Combustion Apparatus For Recovering Heat

a combustion apparatus and heat recovery technology, applied in the direction of lighting and heating apparatus, solid fuel combustion, combustion types, etc., can solve the problems of difficult to achieve a continuous combustion process, difficult to process the automatic disposal of these remaining ashes, waste of materials, etc., to reduce environmental pollution, improve thermal efficiency, and reduce the effect of cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

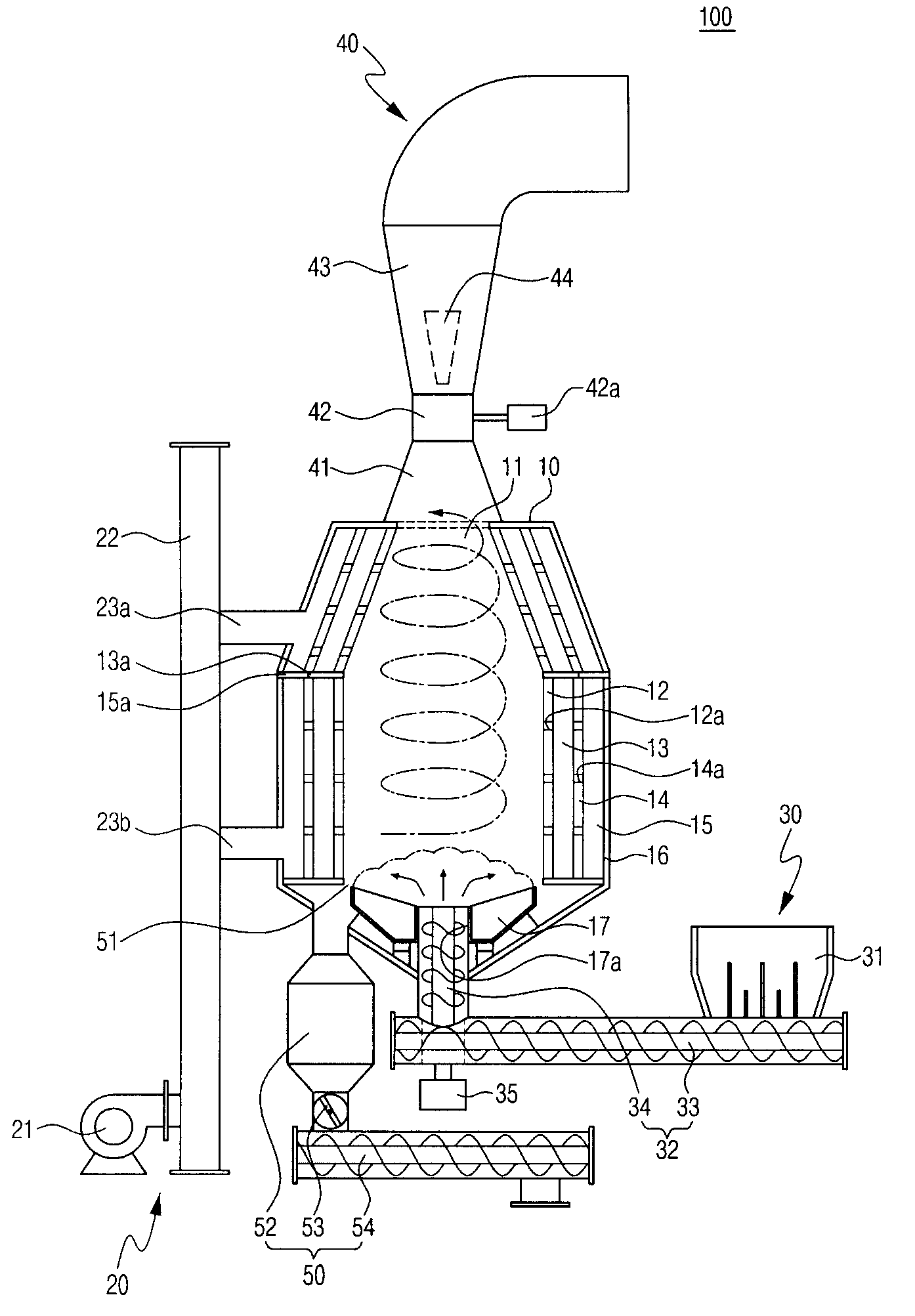

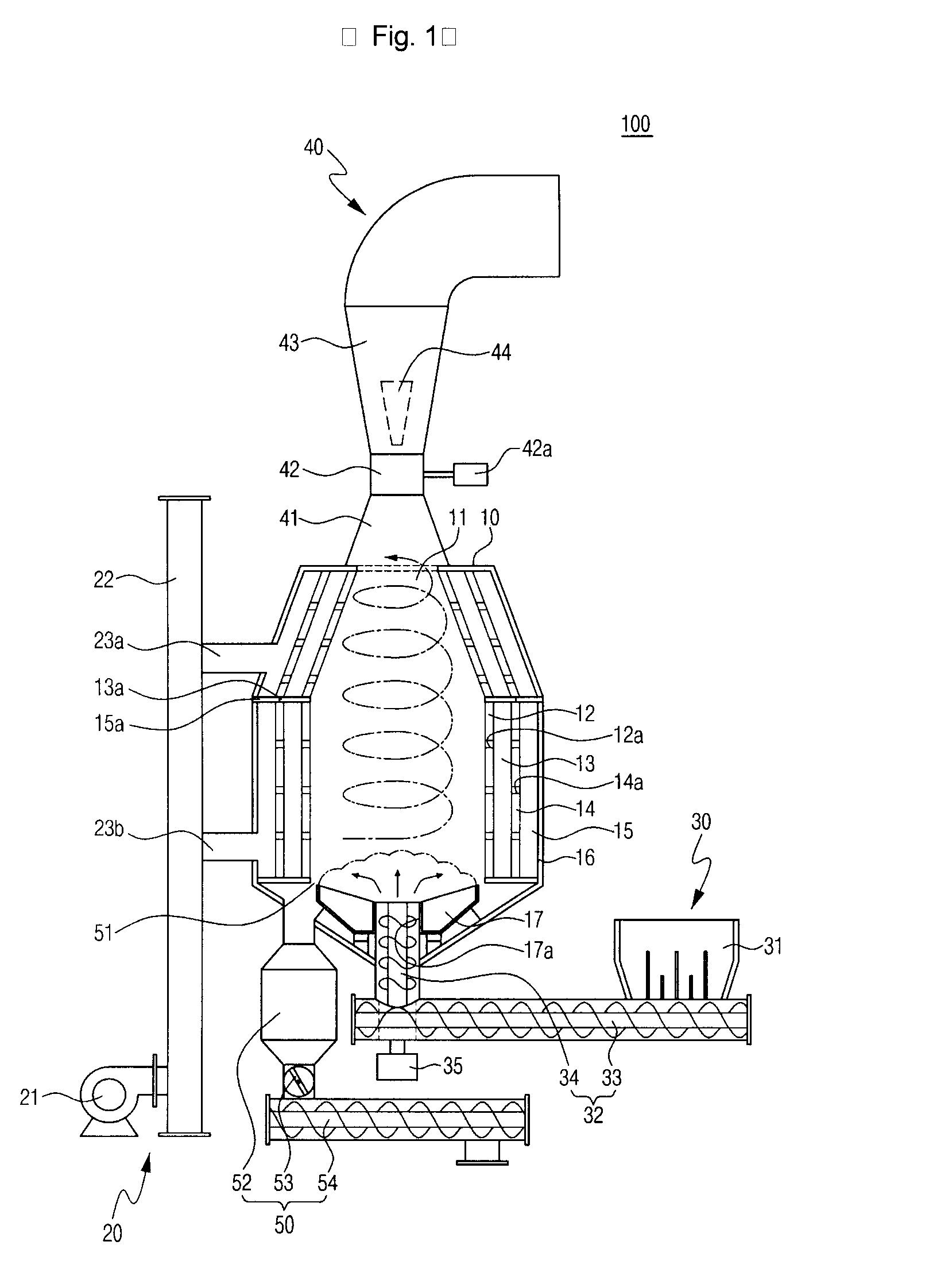

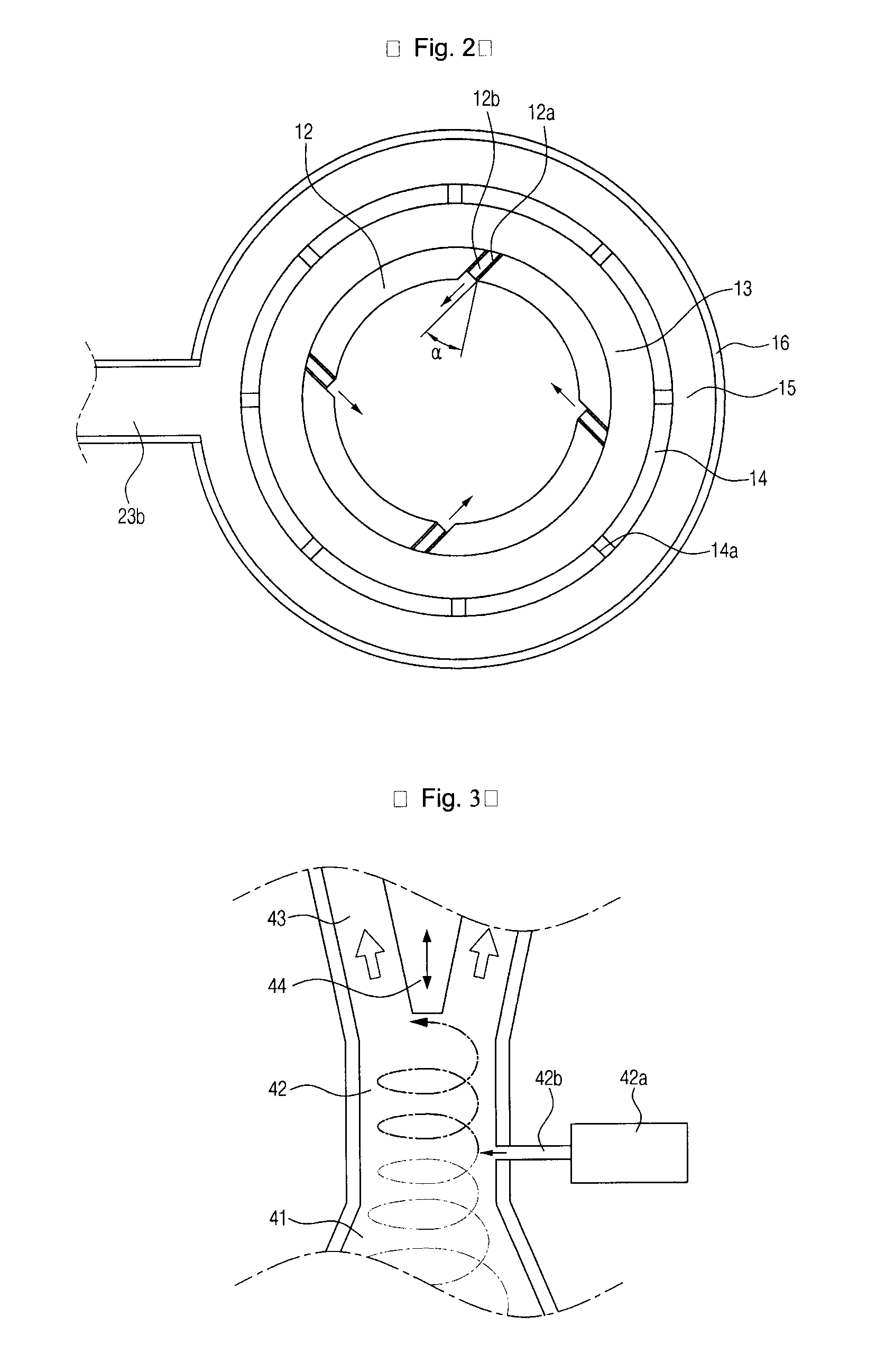

[0024]FIG. 1 is the longitudinal section of a combustion apparatus for recovering heat according to the present invention, FIG. 2 is the cross section of a combustion tank shown in FIG. 1, FIG. 3 is the partially enlarged cross section of a combustion gas exhausting tube shown in FIG. 1, and FIG. 4 is cross section of a narrowed part in the combustion gas exhausting tube shown in FIG. 3.

[0025]A combustion apparatus(100) for recovering heat according to the first preferable embodiment of this invention comprises a combustion tank(10) in which fuel is burned, a combustion air supply part(20), a fuel supply part(30), a combustion gas exhausting tube(40), and an ash discharge part(50).

[0026]Firstly, the combustion tank(10) of cylindrical shape is to receive and burn fuel in the interior, the upper end of the tank(10) is opened to exhaust the combustion gas, on the lower edge of the tank is formed an ash outlet(51) for discharging the burned ash of solid fuel, the outermost side of the t...

second embodiment

[0048]Next, the combustion apparatus for recovering heat(101) according to the present invention is described with reference to the attached drawings.

[0049]The constitution of the combustion apparatus for recovering heat(101) according to the second embodiment of this invention is described only stating the differences from the first embodiment. As compared with the first embodiment, in the combustion apparatus(101) according to the second embodiment, an ash discharge chamber(19) is defined between the combustion chamber(11) and the swirl flow apply chamber(13) of the combustion tank(11), that is to say, the ash discharge chamber(19) is around the outer of the inner wall(12) in the combustion chamber(11), and an ash discharge hole(12c) is defined in the inner wall(12). To this constitution, a space wall(18) is defined between the inner wall(12) and the intermediate wall(14), the ash discharge chamber(19) is defined in the space between the inner wall(12) and the space wall(18), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com