Novel organic heat carrier furnace of biomass combustion membrane type wall

A heat carrier furnace and membrane wall technology, applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as low biomass fuel processing efficiency, avoid furnace wall cracking, and reduce maintenance costs. , the effect of wide applicability of fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

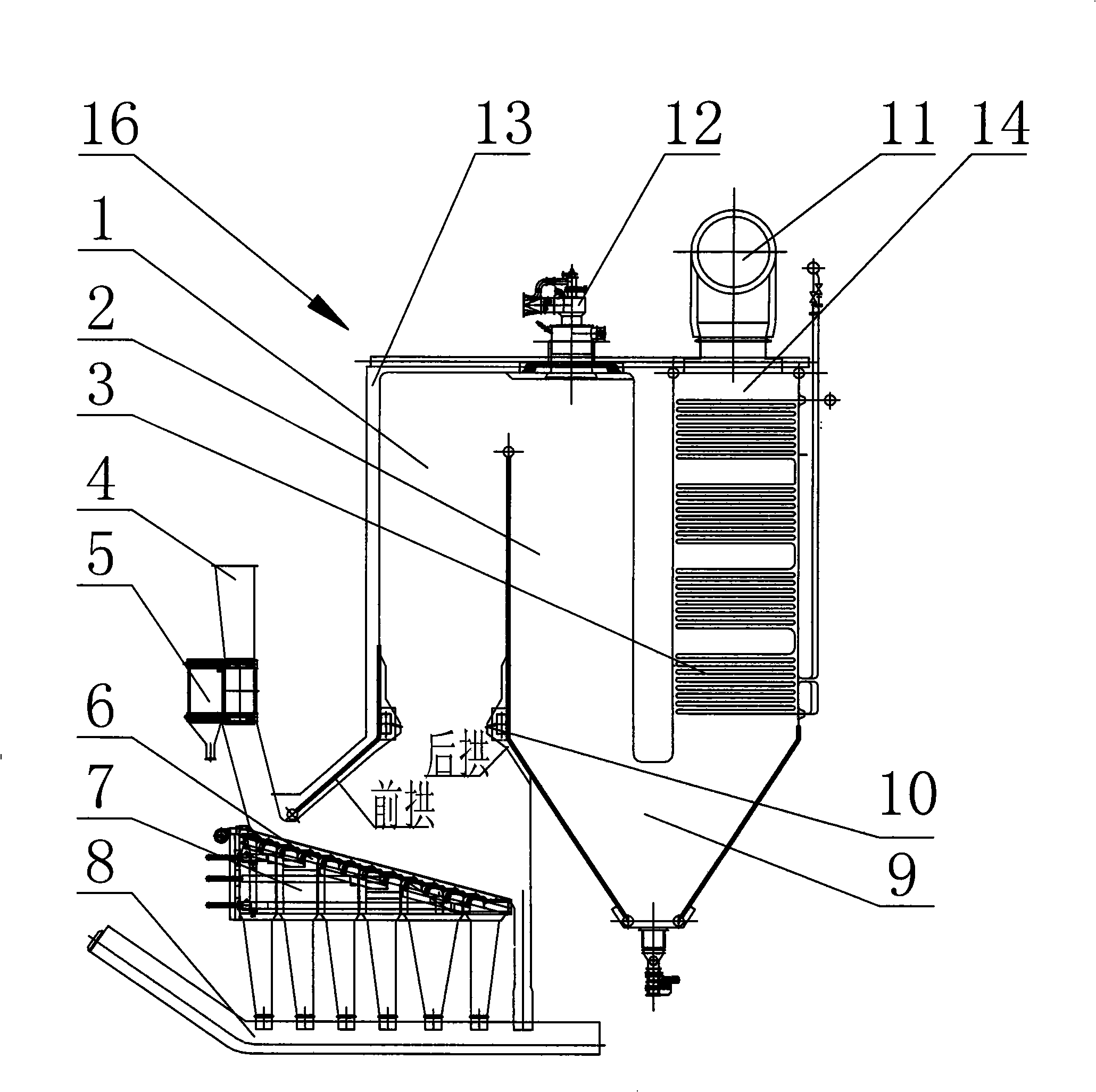

[0020] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and working principle.

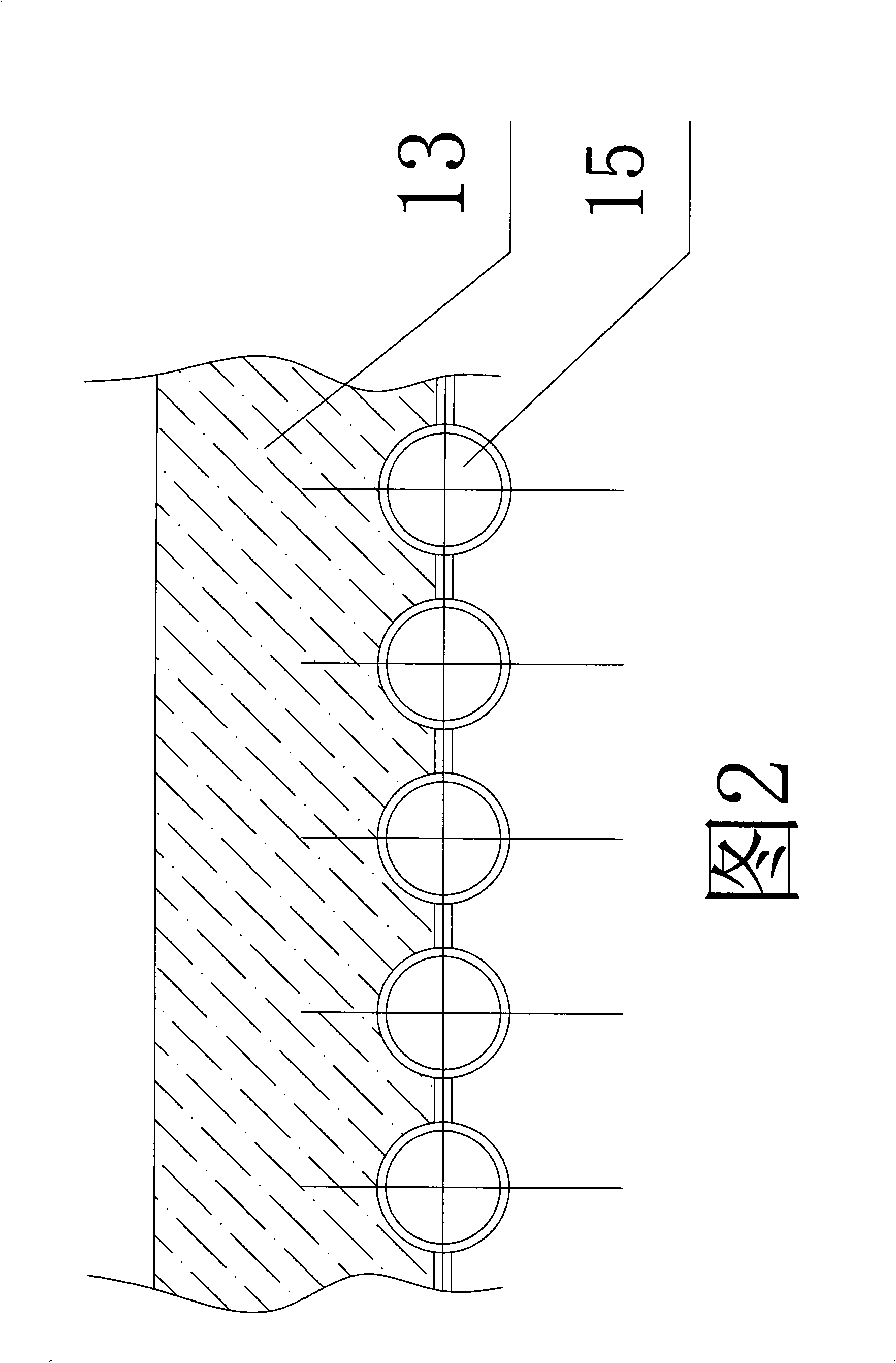

[0021] Body of furnace 16 is provided with combustion equipment, furnace hearth 1, burner chamber 2 and tail flue 14, and the surrounding side walls of furnace hearth 1, burner chamber 2 and tail flue 14 on body of heater 16 are membrane type walls, and it is formed by the outside The insulating material layer 13 is formed with the heat-conducting oil pipe 15 inside. The combustion equipment has a fire grate 6 arranged below the furnace body 1 and a charging device 4 correspondingly arranged above one end thereof, and the charging device 4 also has a discharge port 5 for discharging excess fuel substances in the charging device. The fire grate 6 is a hydraulically driven, forward-push reciprocating fire grate, which forms a certain inclination angle with the horizontal, and the end corresponding to the charg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com