Biomass combustion furnace

A biomass combustion furnace and combustion tank technology, which is applied in combustion methods, control combustion, combustion equipment, etc., can solve the problems of low work efficiency, insufficient fuel combustion, low utilization rate, etc., and achieve smooth and fast ignition process. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

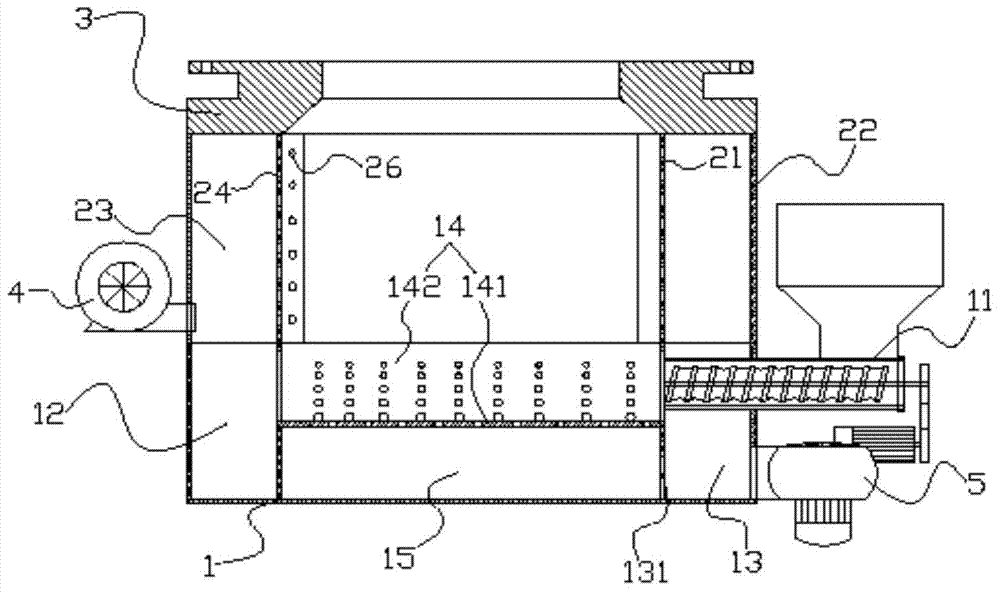

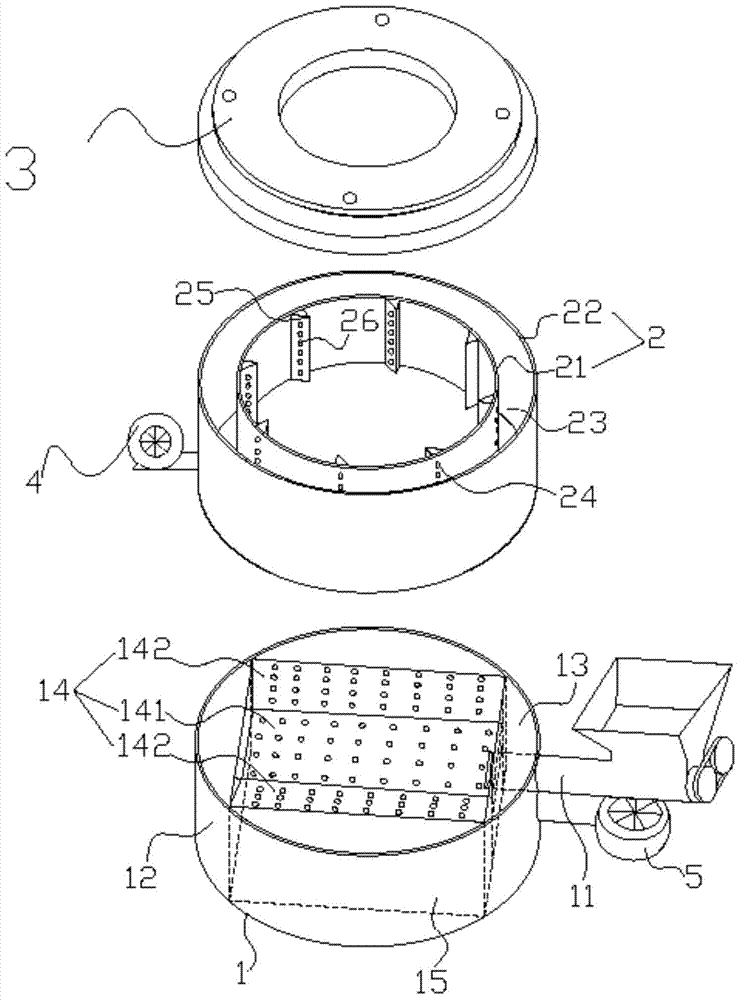

[0025] refer to figure 1 , figure 2 , image 3 , a biomass combustion furnace, comprising a combustion base (1), a combustion chamber (2) disposed on the combustion base (1), a flange (3) disposed on the combustion chamber (2), and a The first blower (4) outside the combustion chamber (2), the combustion chamber (2) consists of a cylindrical wall (21), is located outside the cylindrical wall (21) and is connected to the cylindrical wall (21) The concentric shell (22) is composed of a cylindrical wall (21) and the shell (22) to form an air inlet chamber (23). The air inlet chamber (23) communicates with the first blower (4), and the cylindrical wall On the body (21), 8 rows of air inlets (24) connected with the air inlet chamber (23) are distributed in 8 rows and each row is arranged vertically around the axis; the air inlet holes (24) are straight holes, and the air inlet holes ( 24) The side of the hole on the inner wall of the cylindrical wall (21) is provided with a win...

Embodiment 2

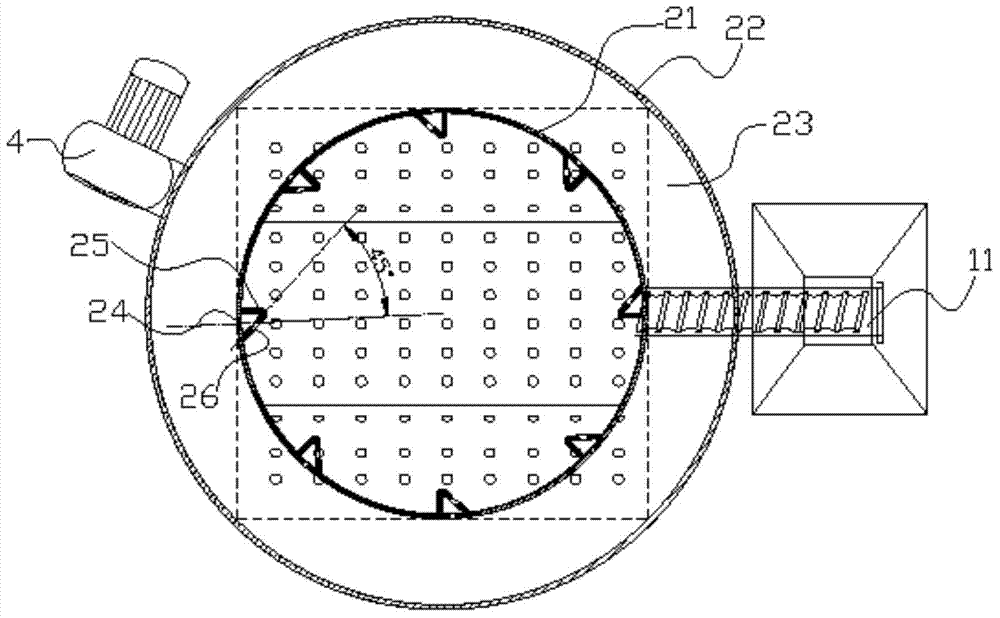

[0027] refer to Figure 4 , Figure 5, a biomass combustion furnace, including a combustion base (1), a combustion chamber (2) disposed on the combustion base (1), a flange disposed on the combustion chamber (2), and a combustion chamber ( 2) The outer first air blower, the combustion chamber (2) consists of a cylindrical wall (21), a shell (22) that is located outside the cylindrical wall (21) and concentric with the cylindrical wall (21) The air inlet chamber (23) is formed between the cylindrical wall (21) and the casing (21), the air inlet chamber (23) communicates with the first blower (4), and the cylindrical wall (21) is surrounded by 12 rows of 10 longitudinally arranged air inlet holes (24) communicated with the air inlet chamber (23) are evenly distributed on the axis, and the air inlet holes (24) are located on the inner wall of the cylindrical wall (21). A windshield (27) is provided on the side to deflect the wind entering from the air inlet (24), and the includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com