Novel hearth structure of biomass chain boiler

A chain boiler and furnace structure technology, which is applied in the directions of combustion air/fuel supply, non-flammable liquid/gas transportation, combustion method, etc., can solve the problems of lack of shape and size, ash and slagging, and low combustion efficiency. Achieve the effect of high fullness, uniform heat load and improved combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

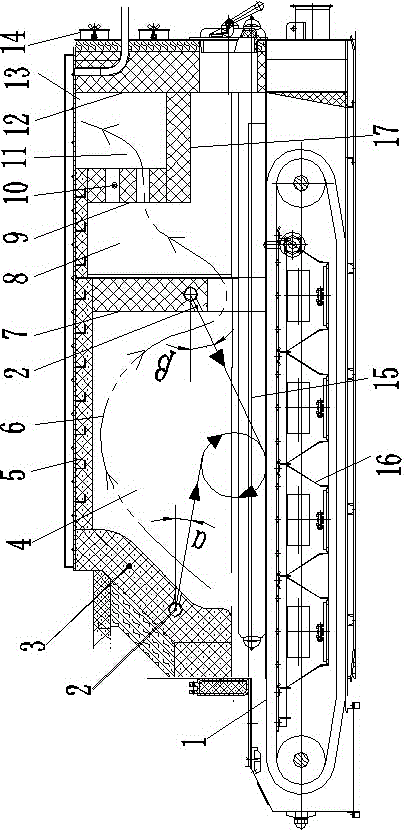

[0017] Depend on figure 1 The new furnace structure of the biomass chain boiler shown includes a chain grate 1, and the top of the chain grate 1 is provided with a front arch 3, a middle arch and a rear arch in sequence from front to back.

[0018] The front arch 3 extends obliquely upward from the front to the back, the front arch 3 forms an angle of 50° with the horizontal line, and the arch height is 950mm.

[0019] The middle arch is made of a vertical flame-folding wall 7, and the flame-folding wall 7 extends vertically. The bottom of the flame-folding wall 7 is 350mm from the chain grate, and 1500mm from the center line of the front arch.

[0020] The rear arch comprises a vertical flower wall 9 and horizontal horizontal walls 17 arranged on the rear side of the bottom of the flower wall 9, the horizontal wall is 450mm away from the chain grate, the flower wall is 550mm away from the central line of the arch, and the flower wall ventilation hole diameter is 80mm. The fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com