Patents

Literature

519results about "Baffles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

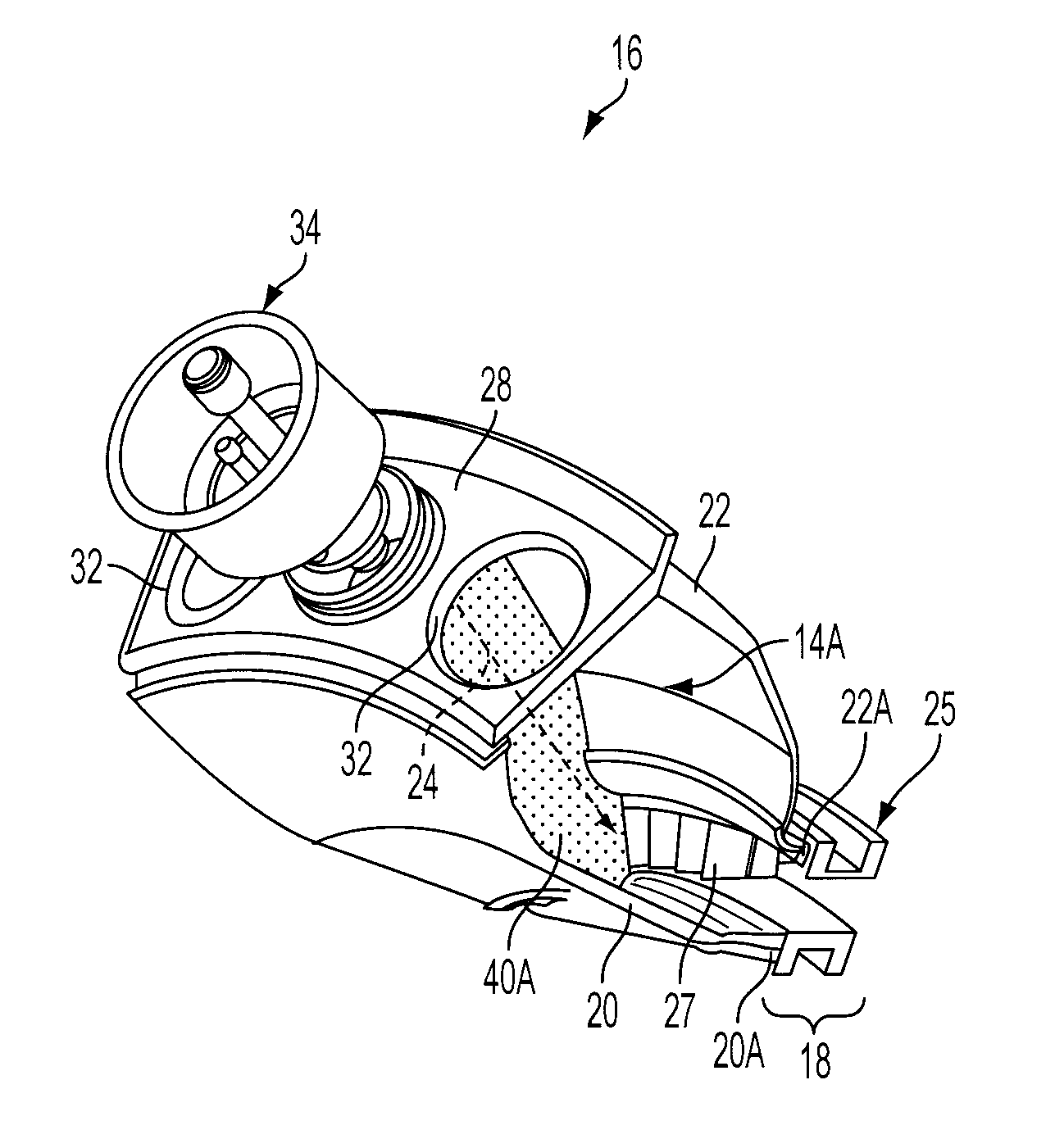

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

InactiveUS6123542AAvoiding particulate inspiration.TheControl expansionGlass furnace apparatusGlass melting apparatusParticulatesCombustor

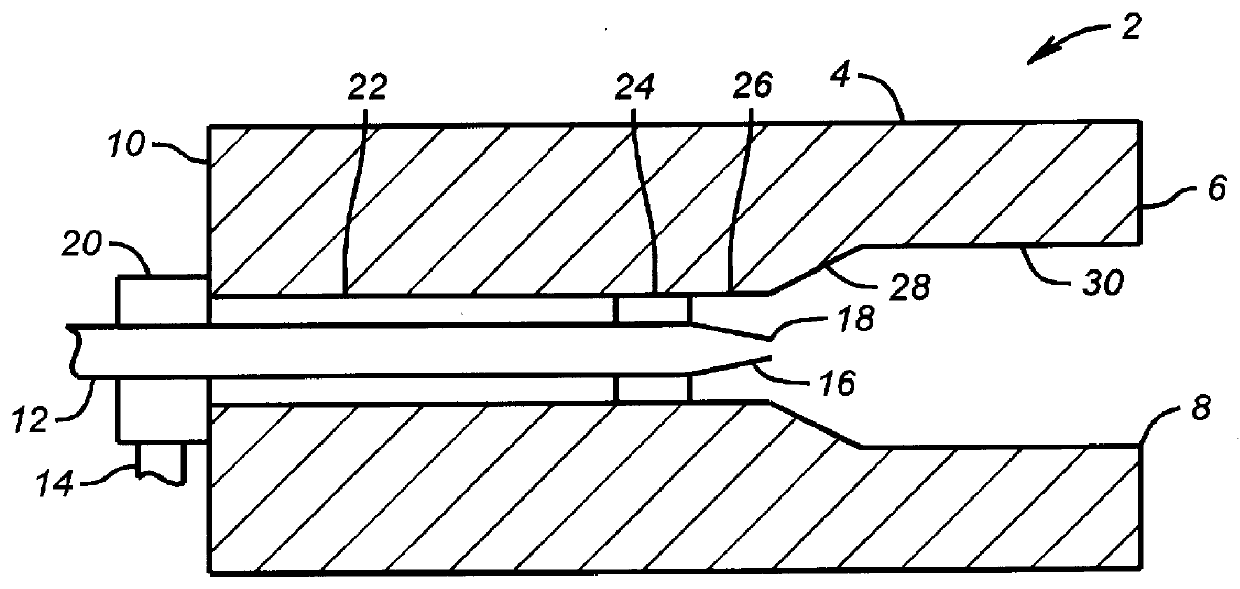

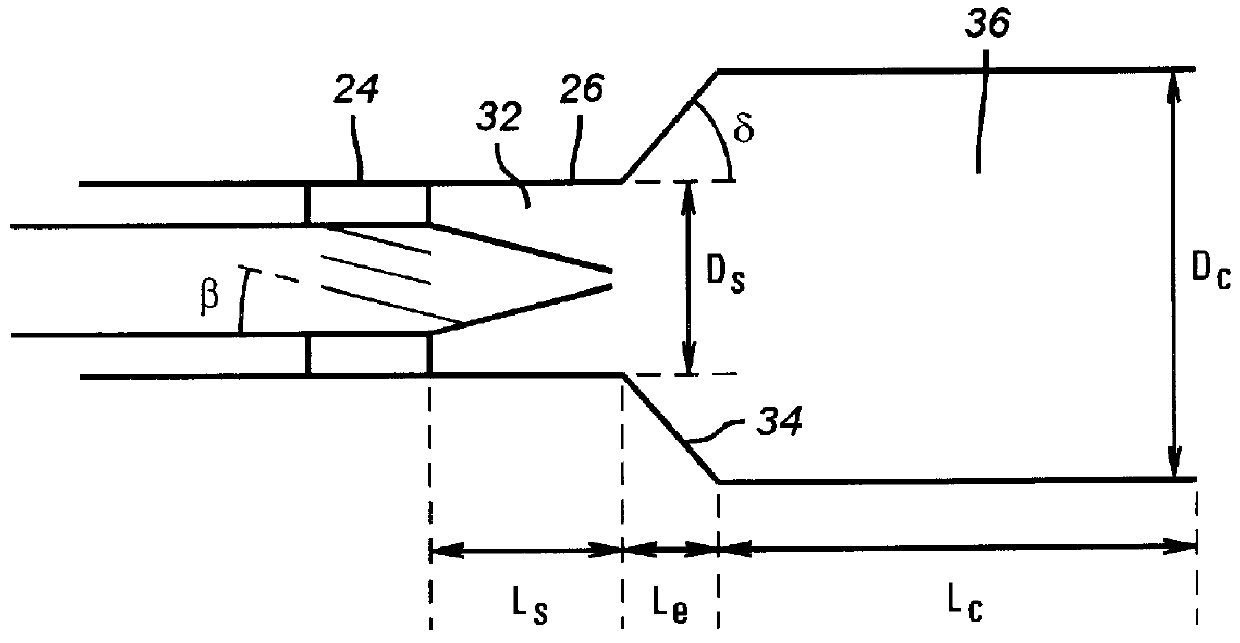

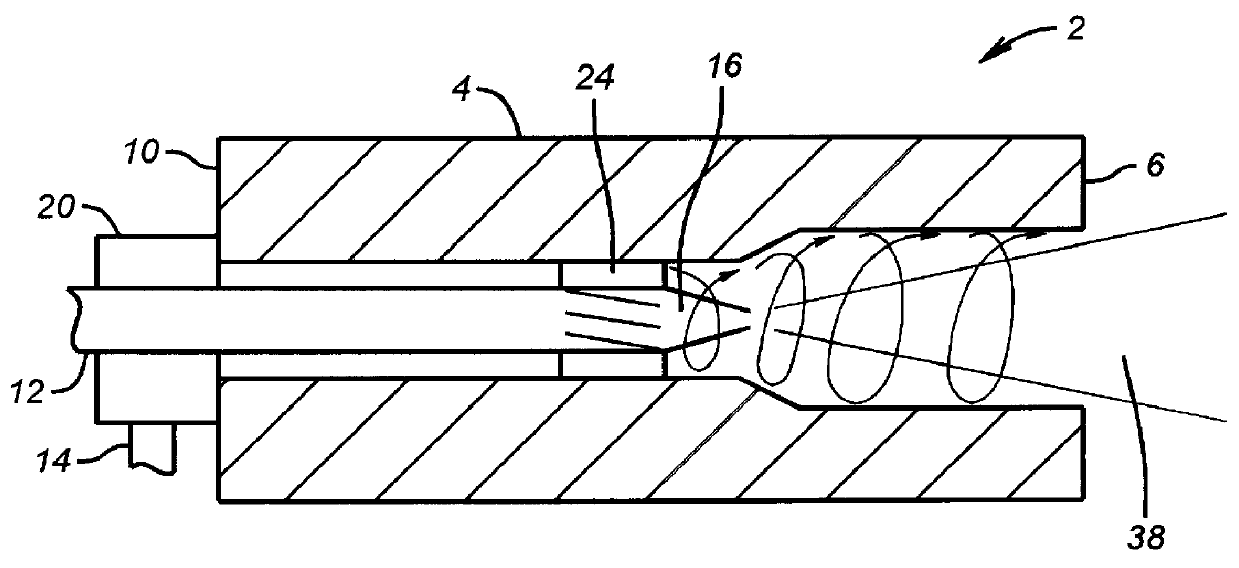

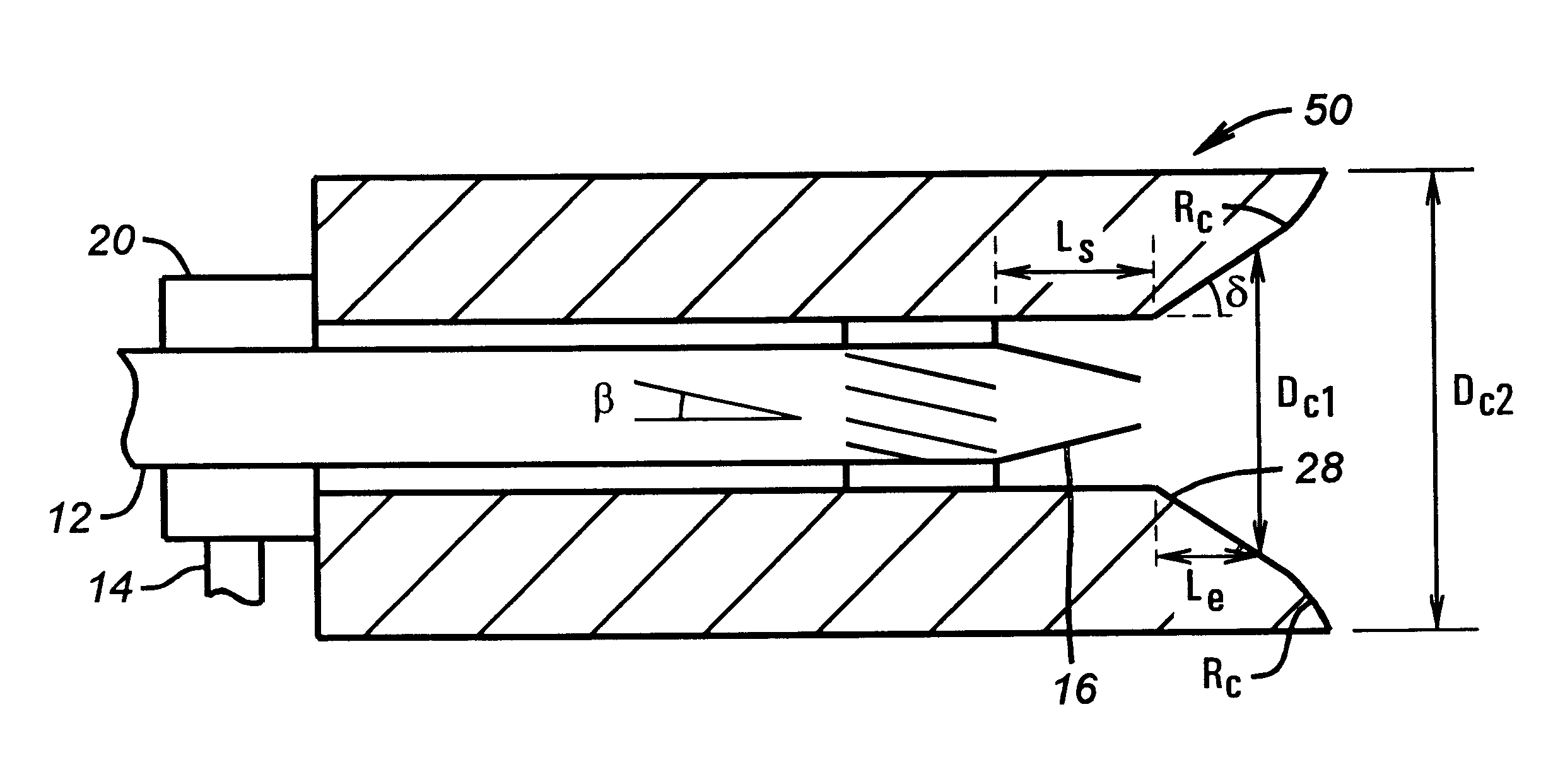

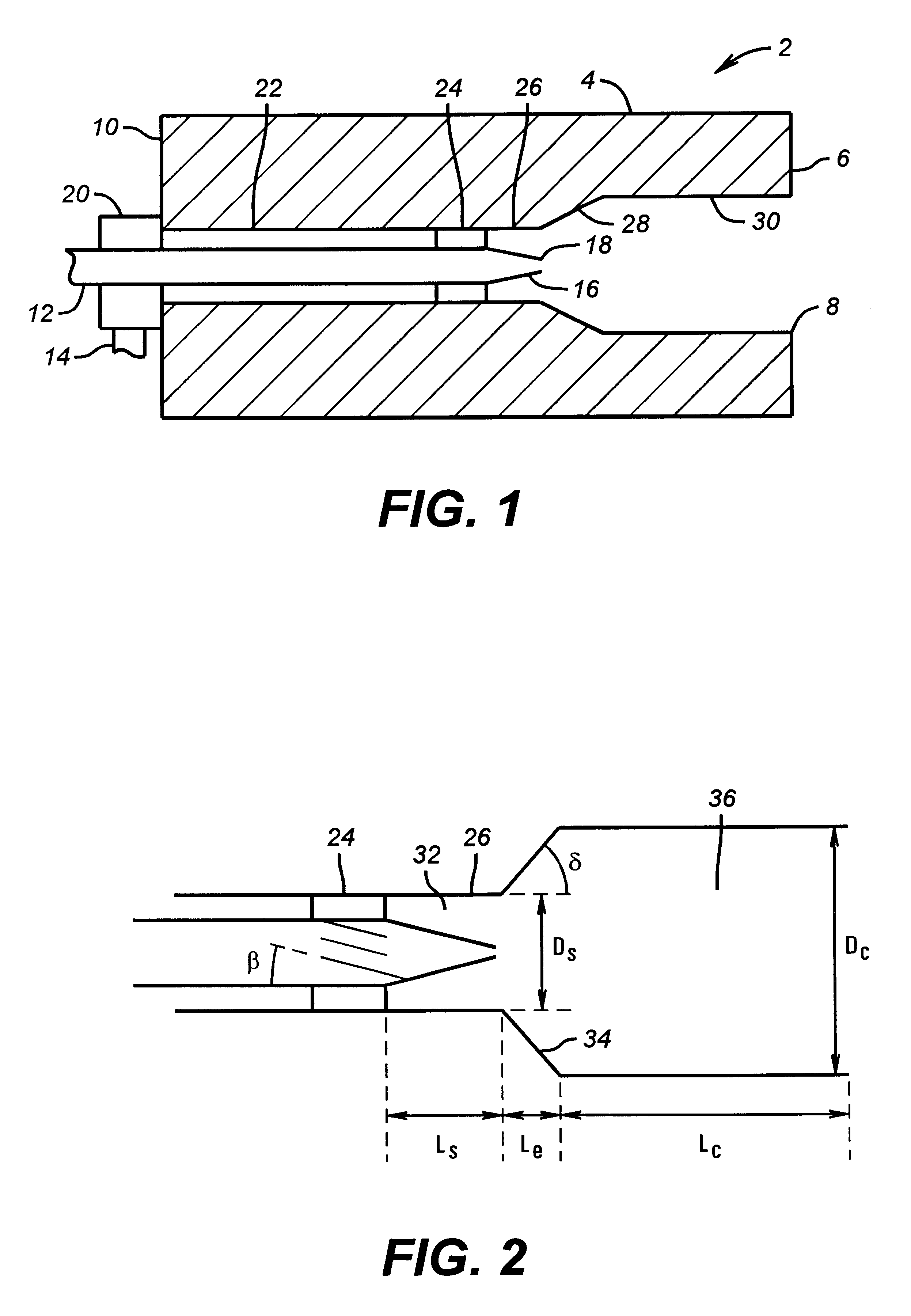

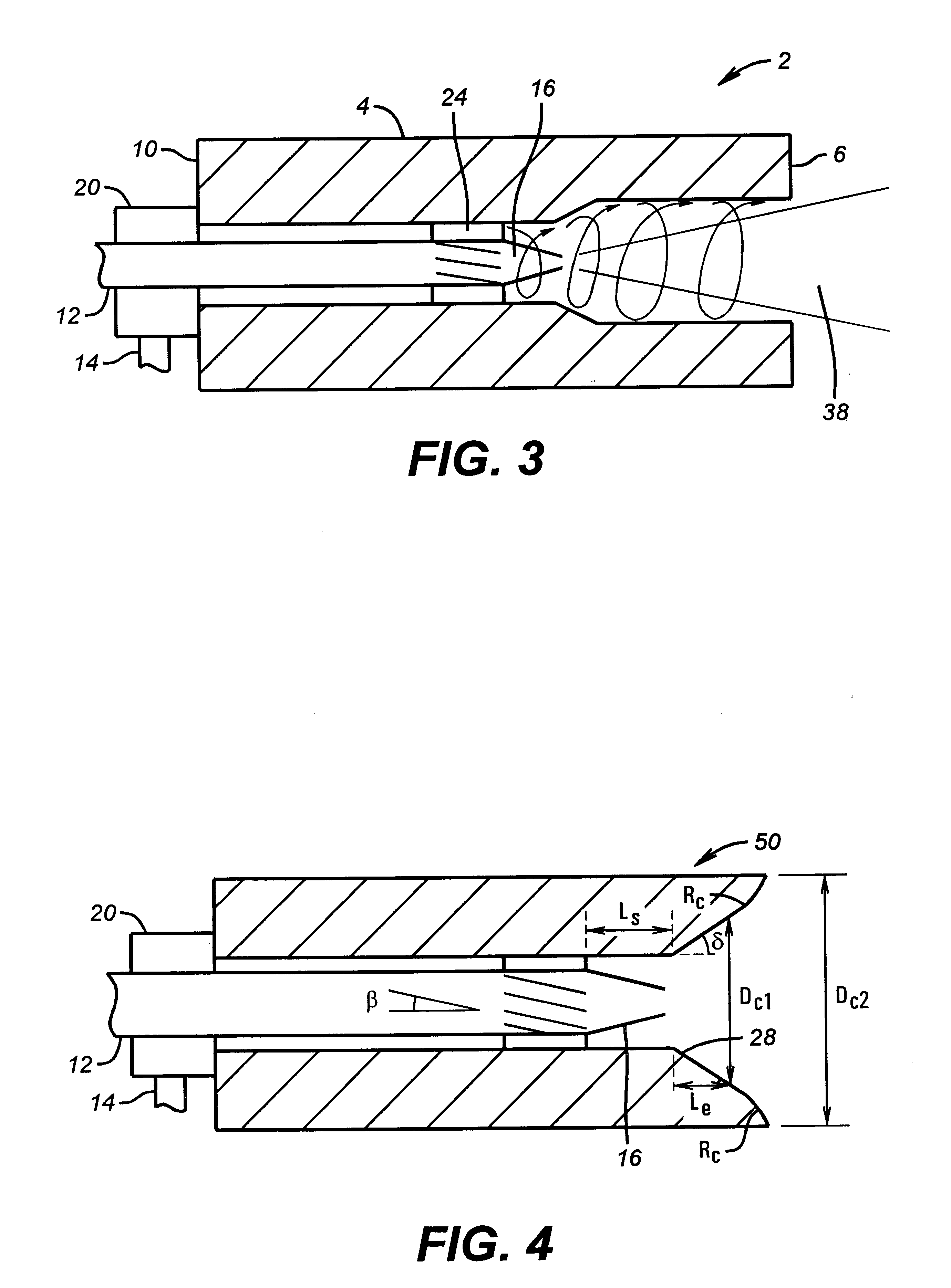

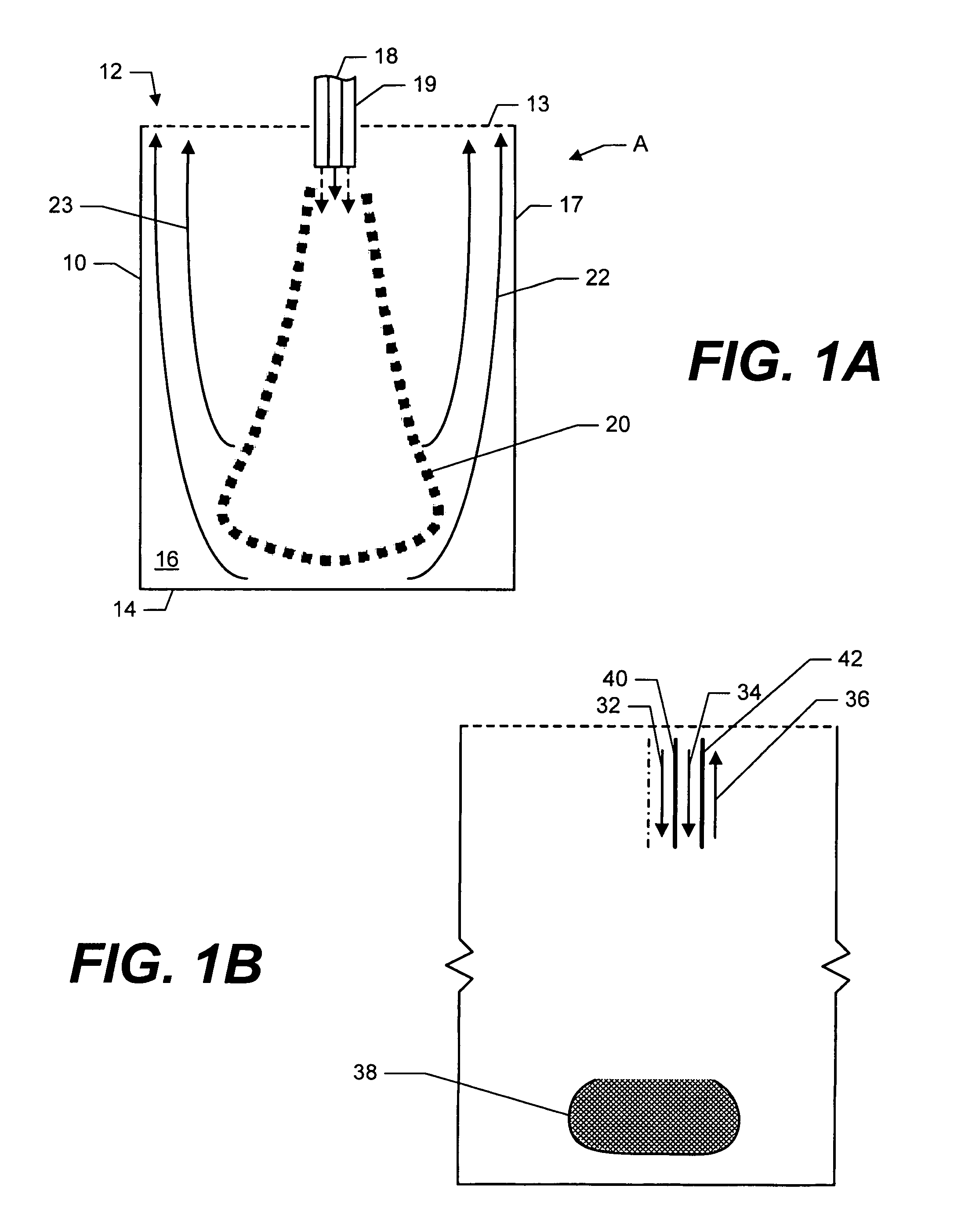

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200 DEG F. to 3000 DEG F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:LAIR LIQUIDE SA POUR L ETUD ET LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

InactiveUS6210151B1Avoiding particulate inspiration.TheControl expansionIndirect carbon-dioxide mitigationGaseous fuel burnerParticulatesVolatiles

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

Oxidizing oxygen-fuel burner firing for reducing NOx emissions from high temperature furnaces

InactiveUS6171100B1Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFurnace temperatureEquivalence ratio

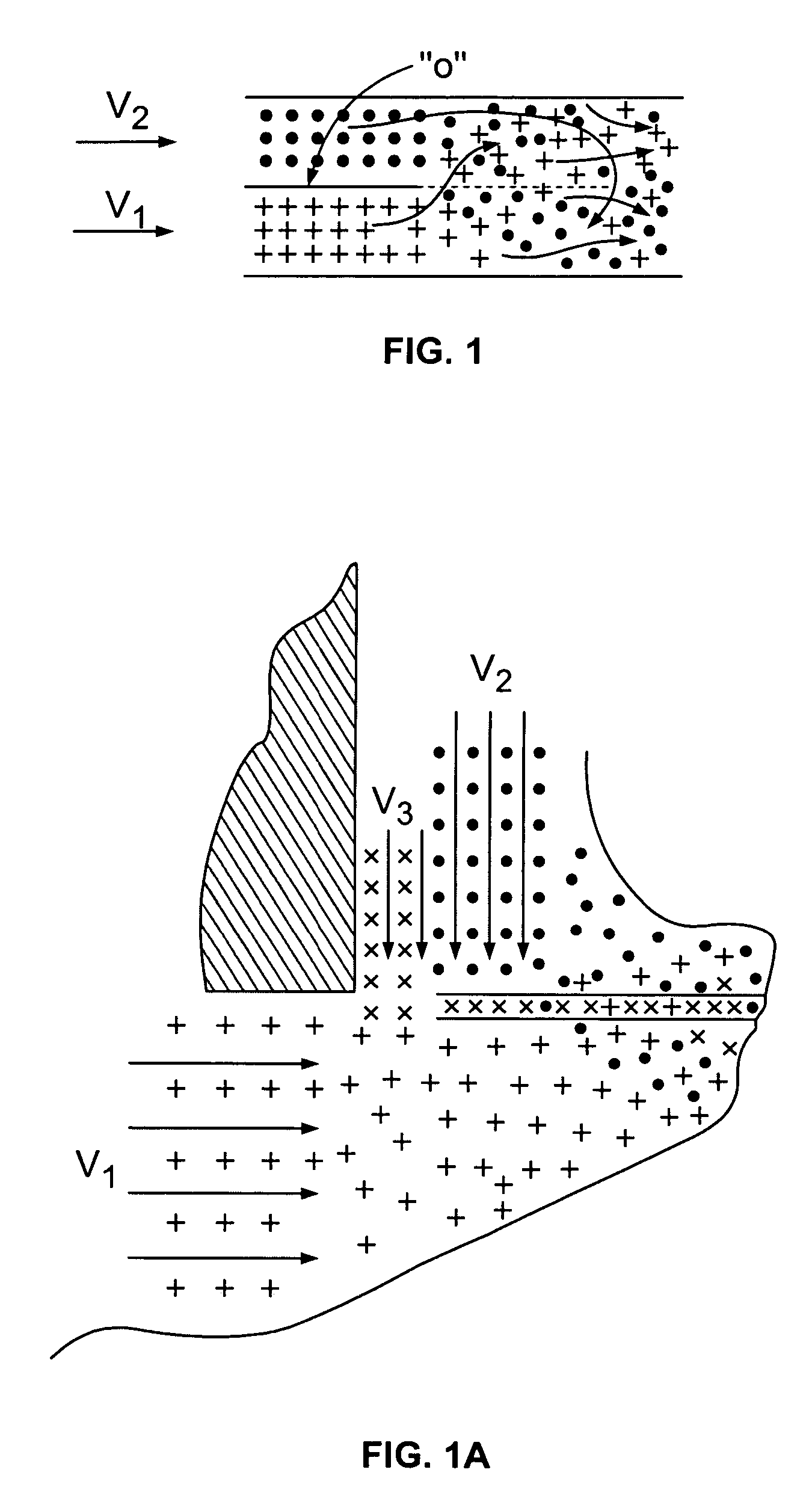

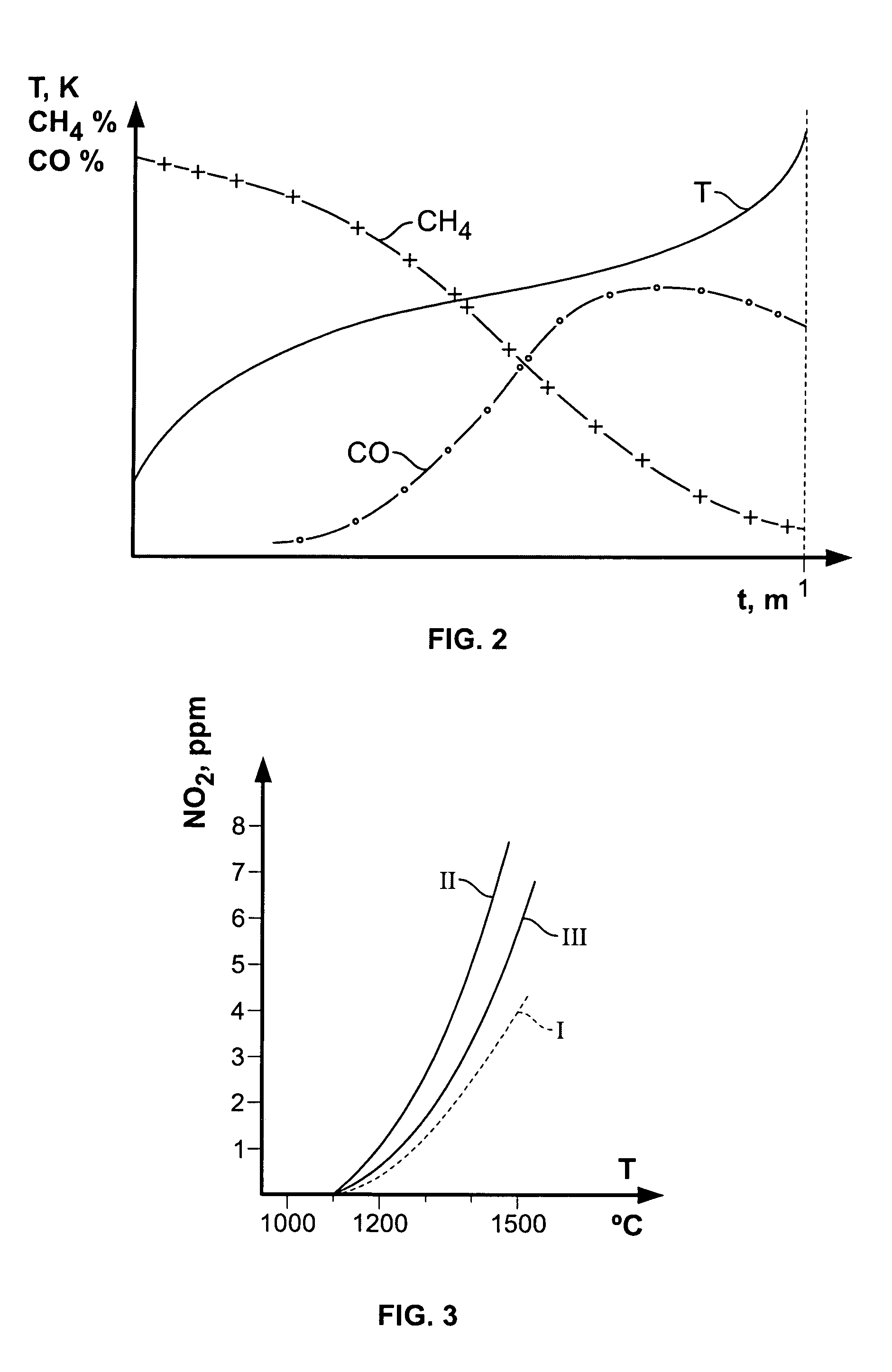

Burner firing method and device are presented where an oxidizing oxygen-fuel burner is fired at an angle to the reducing air-fuel burner flame to reduce overall NOx emissions from high temperature furnaces. The oxidizing oxy-fuel burner stoichiometric equivalence ratio (oxygen / fuel) is maintained in the range of about 1.5 to about 12.5. The reducing air-fuel burner is fired at an equivalence ratio of 0.6 to 1.00 to reduce the availability of oxygen in the flame and reducing NOx emissions. The oxidizing flame from the oxy-fuel burner is oriented such that the oxidizing flame gas stream intersects the reducing air-fuel flame gas stream at or near the tail section of the air-fuel flame. The inventive methods improve furnace temperature control and thermal efficiency by eliminating some nitrogen and provide an effective burnout of CO and other hydrocarbons using the higher mixing ability of the oxidizing flame combustion products. The simultaneous air-fuel and oxy-fuel burner firing can reduce NOx emissions anywhere from 30% to 70% depending on the air-fuel burner stoichiometric ratio.

Owner:AIR LIQUIDE AMERICA INC +1

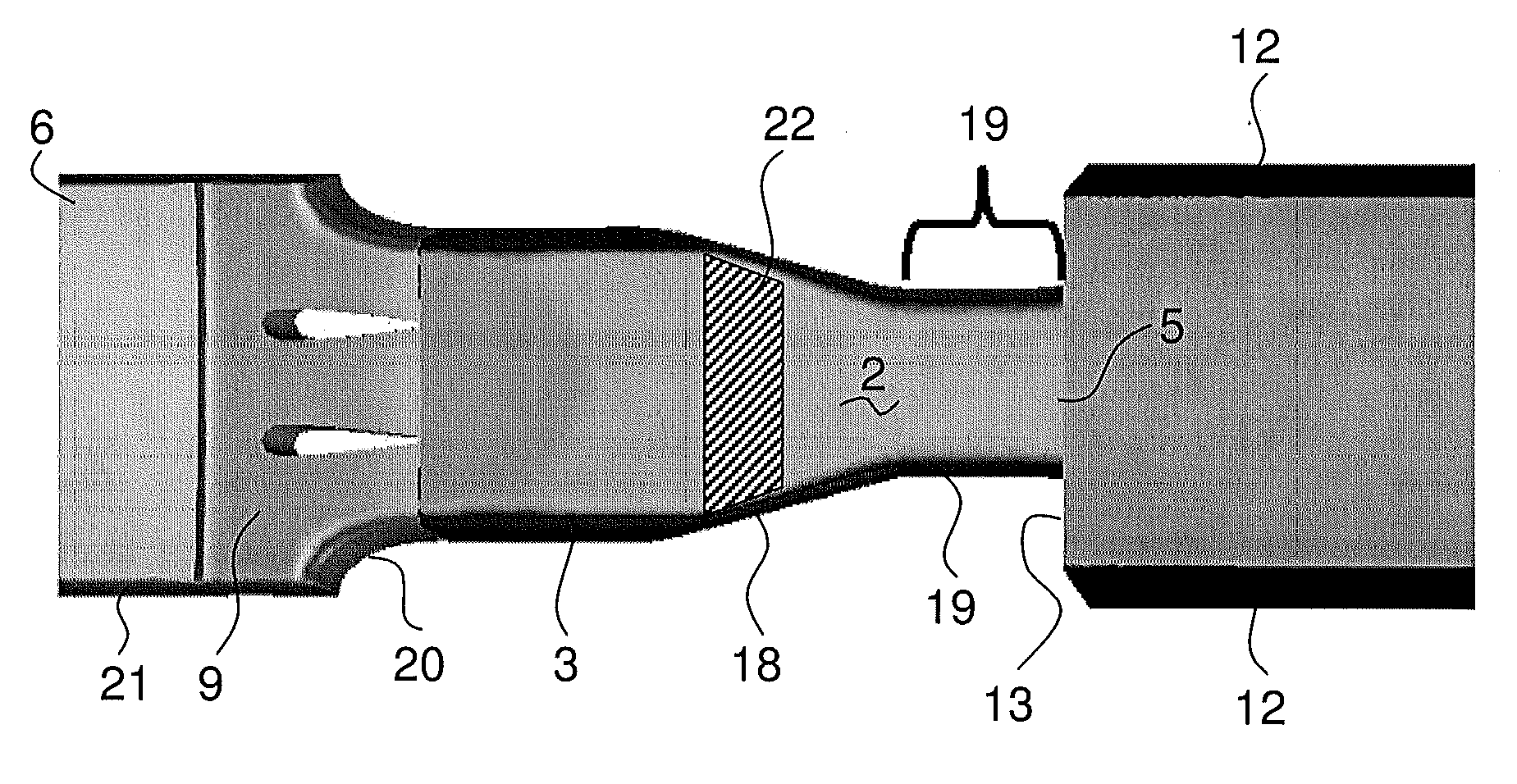

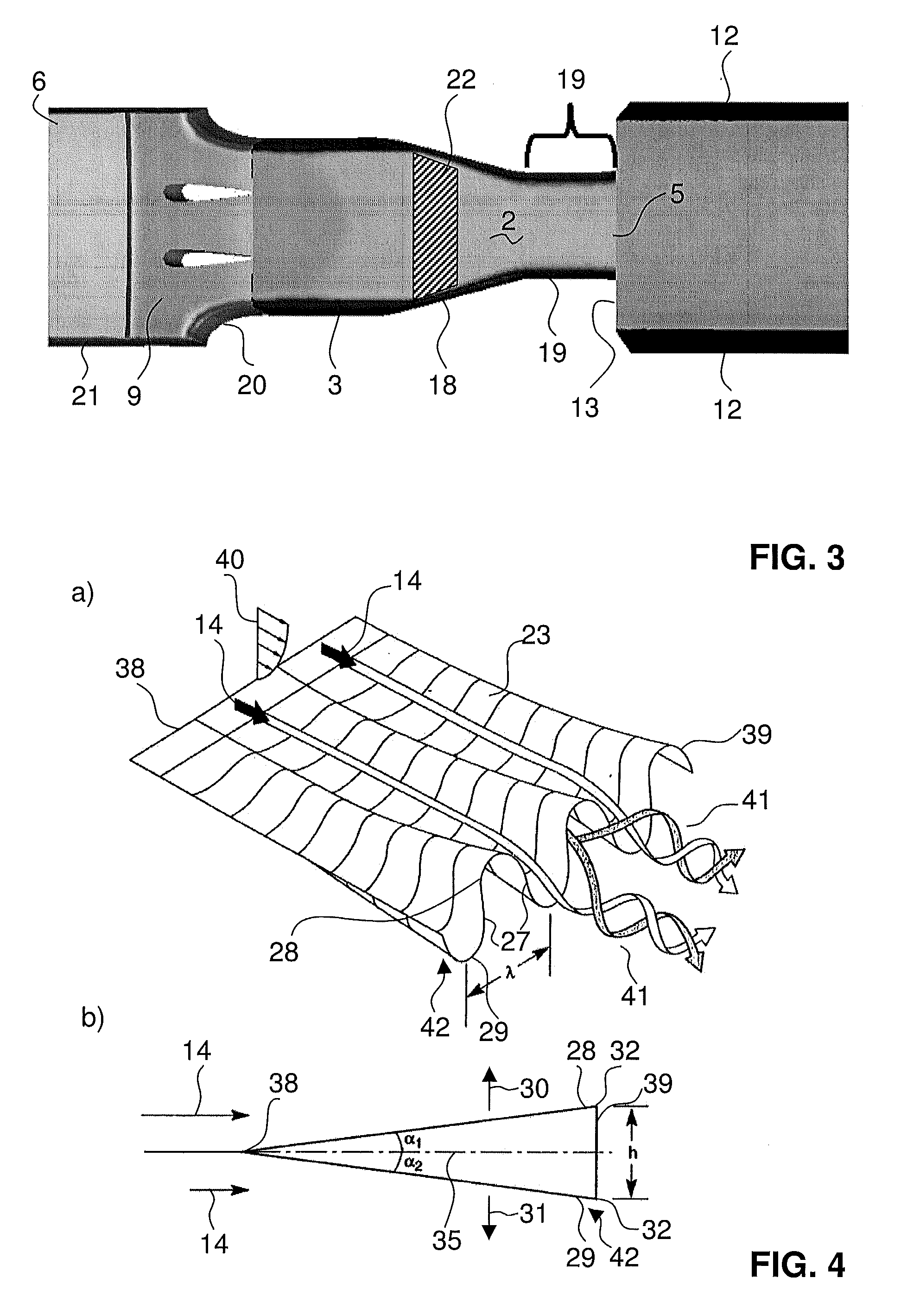

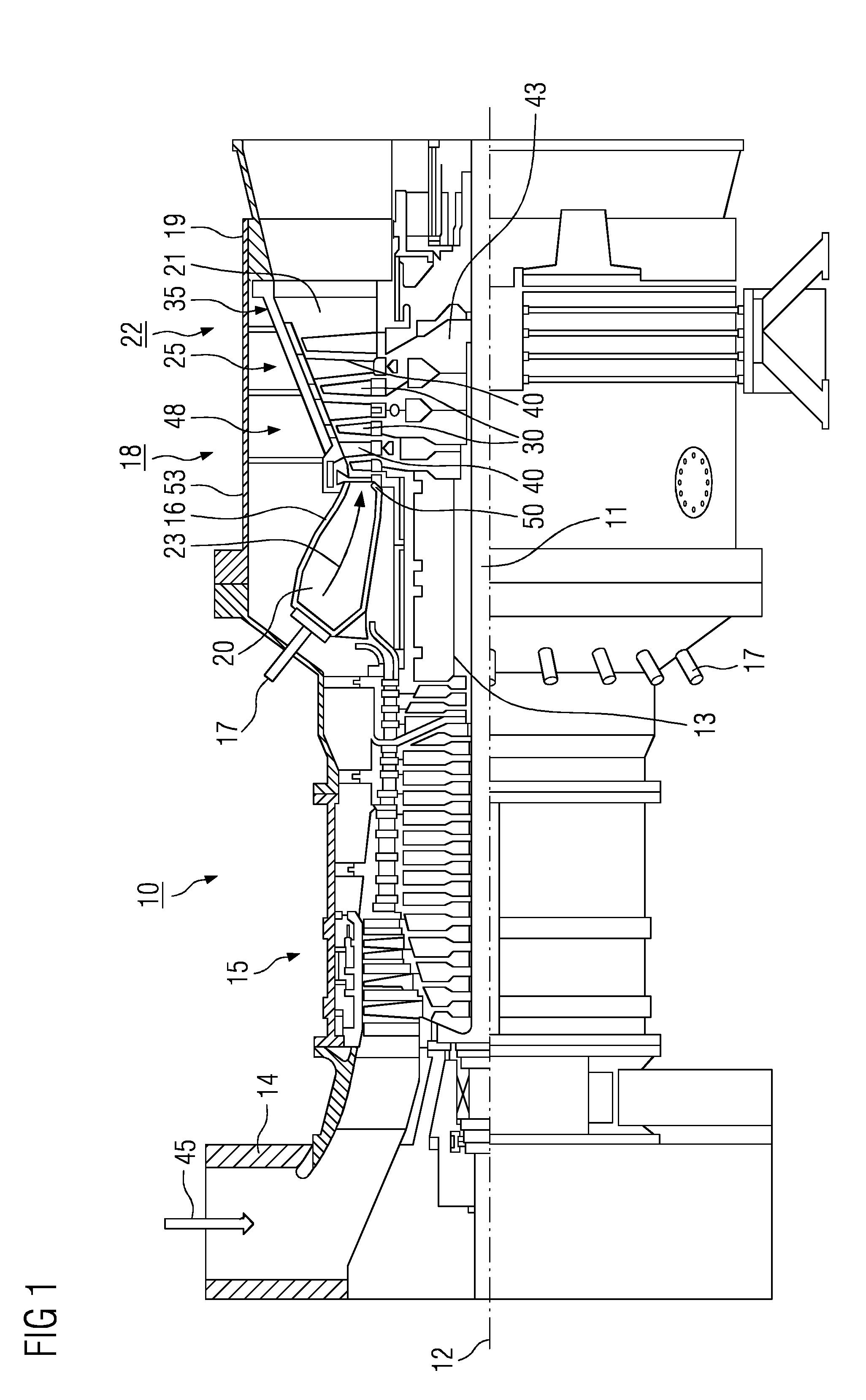

Process for operation of a burner with controlled axial central air mass flow

InactiveUS6901760B2Reduce the amount requiredAffect intensityCombustion using gaseous and pulverulent fuelContinuous combustion chamberCombustorEngineering

Owner:ANSALDO ENERGIA SWITZERLAND AG

Self-cooled oxygen-fuel for use in high-temperature and high-particulate furnaces

InactiveUS6276924B1Avoiding particulate inspiration.TheControl expansionGlass furnace apparatusGlass melting apparatusParticulatesCombustor

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

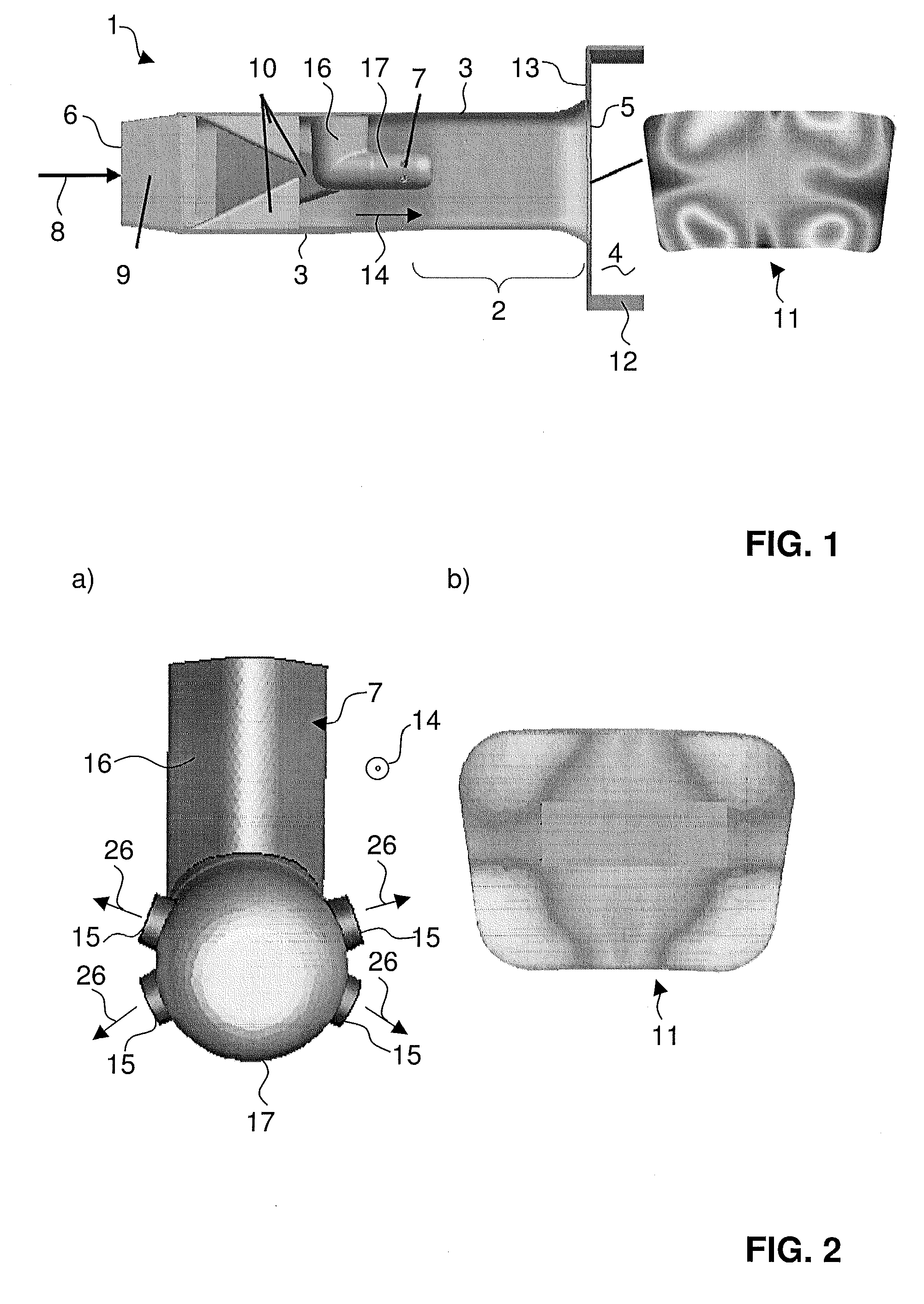

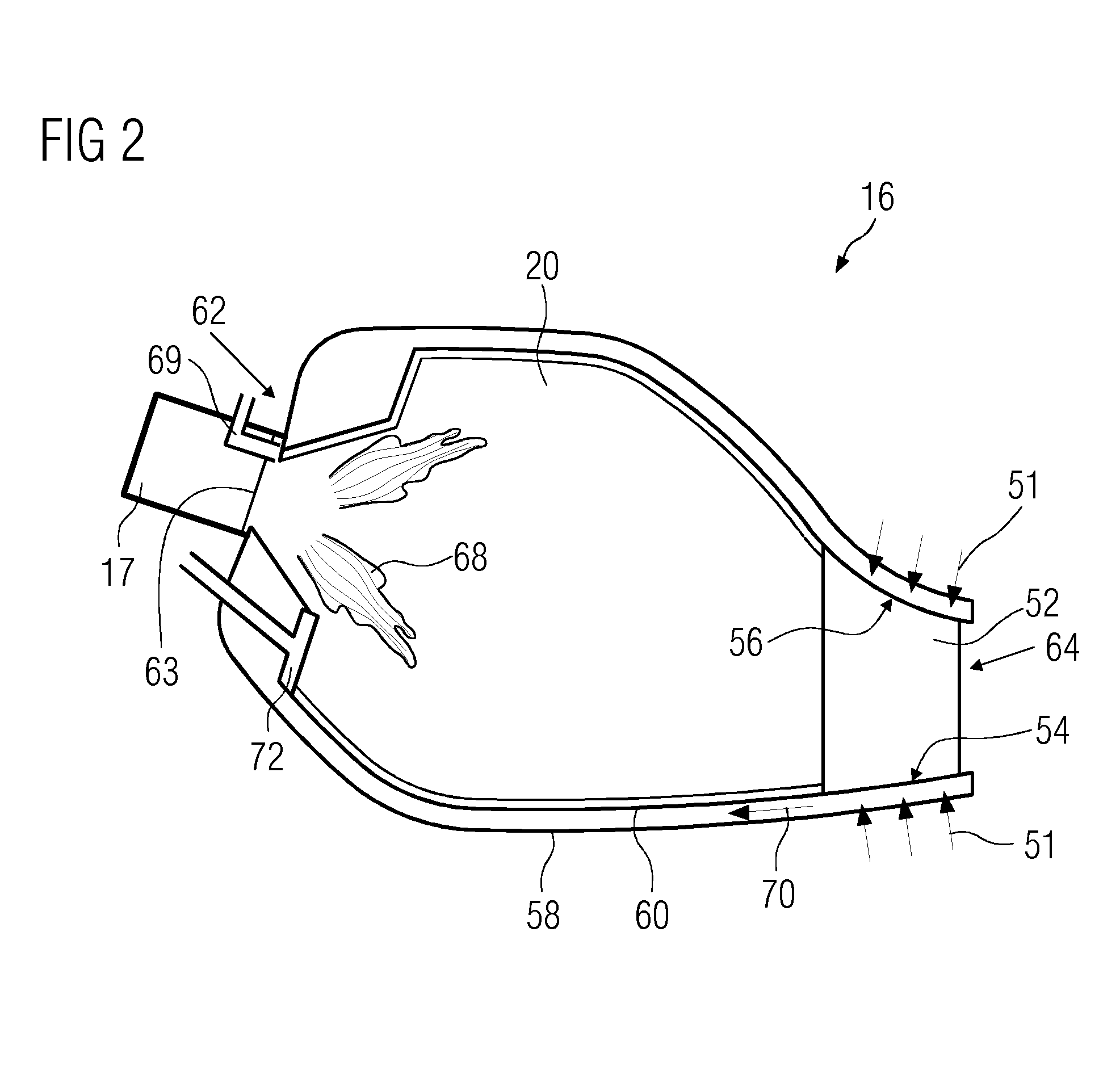

Combustion method and apparatus for carrying out same

InactiveUS7086854B2Increase speedTransfer is bulkyContinuous combustion chamberGas turbine plantsChemical reactionCombustor

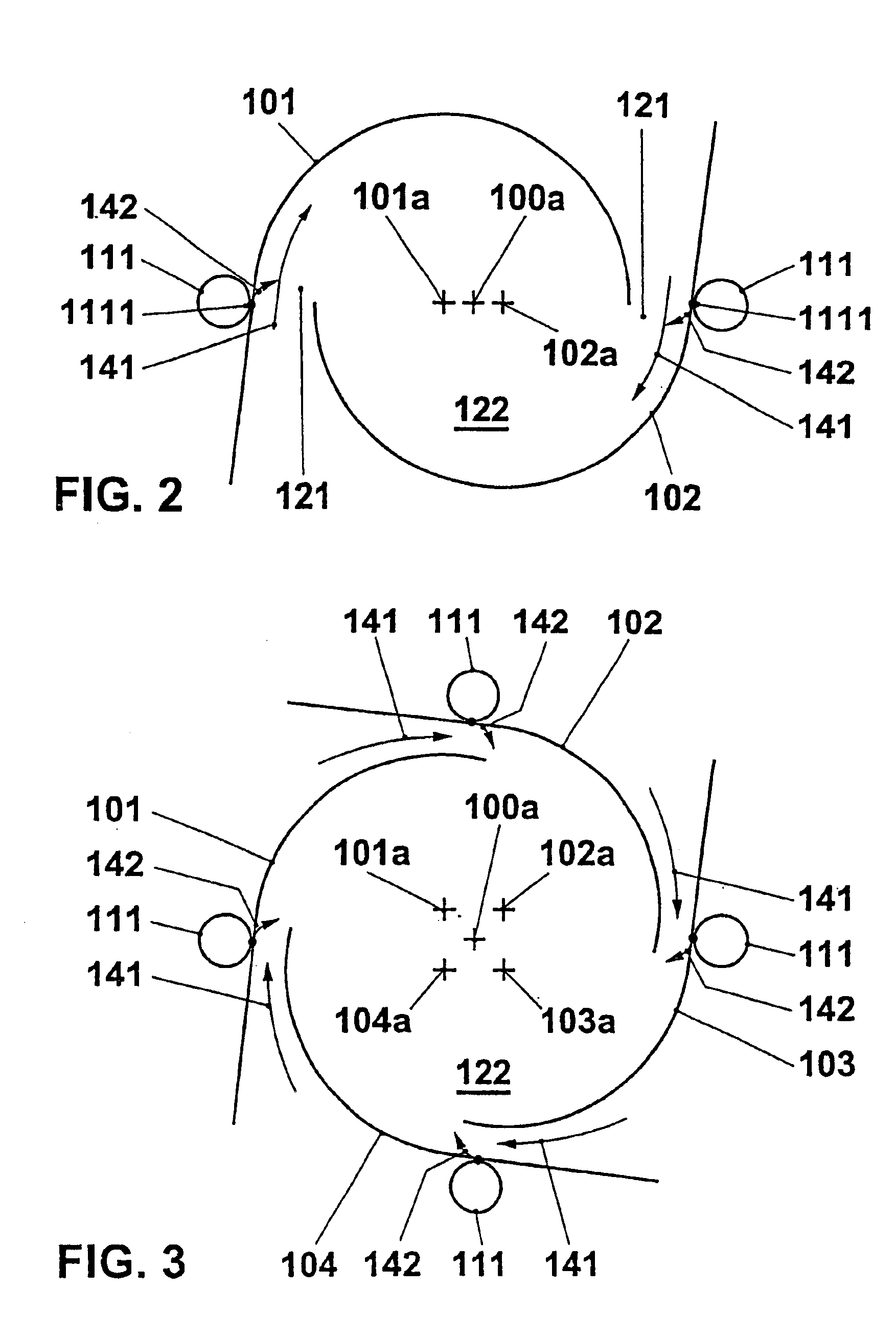

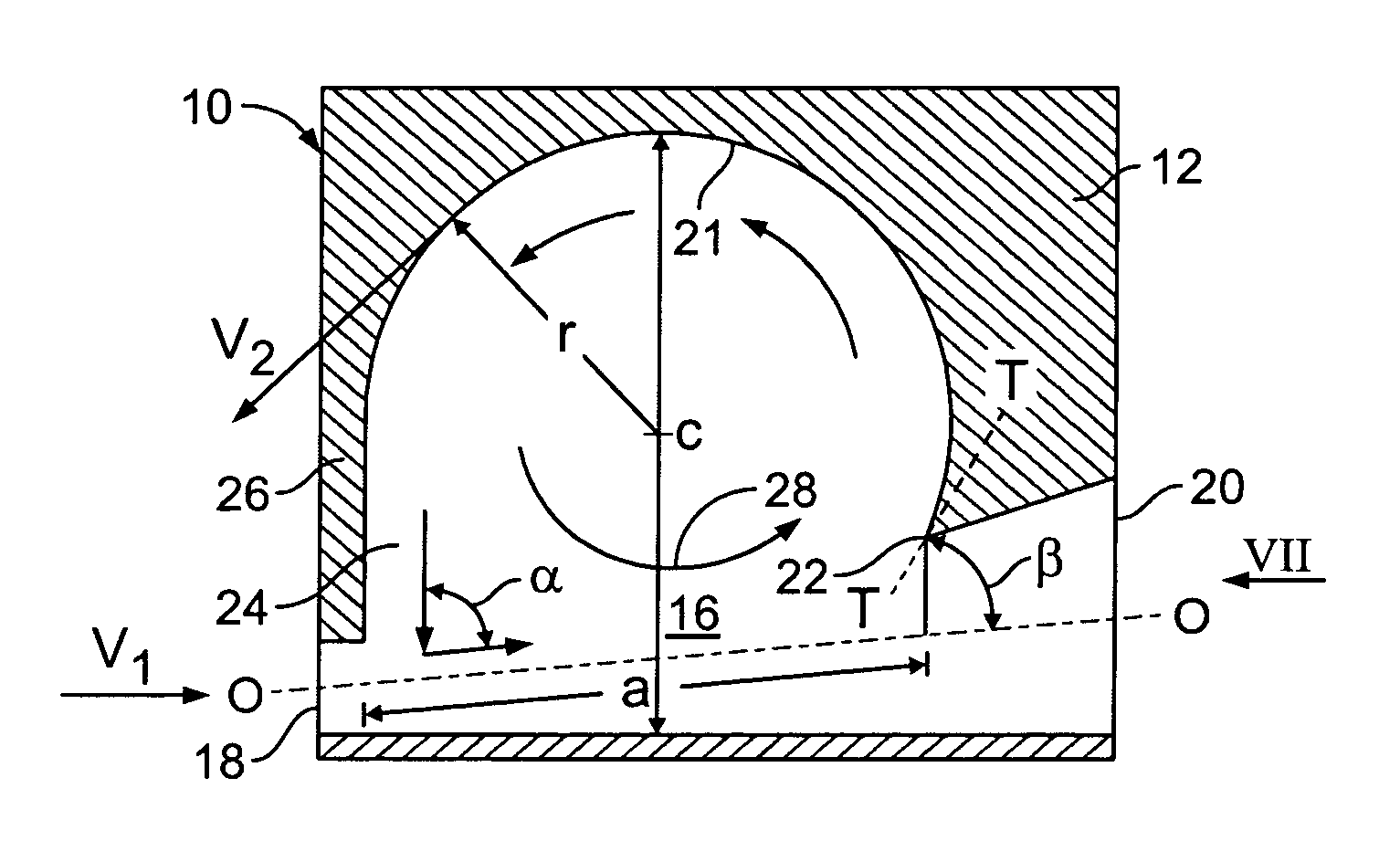

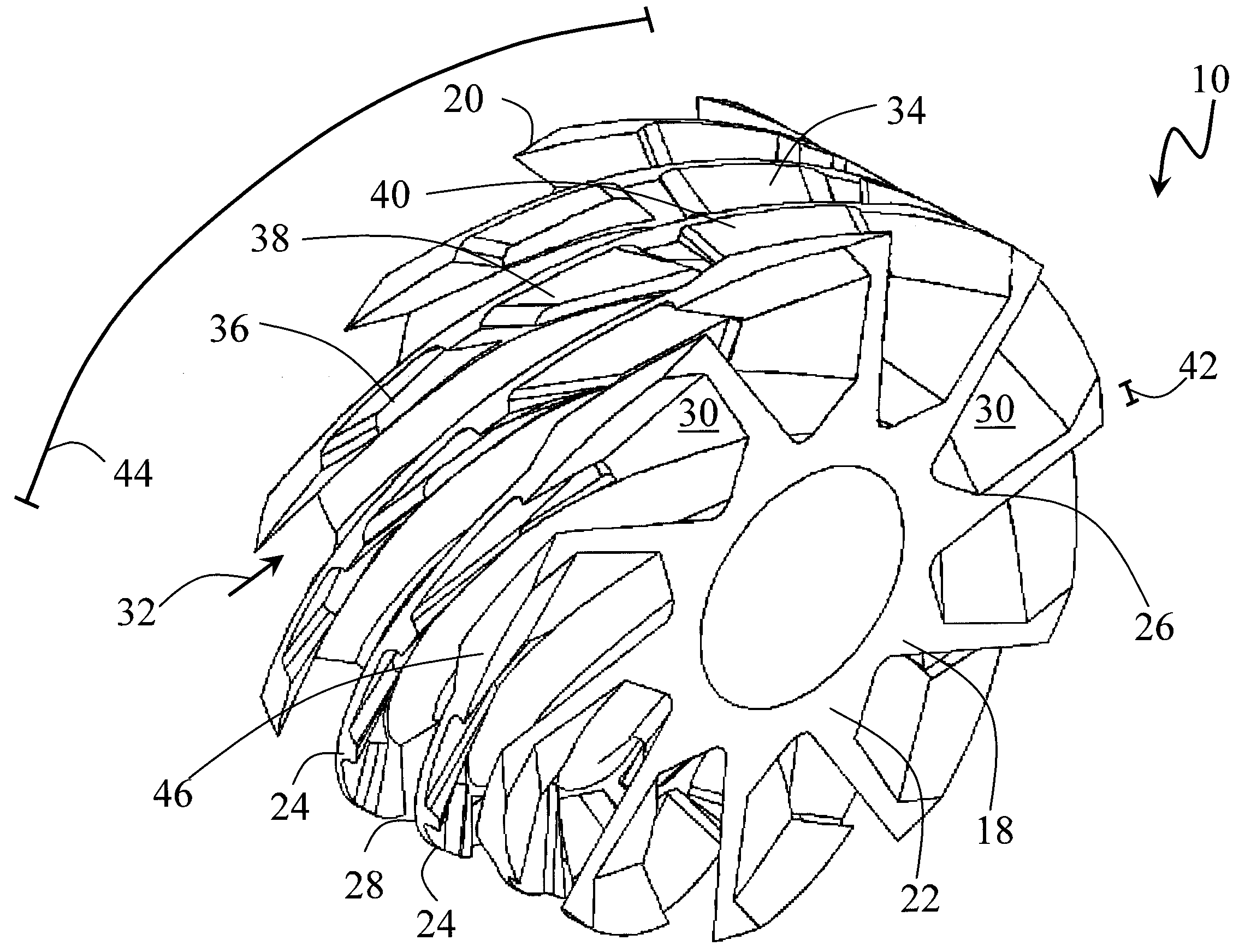

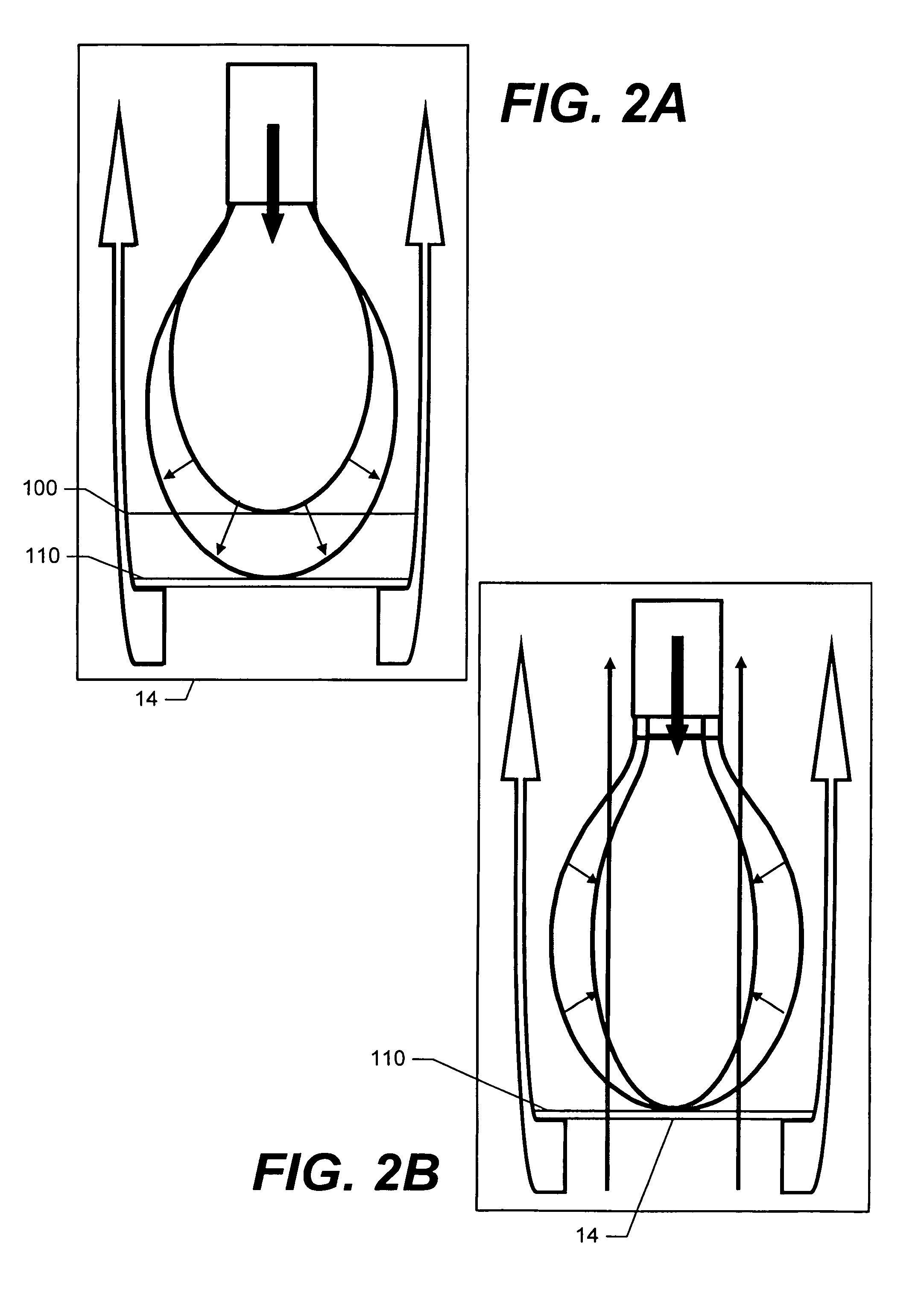

The invention relates to recirculation flow combustors having a generally curved recirculation chamber and unobstructed flow along the periphery of the boundary layer of the vortex flow in this chamber, and methods of operating such combustors. Such combustors further have a border interface area of low turbulence between the vortex flow and the main flow in the combustor, in which chemical reactions take place which are highly advantageous to the combustion process, and which promote a thermal nozzle effect within the combustor. A combustor of this type may be used for burning lean and super-lean fuel and air mixtures for use in gas turbine engines, jet and rocket engines and thermal plants such as boilers, heat exchanges plants, chemical reactors, and the like. The apparatus and methods of the invention may also be operated under conditions that favor fuel reformation rather than combustion, where such a reaction is desired.

Owner:LEAN FLAME INC

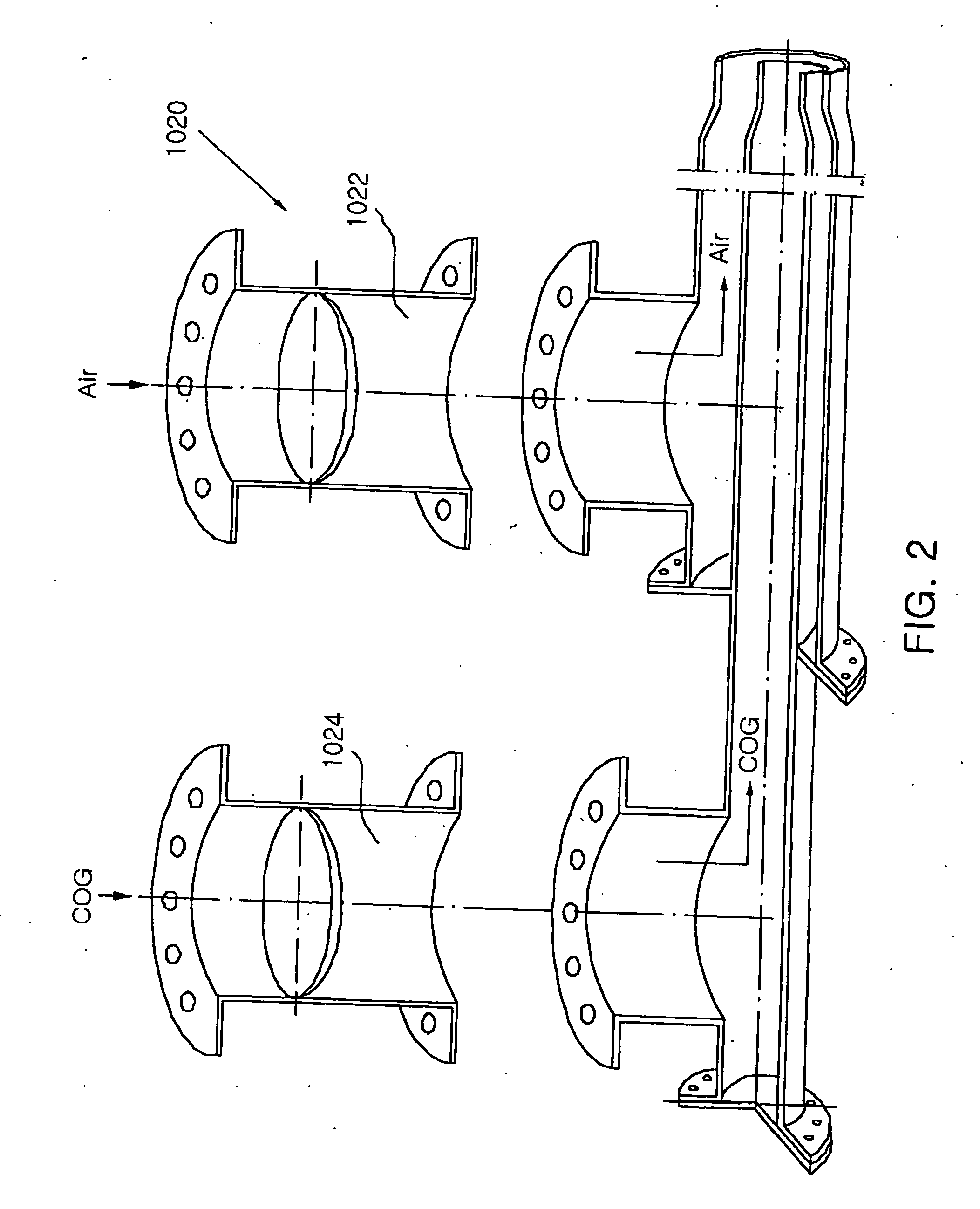

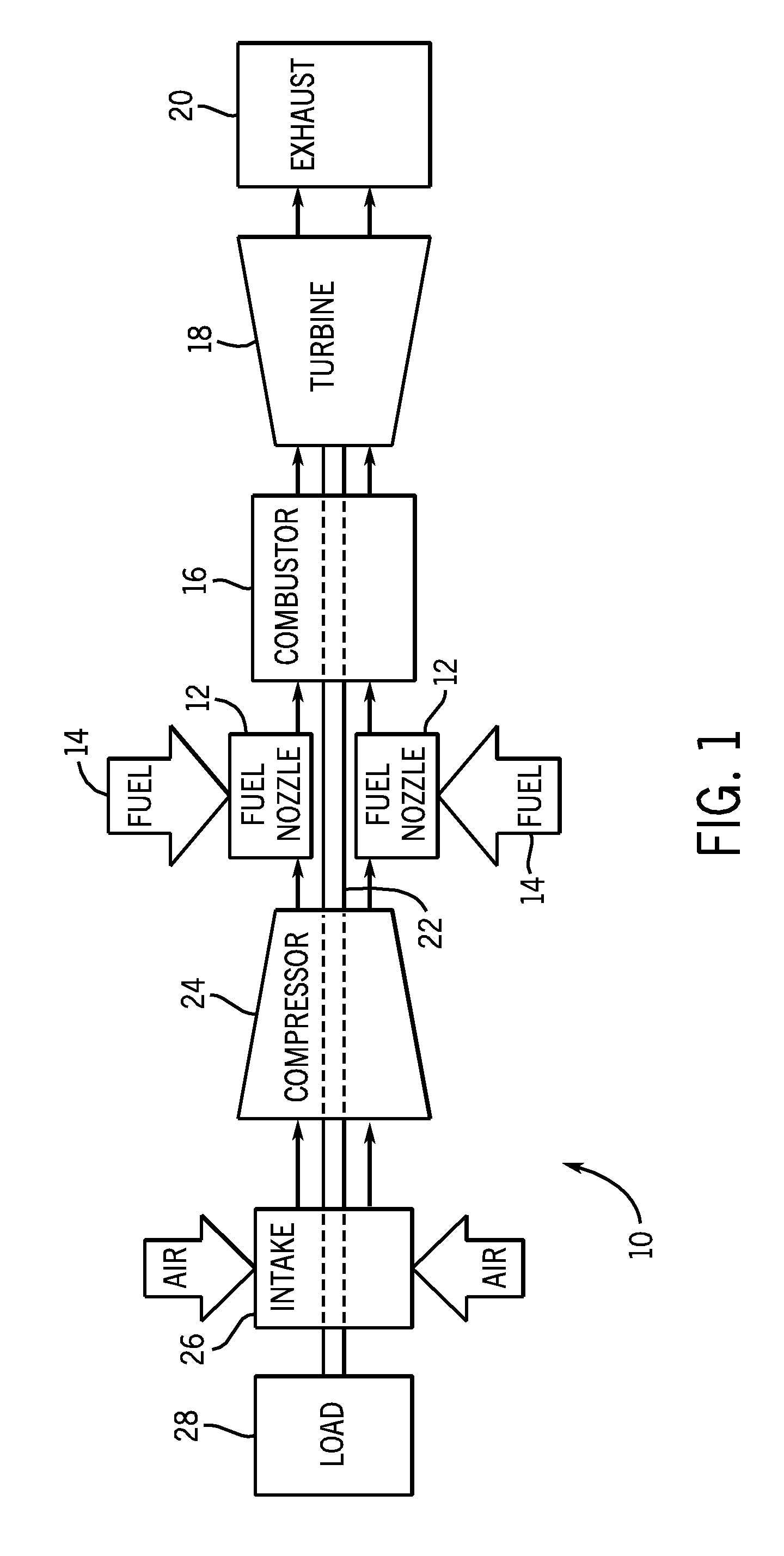

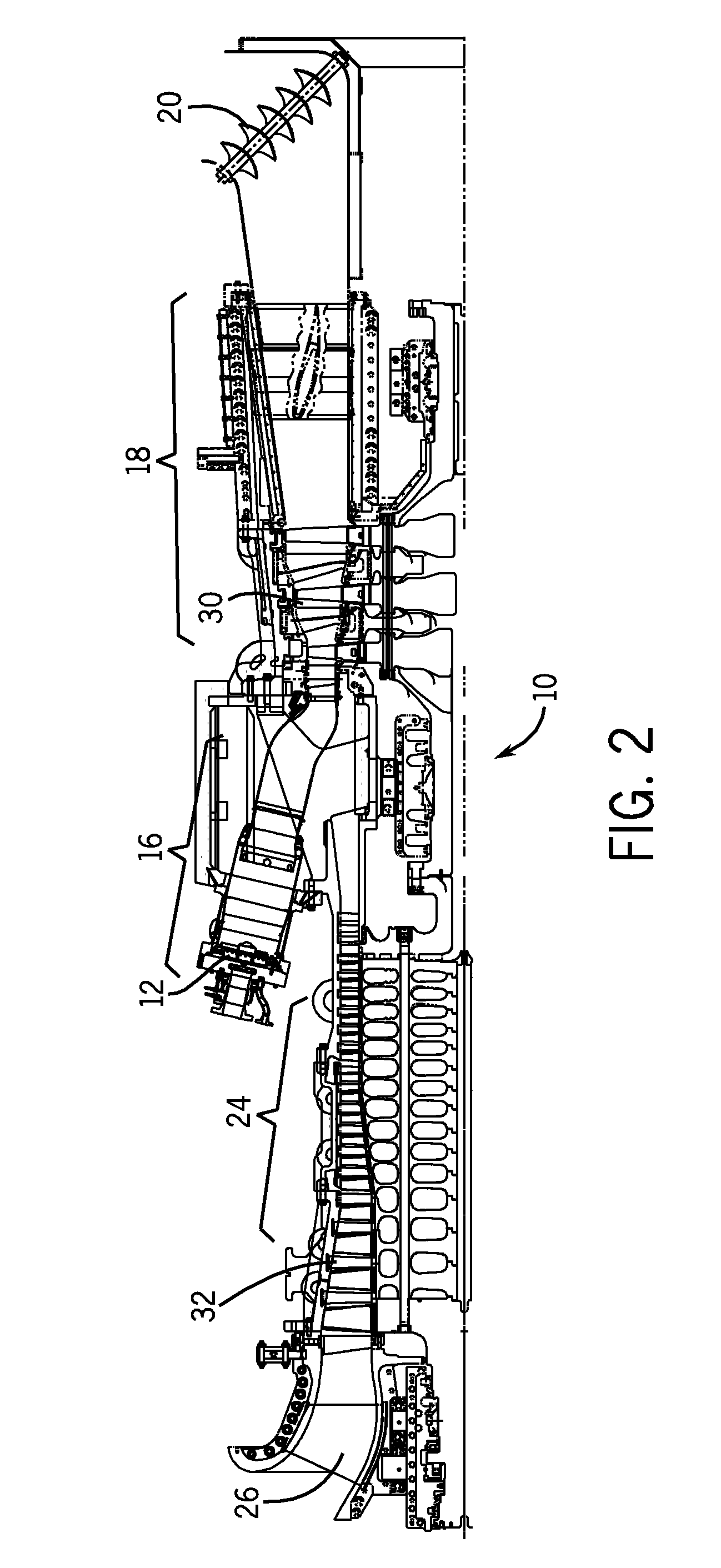

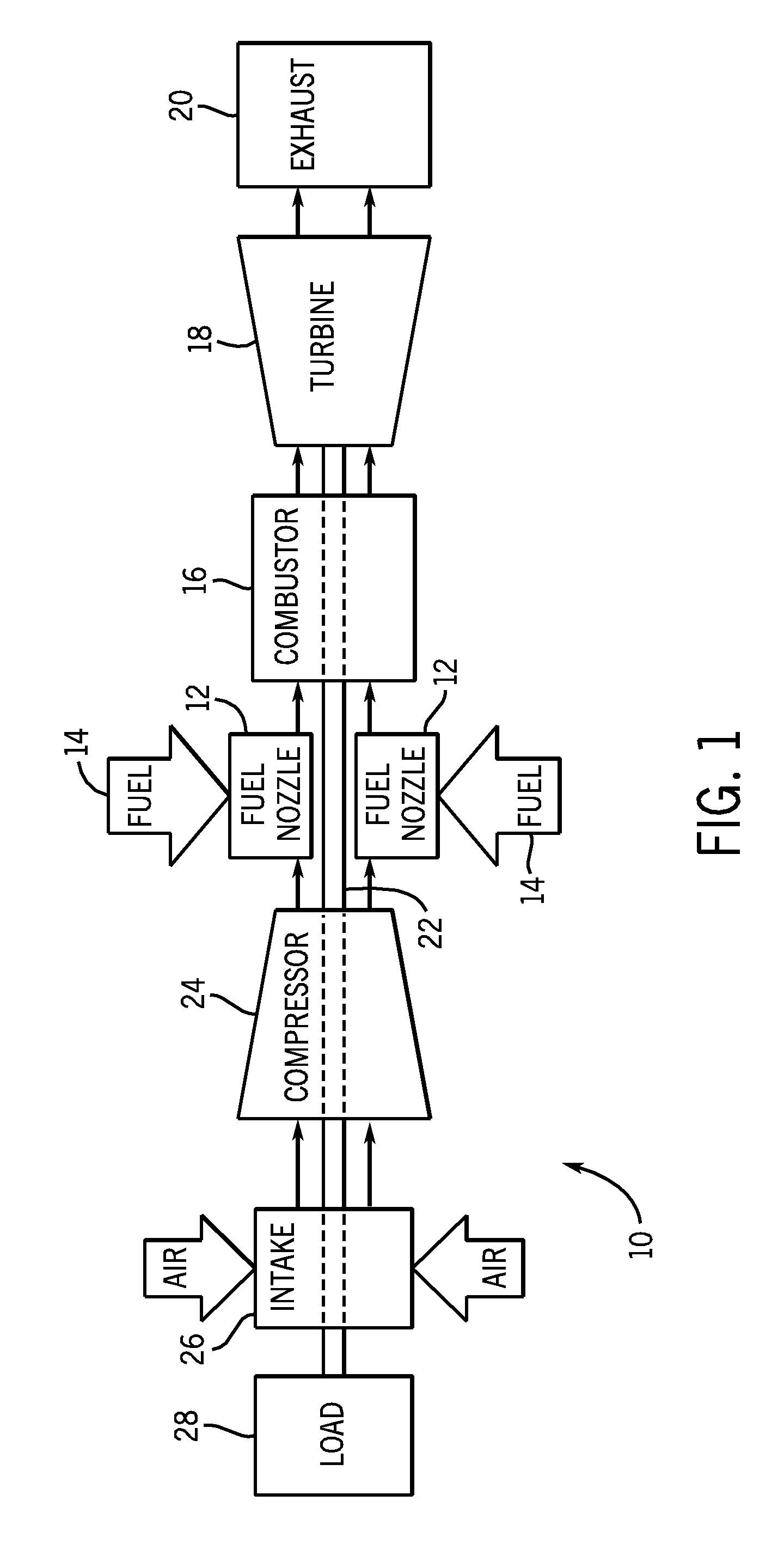

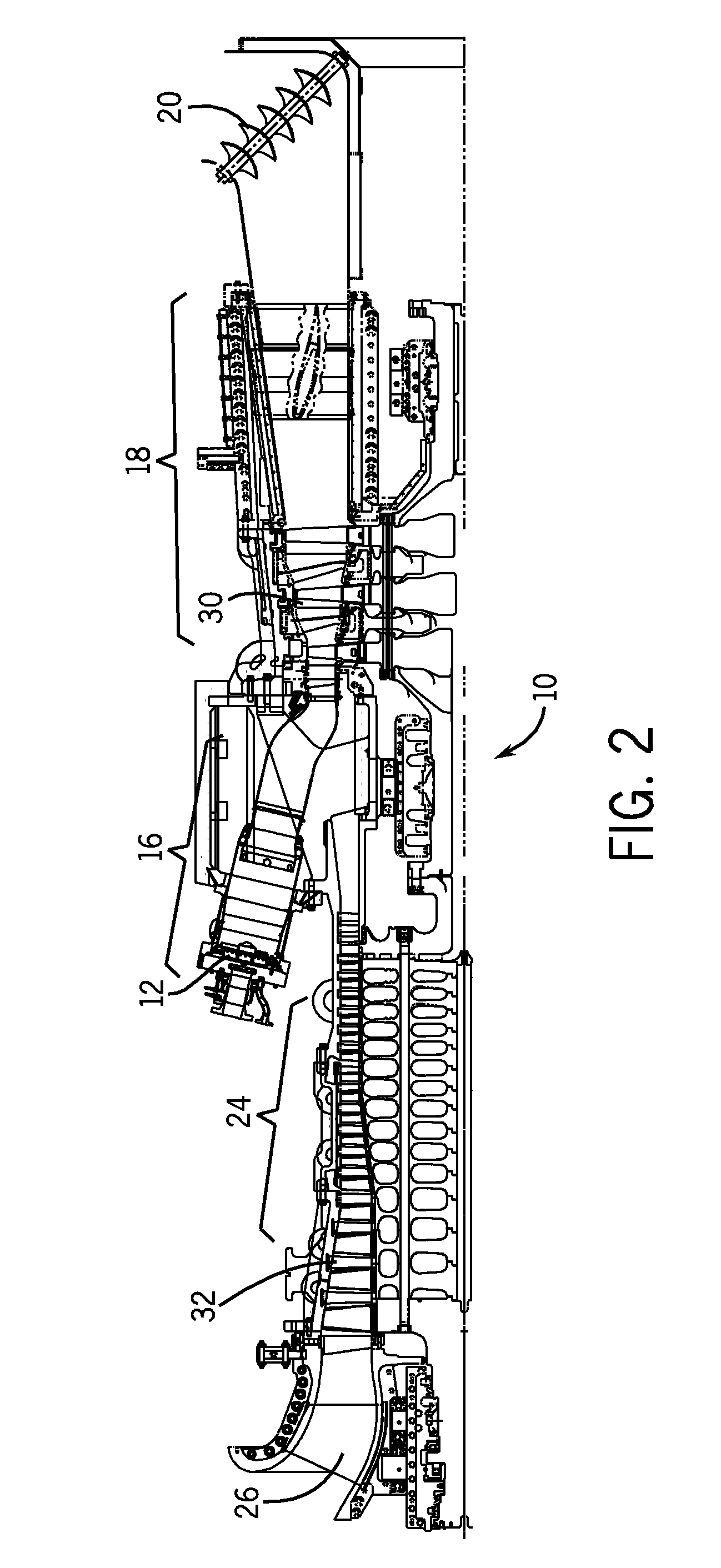

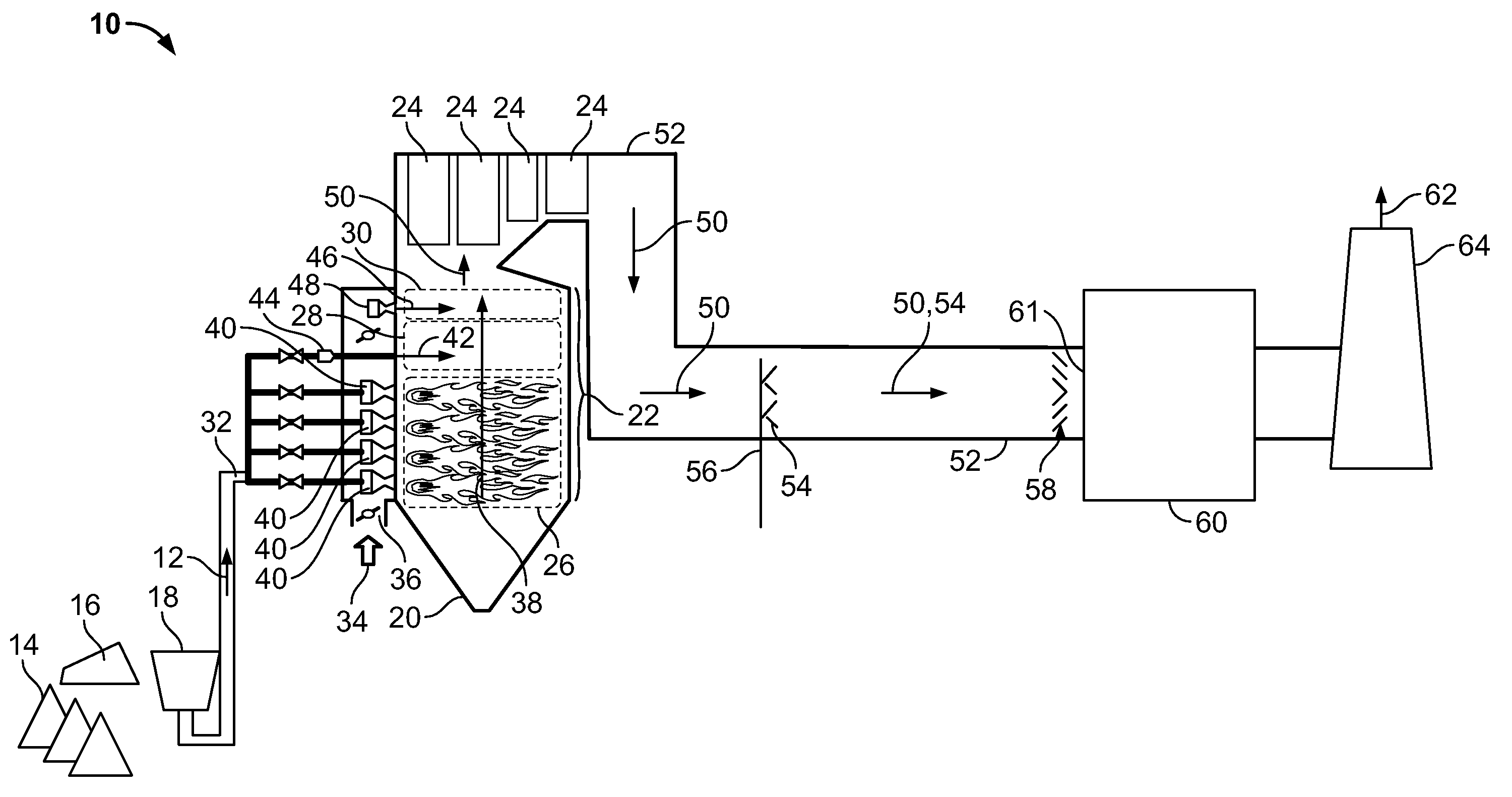

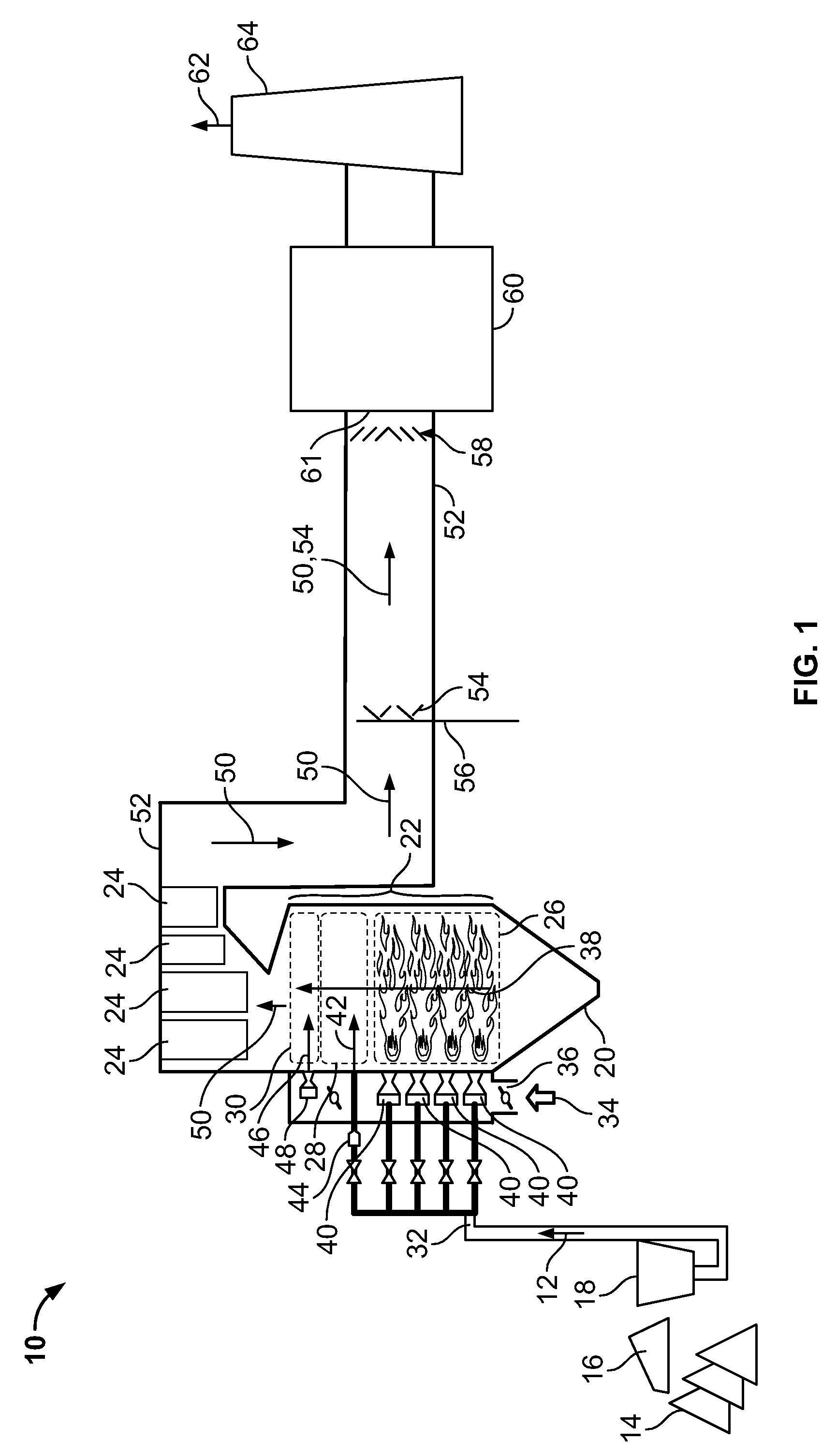

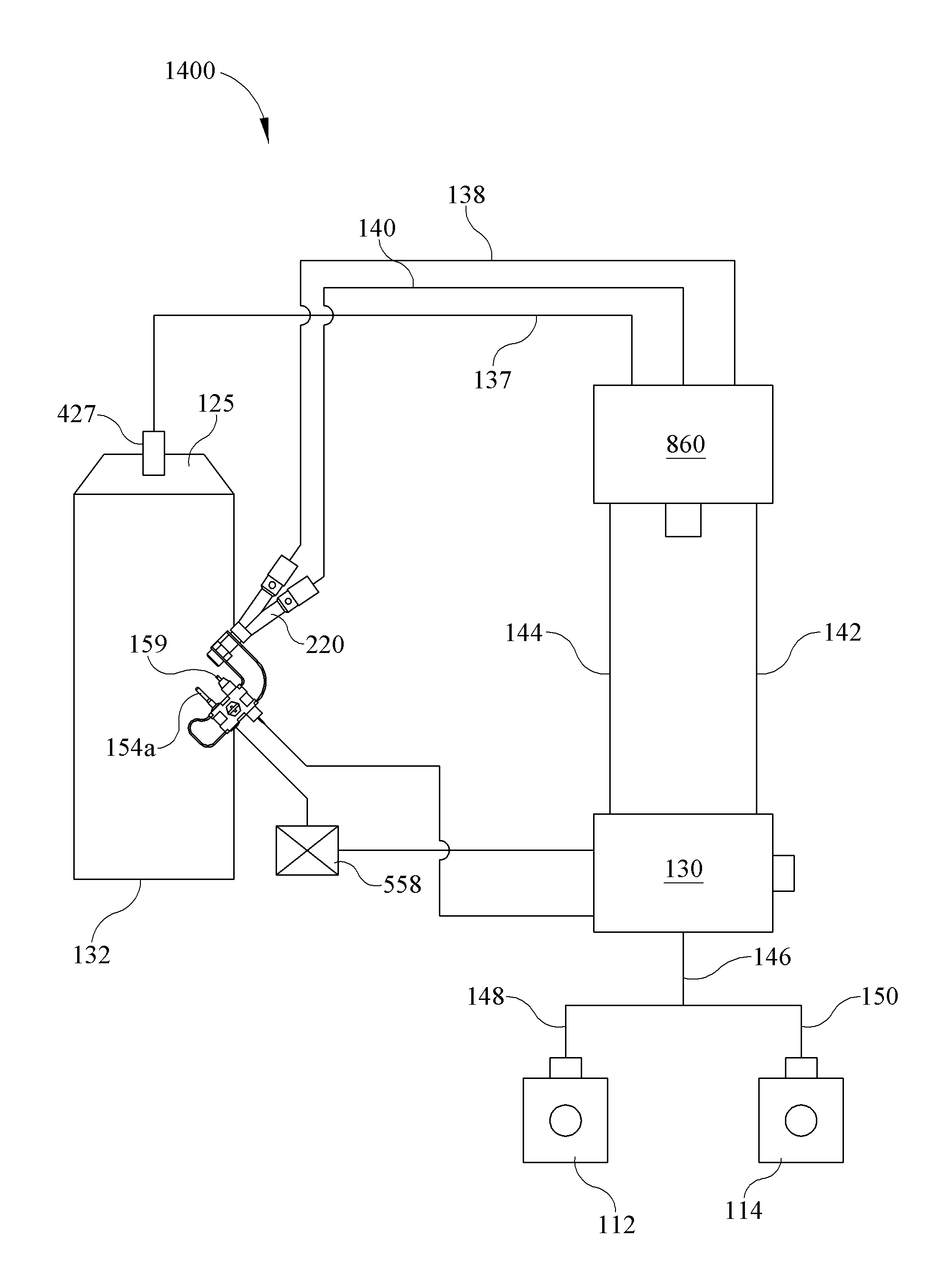

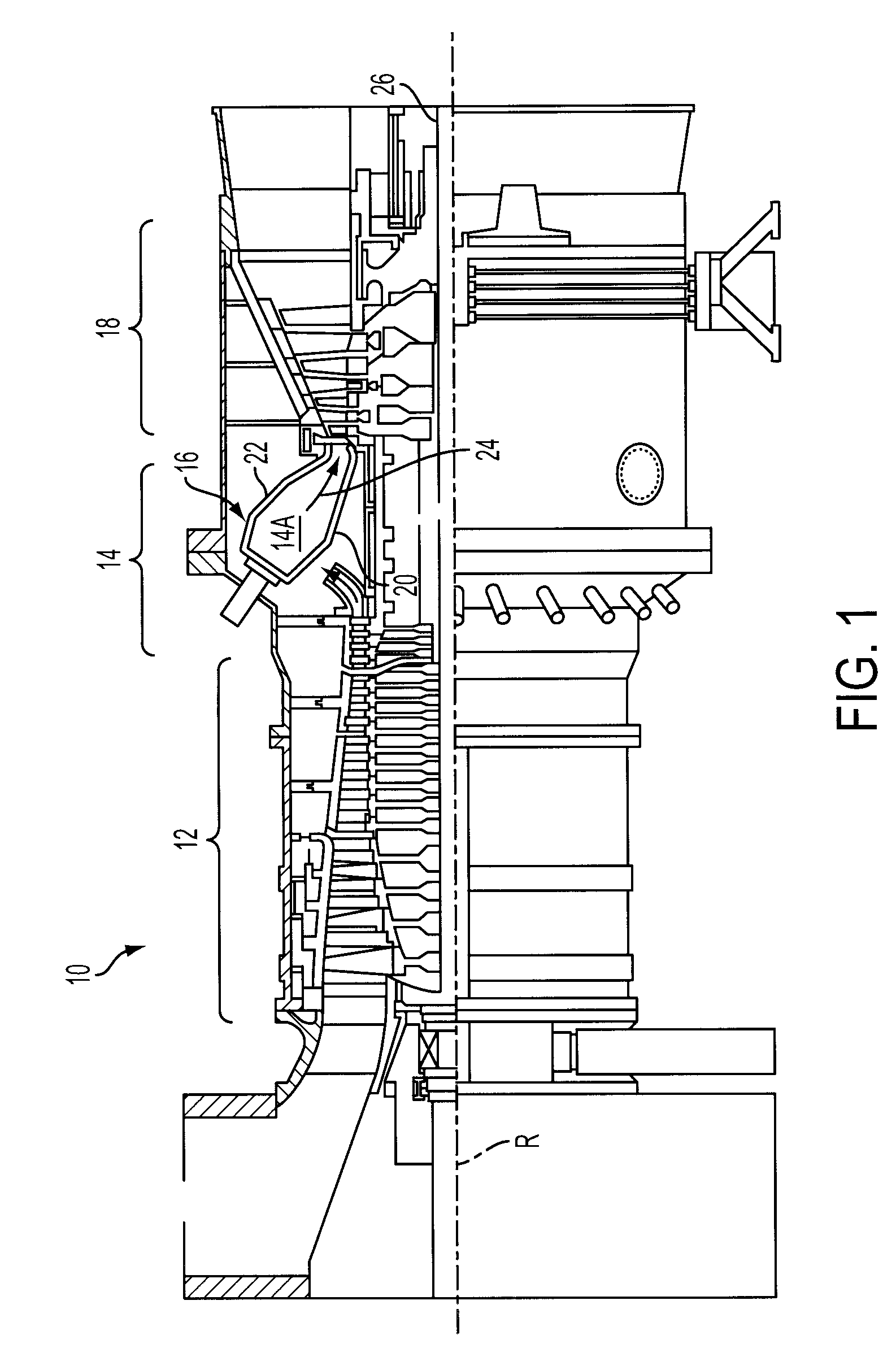

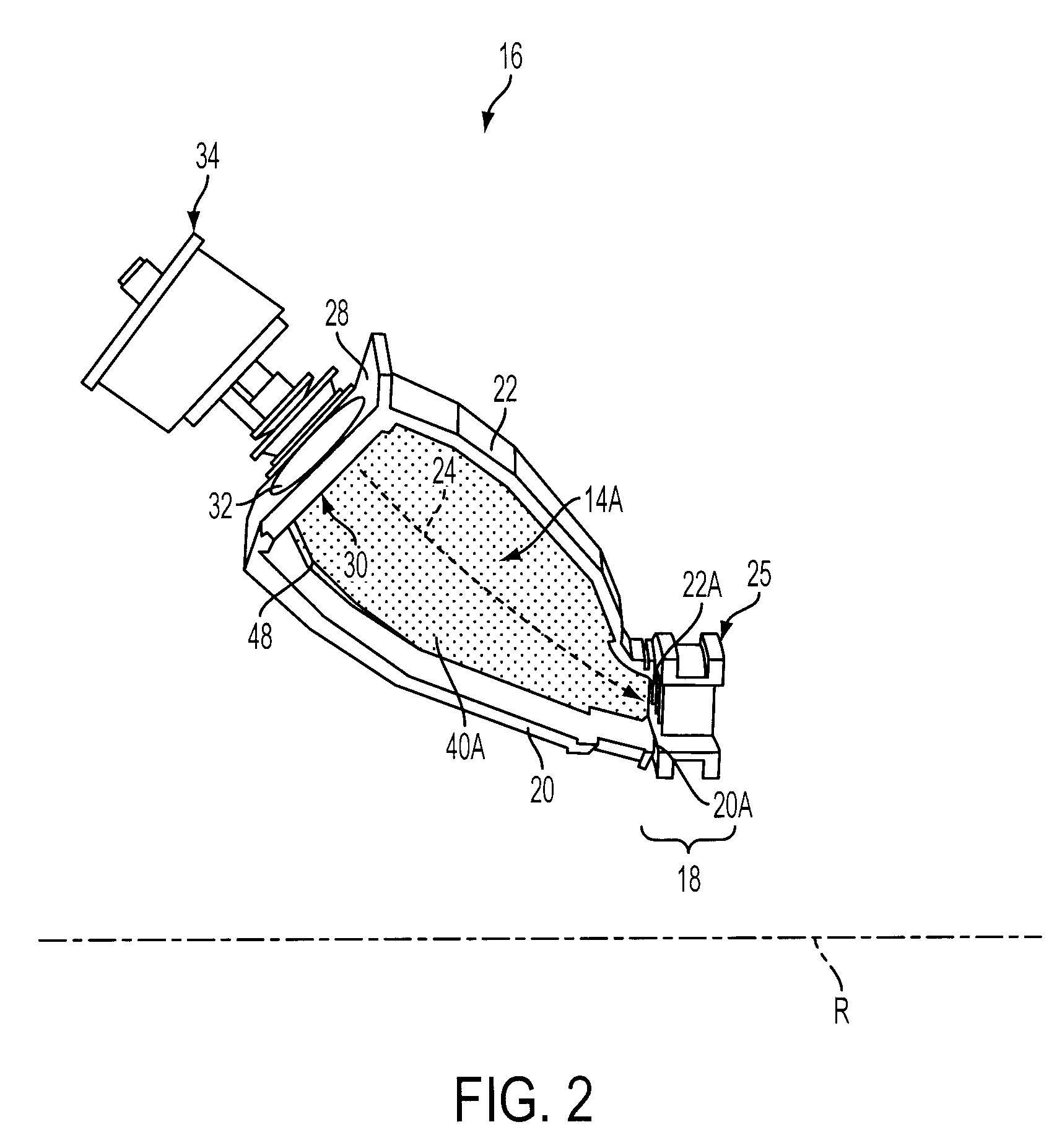

Apparatus and method for a gas turbine entrainment system

ActiveUS20090178412A1Reduce lossesFacilitate turbulenceContinuous combustion chamberEngine manufactureCombustion chamberCombustor

This invention relates to an apparatus for an entrainment system of a vortex burning combustion chamber or a vortex burning inter-turbine burner in a gas turbine. The entrainment system rapidly and thoroughly mixes hot combustion gases with non-combustion gases to reduce the gas temperature before entering a turbine. The entrainment system includes a plurality of helical vanes forming trenches and resulting in a highly helical flow path. The highly helical flow path provides an increased residence time for mixing of the combustion gases and non-combustion gases. Radial cavities in the helical vanes, canted vane angles and varying geometries further facilitate mixing while reducing losses. This invention also includes a method of mixing combustion and non-combustion gases in an entrainment system.

Owner:SPYTEK AEROSPACE CORP

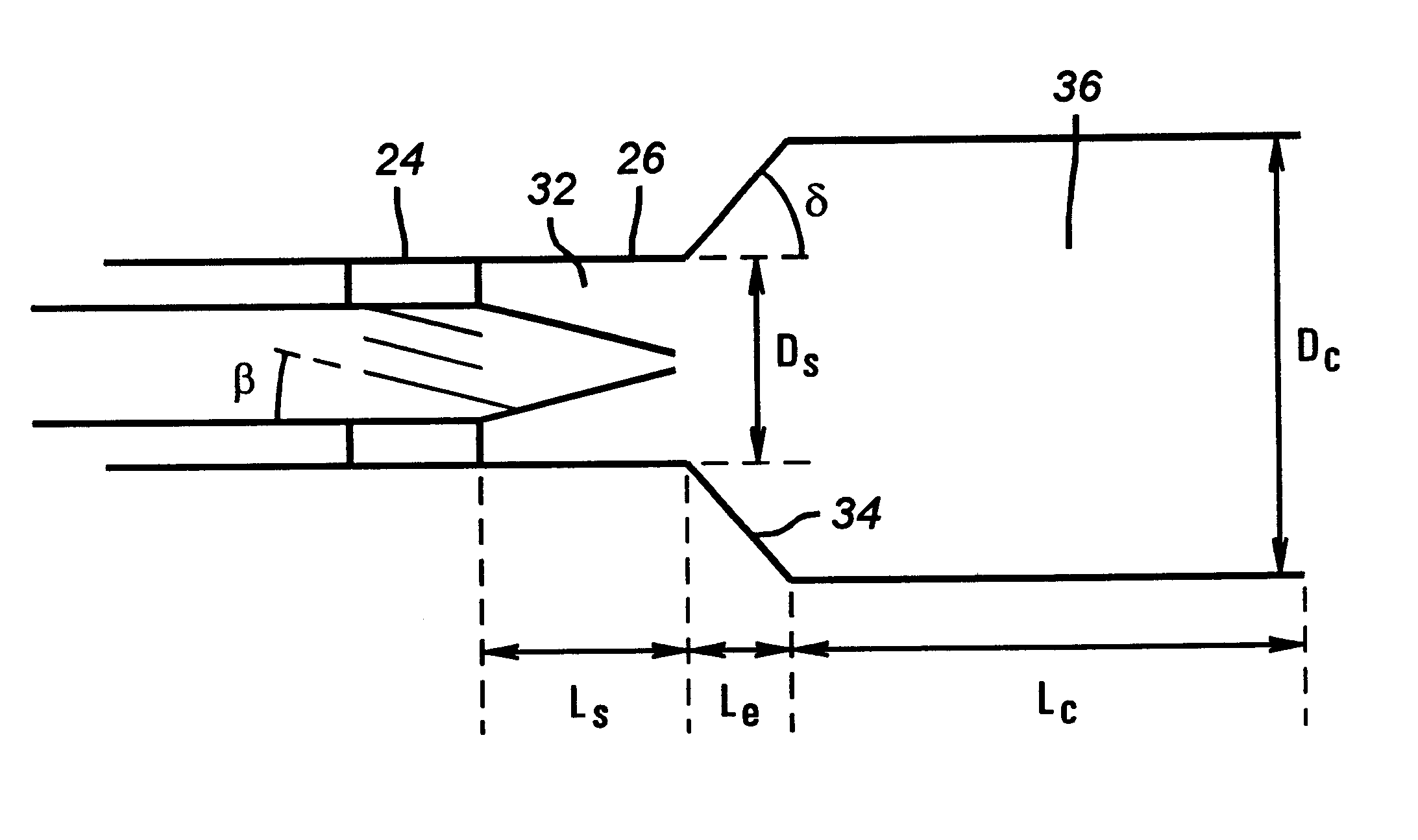

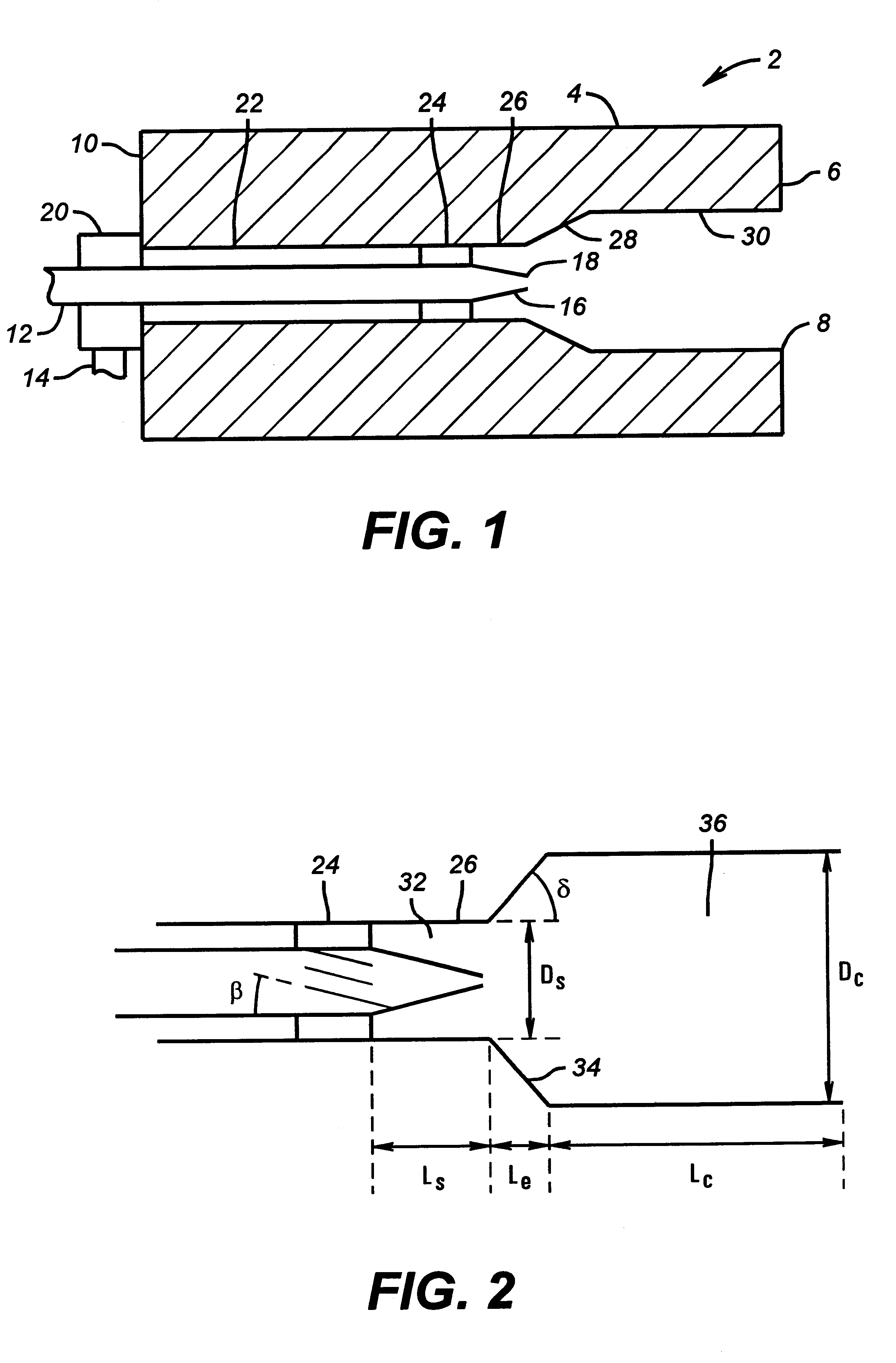

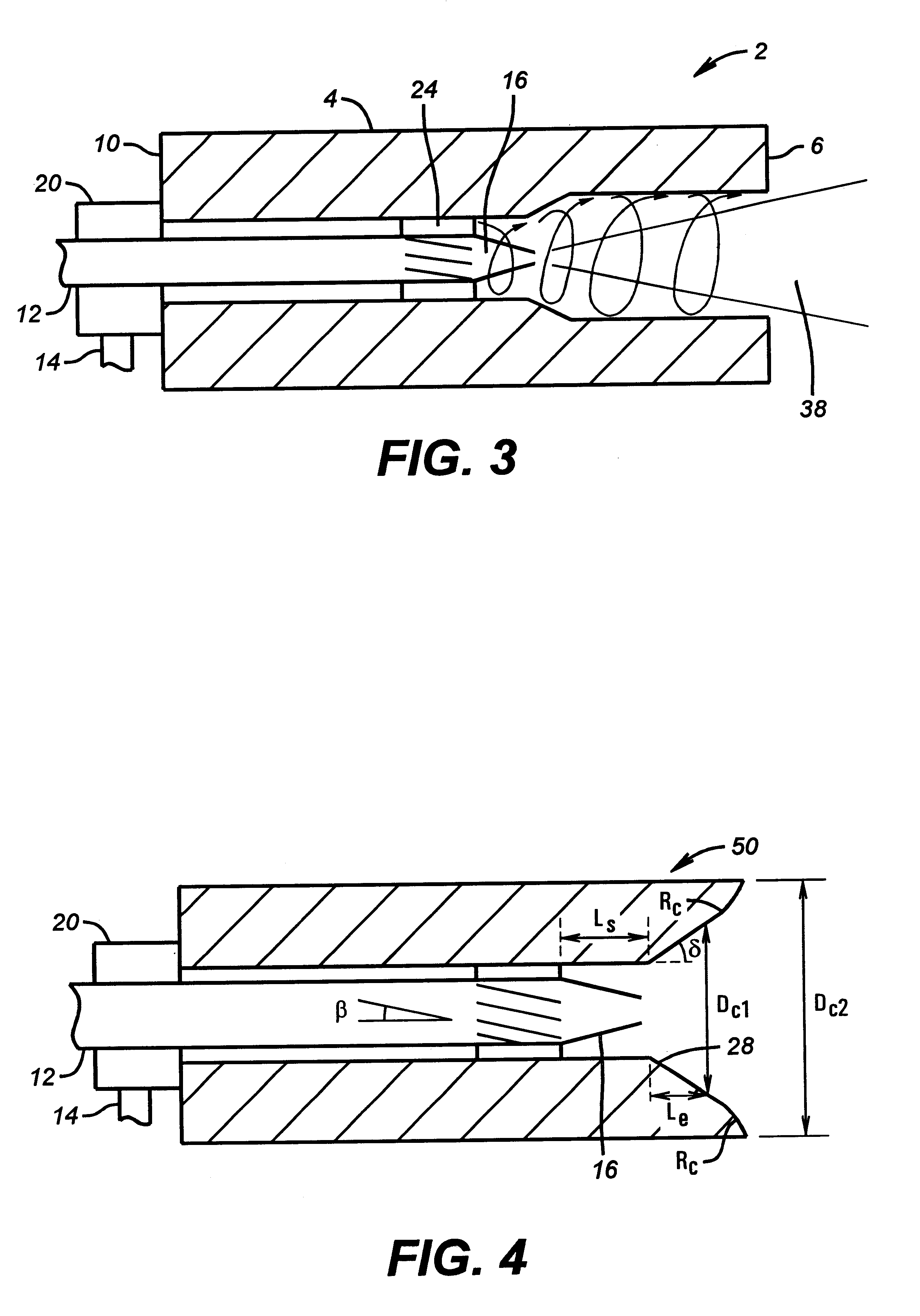

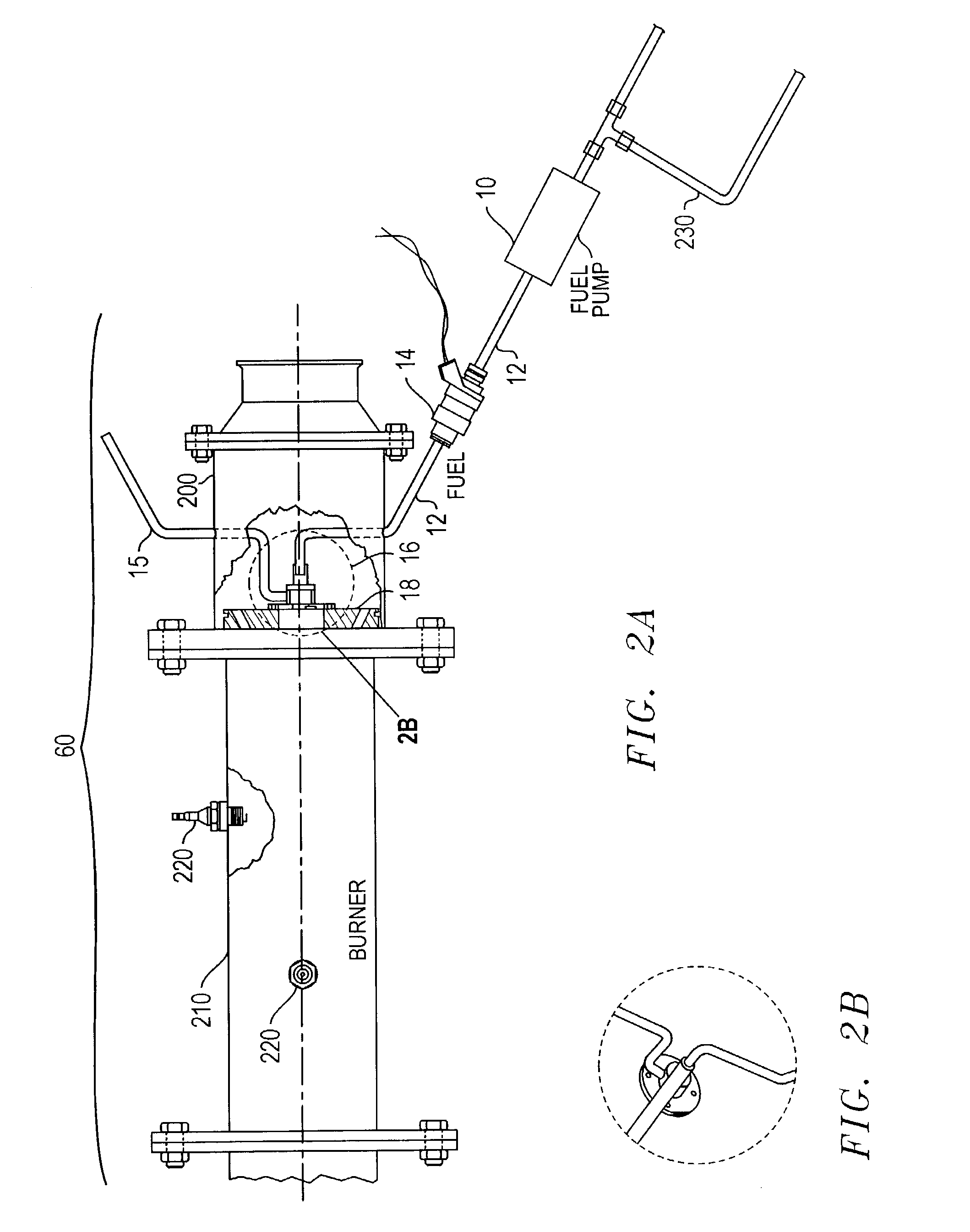

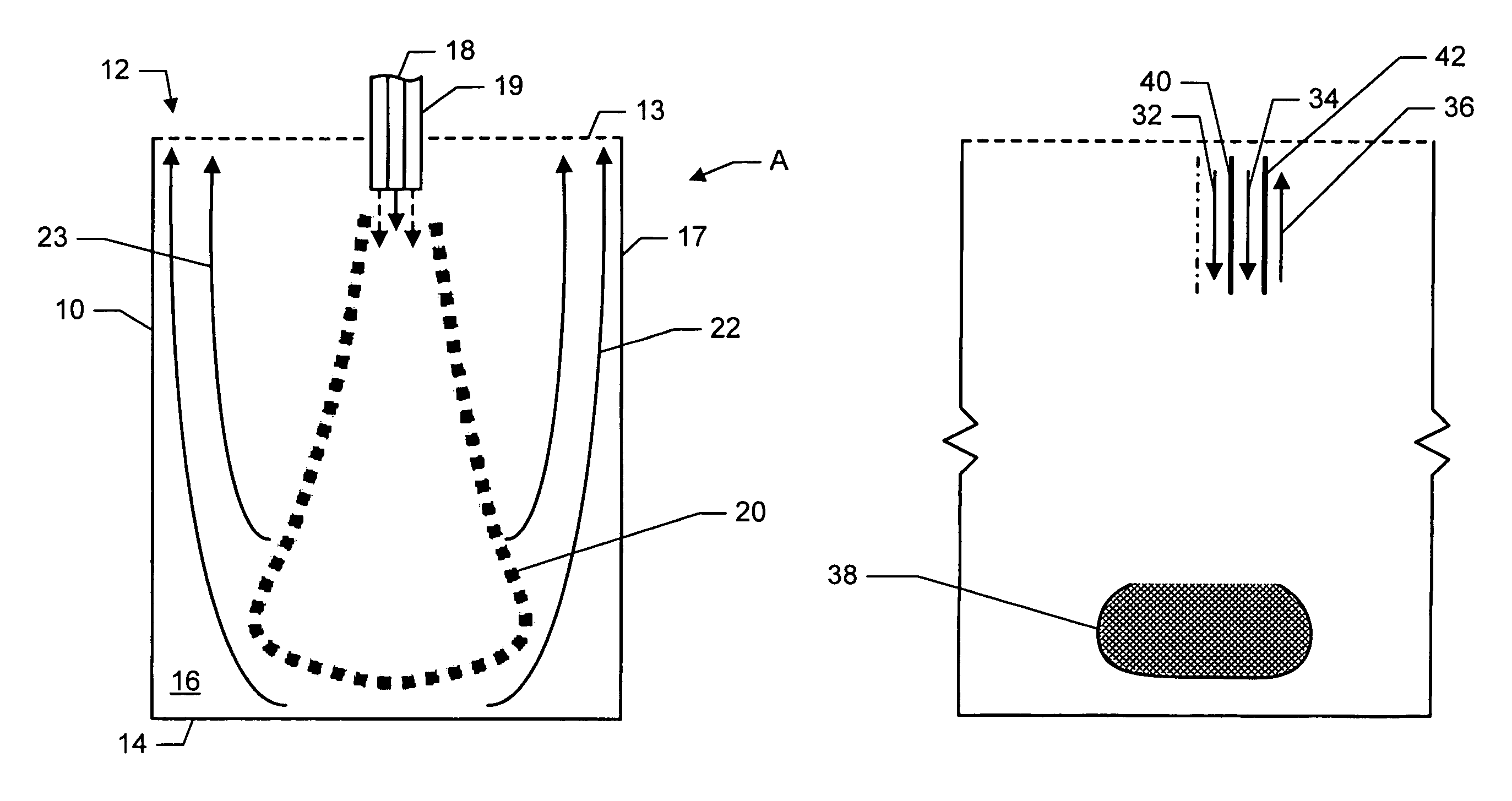

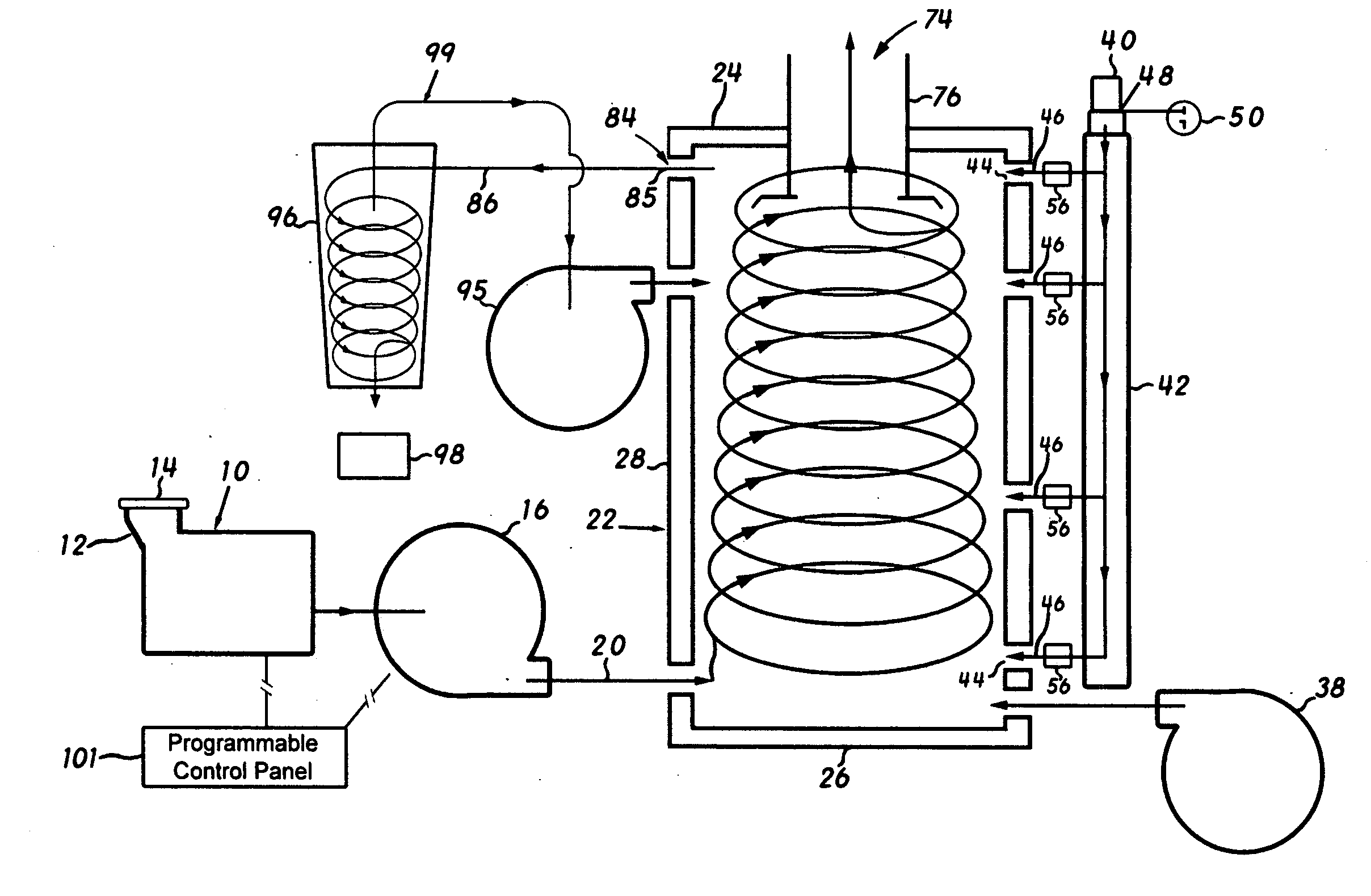

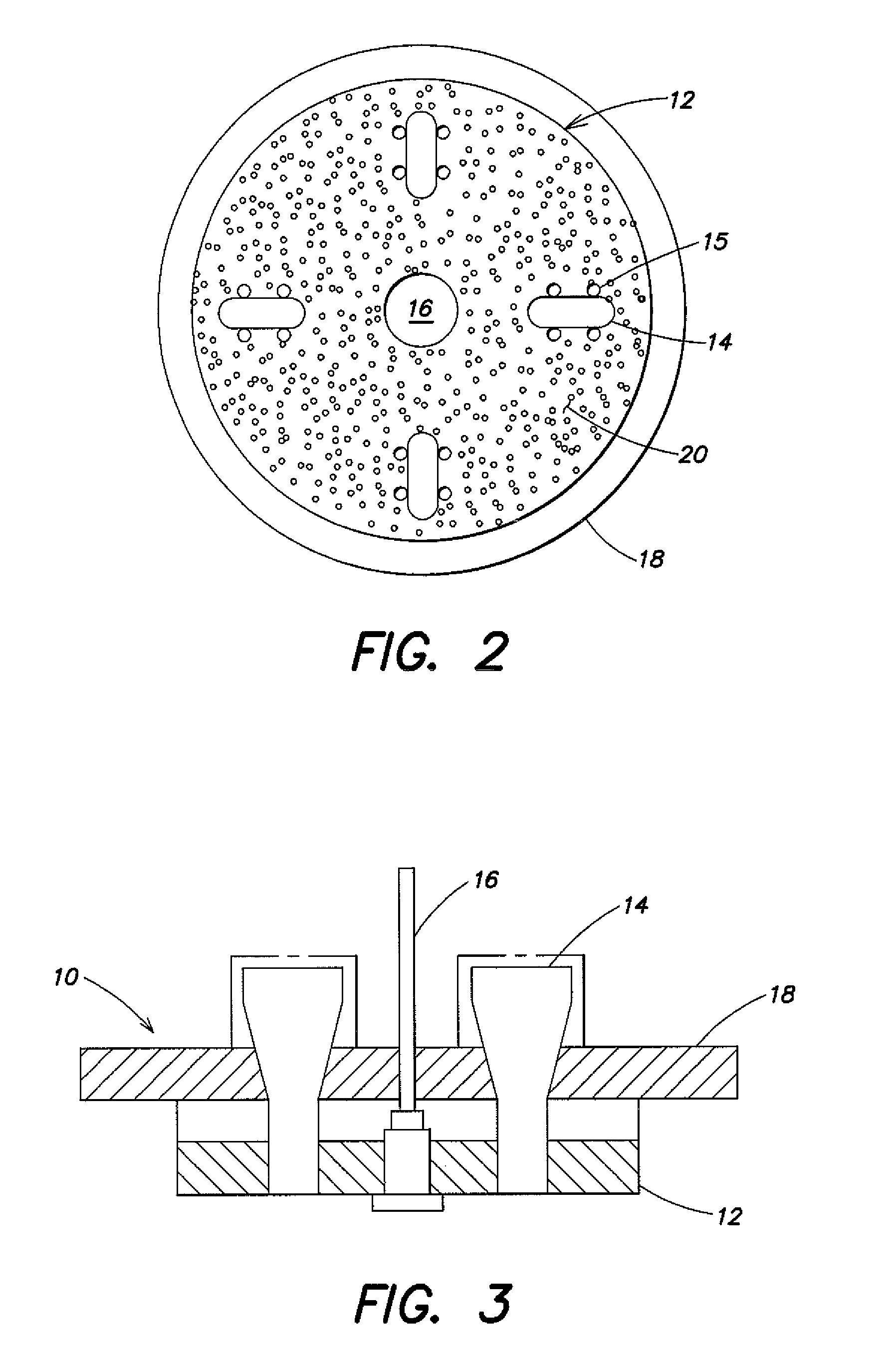

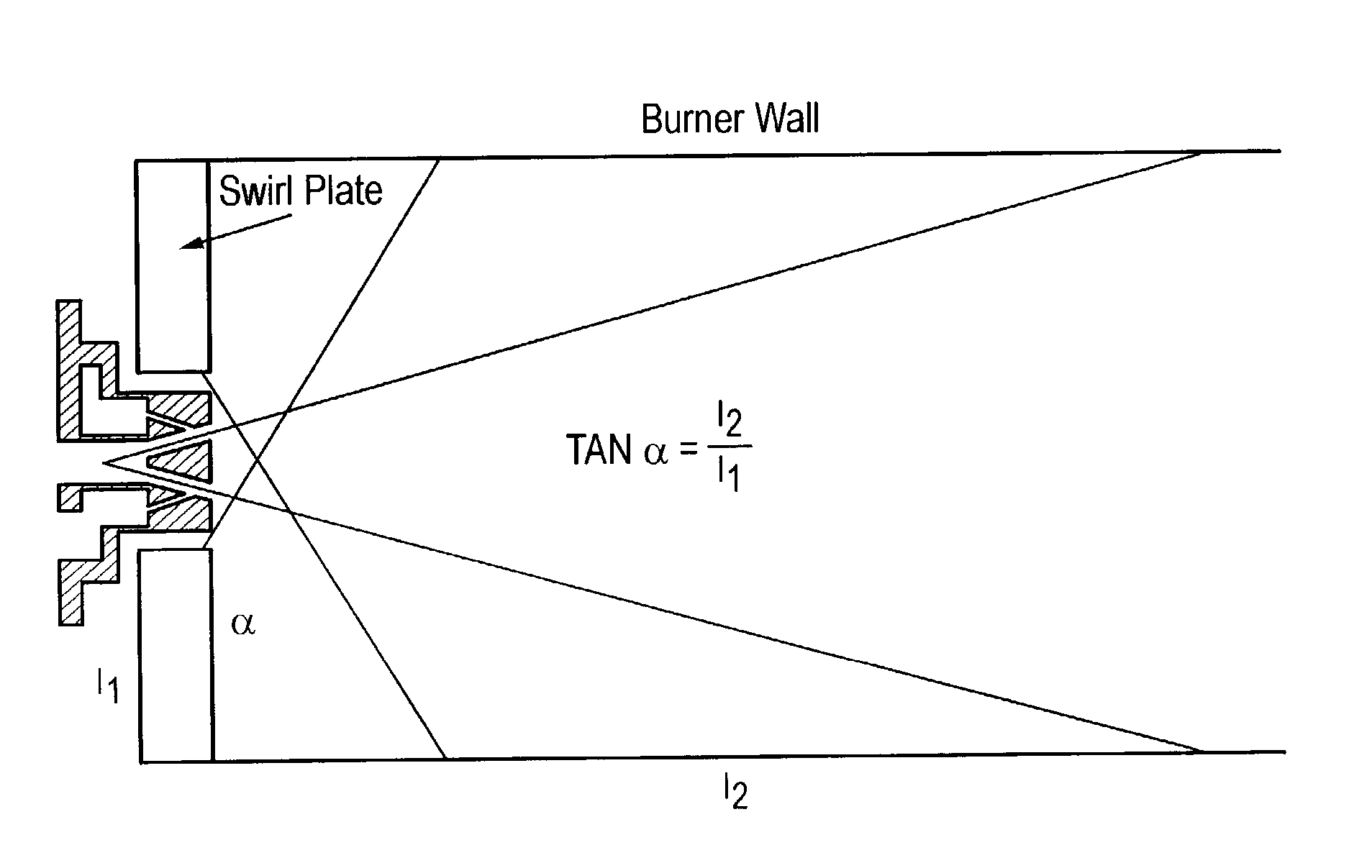

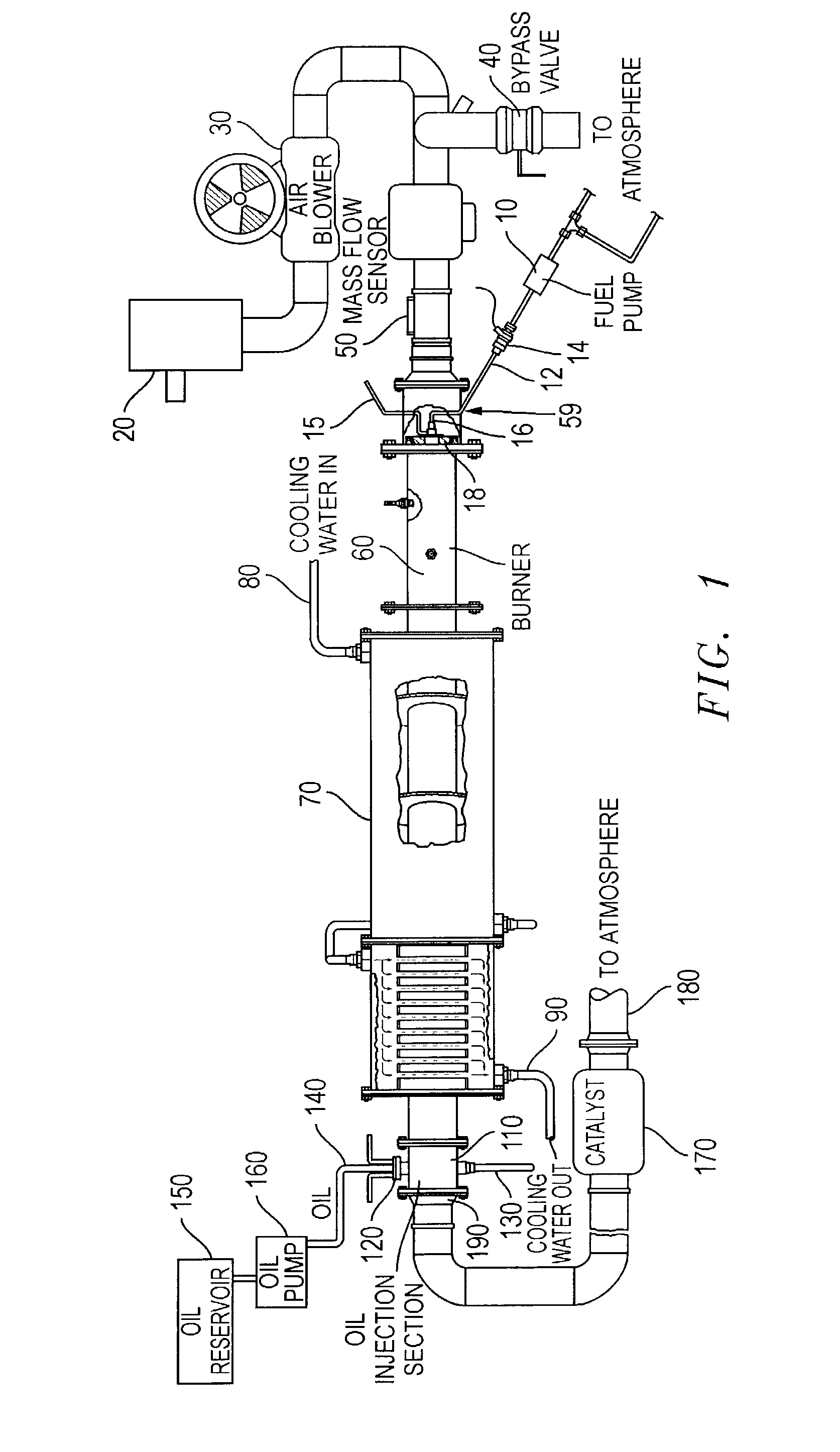

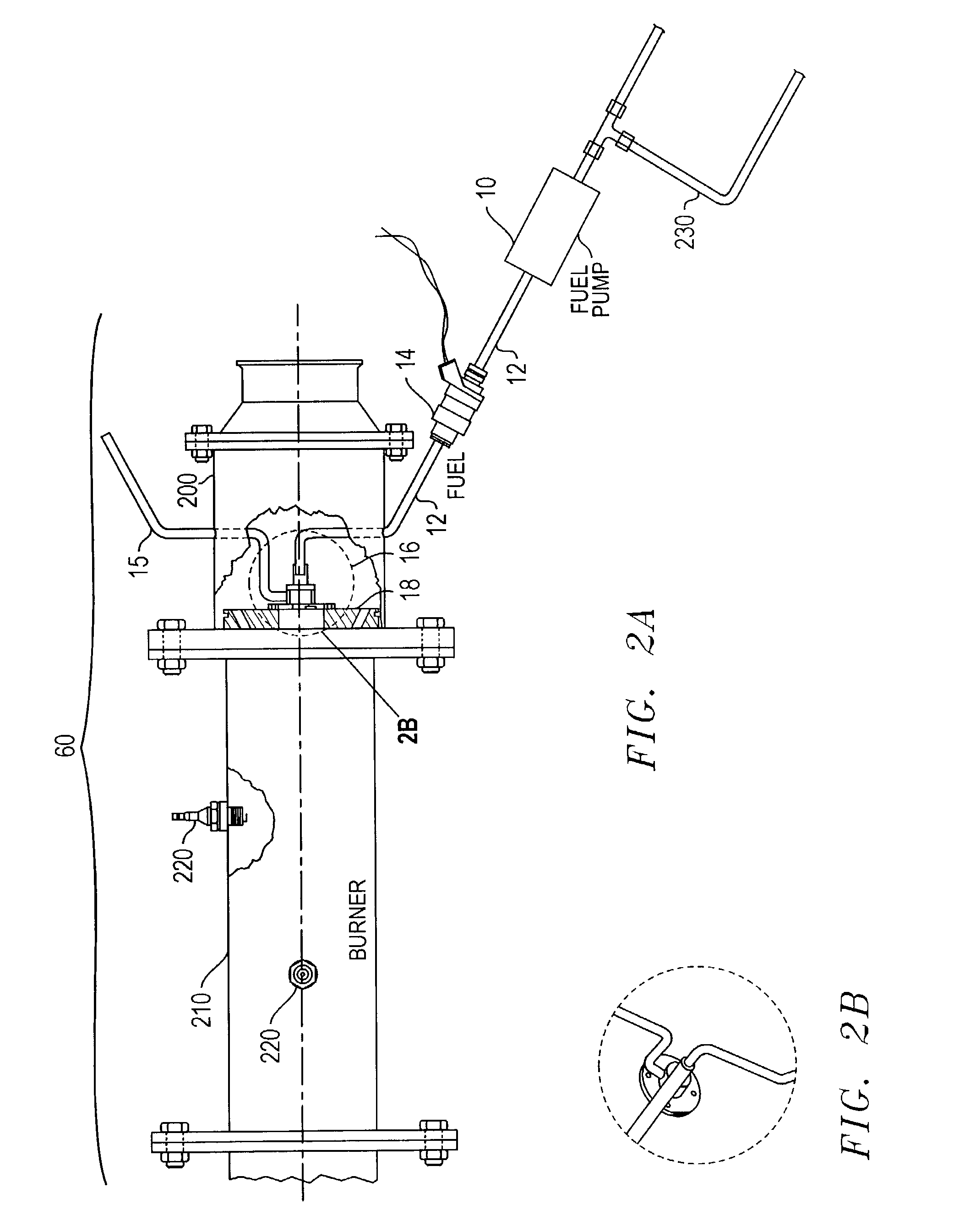

Method and apparatus for testing catalytic converter durability

InactiveUS20030079520A1Internal combustion piston enginesExhaust apparatusCombustorChemical measurement

The present application relates in general to an apparatus and to methods for testing the performance of an automotive catalytic converter under conditions simulating those which occur in motor vehicles over extended driving conditions. The application provides a novel swirl plate and a novel fuel injector which enable the burner to run stoichiometric for extended periods of time.

Owner:SOUTHWEST RES INST

Reheat burner injection system

The disclosure relates to a burner for a combustion chamber of a gas turbine, with an injection device for the introduction of at least one gaseous and / or liquid fuel into the burner, wherein the injection device has at least one body which is arranged in the burner with at least one nozzle for introducing the at least one fuel into the burner, the at least one body being configured as a streamlined body which has a streamlined cross-sectional profile and which extends with a longitudinal direction perpendicularly or at an inclination to a main flow direction prevailing in the burner. The at least one nozzle has its outlet orifice at or in a trailing edge of the streamlined body, and with reference to a central plane of the streamlined body, the trailing edge is provided with at least two lobes extending in opposite transverse directions.

Owner:ANSALDO ENERGIA SWITZERLAND AG

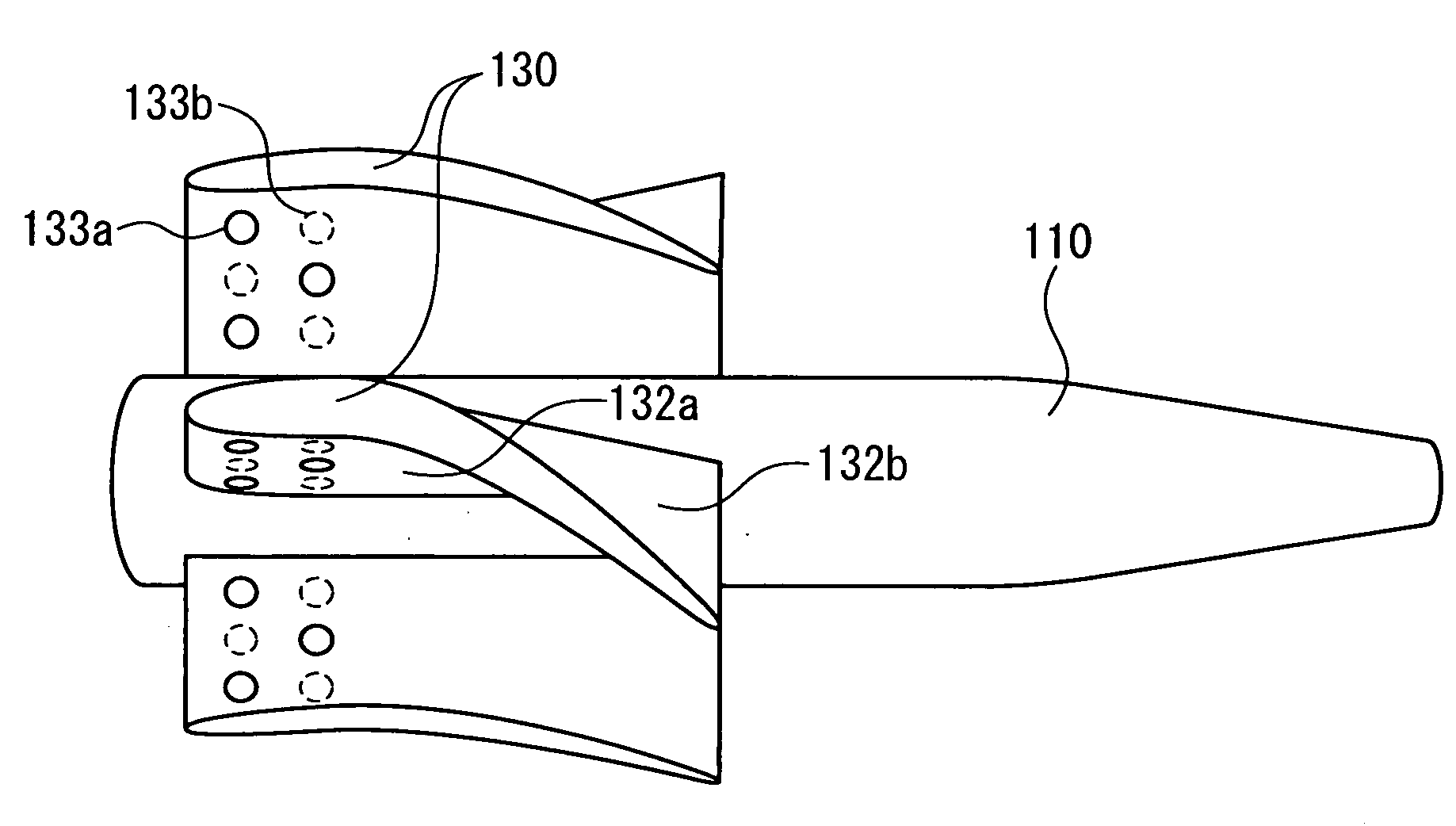

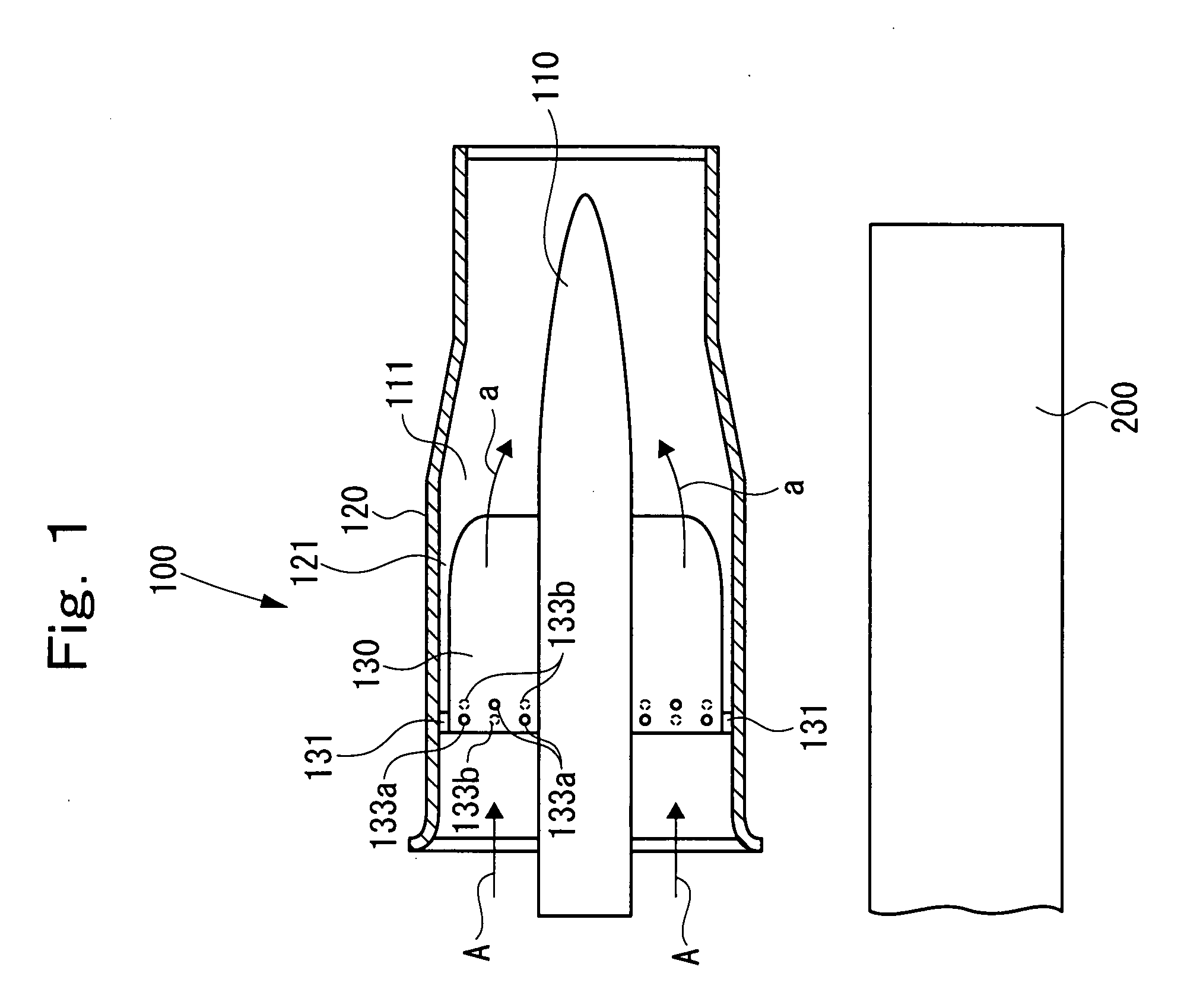

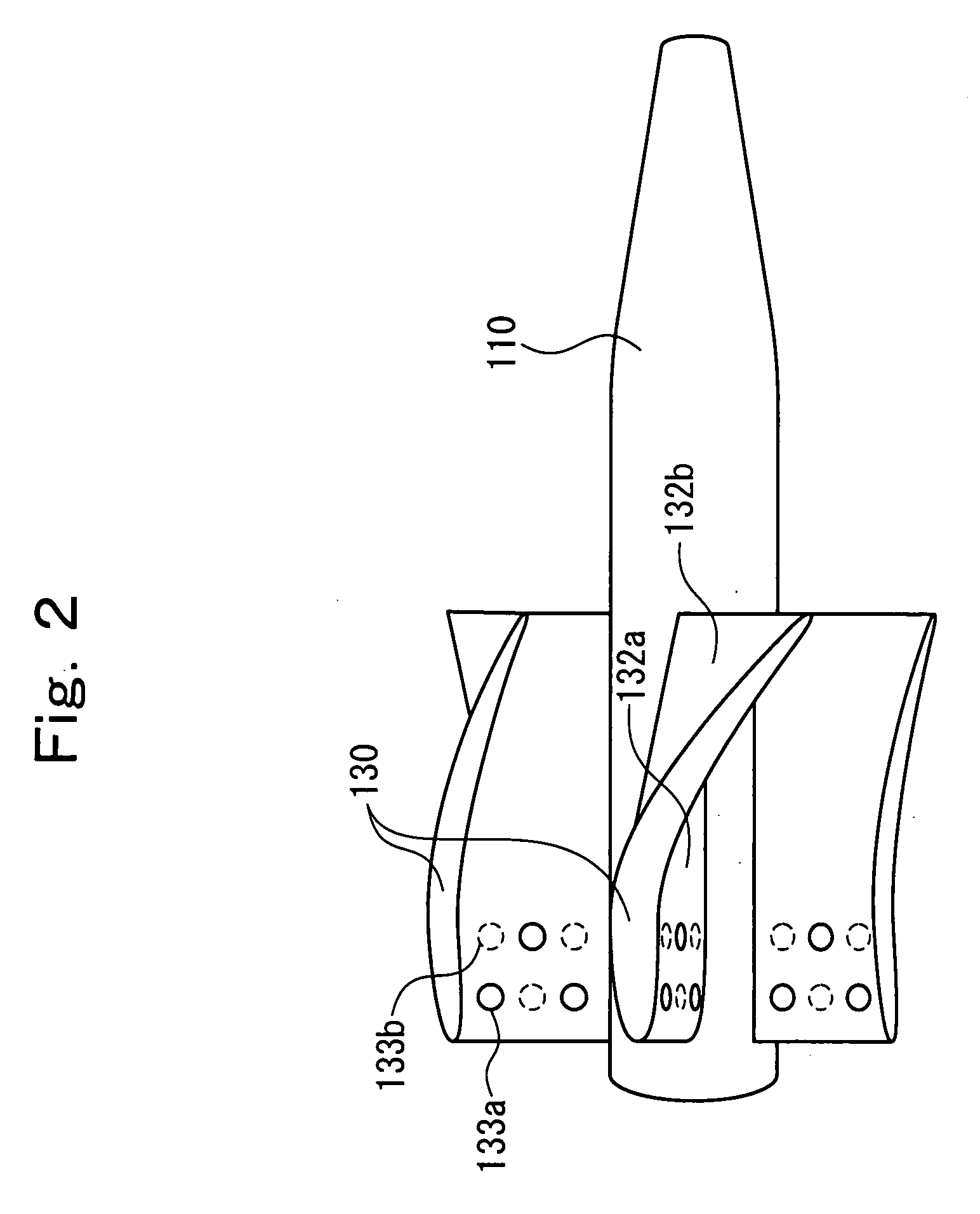

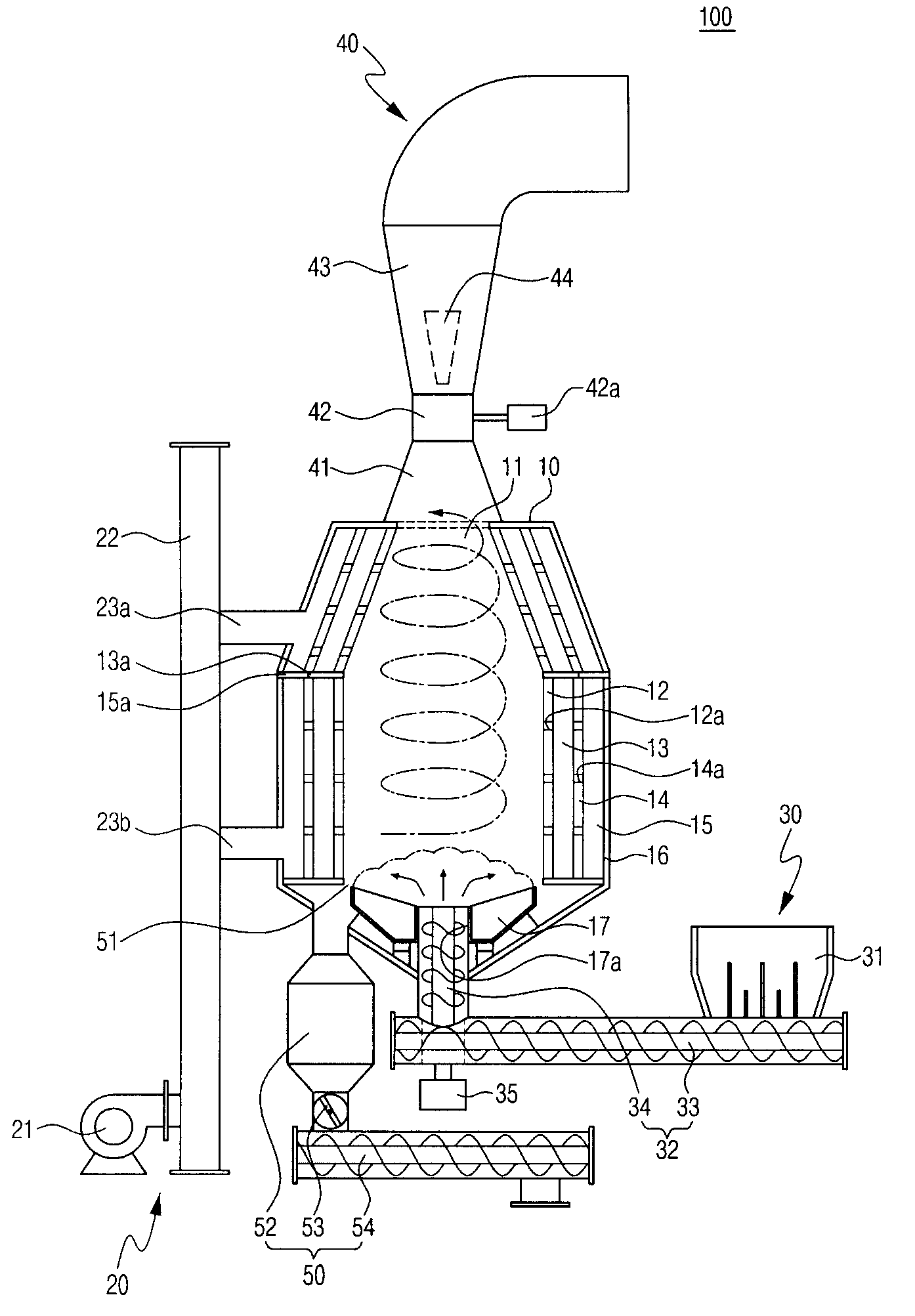

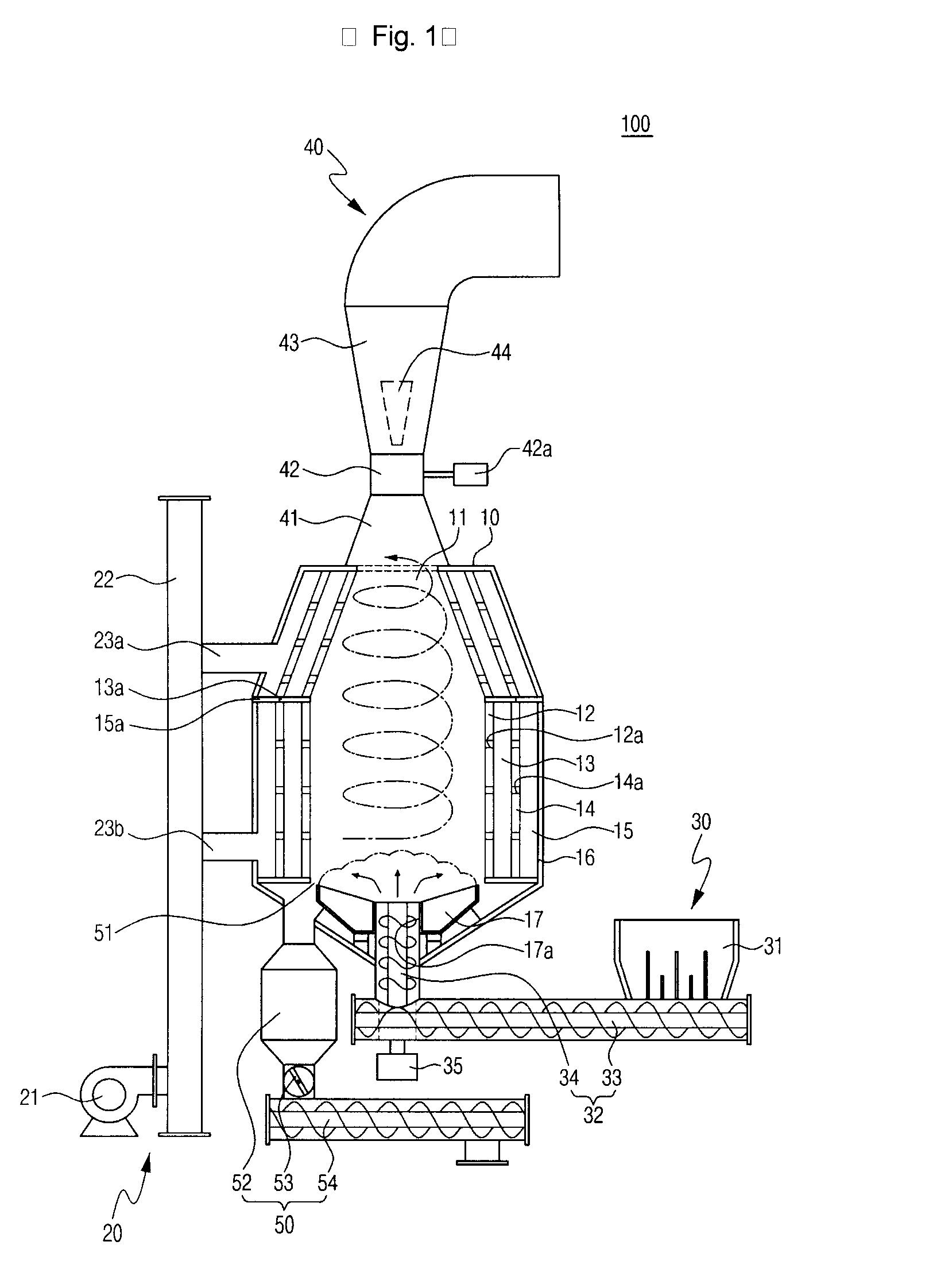

Premixed Combustion Burner of Gas Turbine Technical Field

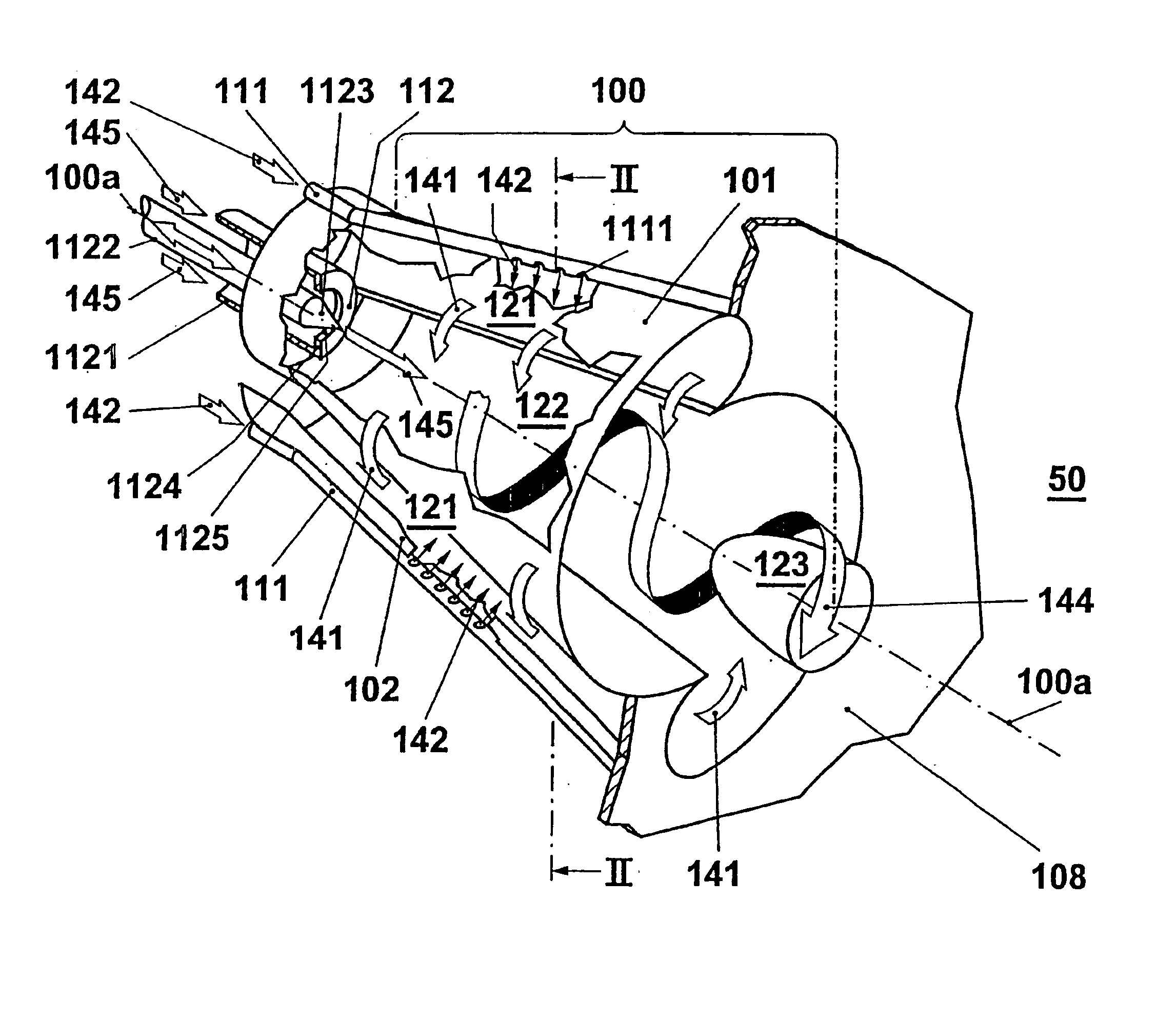

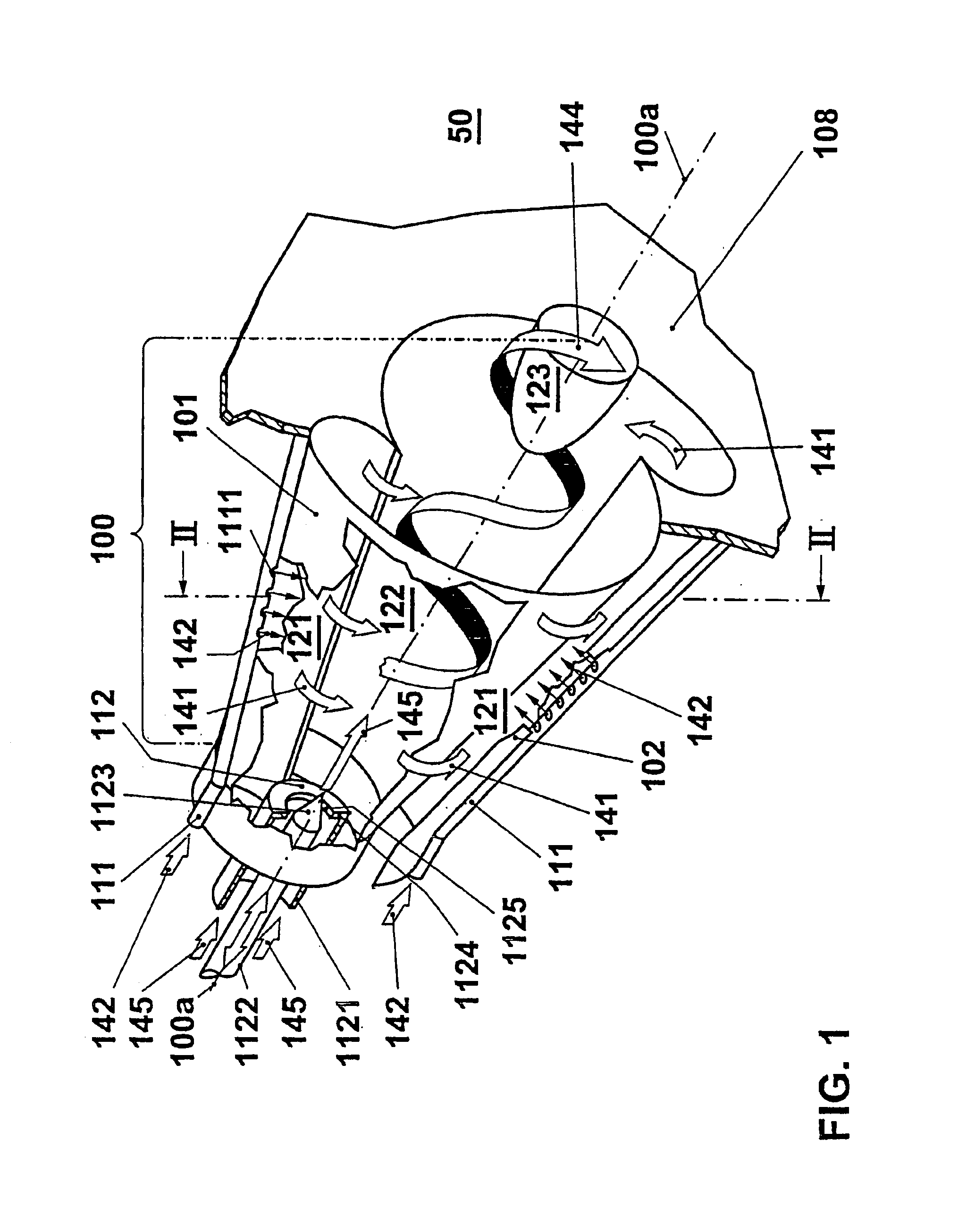

ActiveUS20080148736A1Avoid it happening againFuel concentration becomes uniformContinuous combustion chamberGas turbine plantsCombustorEngineering

A fuel nozzle 110 having a plurality of swirl vane 130 on an outer peripheral surface thereof is installed within a burner tube 120, with a clearance 121 being provided. Each swirl vane 130 progressively curves from an upstream side toward a downstream side (inclines along a circumferential direction) in order to swirl compressed air A flowing through an air passage 111 to form a swirl air flow a. Here, curvature of each swirl vane 130 is greater on its outer peripheral side than on its inner peripheral side. By suppressing occurrence of an air streamline heading from the inner peripheral side toward the outer peripheral side, therefore, flow velocity on the inner peripheral side and flow velocity on the outer peripheral side become equal, thus preventing flashback on the inner peripheral side. Moreover, a swirl imparting force in the circumferential direction per unit length on the inner peripheral side and that on the outer peripheral side become equal, equalizing the fuel concentration on the inner peripheral side and the fuel concentration on the outer peripheral side. Furthermore, a leakage flow, which passes from the vane dorsal surface side through the clearance 121 and leaks to the vane ventral surface side, generates a vortex air flow, promoting mixing of fuel and air.

Owner:MITSUBISHI POWER LTD

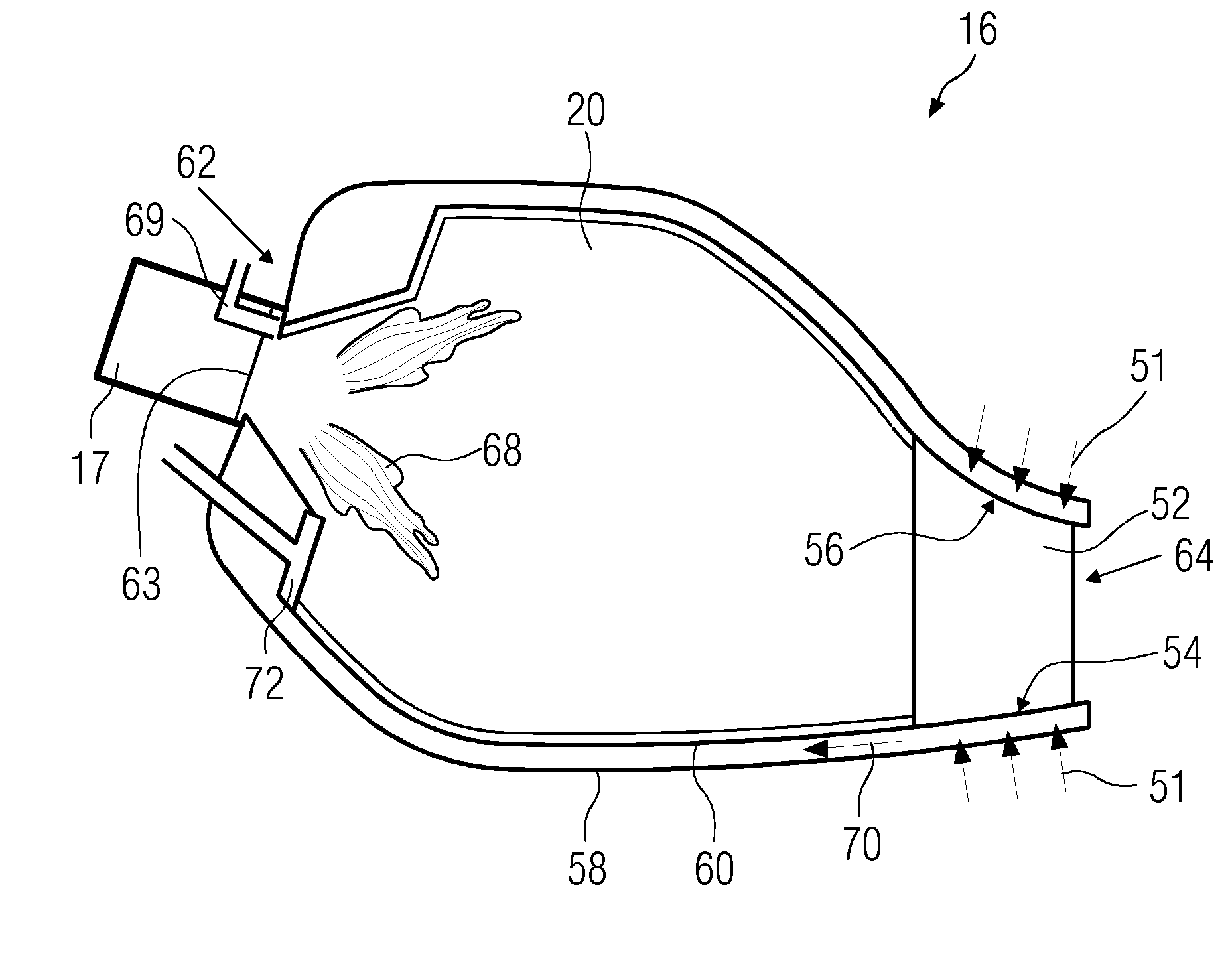

Stagnation point reverse flow combustor

InactiveUS7425127B2Combustion using gaseous and pulverulent fuelContinuous combustion chamberStagnation pointCombustor

A method for combusting a combustible fuel includes providing a vessel having an opening near a proximate end and a closed distal end defining a combustion chamber. A combustible reactants mixture is presented into the combustion chamber. The combustible reactants mixture is ignited creating a flame and combustion products. The closed end of the combustion chamber is utilized for directing combustion products toward the opening of the combustion chamber creating a reverse flow of combustion products within the combustion chamber. The reverse flow of combustion products is intermixed with combustible reactants mixture to maintain the flame.

Owner:GEORGIA TECH RES CORP

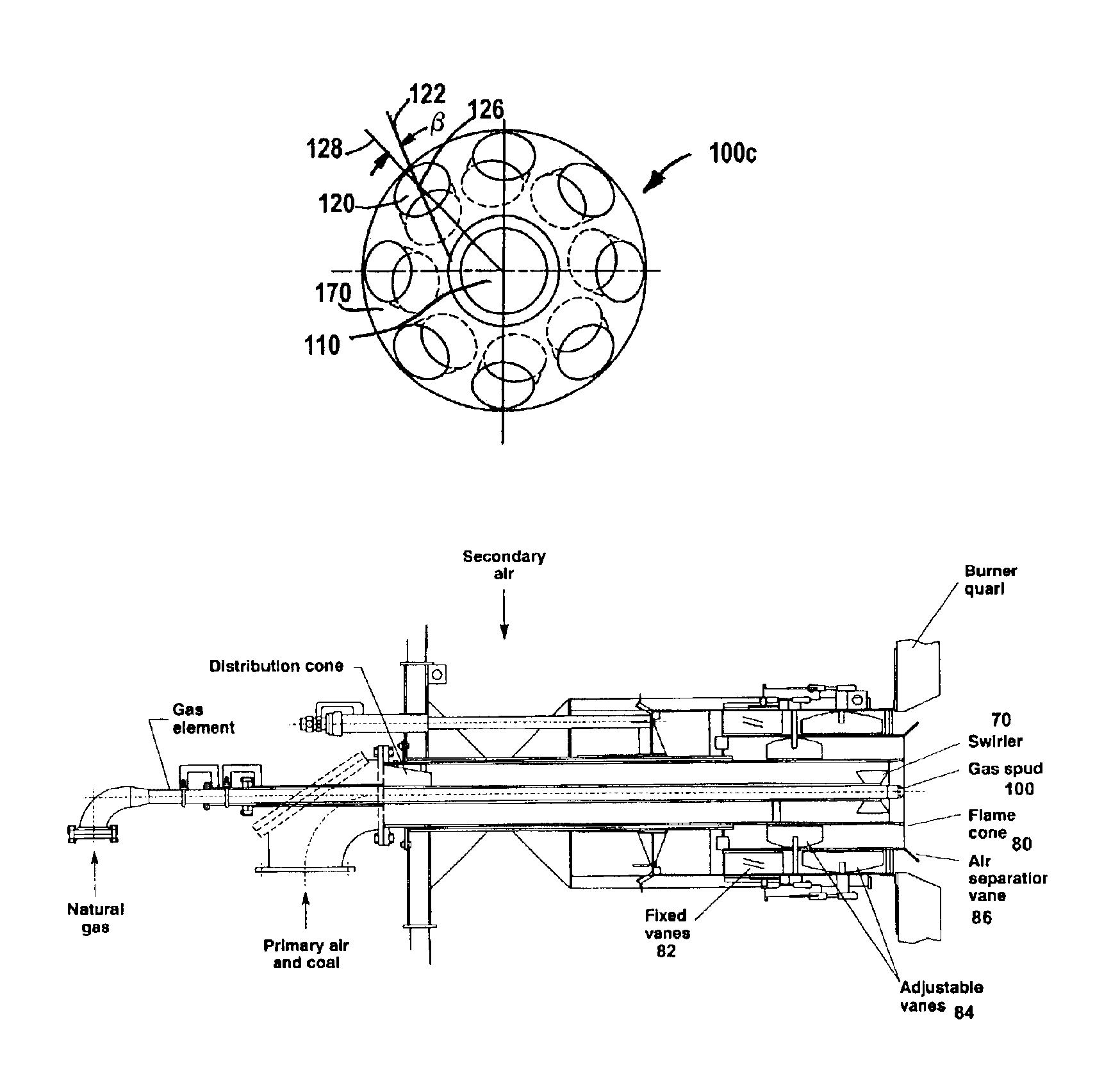

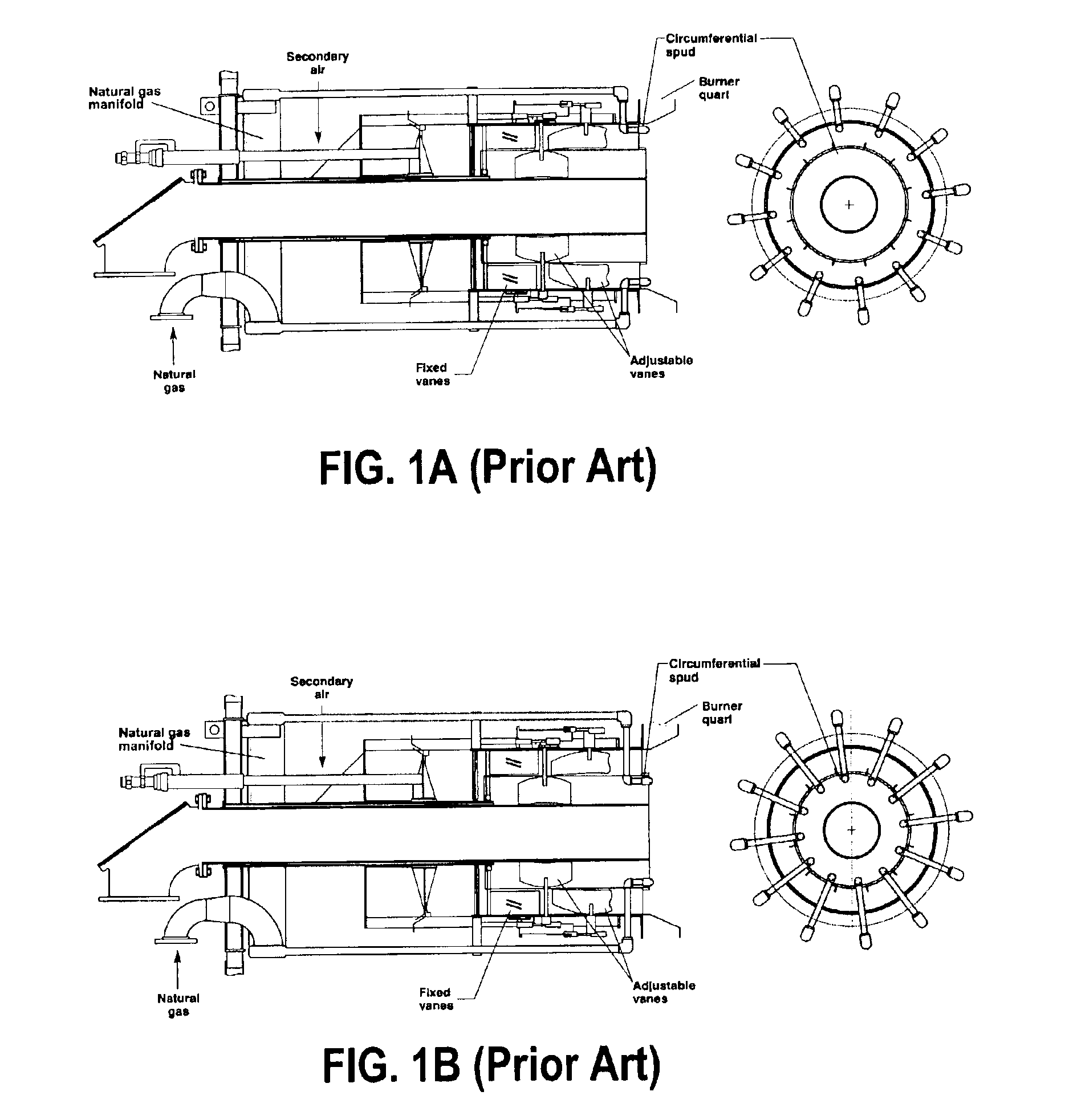

Dual fuel burner for a shortened flame and reduced pollutant emissions

InactiveUS6951454B2Emission reductionShorten the lengthCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBoiler furnacePollutant emissions

A dual fuel burner including an elongated supply pipe and a gas injector for a boiler furnace having a plurality of peripheral openings around a center opening. The peripheral openings are pitched radially away from the longitudinal axis of the gas injector and also pitched either clockwise or counter-clockwise, to impart a swirling motion to gaseous fuel exiting the injector through the openings. A first sleeve member is concentrically spaced about the supply pipe and the gas injector to form an inner annular passageway for conveying a mixture of primary air and pulverized coal to the furnace combustion zone. A second sleeve member is concentrically spaced about the first sleeve member to form an outer annular passageway for conveying secondary air to the furnace combustion zone, and a plurality of circumferentially spaced vanes mounted within the outer annular passageway for inducing a swirling motion to the secondary air discharging from the outer annular passageway into the furnace combustion zone.

Owner:THE BABCOCK & WILCOX CO

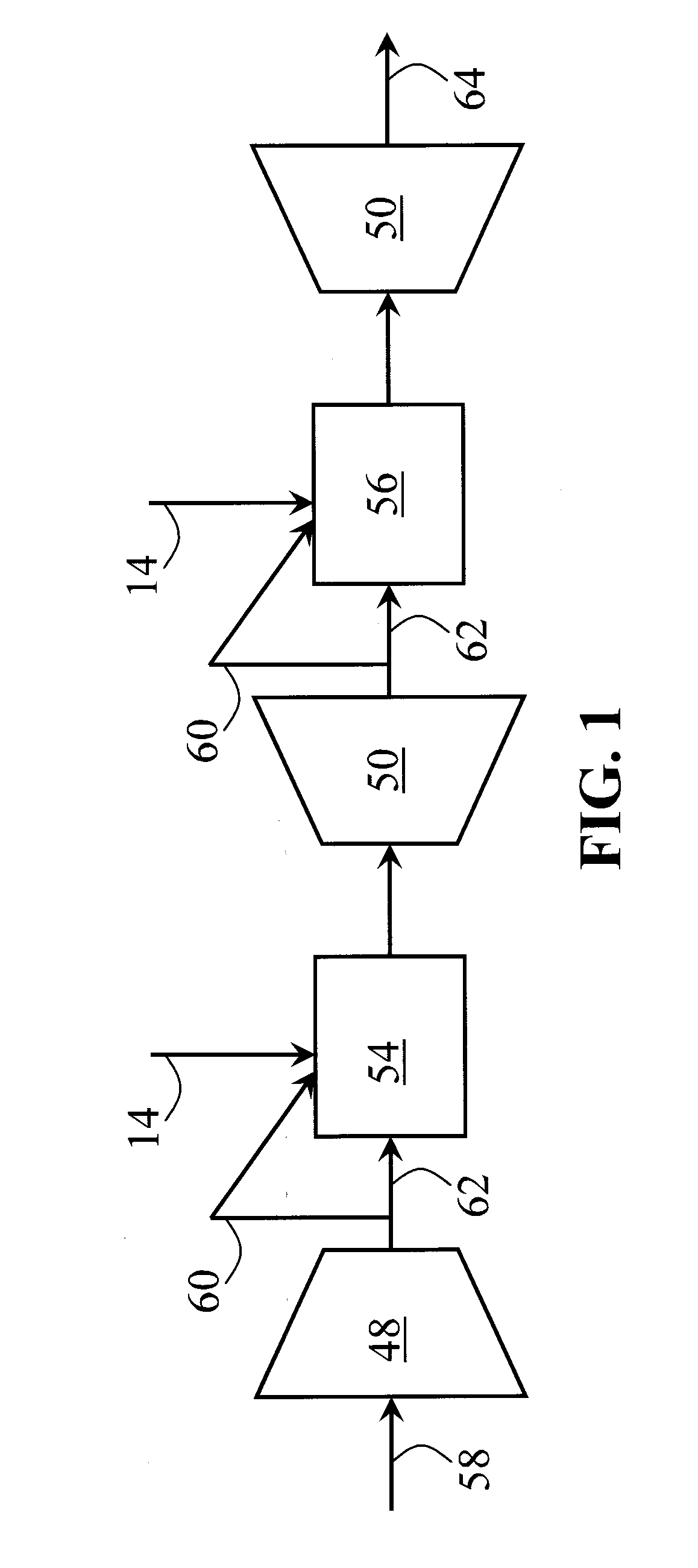

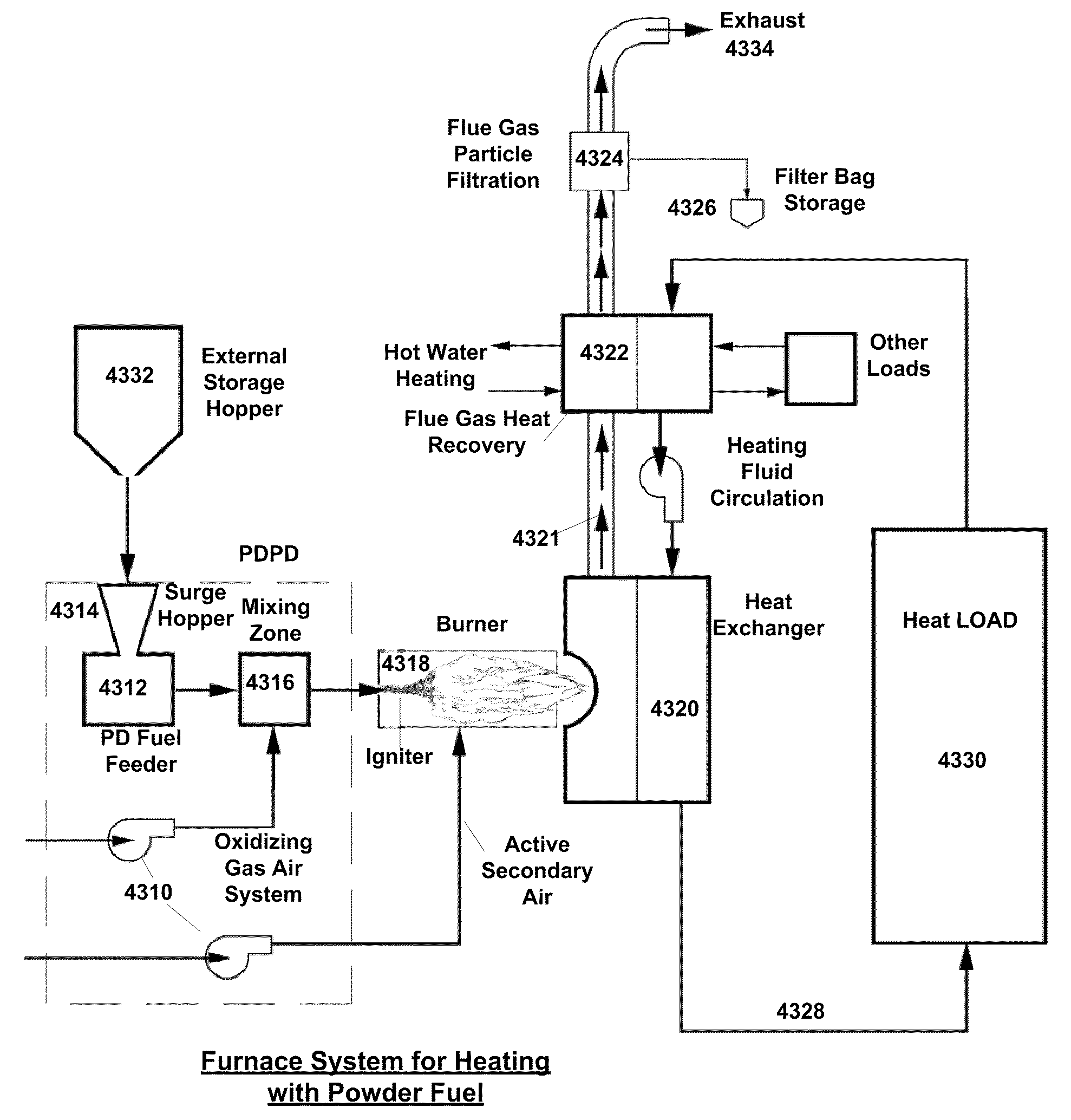

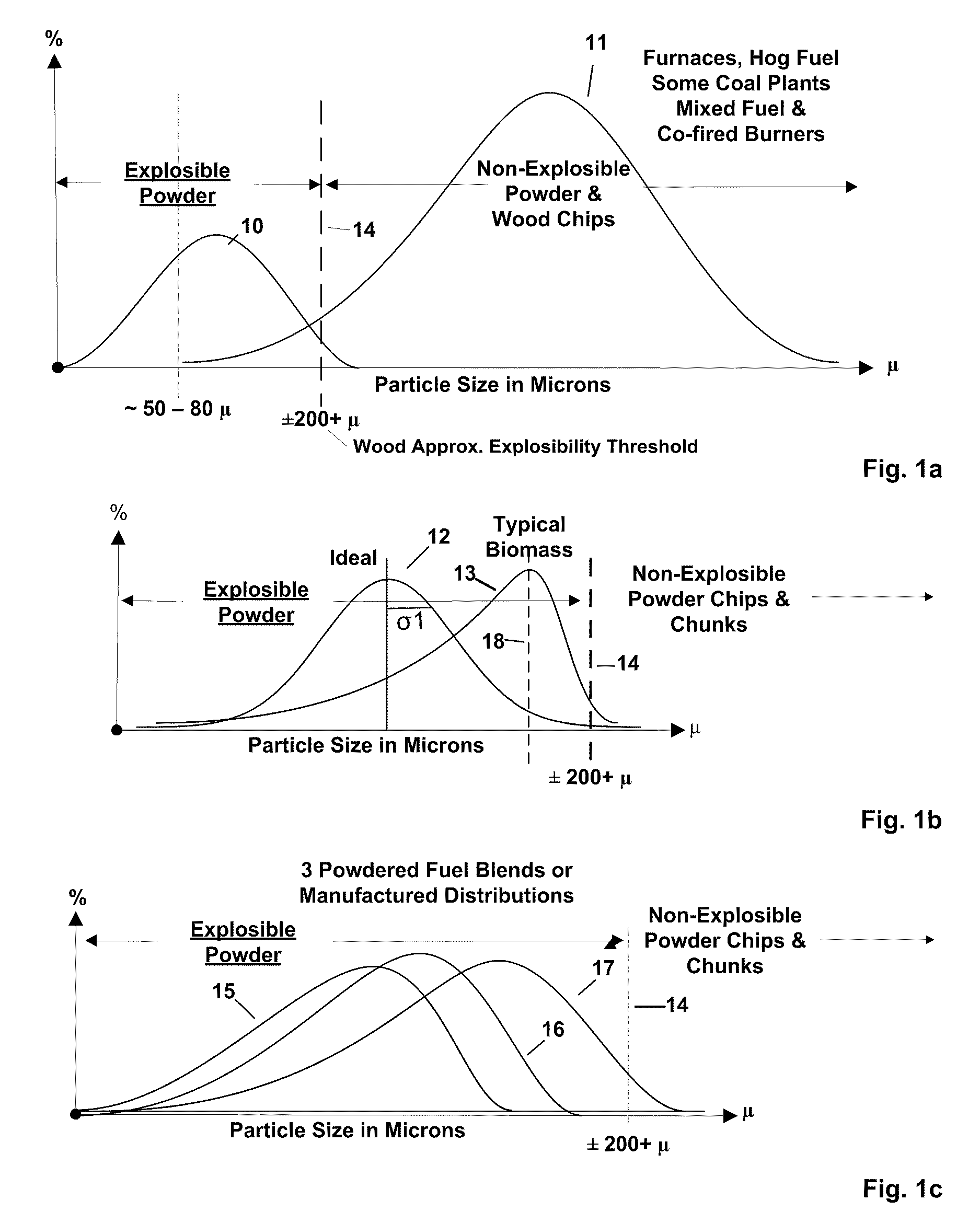

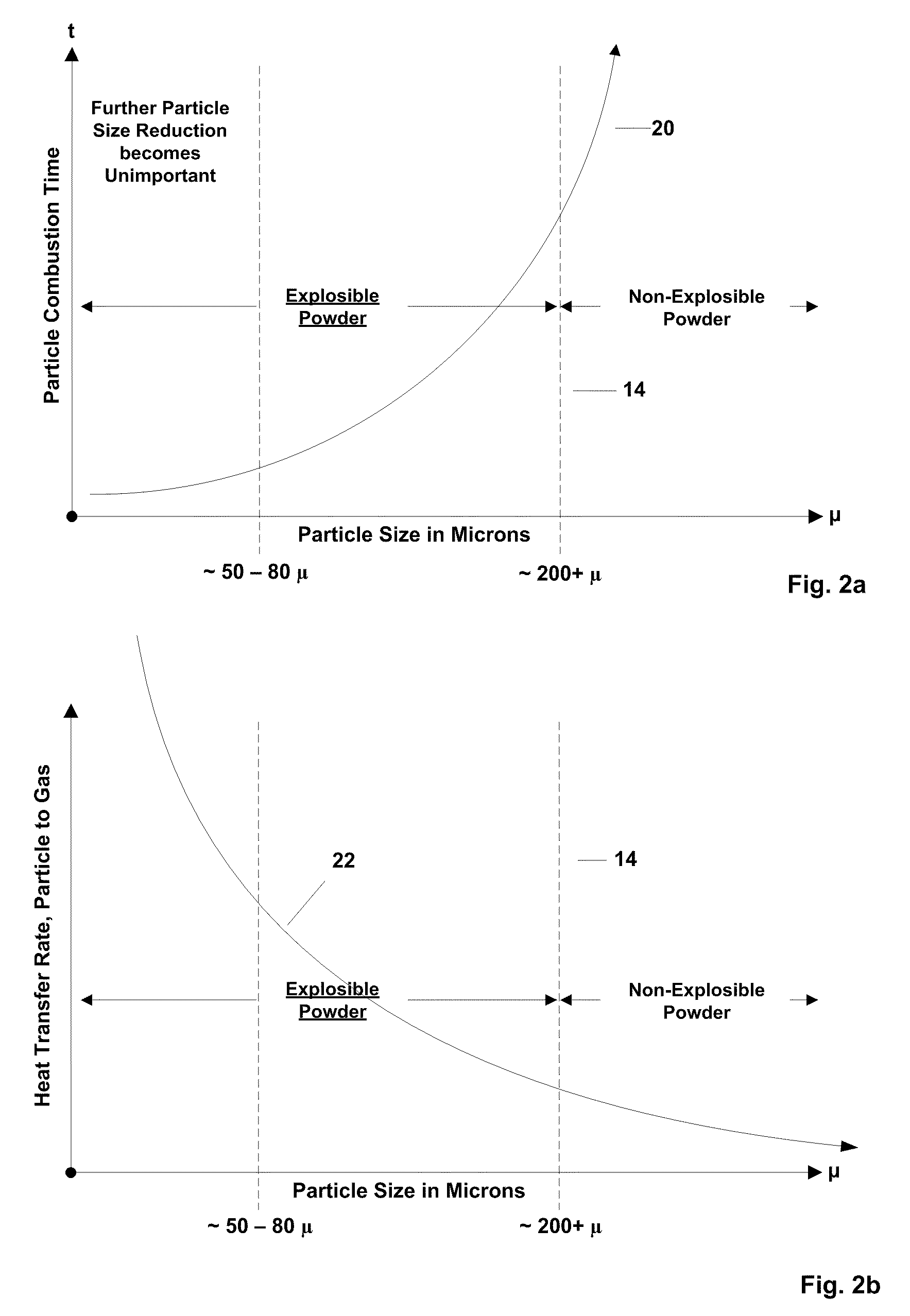

Powdered fuel conversion systems and methods

The burner preferably exclusively burns substantially explosible solid fuels and preferably has instant ON-OFF thermostat control, wastes no energy preheating the enclosure or external air supply, achieves stable combustion the moment the powder-air mix is ignited in our burner, is used in the upward vertical mode except for oil burner retrofits, burns a solid fuel in a single-phase regime as if it were a vaporized liquid or gas, is designed to complete combustion within the burner housing itself rather than in a large, high temperature furnace enclosure which it feeds, has an ultra-short residence time requirement, is a recycle consuming burner with self-contained management of initially unburned particles, is much smaller, simpler and lower cost, has a wider dynamic range / turndown ratio, is more efficient in combustion completeness and thermal efficiency, and operates with air-fuel mix approximately at the flame speed.

Owner:MCKNIGHT JAMES K +2

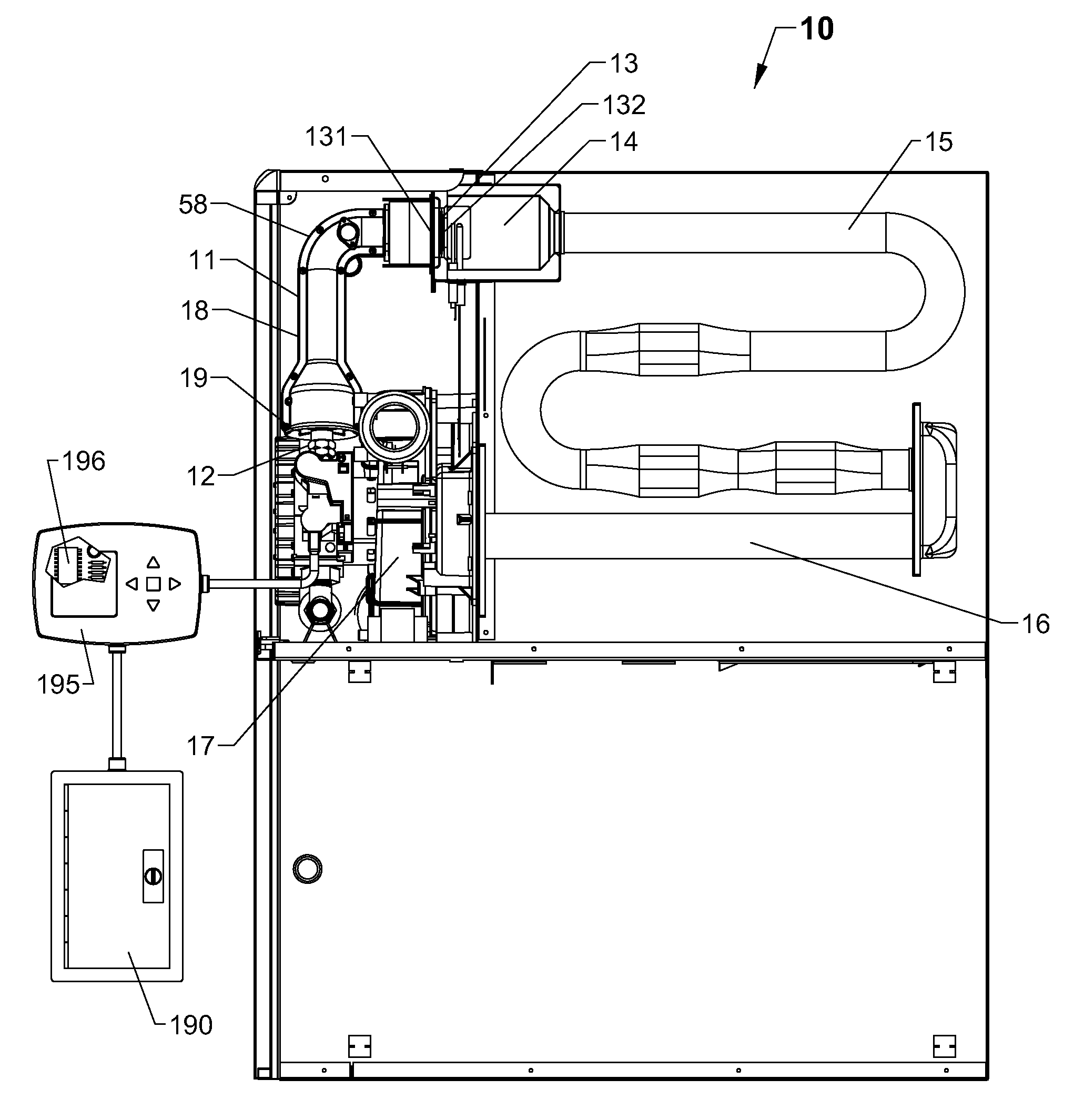

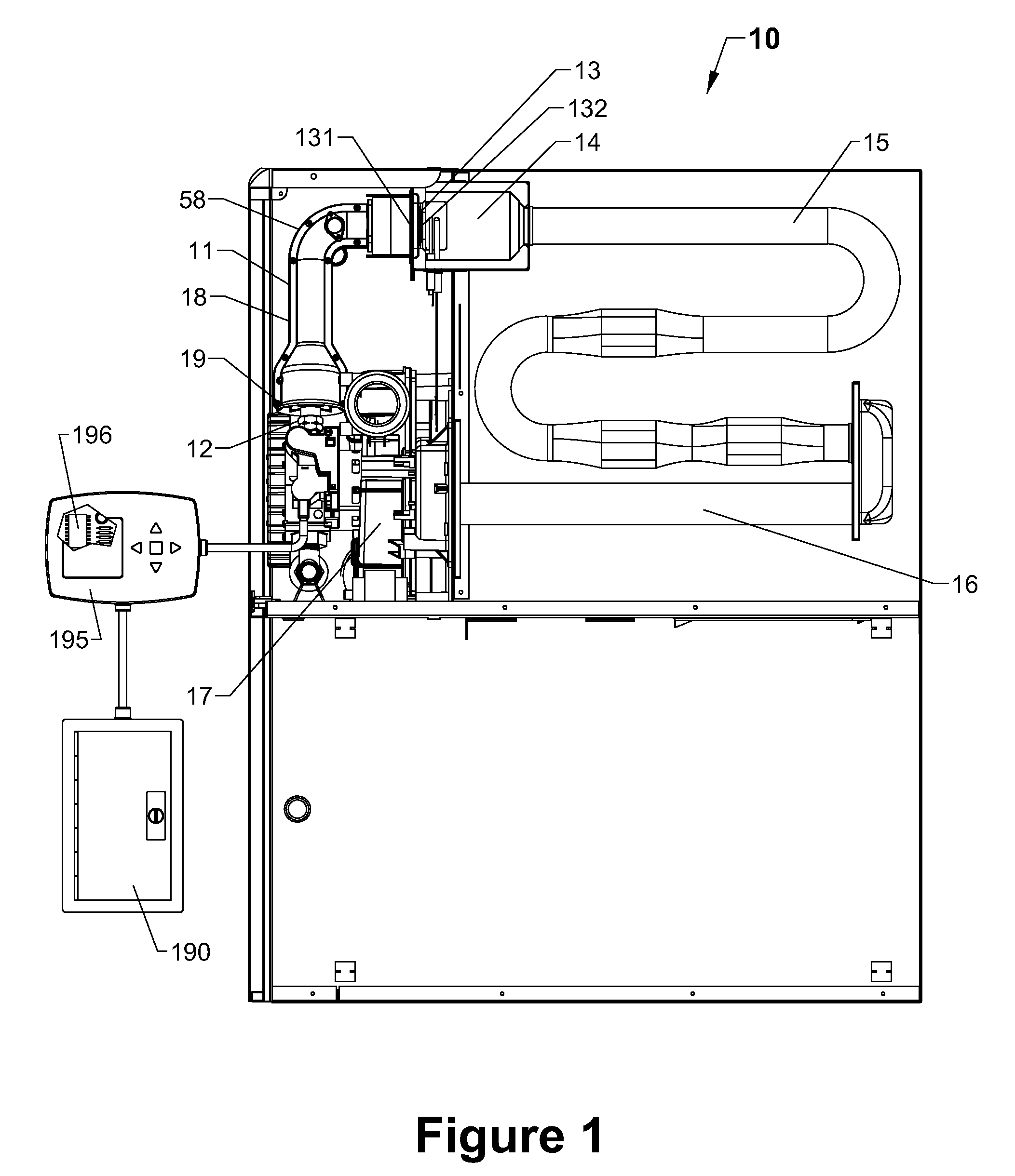

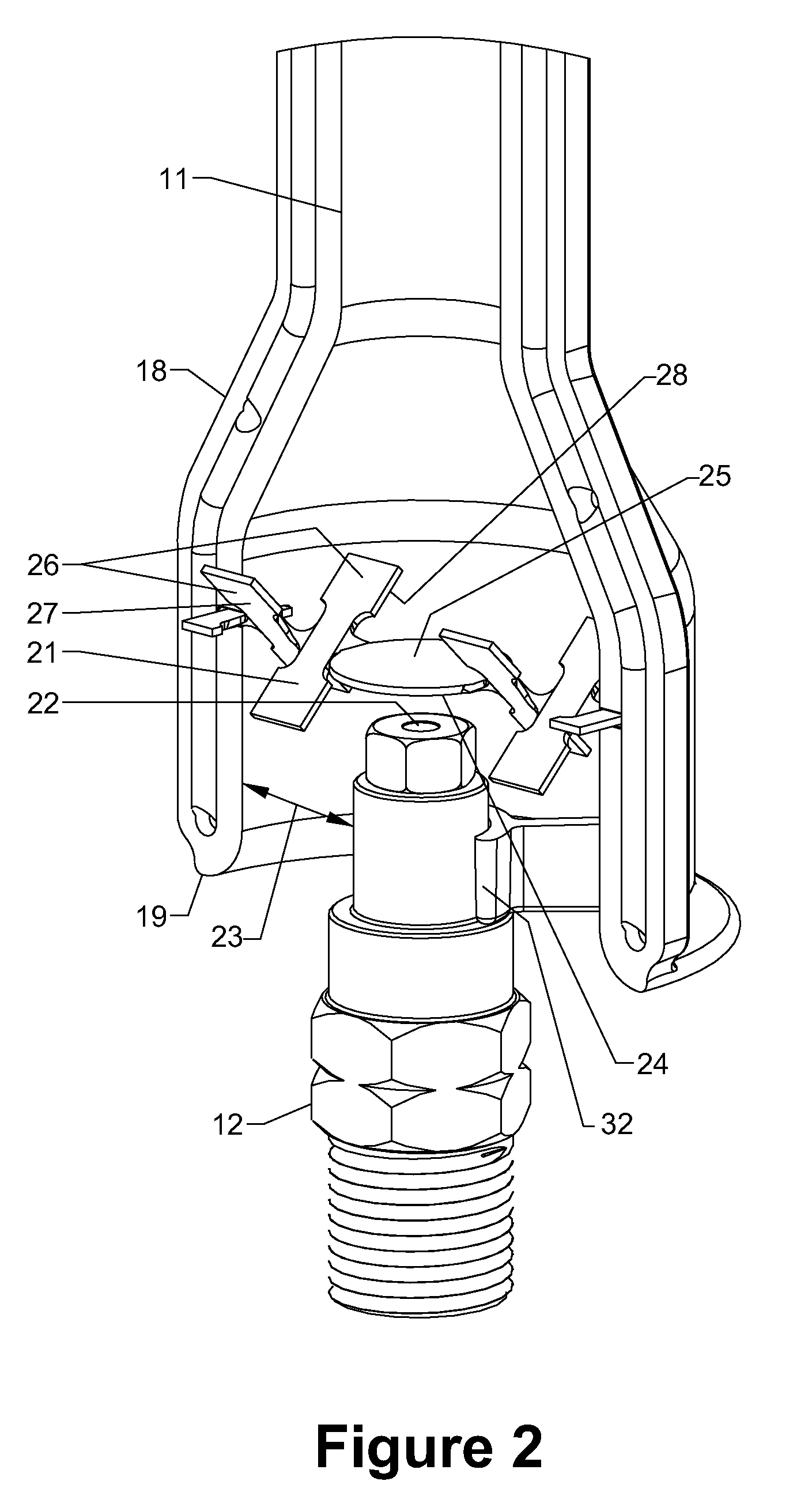

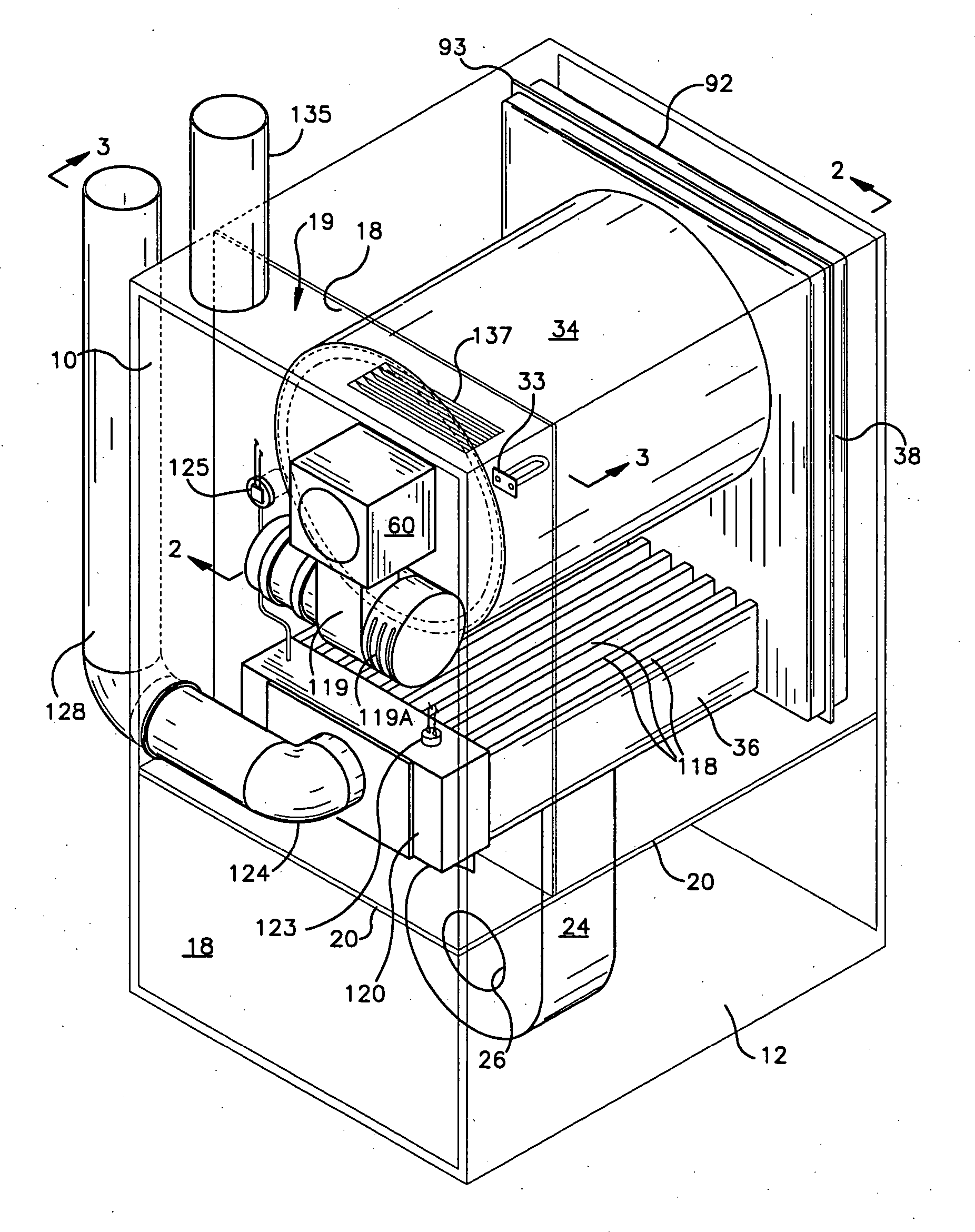

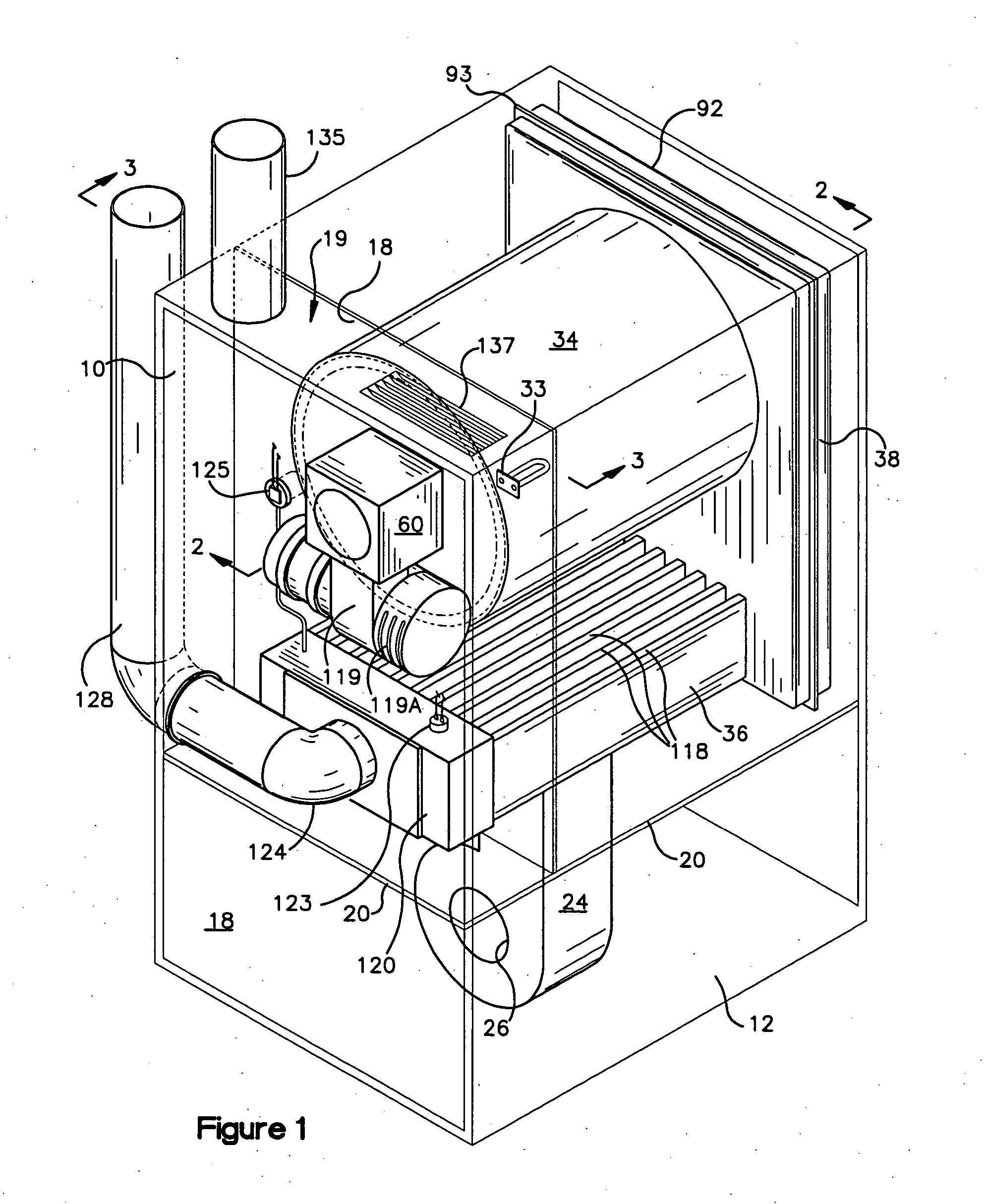

Premix furnace and methods of mixing air and fuel and improving combustion stability

ActiveUS20100310998A1Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberCombustor

Premix furnace for heating an occupied space while producing lower NOx emissions and methods of mixing air and fuel delivered to a premix burner and of improving combustion stability. A mixing device may be located within an inlet tube, may have a flat surface that is perpendicular to the direction of fuel flow, or may have two surfaces held at substantially opposite angles to induce swirl. A mixing device may be attached to the fuel injector, may be made from a piece of sheet metal, and may have bends and a hole for attachment to the fuel injector. A fluidic diode in the inlet tube may improve combustion stability and may include a hollow frustum or a frustoconical portion, a cylinder concentric with the inlet tube, or a combination thereof. Some embodiments include refractory insulation lining the combustion chamber or may adjust for elevation or fuel characteristics.

Owner:NORTEK GLOBAL HVAC

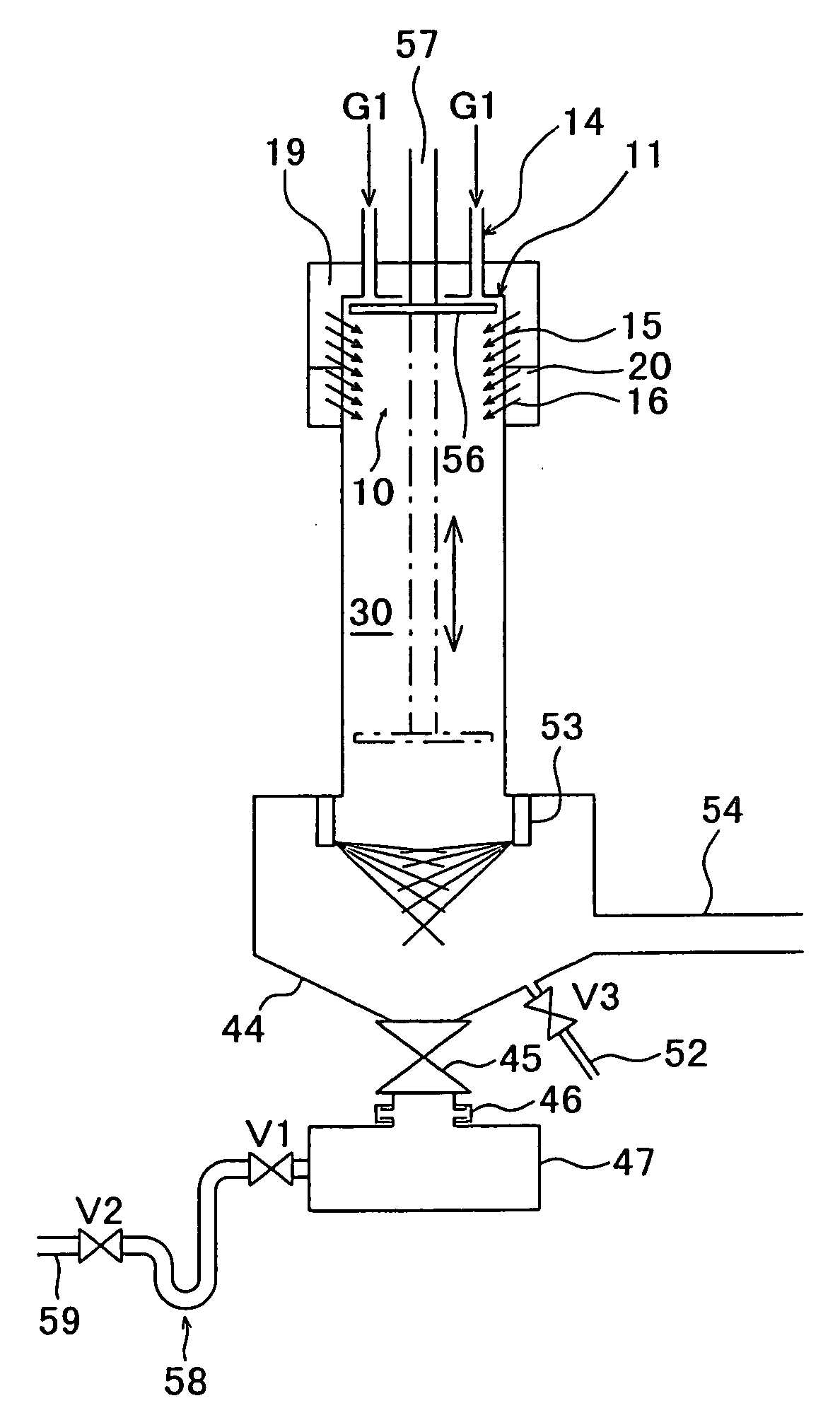

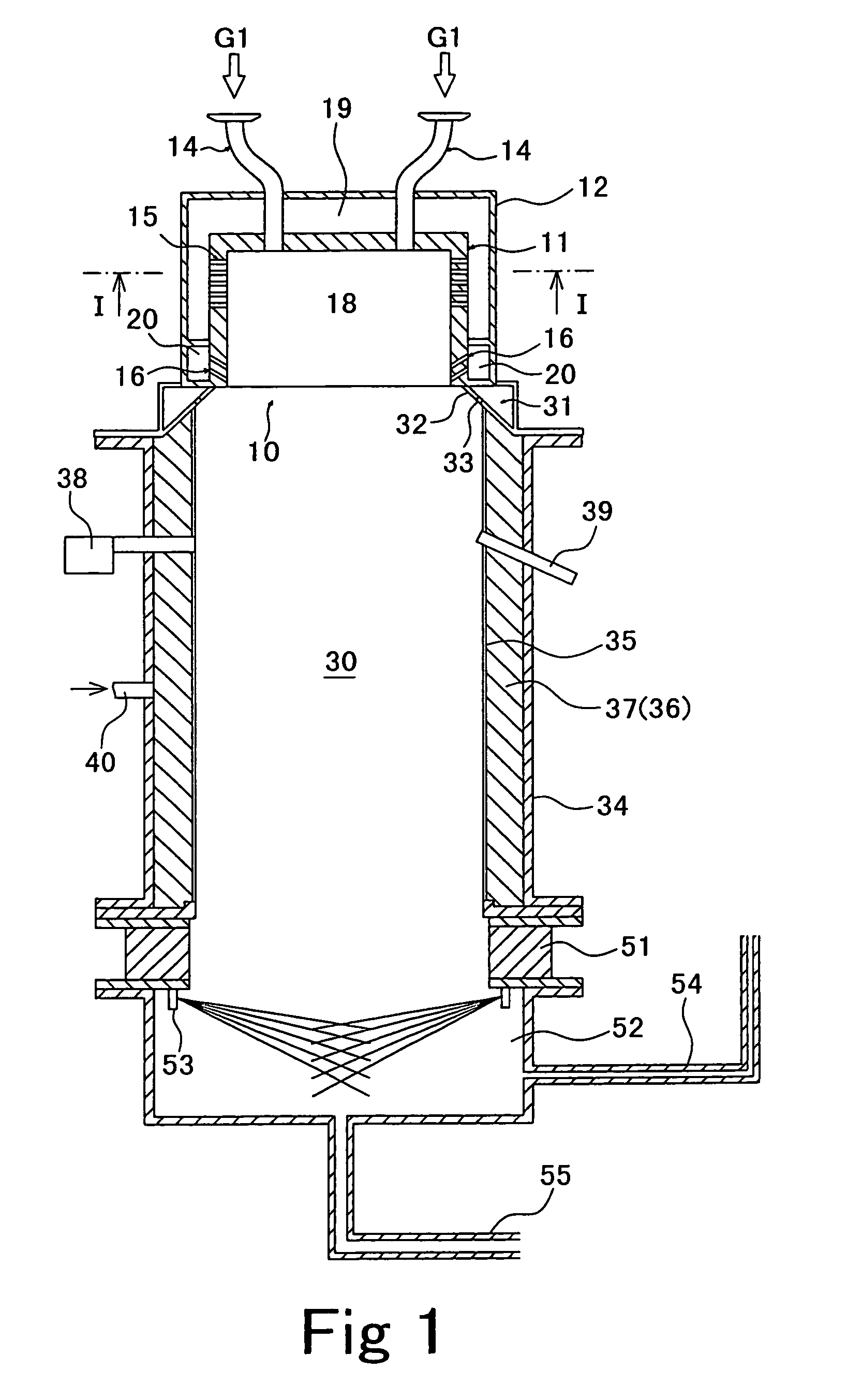

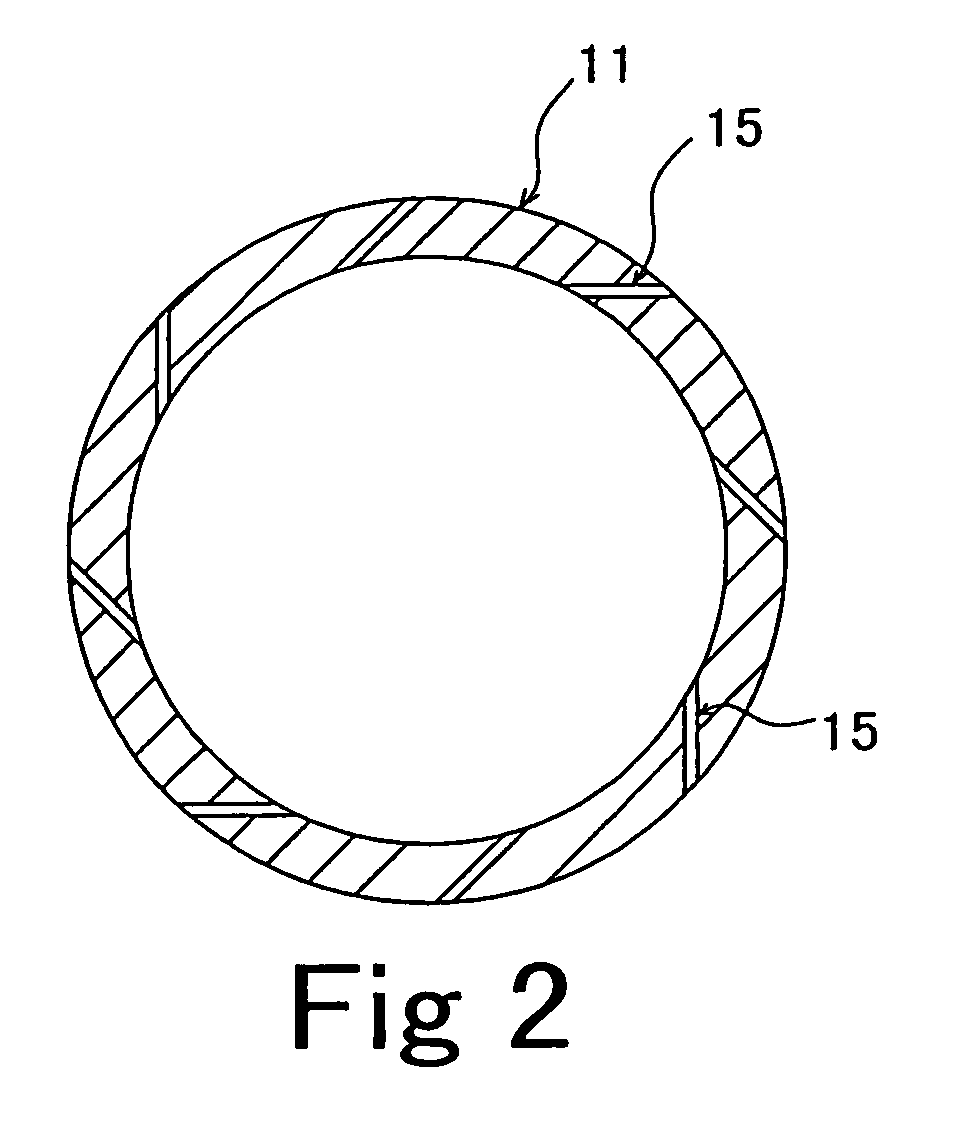

Exhaust gas treating device

InactiveUS6969250B1Efficiently captured and absorbedWear minimizationGas treatmentDispersed particle separationFiberCombustion chamber

A waste gas treatment system having a burner part and a combustion chamber provided at a downstream side of the burner part. Combustion flames are formed from the burner part toward the combustion chamber, and a waste gas is introduced into the combustion flames, thereby oxidatively decomposing the waste gas. The combustion chamber is formed from an inner wall made of a fiber-reinforced ceramic material. Therefore, the wear of the inner wall due to heat and corrosion is minimized, and thermal stress cracking is also reduced. Consequently, the lifetime of the system increases, and the cost of equipment and the availability factor can be improved. In addition, because the inner wall exhibits no catalytic effect, the formation of thermal NOx is suppressed, and it is possible to achieve environmental preservation and to simplify the treatment equipment.

Owner:EBARA CORP

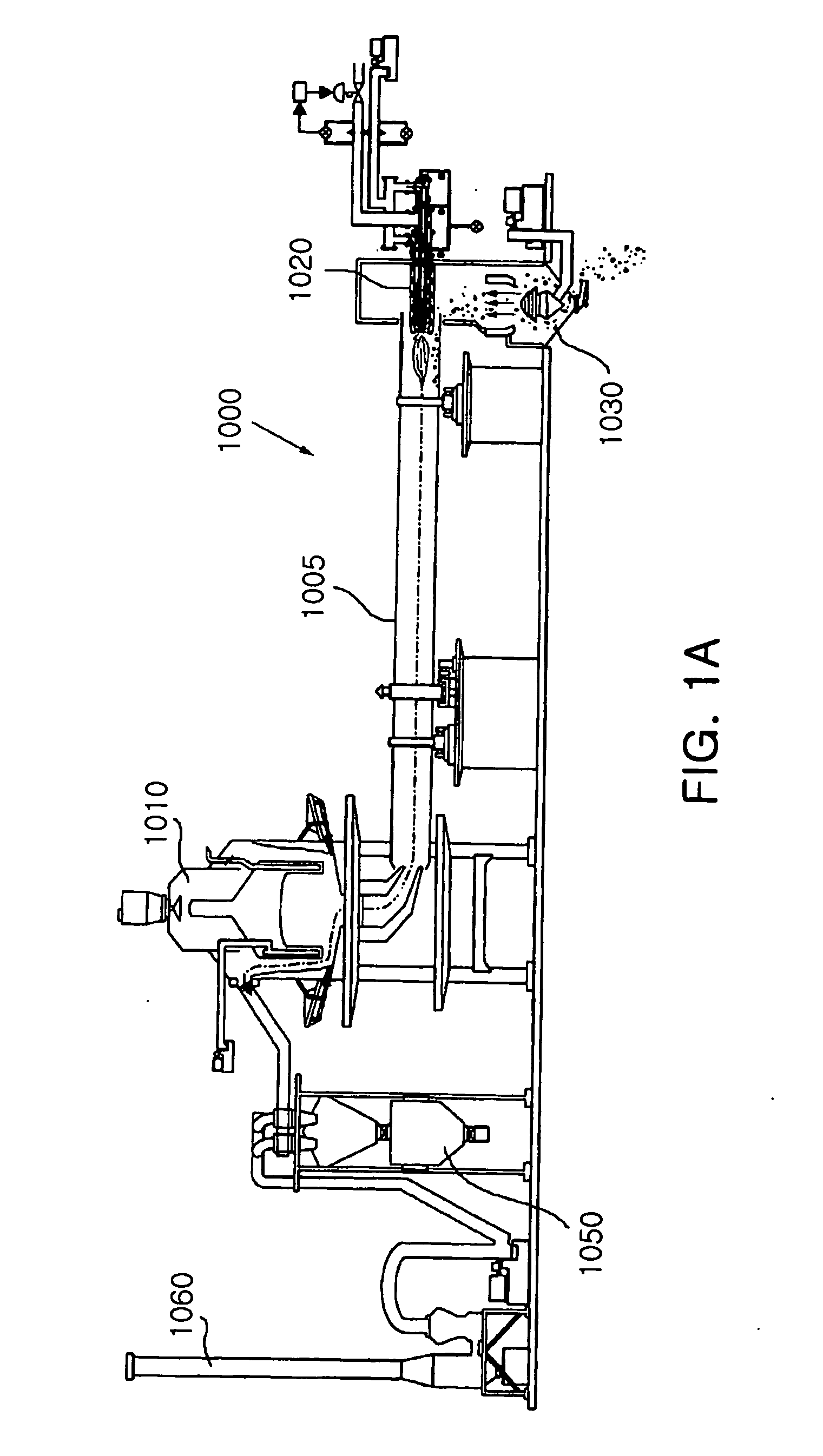

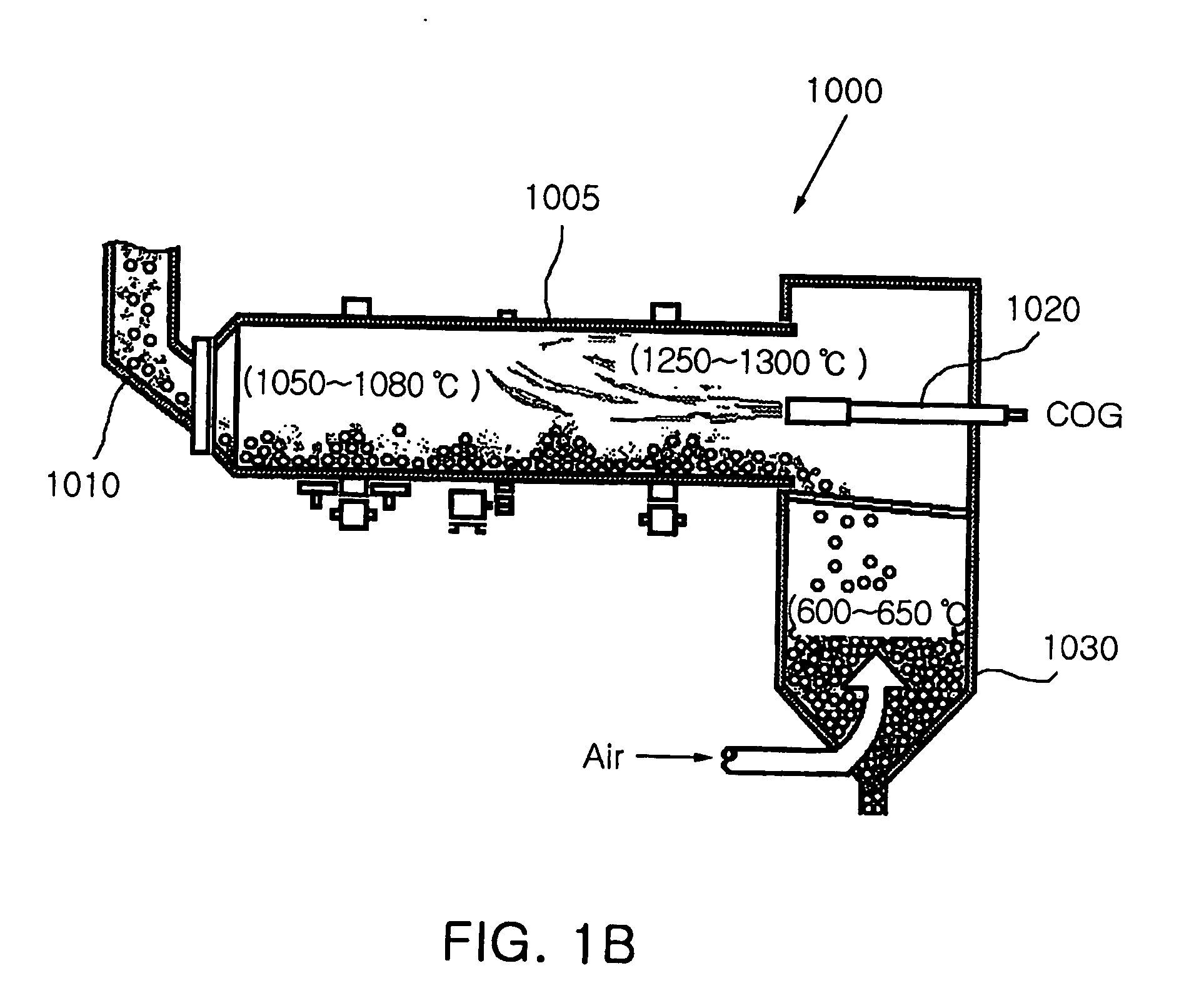

Method and burner apparatus for injecting a pulverized coal into rotary kilns, method and apparatus for producing cao using them

InactiveUS20060169181A1Reduce concentrationMinimize diameter variationPigmenting treatmentSolid fuel pretreatmentCombustorEngineering

The invention relates to a method and burner for injecting pulverized coal into a rotary kiln that uses pulverized coal as fuel in order to produce quick lime of excellent hydration level. The invention calcines lime stone charged into the rotary kiln, and uses pulverized coal as fuel of a heat source applied to the lime stone charged in the rotary kiln. The invention also provides a method and apparatus for producing quick lime by using the pulverized coal. The invention can use pulverized fossil fuel (hereinafter will be referred to as pulverized coal), which is created during coke manufacturing and cooling processes and collected by a dust collector, in order to produce quick lime of excellent hydration level while decreasing SOx (sulfide) and NOx (nitride) generation.

Owner:POHANG IRON & STEEL CO LTD

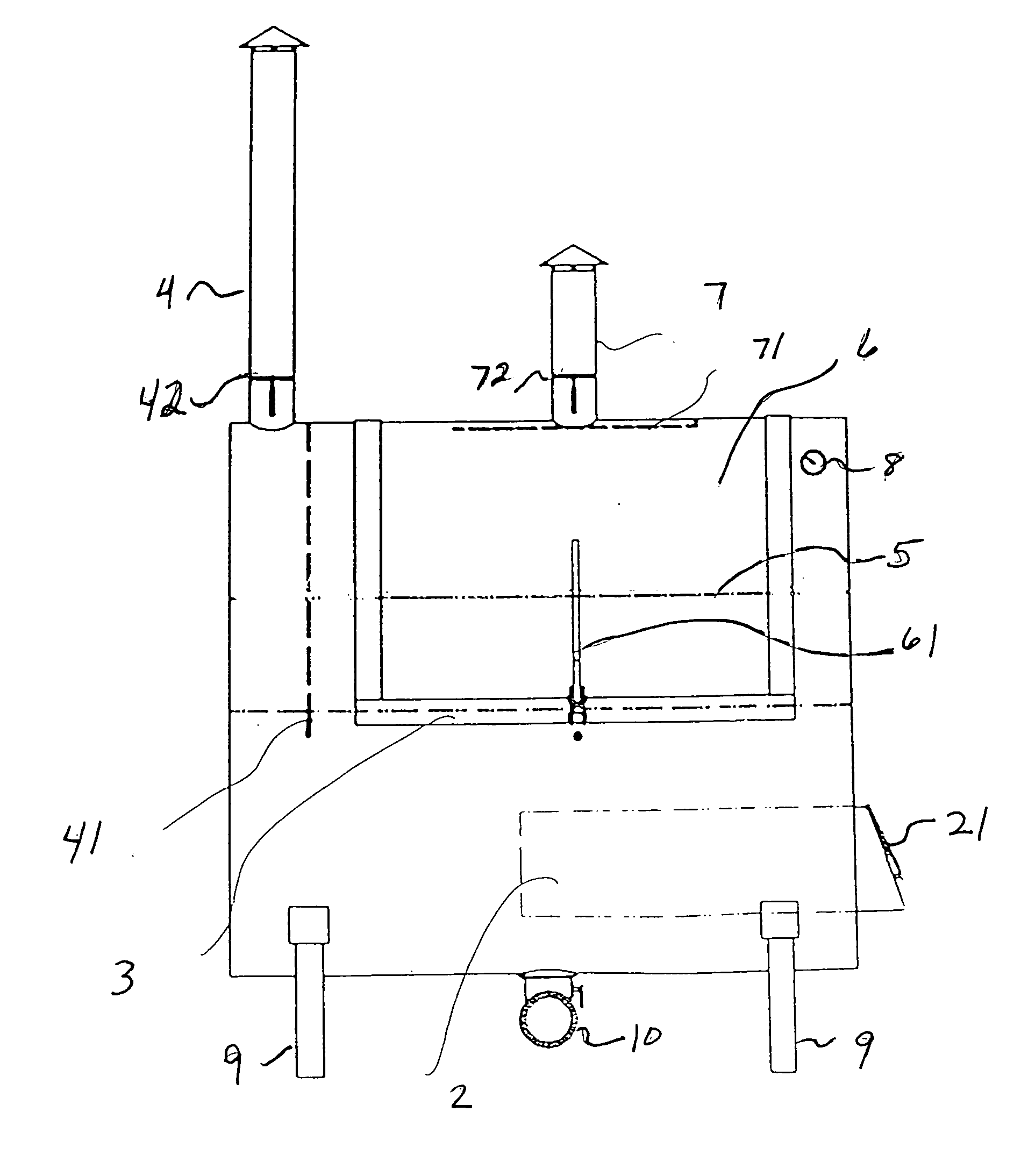

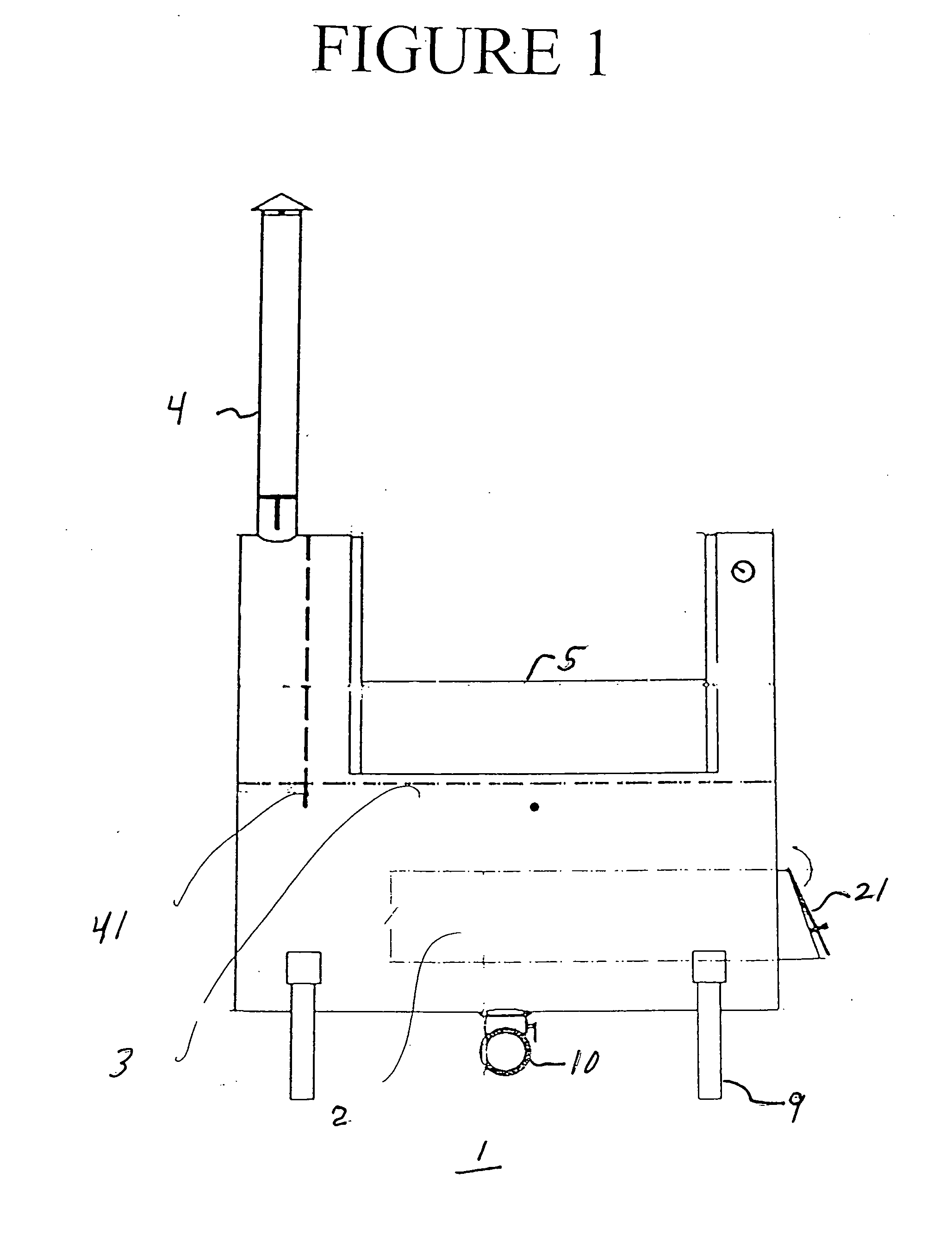

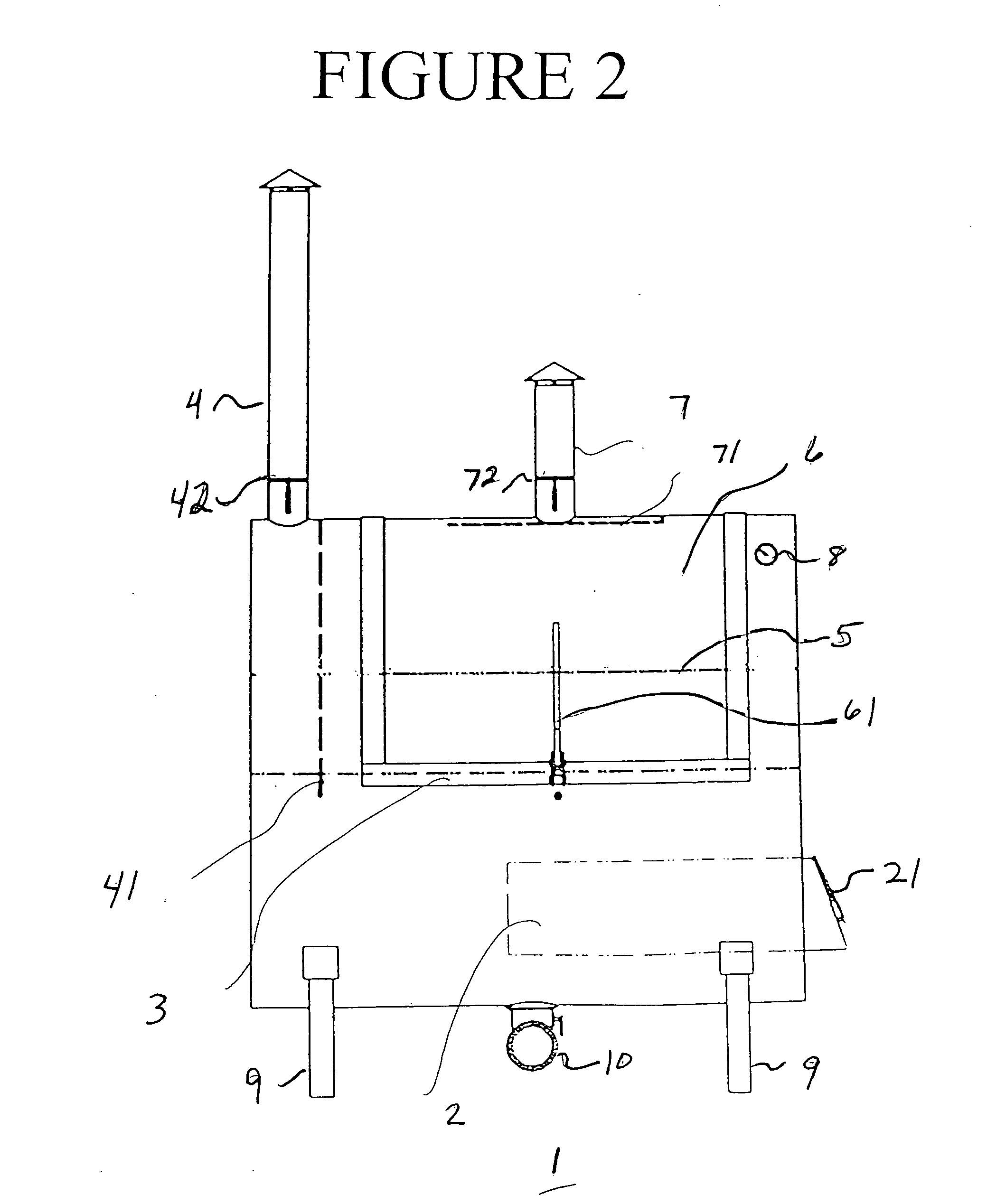

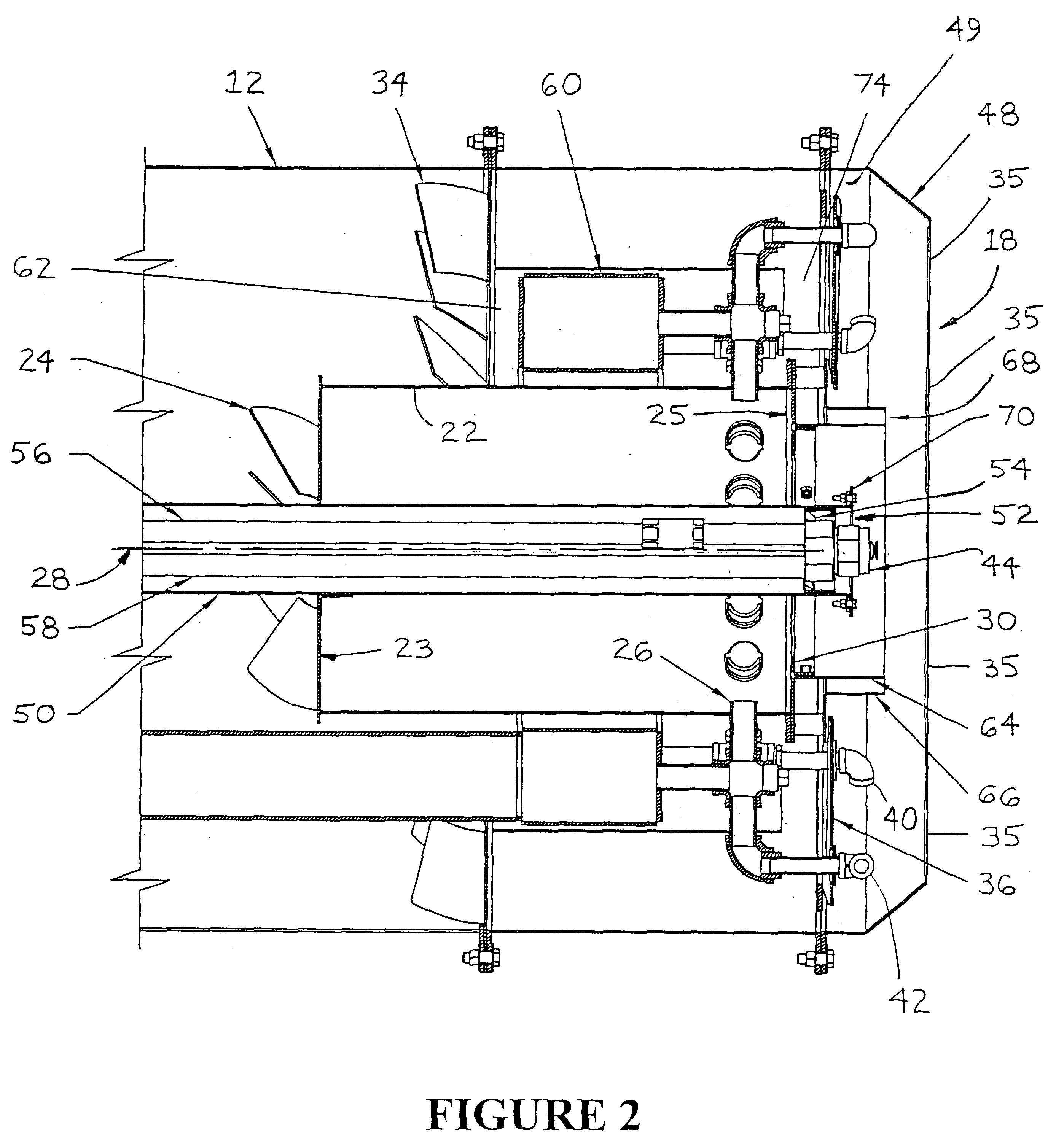

Outdoor cooker having improved heat and combustion gas controls

InactiveUS20050217659A1Avoid contactDomestic stoves or rangesCooking fumes removalCombustionProcess engineering

An improved outdoor cooker contains a number of expedients for controlling temperature and diverting combustion byproducts such as ash and noxious gases away from the cooking area. The temperature is controlled using a convection plate, an extended chimney flue and a secondary chimney on a removable hood. Controls are provided to balance smoke, steam and heat.

Owner:MCCLENAHAN JAMES

Turbine air flow conditioner

InactiveUS20100275601A1Continuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberCombustor

A system includes an air flow conditioner configured to mount in an air chamber separated from a combustion chamber of a turbine combustor. The air flow conditioner comprises a perforated annular wall configured to direct an air flow in both an axial direction and a radial direction relative to an axis of the turbine combustor. In addition, the air flow conditioner is configured to uniformly supply the air flow into air inlets of one or more fuel nozzles.

Owner:GENERAL ELECTRIC CO

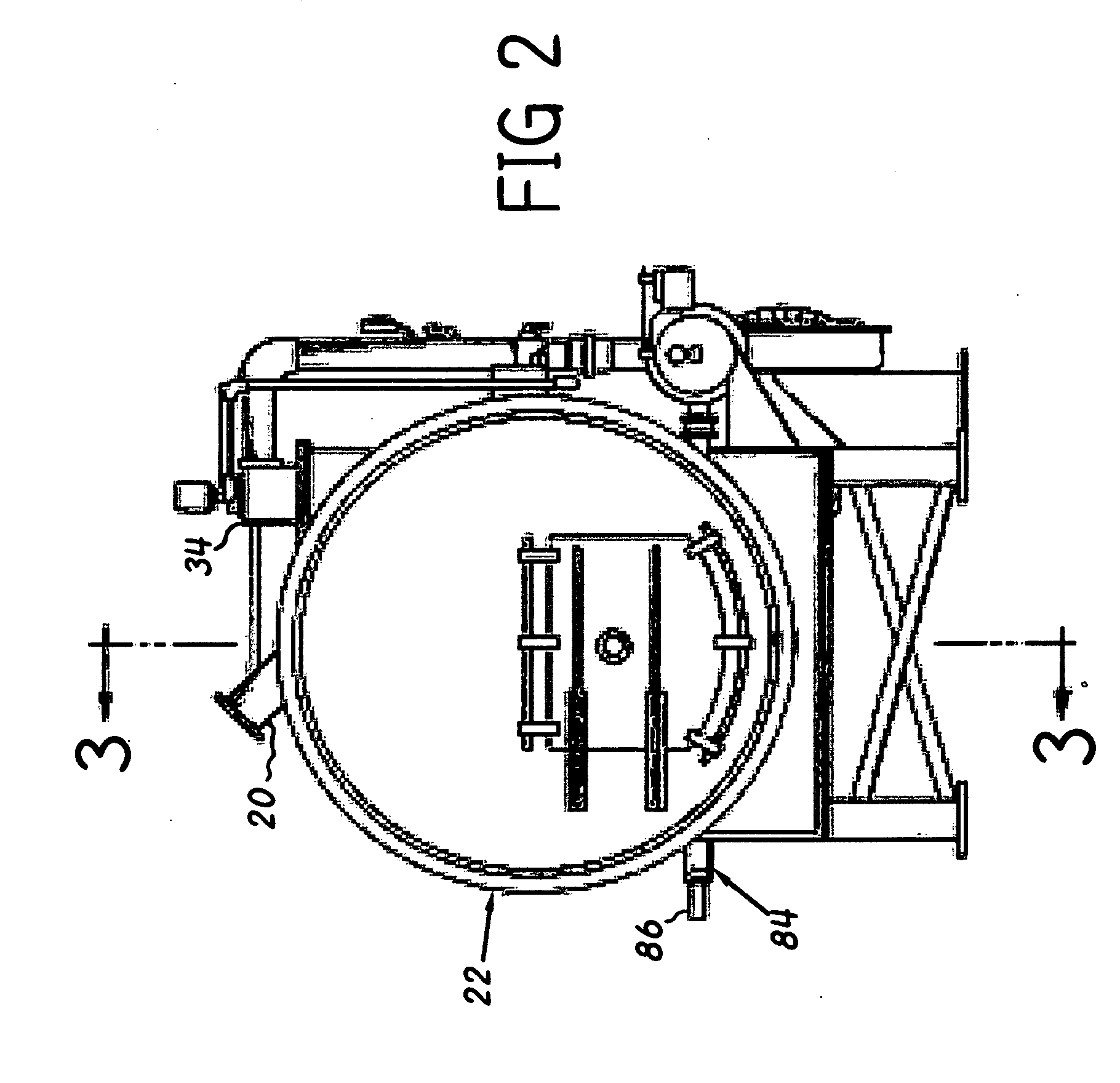

Vortex incinerator

InactiveUS20110100272A1Minimize air pollutionMinimize water pollutionAir supply regulationAir/fuel supply for combustionCombustion chamberGuide tube

An incinerator for burning waste material includes a horizontally extended combustion chamber through which a mixture of waste material and air is introduced under pressure tangentially for establishing a vortical movement of the waste material toward one of the end walls. The waste material is ignited during its vortical movement. A second discharge port extends for discharging from the chamber non-combustible material entrained in the outer region of the vortex. The discharged material is conveyed through a conduit to a separator which separates the discharged gases and solid material. A baffle is mounted on the flue adjacent its open end for deflecting outwardly toward the side wall solid material which moves from adjacent the one end wall toward the open end of the flue. Additionally, control means are provided for the use of specialized sensors to monitor the temperature, air flow and volume of the chamber.

Owner:HASSELBRING ROBERT JOEL +1

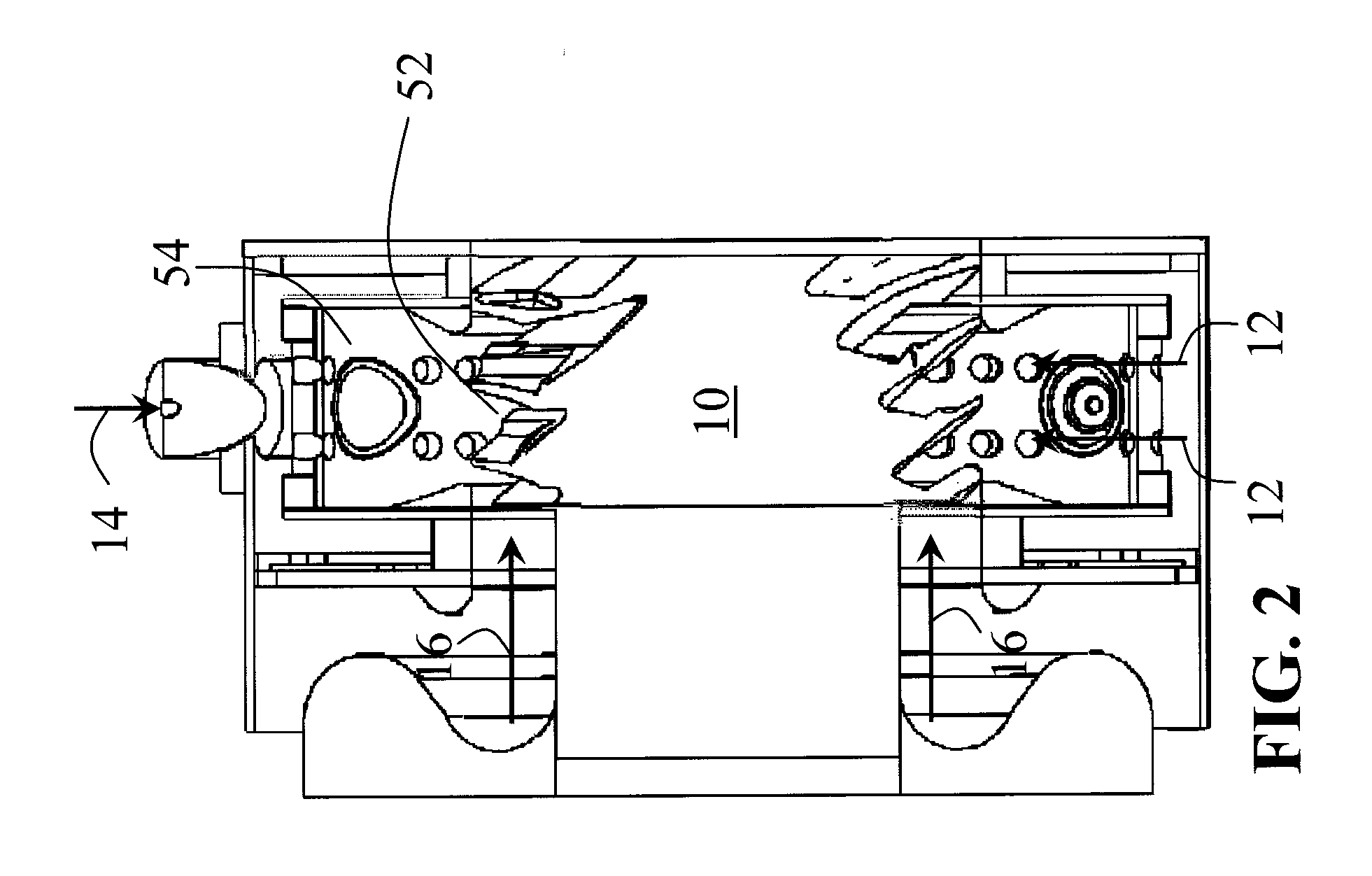

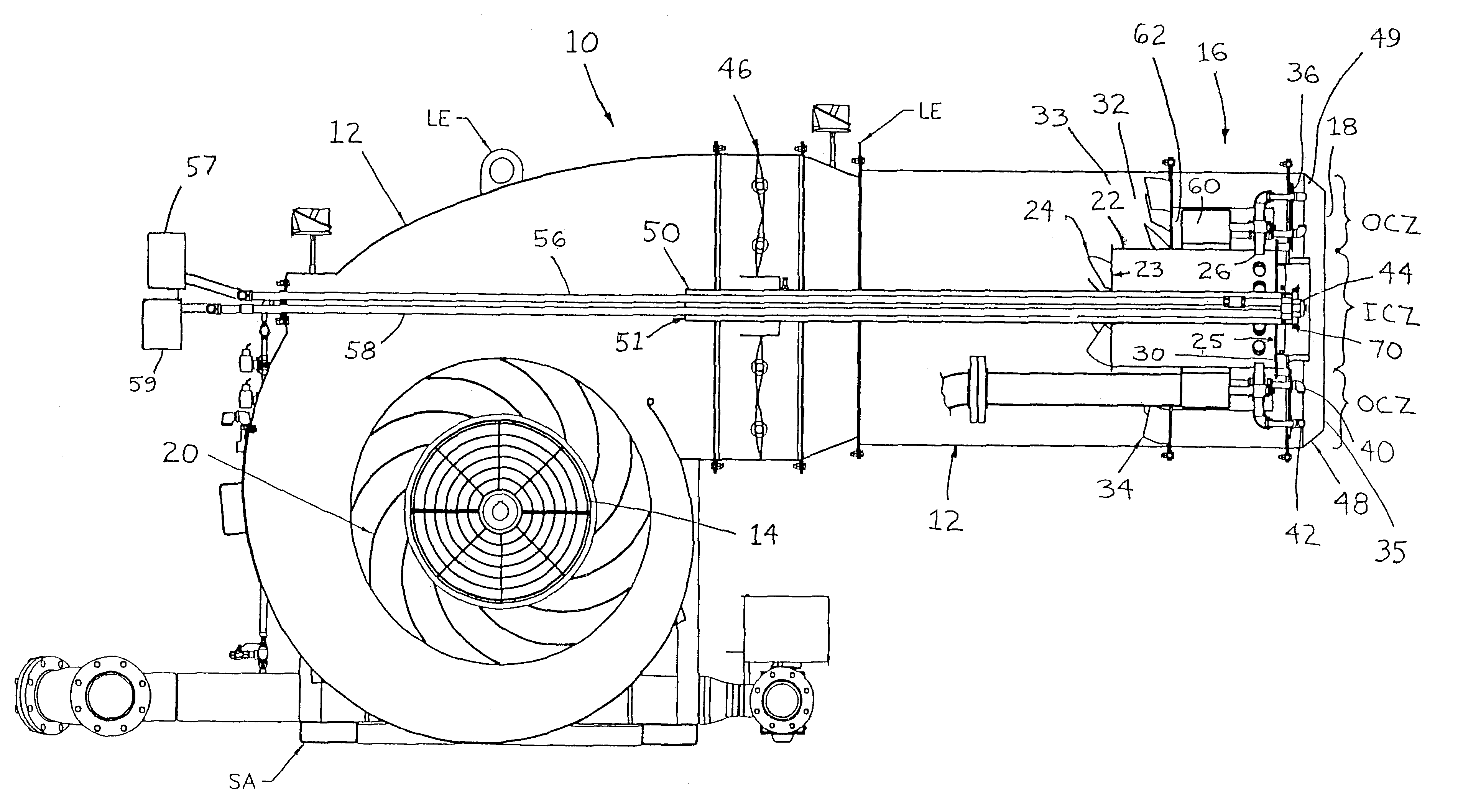

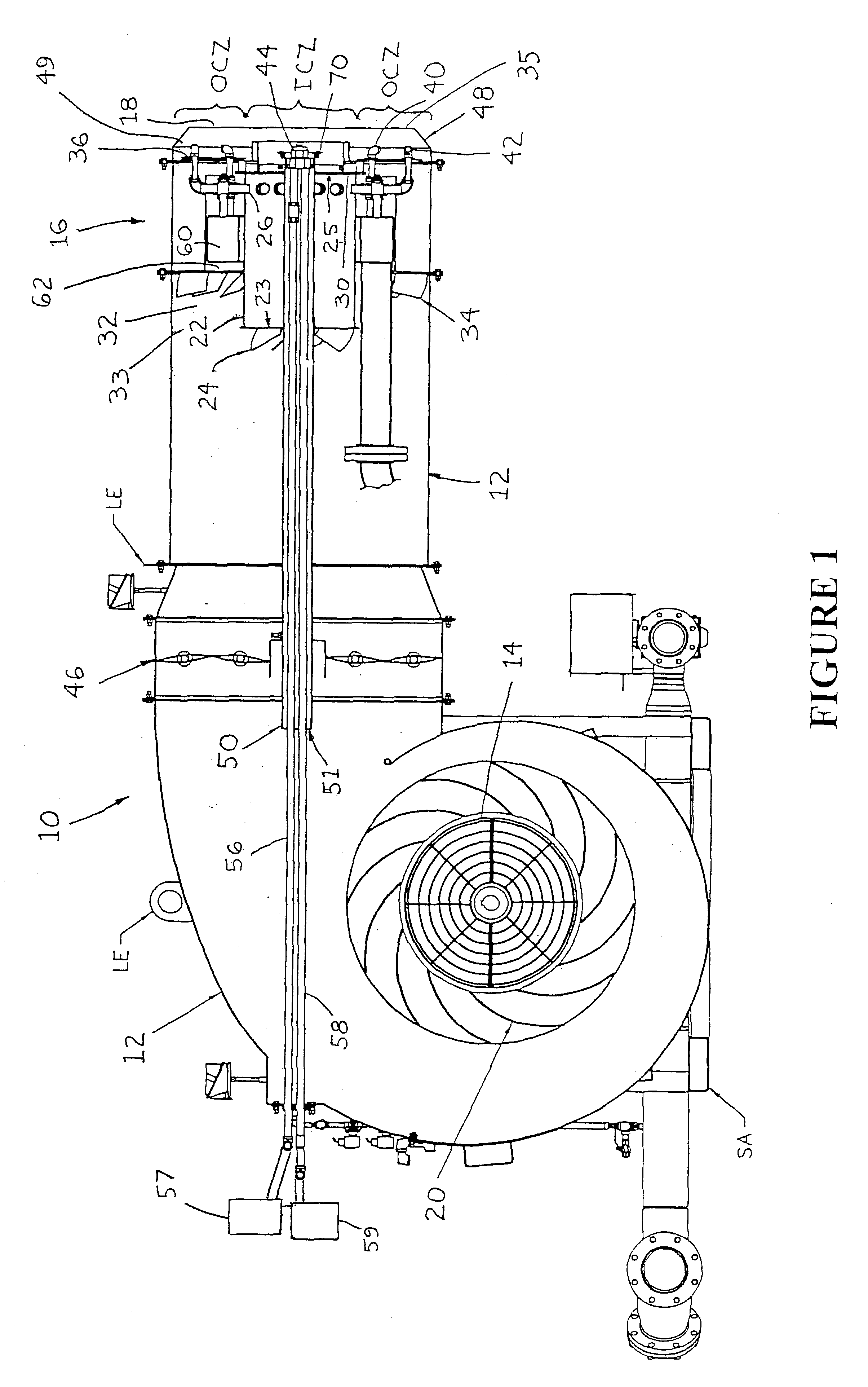

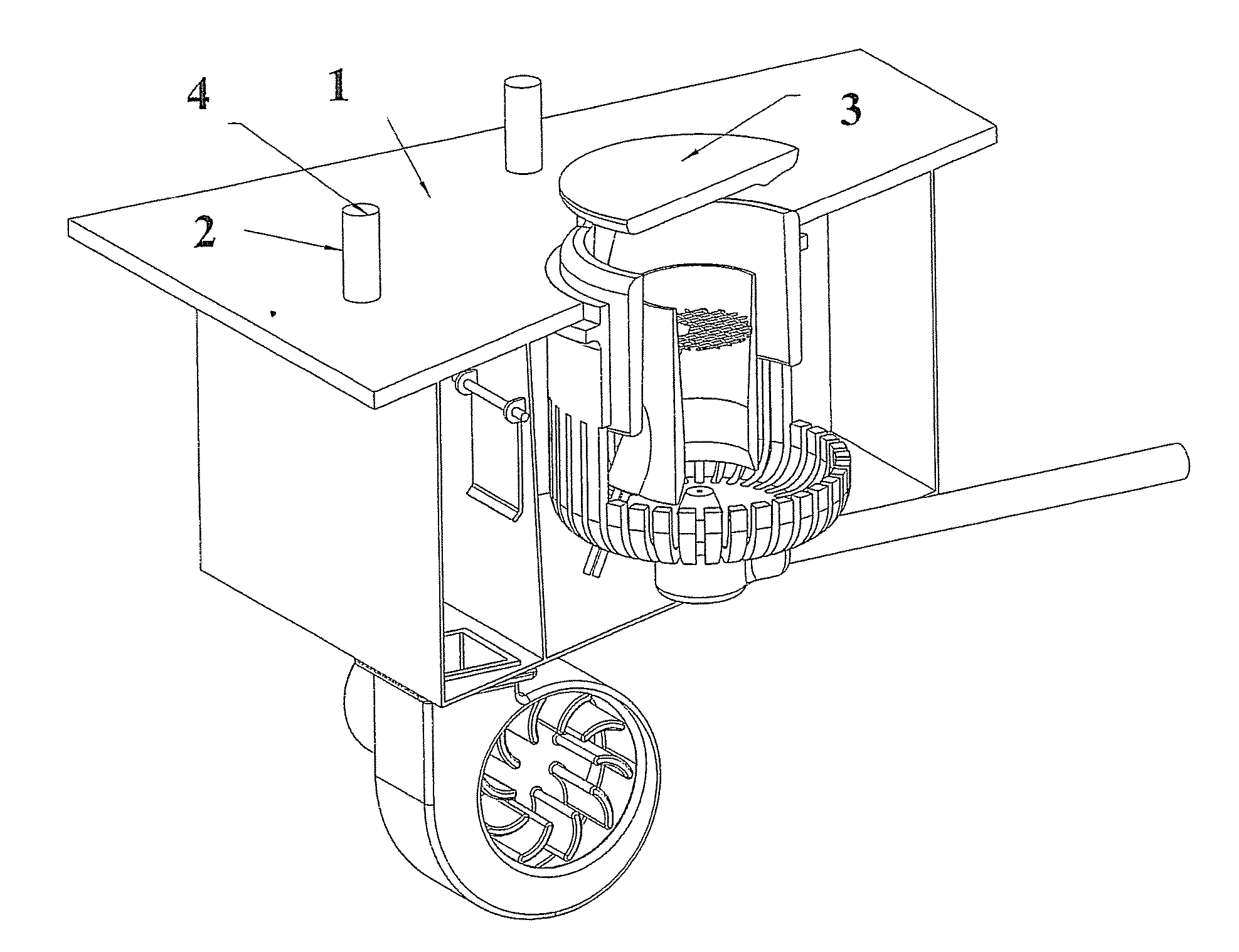

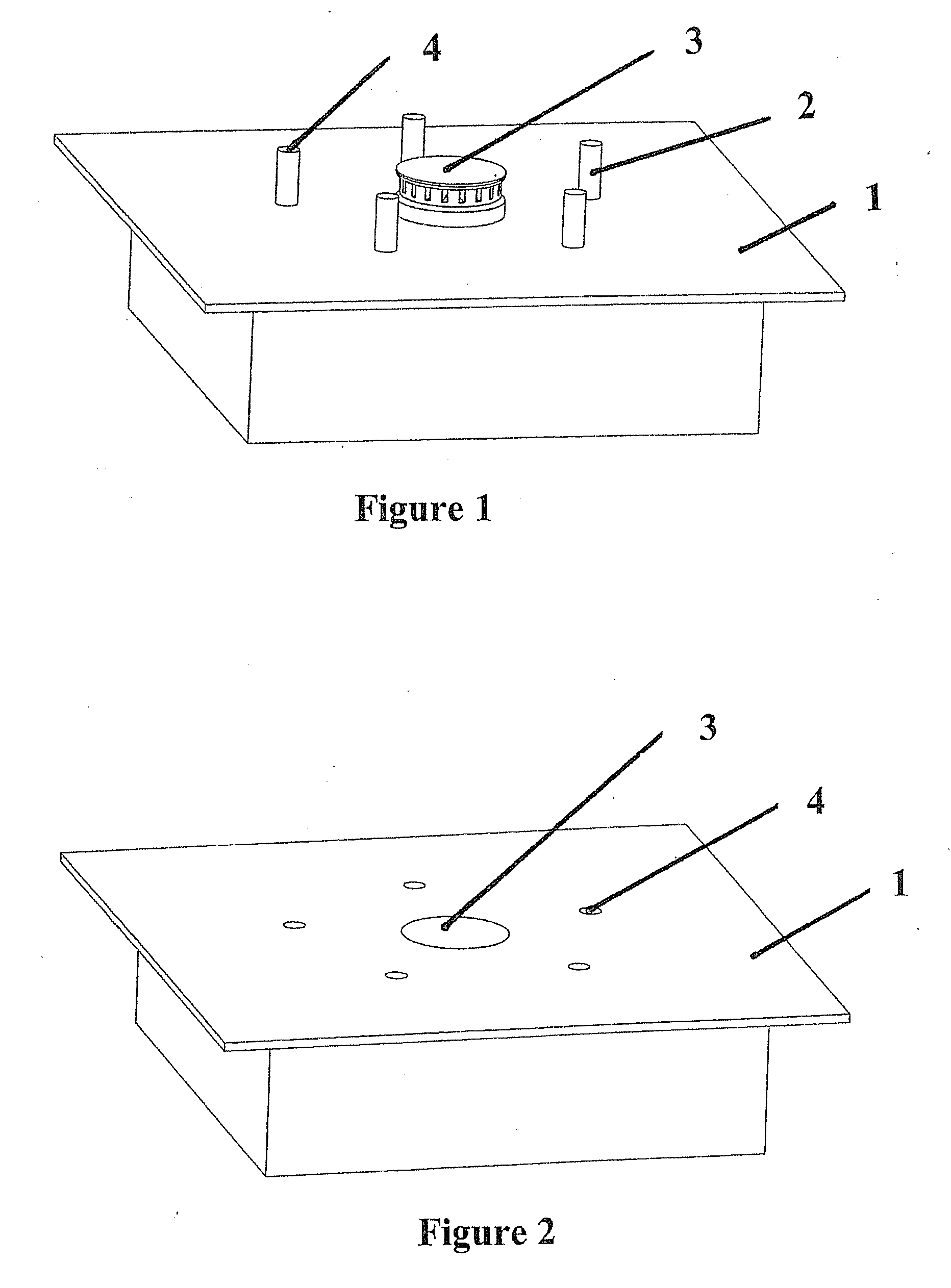

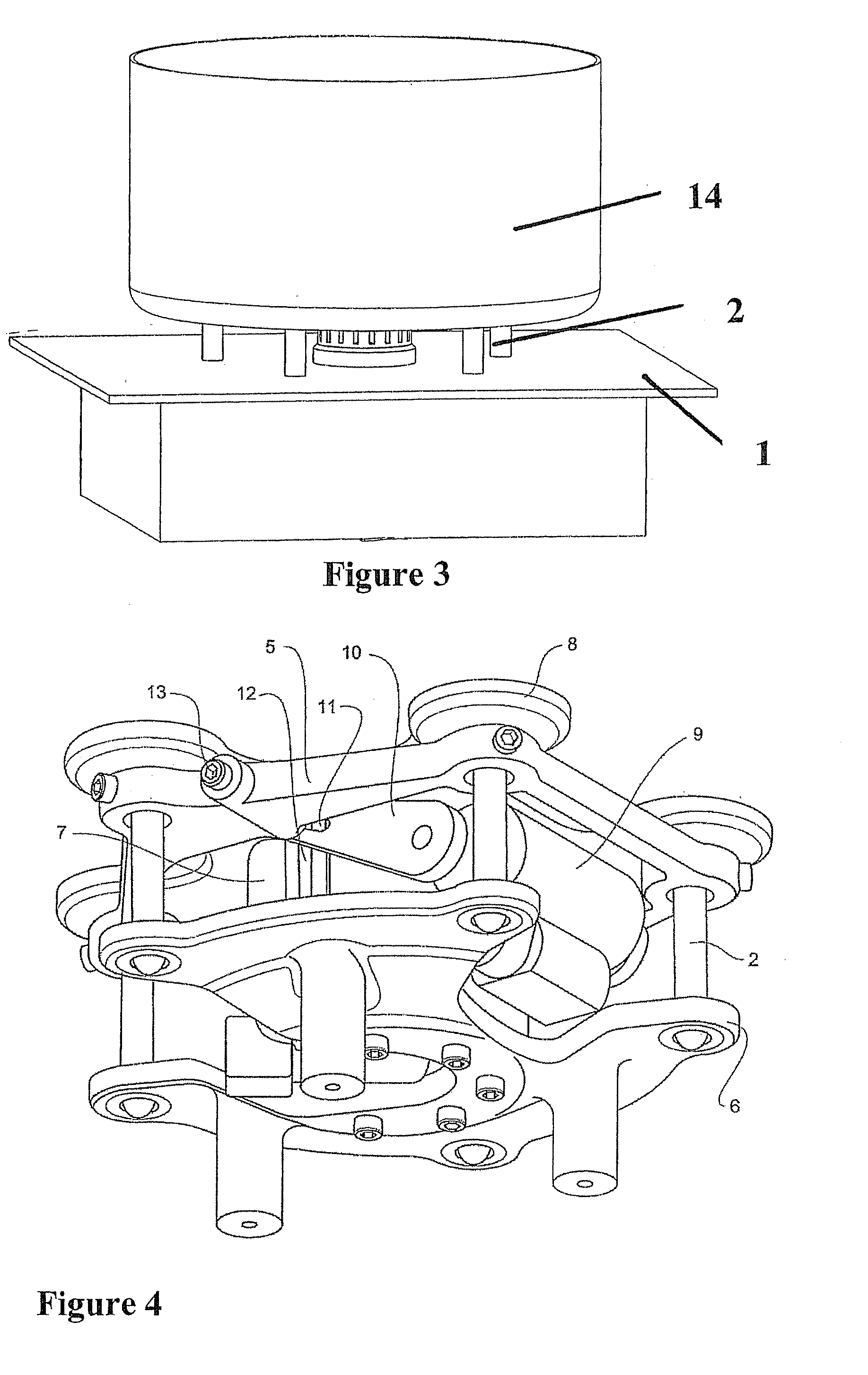

Burner assembly

InactiveUS6652268B1Improve combustion intensityReducing combustion space requiredPilot flame ignitersBafflesImpellerCombustor

A burner assembly including a housing having an air inlet and a burner end. An impeller that is mounted in the housing is in communication with the air inlet and adapted to direct air toward the burner end of the housing. The burner assembly also includes an inner air tube that is mounted in the burner end of the housing so as to define an inner combustion zone and an outer combustion zone. The assembly further includes a plurality of radiation plates that are mounted in the burner end of the housing adjacent to the outer combustion zone, an inner air spin vane that is mounted on the inner air tube so as to direct some of the air from the impeller into the inner combustion zone, an inner gas injection nozzle mounted on the inner air tube so as to direct gaseous fuel into the inner combustion zone, an outer air spin vane that is mounted in the burner end of the housing so as to direct some of the air from the impeller into the outer combustion zone, and a plurality of outer gas injection nozzles that are mounted in the burner end of the housing so as to direct gaseous fuel into the outer combustion zone. A first castellated ring is mounted around the periphery of the inner air tube, and a second castellated ring is mounted around the periphery of the burner end of the housing.

Owner:ASTEC

Turbine air flow conditioner

A system includes an air flow conditioner configured to mount in an air chamber separated from a combustion chamber of a turbine combustor. The air flow conditioner comprises a perforated annular wall configured to direct an air flow in both an axial direction and a radial direction relative to an axis of the turbine combustor. In addition, the air flow conditioner is configured to uniformly supply the air flow into air inlets of one or more fuel nozzles.

Owner:GENERAL ELECTRIC CO

Method and apparatus for removing mercury from combustion exhaust gas

A method for reducing mercury emissions in combustion flue gas is provided. The method includes combusting coal such that a flue gas flow is created. The flue gas flow includes at least mercury and carbon-containing fly ash. The method further includes cooling the flue gas flow within a duct and creating turbulence in the flue gas flow. The mercury is removed from the flue gas flow.

Owner:GENERAL ELECTRIC CO

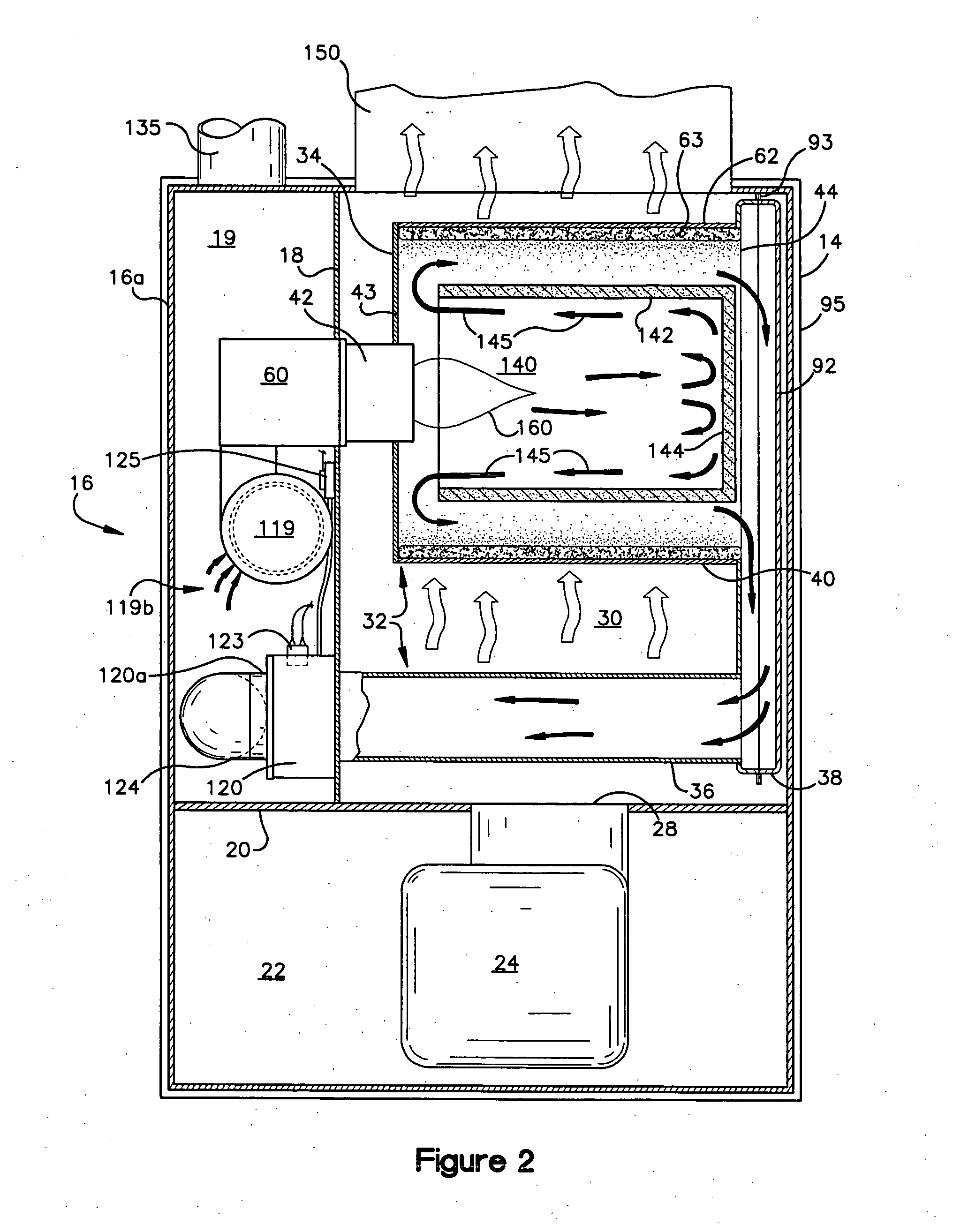

Hot air furnace

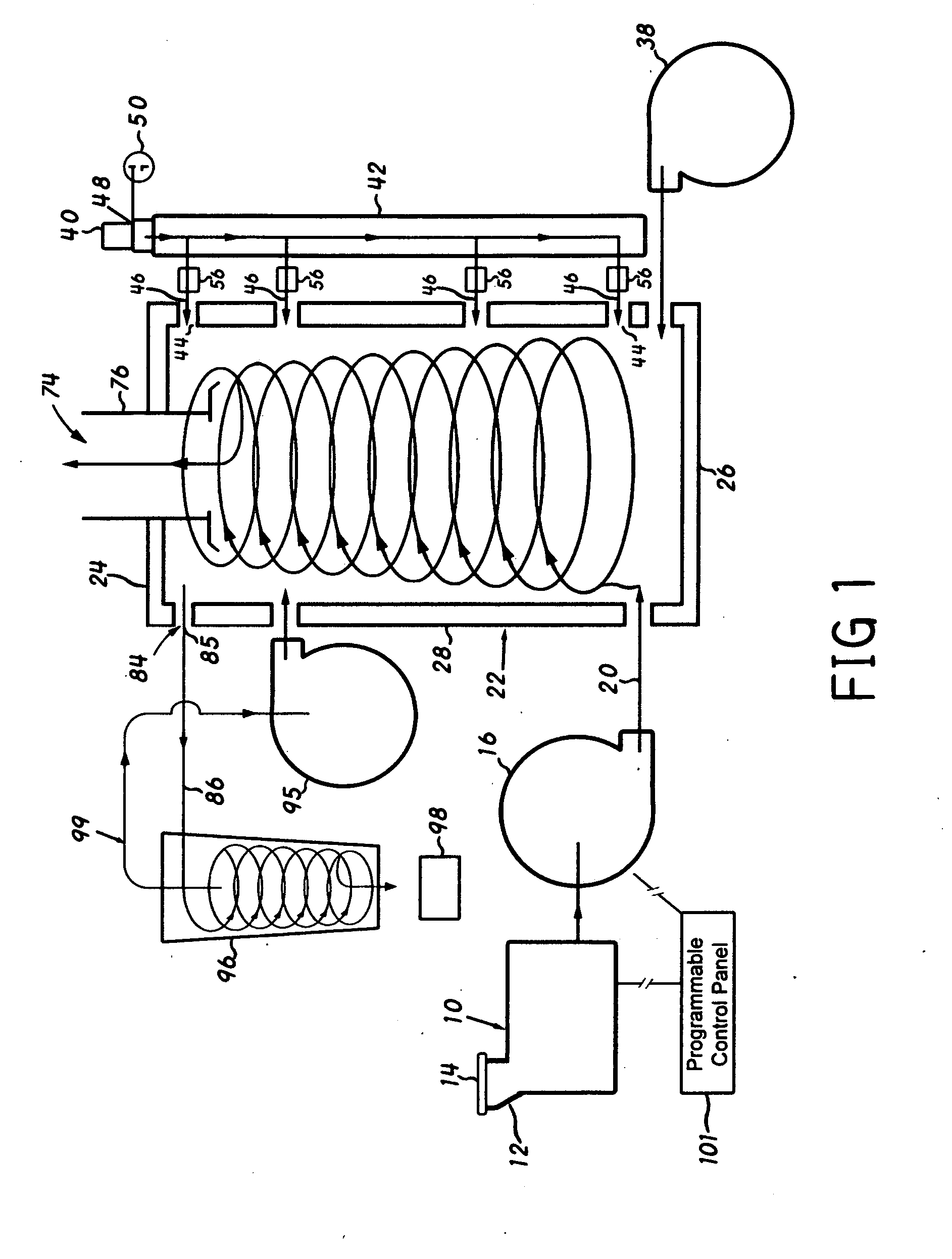

InactiveUS20050092316A1Sufficient dwell timeAvoid elevationDomestic cooling apparatusEnergy efficient heating/coolingCombustorHot air oven

Disclosed is a high efficiency hot air furnace including a heat exchanger assembly located in a heat exchange chamber through with comfort air is passed to be heated. The heat exchanger assembly includes a drum like combustion member located in the flow path of comfort air. A supplemental heat exchanger or condenser is disposed in the flow path of comfort air upstream from the combustion member. A transfer channel extends from one end of the combustion member and communicates combustion products to the condenser. The combustion member includes an insulating material on the inside portion of the cylindrical wall. A diffuser is located within the combustion member which prevents the burner flame from extending into the transfer channel. The burner includes a blower for urging combustion gases through the heat exchanging assembly. Intake air for the blower is provided by an air intake chamber.

Owner:SCHONBERGER SR MARTY L

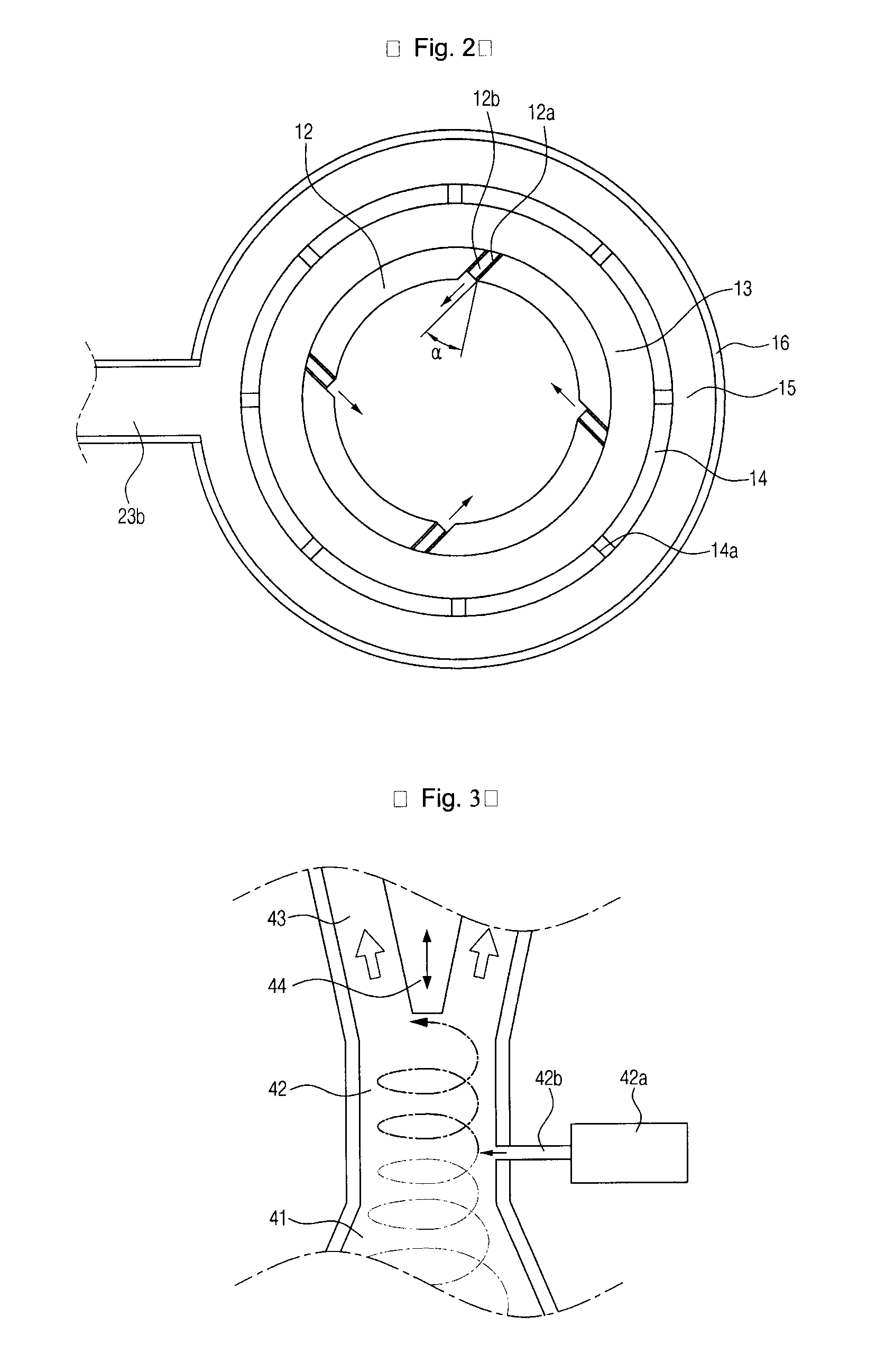

Combustion Apparatus For Recovering Heat

InactiveUS20090126607A1Low costReduce generationPulverulent fuel combustion burnersDamper arrangementCombustion chamberHeat losses

A combustion apparatus for recovering heat according to the present invention comprising a combustion tank for burning fuel contained in the interior by combustion air supplied from the exterior, characterized in that: a combustion chamber surrounded by an inner wall for burning fuel is defined in said combustion tank; a swirl flow supply chamber for supplying a combustion air into said combustion chamber is defined around the outer circumference of the inner wall of said combustion tank; a combustion air supply passage for supplying combustion air from said swirl flow supply chamber into said combustion chamber is defined on the inner wall of said combustion tank; said combustion air supply passage is slanted at a predetermined angle to the vertical direction of the inner face of the inner wall in said combustion tank; and the combustion air generates a swirl flow in the combustion chamber. Furthermore, the combustion apparatus for recovering heat according to the invention characterized in that; an air cooling chamber for supplying combustion air supplied from the exterior into said swirl flow supply chamber is defined around the outer circumference of said swirl flow supply chamber in said combustion tank, and the combustion air supplied from the exterior is supplied through said cooling chamber into the swirl flow supply chamber to decrease a heat loss and to improve a thermal efficiency.

Owner:ENERONE

Dual fuel vent free gas heater

ActiveUS8057219B1Enhanced natural convectionDomestic stoves or rangesLiquid heating fuelControl systemControl valves

A dual fuel vent free gas heater having at least one gas burner with a plurality of gas outlet ports. The gas outlet ports are in flow communication with at least one pilot flame burner. At least one fuel injector feeds fuel to the burner providing for introduction of more than one fuel to the burner. Optionally, an oxygen detection system, manual control valve, linkage, and / or shut off control system may be incorporated into the dual fuel vent free heater.

Owner:COPRECITEC

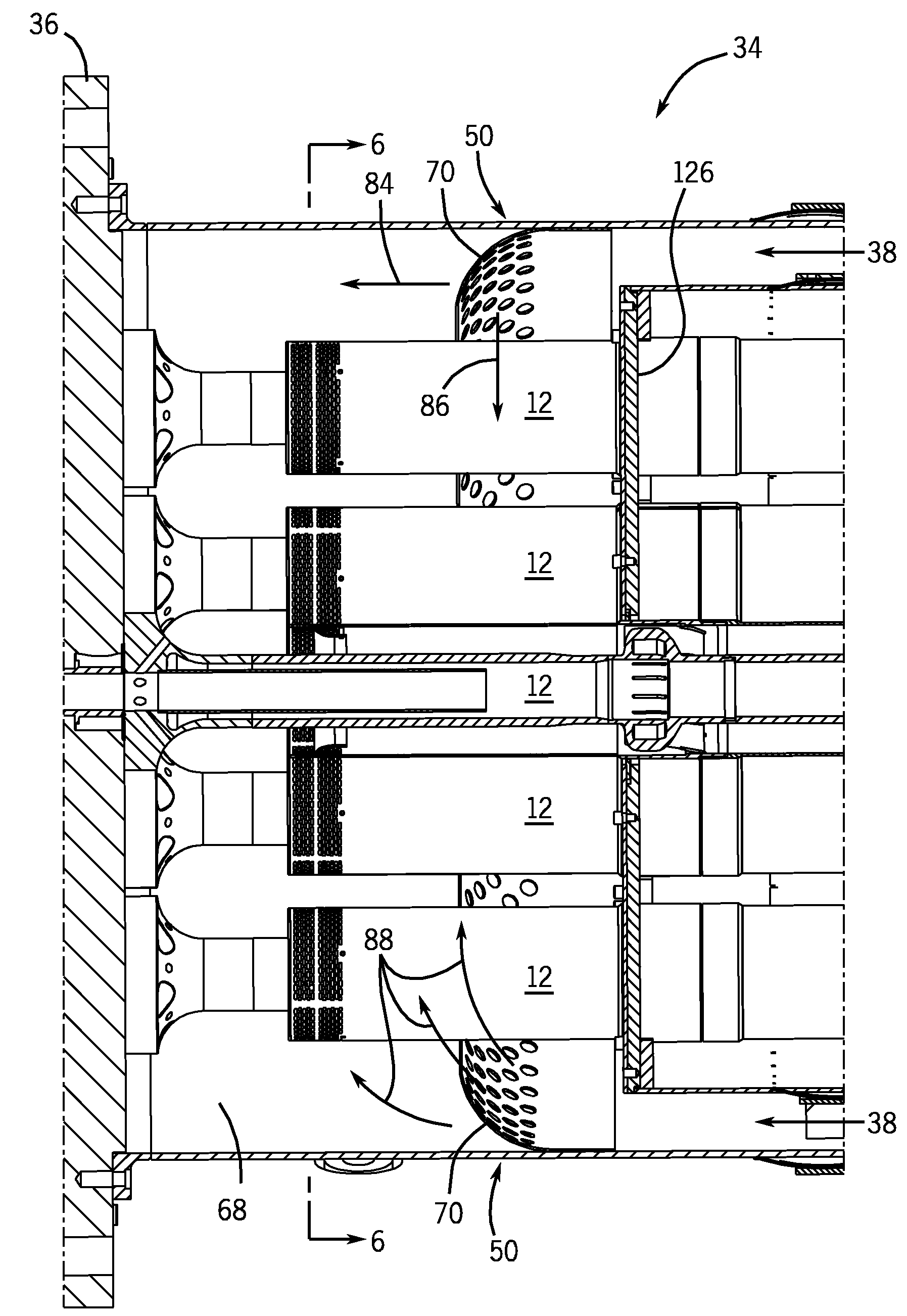

Segmented annular combustor

Owner:SIEMENS ENERGY INC

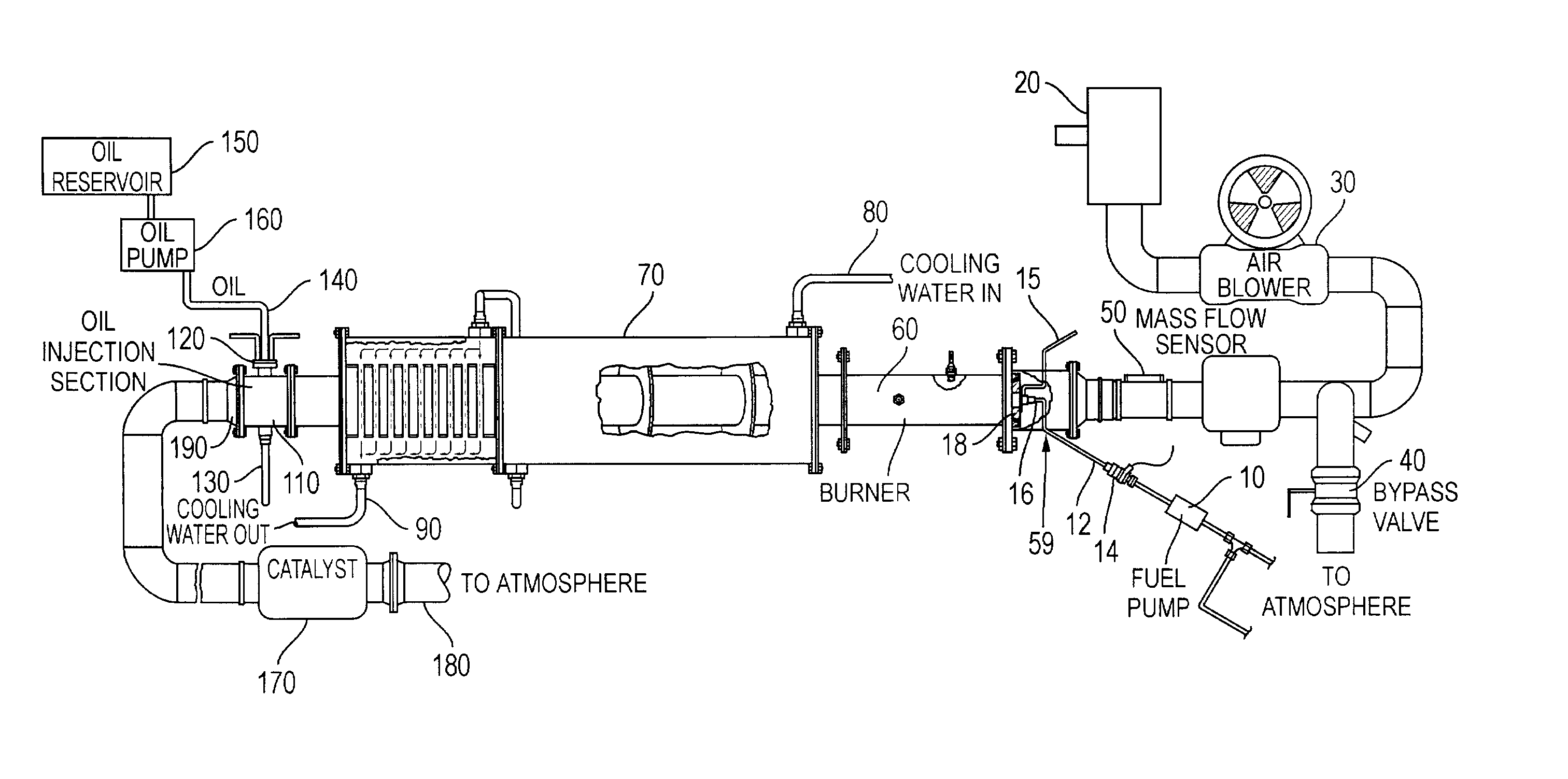

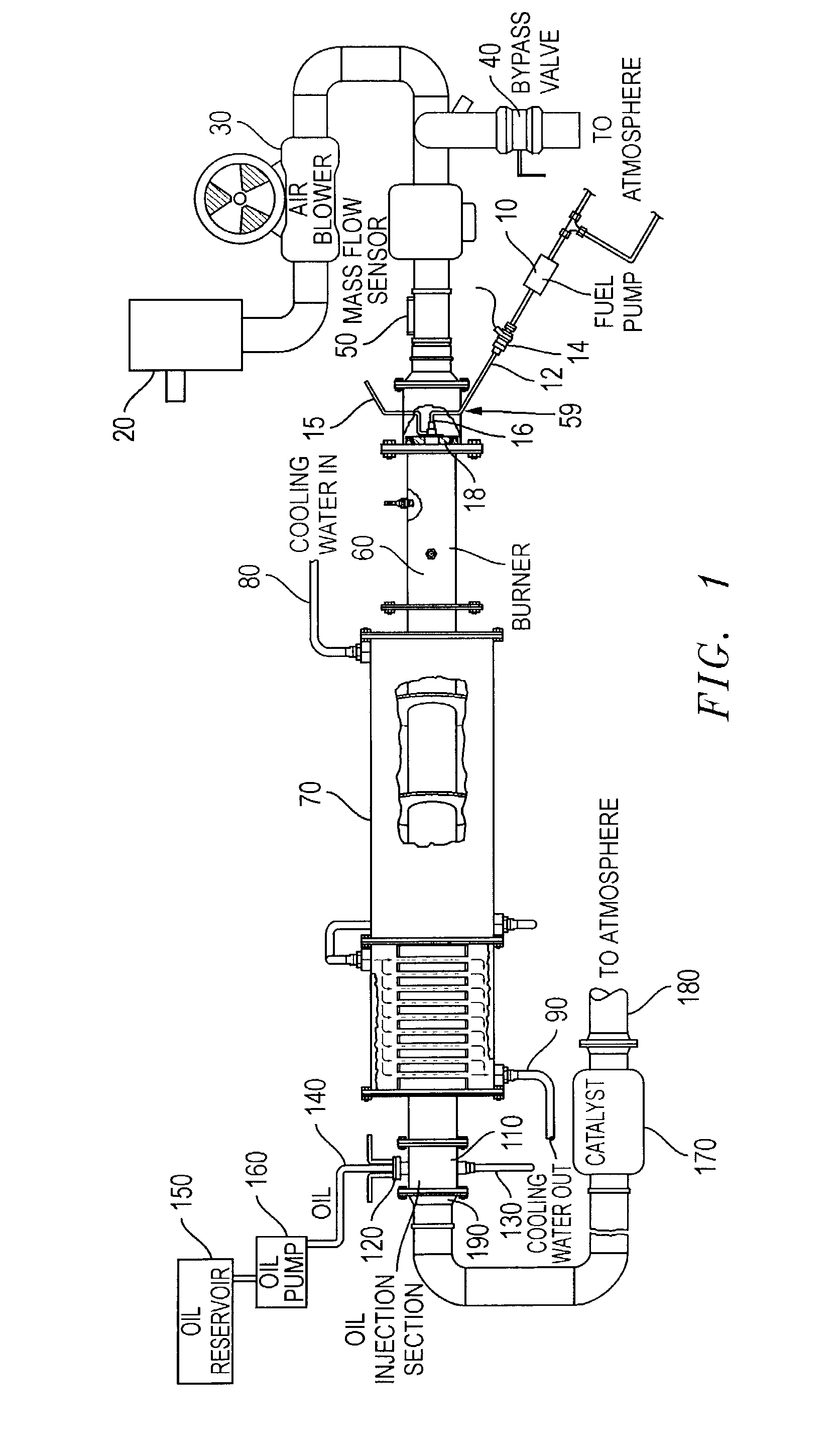

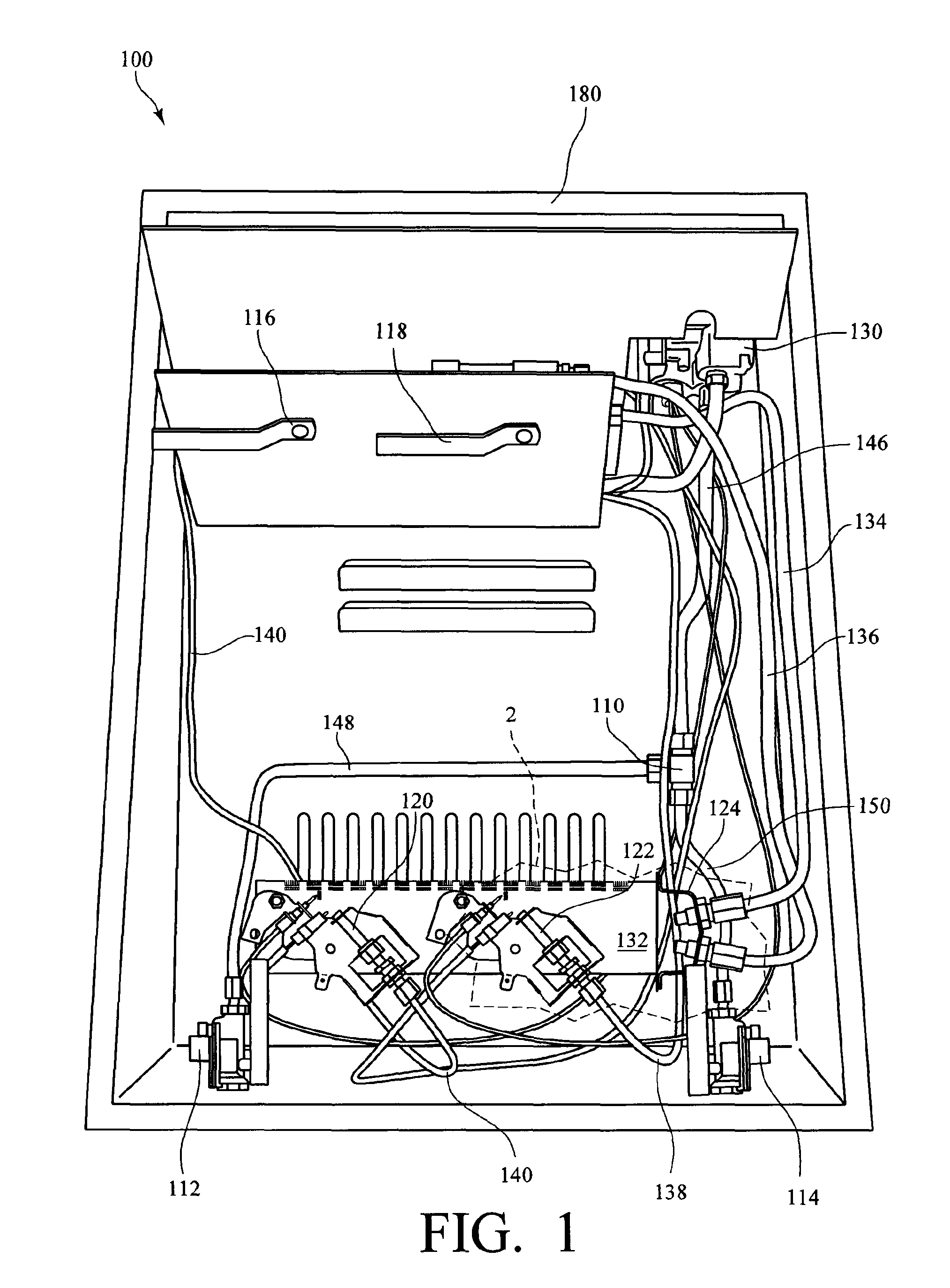

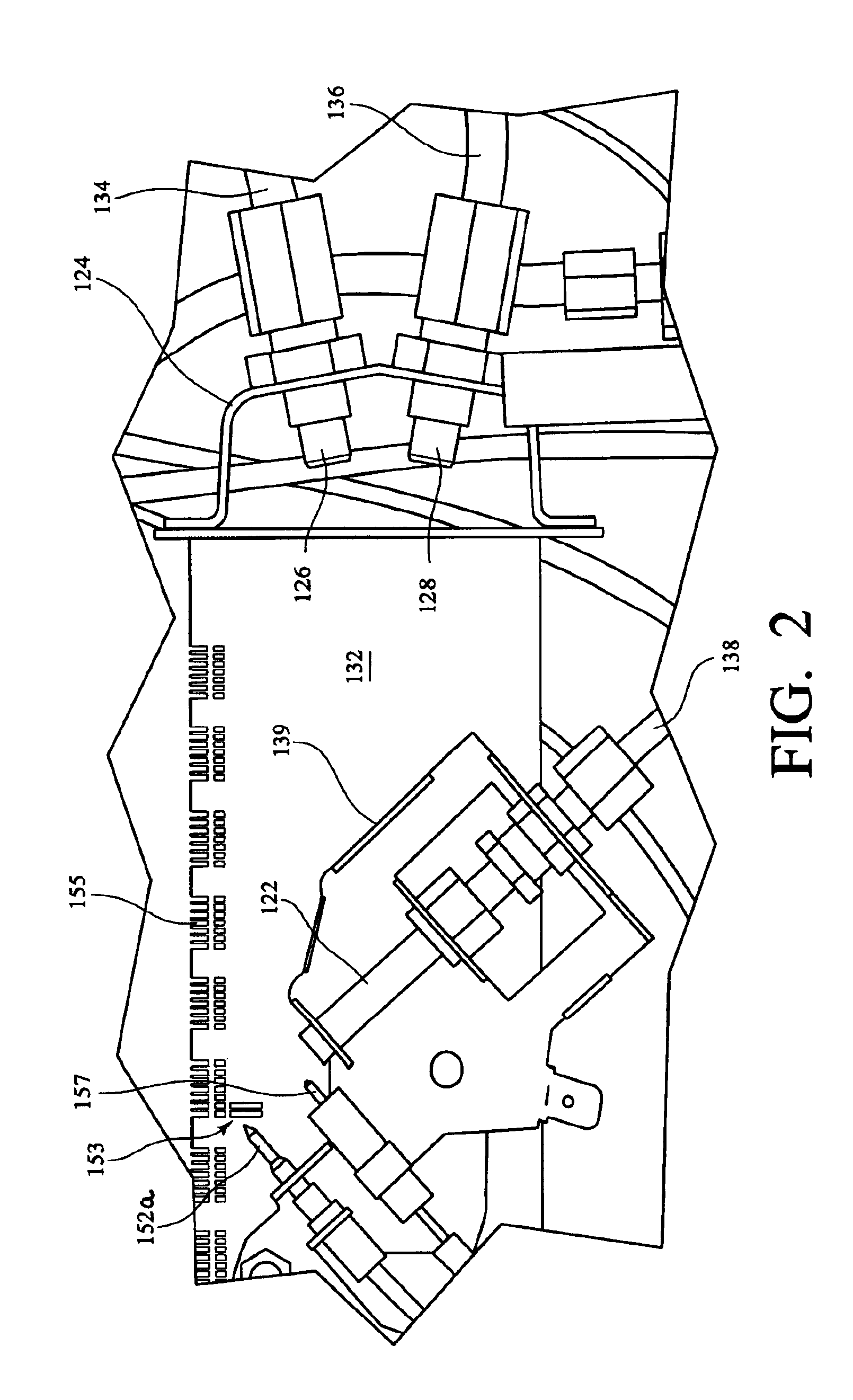

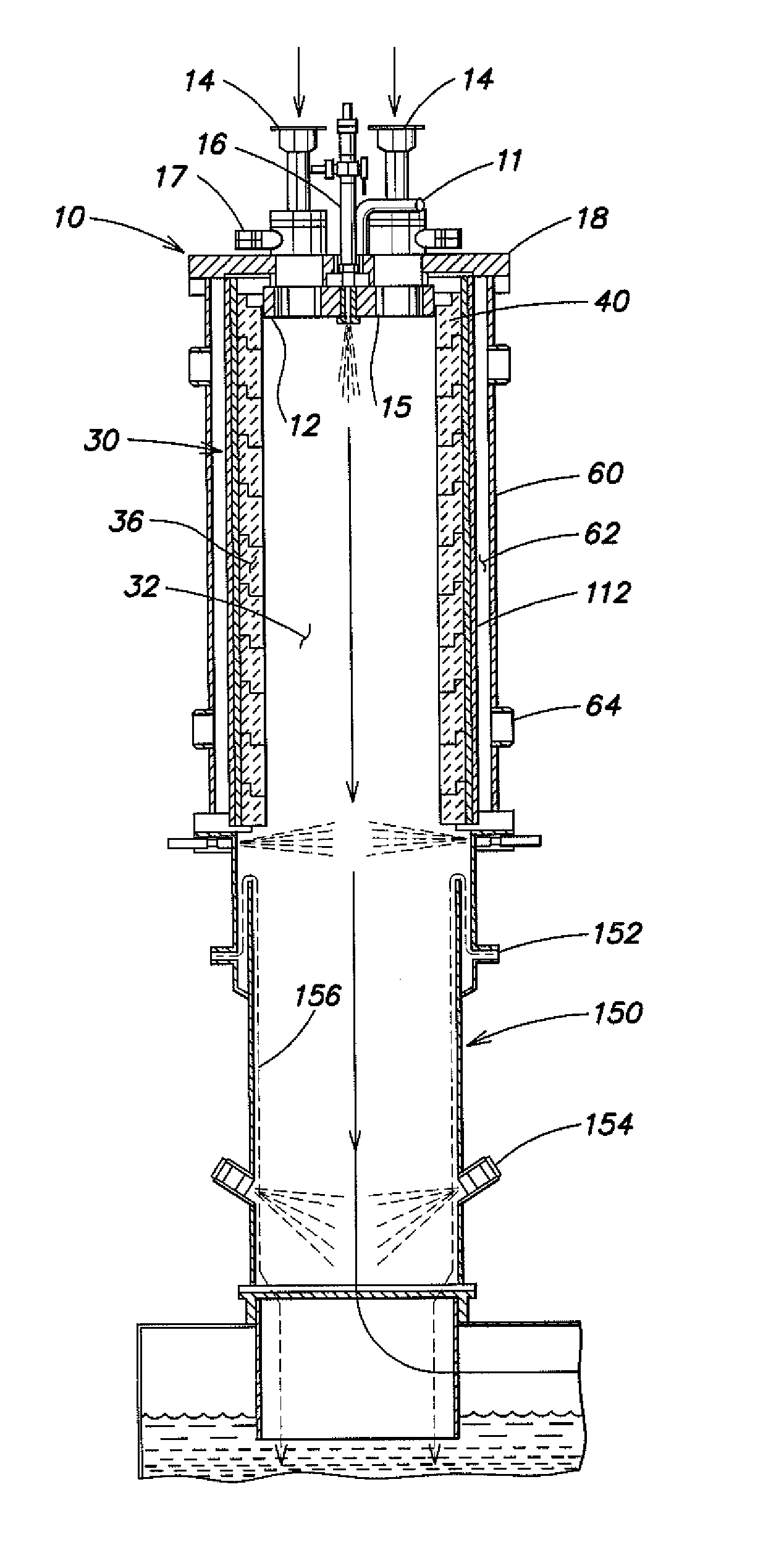

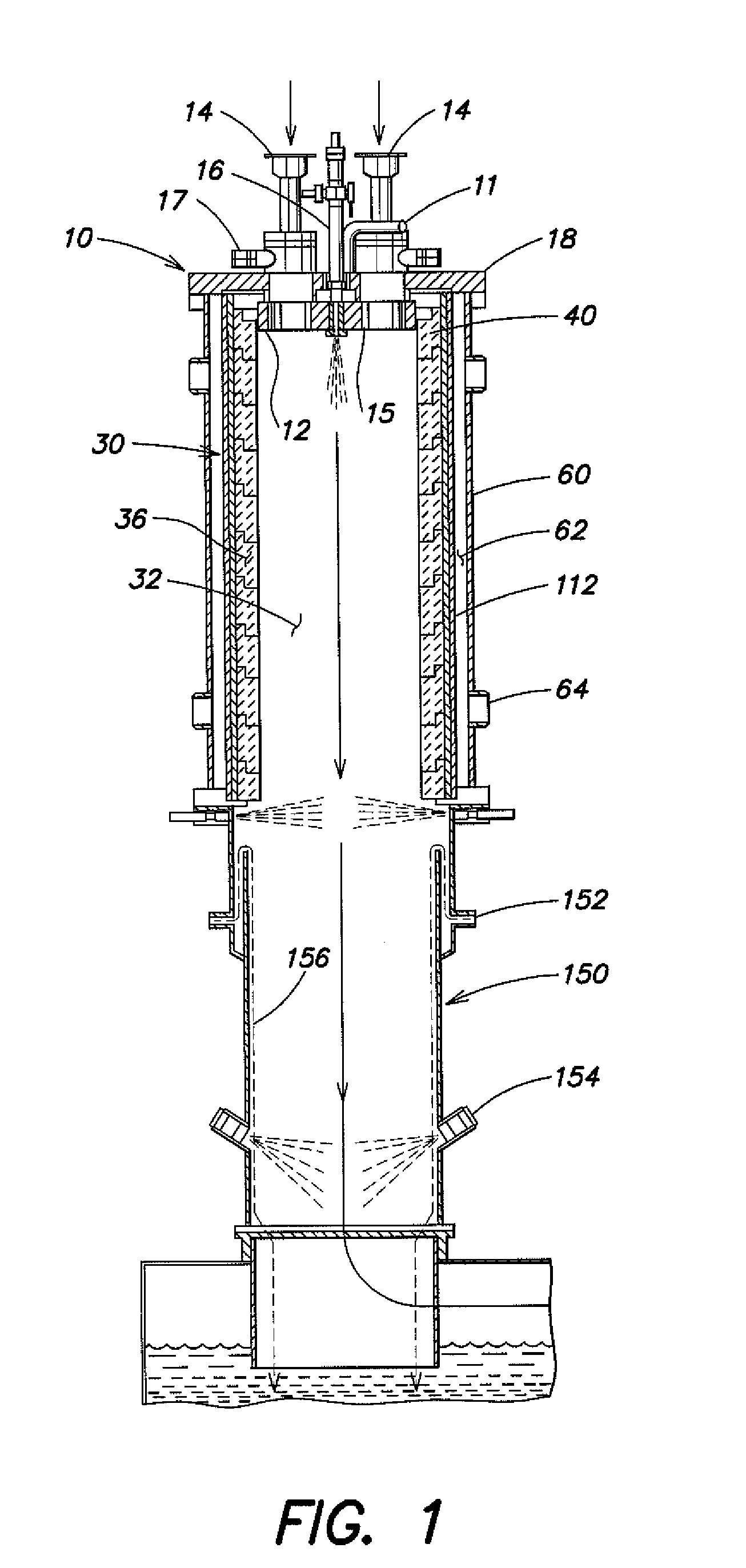

Methods and apparatus for manufacturing a process abatement reactor

InactiveUS20070172398A1Reduce depositionSolve Porosity InsufficiencyCombination devicesBurnersManufacturing technologyThermal expansion

In certain embodiments, methods, systems, and apparatus are provided for use in removing pollutants from a gas stream. The invention includes a thermal reaction unit formed from a plurality of stacked porous ceramic rings. A first of the porous ceramic rings has a first coefficient of thermal expansion (CTE) and a second of the porous ceramic rings has a second CTE. Numerous other aspects are provided.

Owner:APPLIED MATERIALS INC

Method and apparatus for testing catalytic converter durability

The present application relates in general to an apparatus and to methods for testing the performance of an automotive catalytic converter under conditions simulating those which occur in motor vehicles over extended driving conditions. The application provides a novel swirl plate and a novel fuel injector which enable the burner to run stoichiometric for extended periods of time.

Owner:SOUTHWEST RES INST

Cooking appliance

InactiveUS20070145032A1Easy to cleanVisually intuitiveDomestic stoves or rangesGearingThermodynamicsMedicine

In one aspect the invention discloses a gas cooktop which is relatively easy to clean and which is not visually complex. The gas cooktop surface is provided with a trivet having two operating conditions. In a first condition the trivet is retracted and is substantially flush with the cooktop surface. In a second condition the trivet is extended Lo support a cooking vessel above a gas burner. In another aspect the invention discloses an improved gas burner with a high turn-down ratio. The improved burner includes first and second gas flow passages, a flame front locator, in one of the passages and a burner head. Fuel gas is injected into an end of one of said passages and is ignited to establish a flame at the flame front locator. Secondary combustion air is provided through the other of the passages which on a high setting enables secondary combustion and on a low setting may mix with the hot gases and cool them resulting in a lower temperature at the cooking vessel.

Owner:FISHER & PAYKEL APPLIANCES LTD

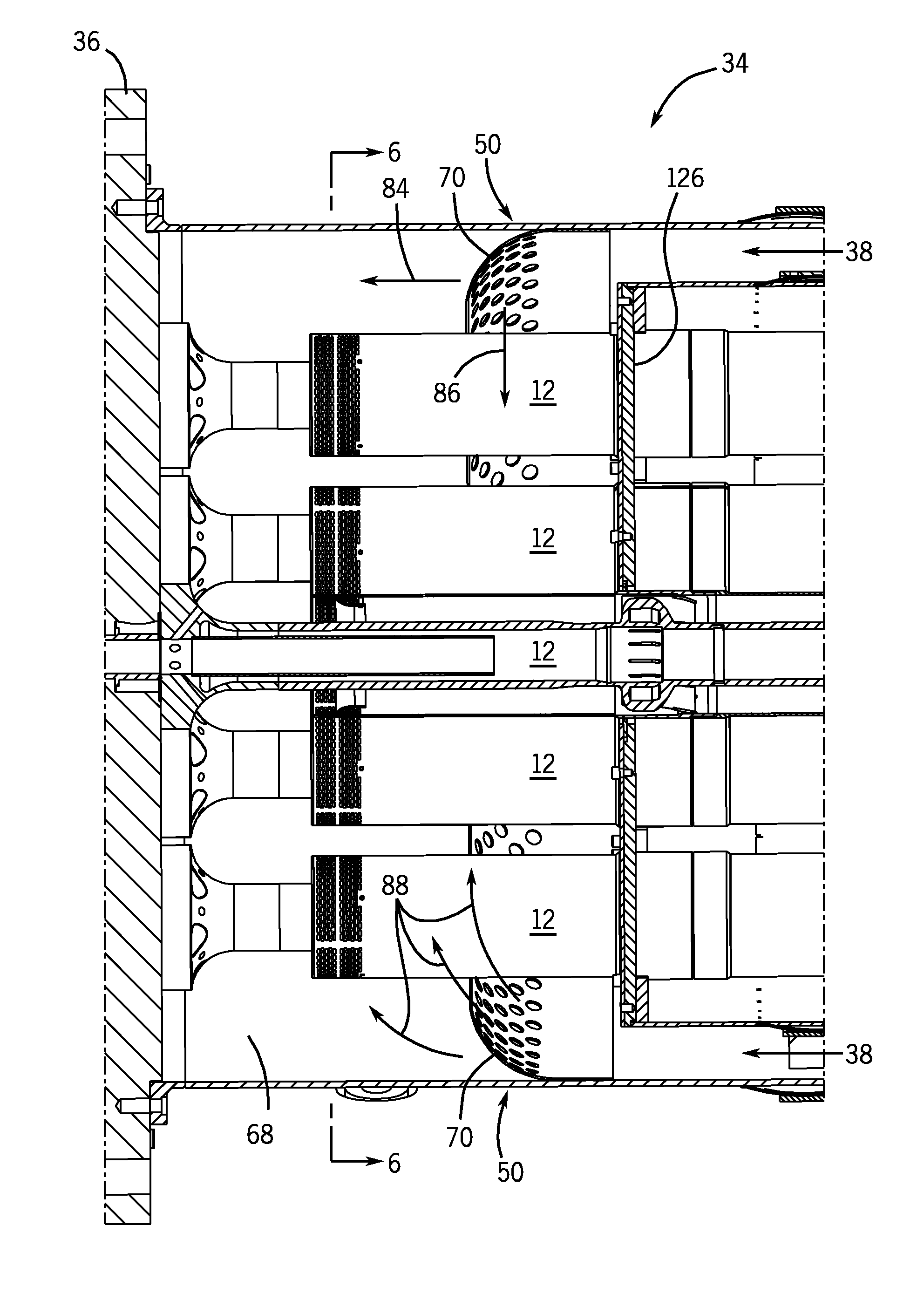

Combustion chamber of a combustor for a gas turbine

ActiveUS20140373548A1Improved swirlWell mixedContinuous combustion chamberGas turbine plantsCombustorCombustion chamber

A combustion chamber of a combustor for a gas turbine is provided. A combustion chamber includes a plurality of segments arranged annularly about an axis of the combustion chamber, each segment comprising a radial inner wall portion and a radial outer wall portion, a first section comprising an opening for the installation of a burner, and a second section at which at least one airfoil extends between the radial inner wall portion and radial outer wall portion of the segment.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com