature pyrolysis treatment system of the present invention includes a waste specific gravity separation device 40, a pyrolysis furnace 41 and a mounting frame 42, and the mounting frame 42 is provided with a first mounting platform 43 and a second mounting platform from top to bottom. 44 and the third installation platform 45, the pyrolysis furnace 41 runs through the second installation platform 44 and is installed on the third installation platform 45, the furnace wall of the pyrolysis furnace 41 is a three-layer structure, and the furnace wall of the three-layer structure will The inner chamber of 41 is divided into heat preservation chamber 46, heating chamber 47 and pyrolysis chamber 48 from outside to inside, and heat preservation chamber 46 is filled with heat preservation medium;

[0033] The first installation platform 43 is provided with a garbage mixing device 49, and the garbage specific gravity separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com