Vortex incinerator

a technology of incinerators and incineration chambers, which is applied in the direction of incinerator equipment, combustion types, lighting and heating equipment, etc., can solve the problems of insufficient cleaning of flue gas, high cost and bulky construction of cleaning equipment, and inability of prior incinerator designs to achieve good combustion of waste materials. , to achieve the effect of reducing air and water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

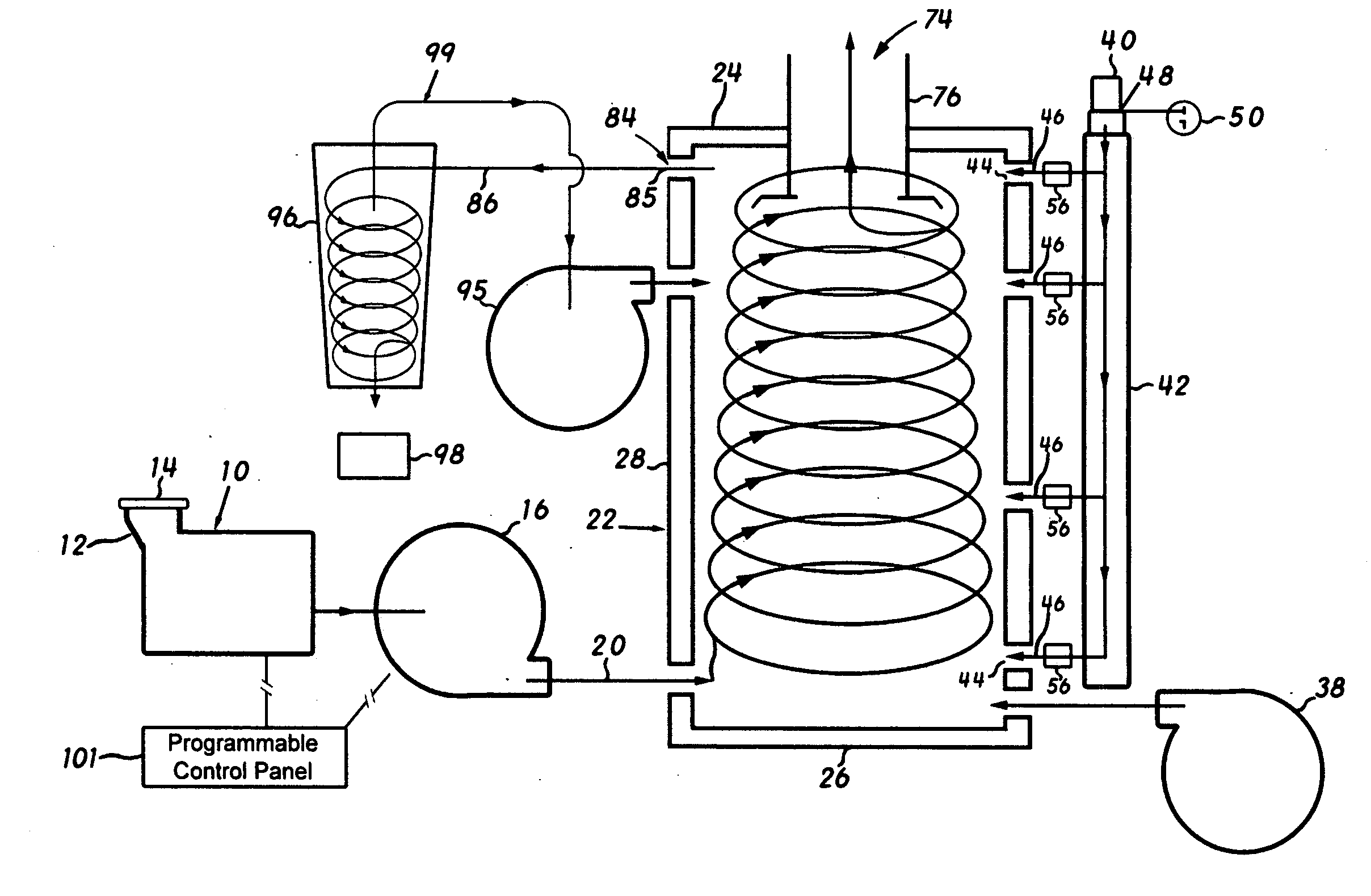

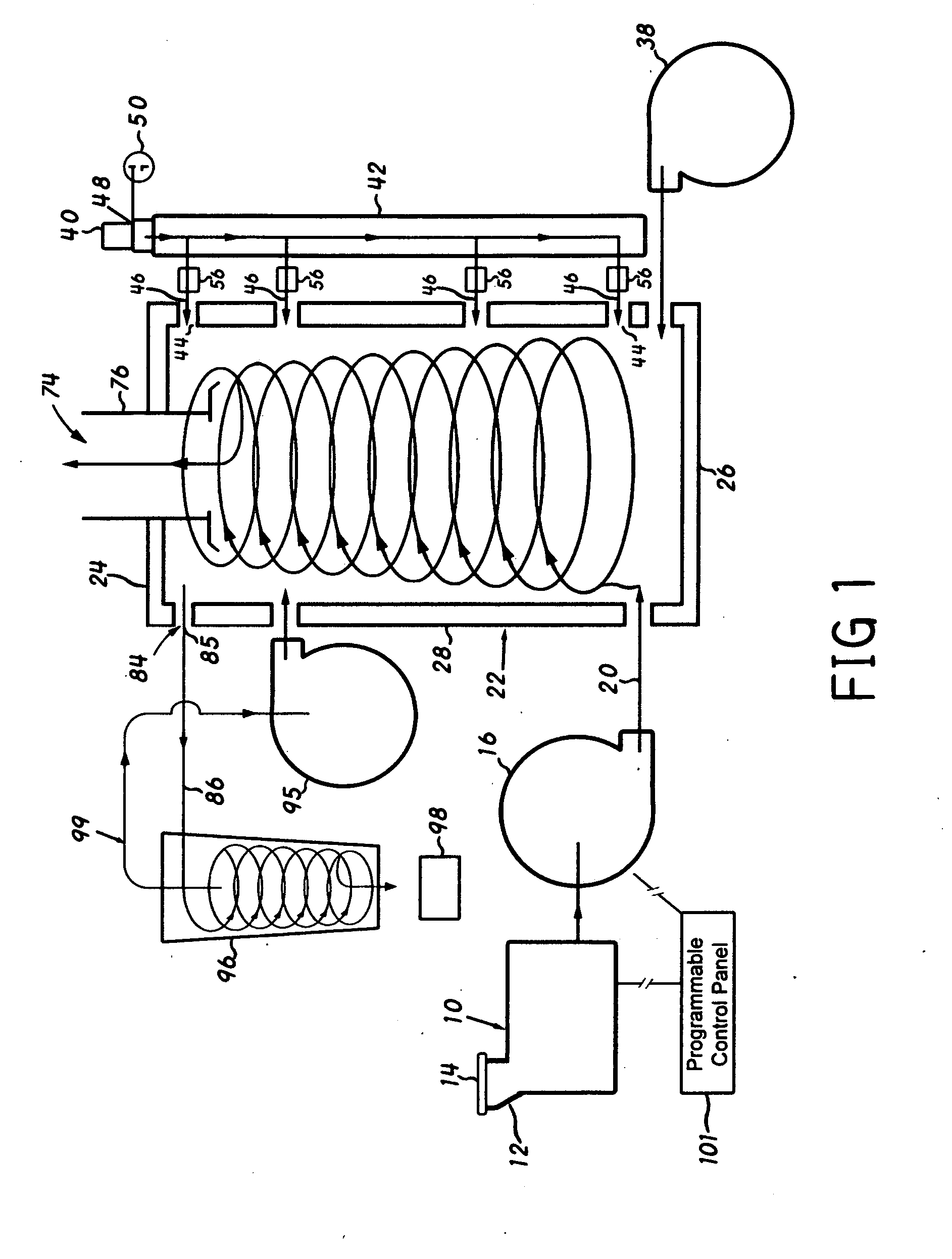

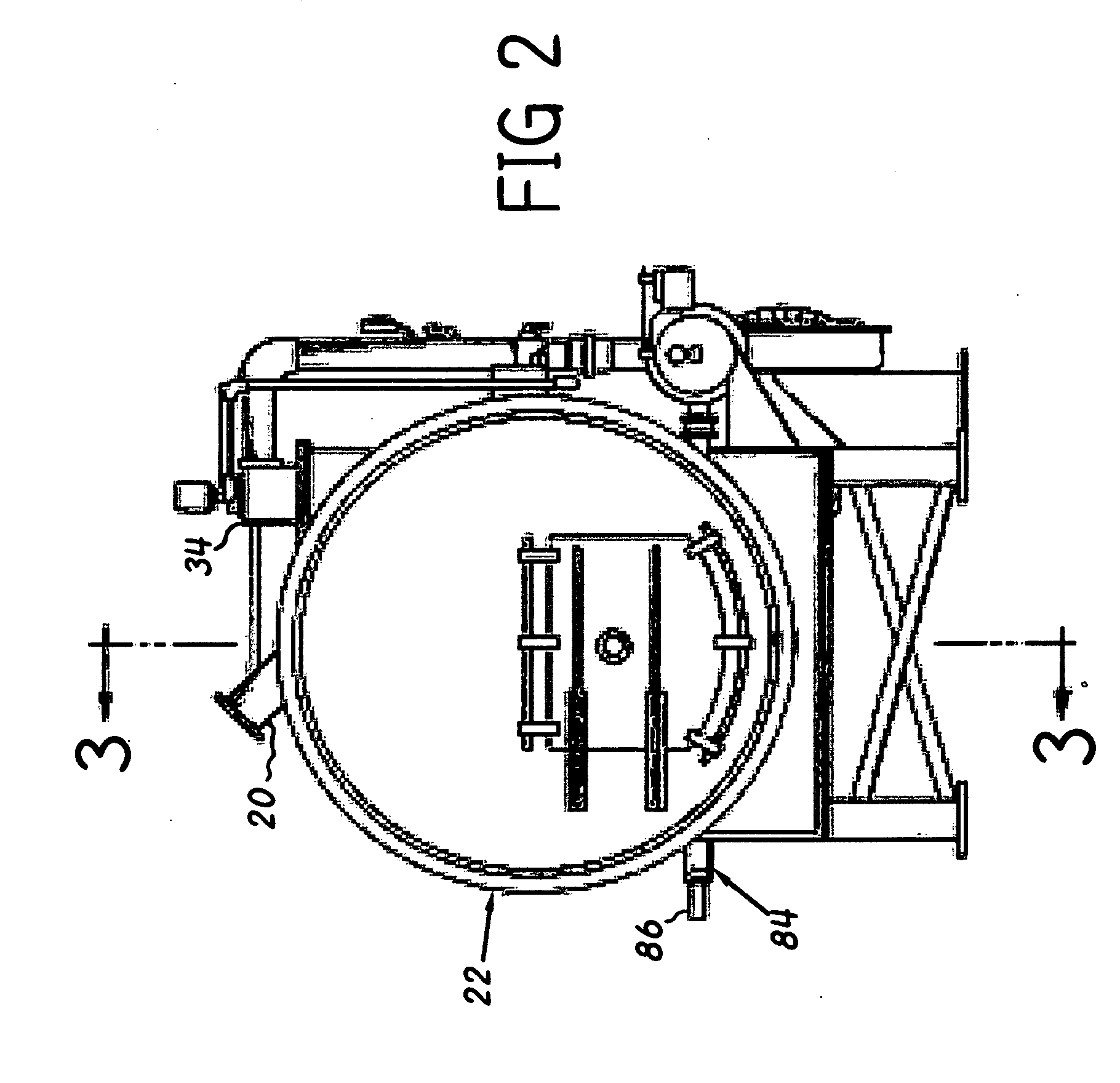

[0025]Referring now to the drawing there is illustrated in FIGS. 1-4 an incinerator embodying the invention and comprising in general a size reduction unit for chopping up the waste material, means for introducing the waste material and primary air into a combustion chamber for establishing a vortical movement of the waste material, means for igniting the waste material during its vortical movement, means for introducing secondary air into the chamber, discharge means for discharging gaseous products of combustion, and non-combustible material from the combustion chamber, and a separator for separating the gaseous and solid material discharged by the discharge means. The incinerator of the present invention is particularly suited for disposing of solid industrial and municipal waste materials, including but not limited to standard waste, such as for example, paper, peanut hulls, cardboard cartons, wood scrap, garbage, foliage, woody biomass, bottles, cans, plastic items and more. Ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com