Reheat burner injection system

a technology of injection system and reheat burner, which is applied in the direction of combustion type, lighting and heating apparatus, combustion using lump and pulverulent fuel, etc., can solve the problems of high nox emission level and higher life cycle cos

Active Publication Date: 2012-11-01

ANSALDO ENERGIA SWITZERLAND AG

View PDF3 Cites 54 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As a result, there can arise high NOx emission levels and higher life cycle costs.

This criterion can pose challenges in obtaining appropriate distribution of the fuel across the burner exit area.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

embodiment 1

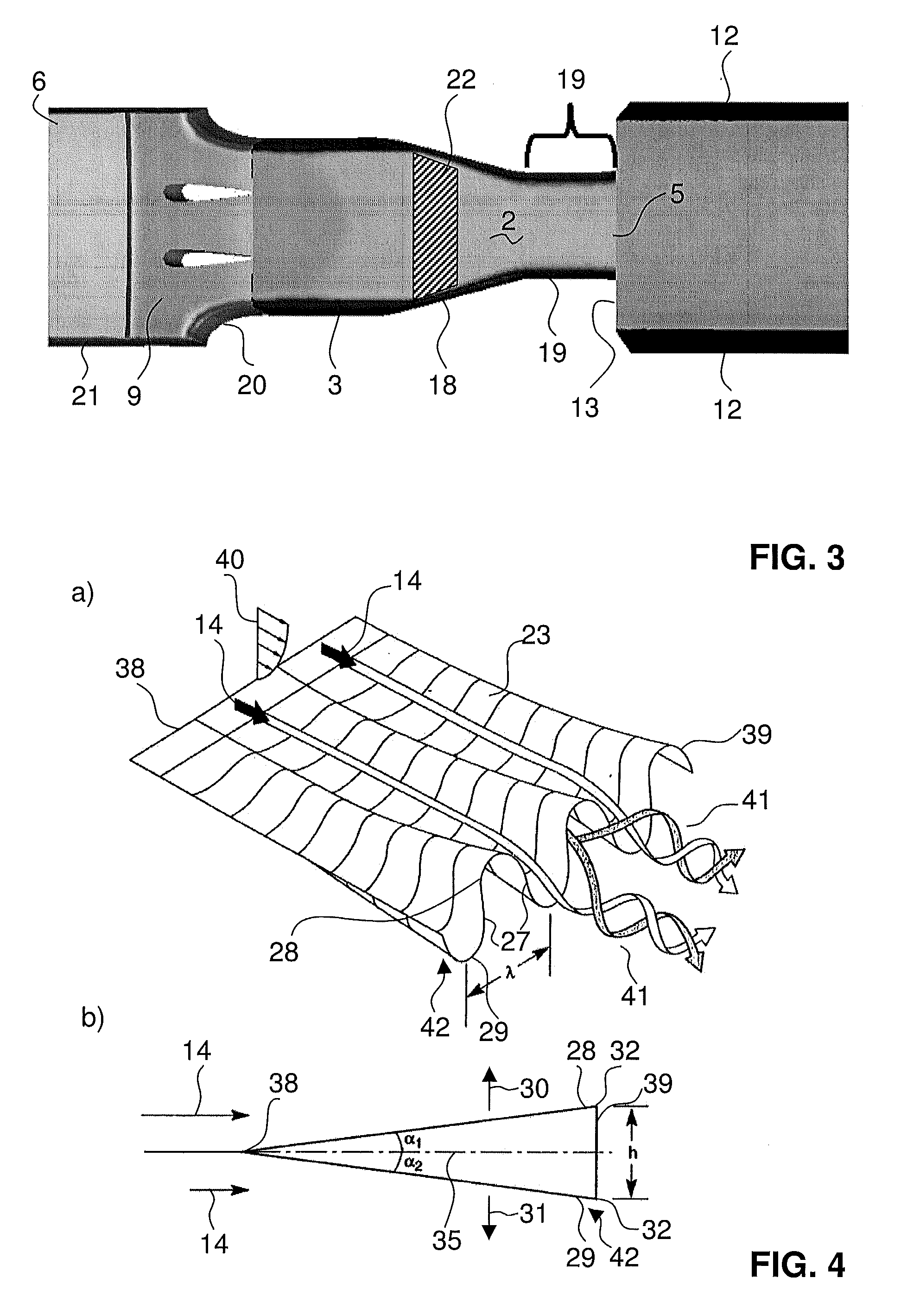

[0101]Staggering of lobes to eliminate vortex-vortex interactions. The vortex-vortex interactions result in not effectively mixing the fuel air streams.

embodiment 2

[0102]Careful placement and location of fuel injection on the lobes: Fuel jets can be placed in the areas of high shear regions in order to best utilize the turbulent dissipation for mixing.

embodiment 3

[0103]Inclined fuel injection in the lobes: This allows fuel to be injected in to the vortex cores.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

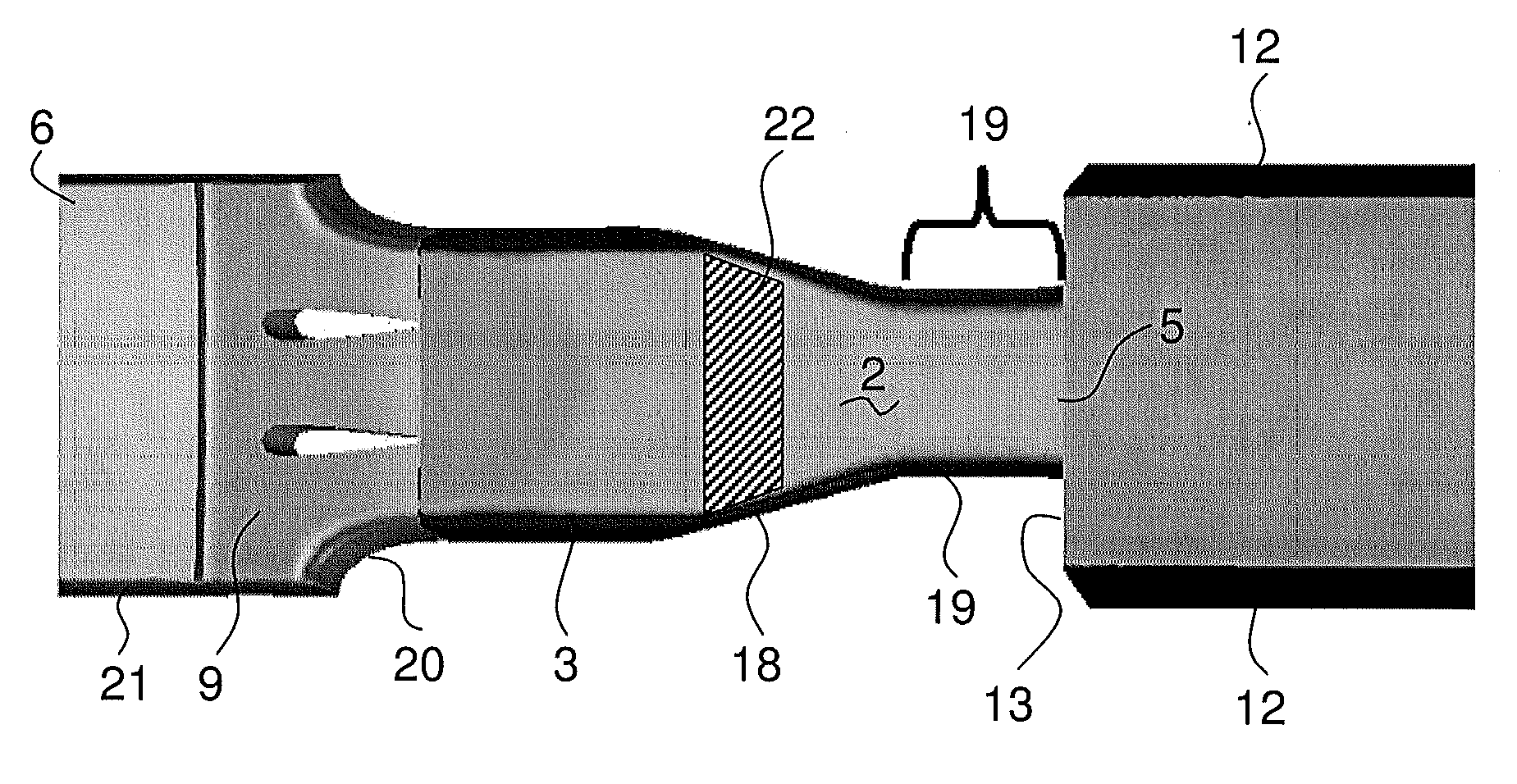

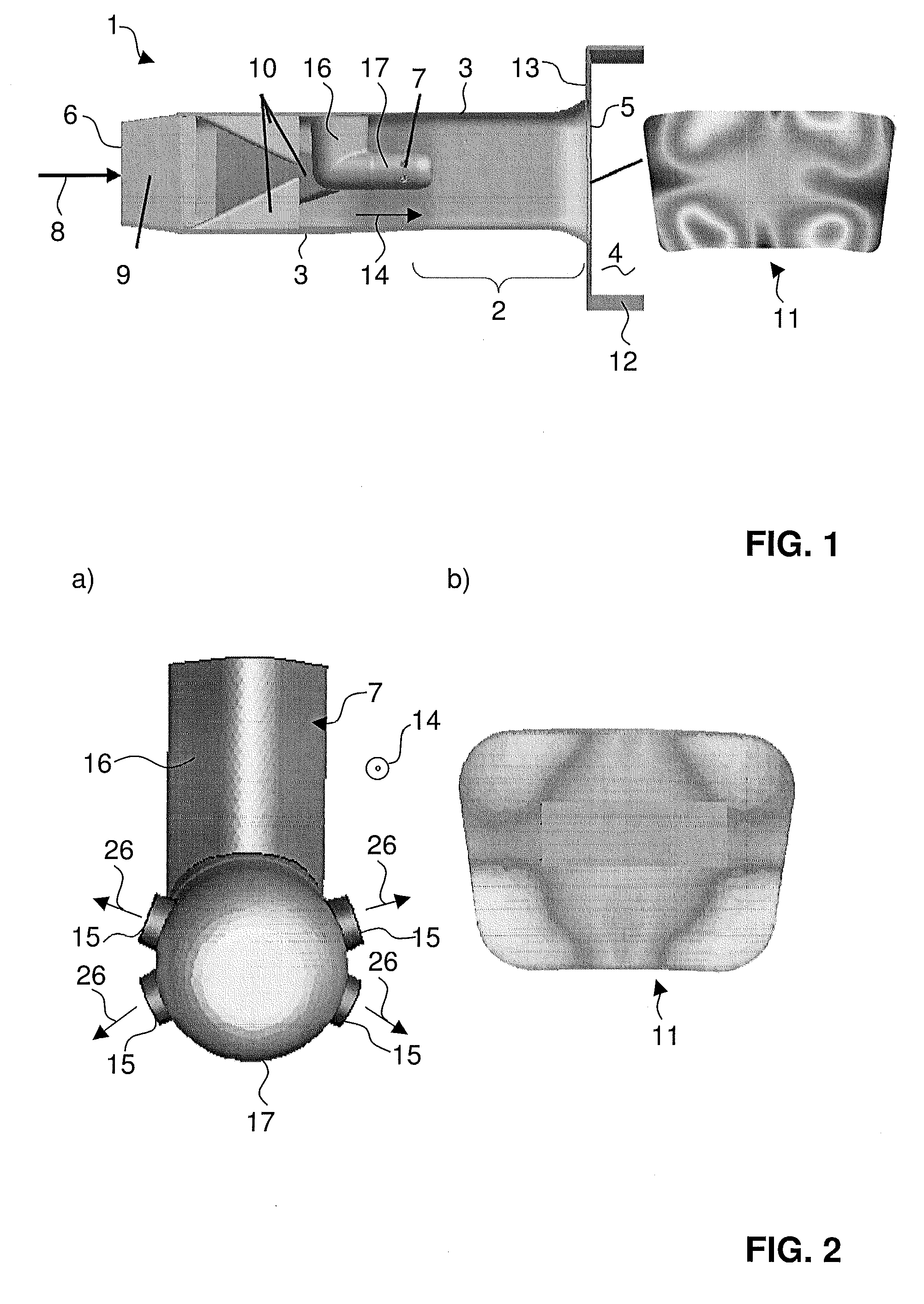

The disclosure relates to a burner for a combustion chamber of a gas turbine, with an injection device for the introduction of at least one gaseous and / or liquid fuel into the burner, wherein the injection device has at least one body which is arranged in the burner with at least one nozzle for introducing the at least one fuel into the burner, the at least one body being configured as a streamlined body which has a streamlined cross-sectional profile and which extends with a longitudinal direction perpendicularly or at an inclination to a main flow direction prevailing in the burner. The at least one nozzle has its outlet orifice at or in a trailing edge of the streamlined body, and with reference to a central plane of the streamlined body, the trailing edge is provided with at least two lobes extending in opposite transverse directions.

Description

RELATED APPLICATION[0001]This application claims priority as a continuation application under 35 U.S.C. §120 to PCT / EP2010 / 066522, which was filed as an International Application on Oct. 29, 2010 designating the U.S., and which claims priority to Swiss Application 01889 / 09 filed in Switzerland on Nov. 7, 2009. The entire contents of these applications are hereby incorporated by reference in their entireties.FIELD[0002]A burner is disclosed for a combustion chamber of a gas turbine, such as a secondary combustion chamber with sequential combustion having first and secondary combustion chambers, and with an injection device for the introduction of at least one gaseous and / or liquid fuel into the burner.BACKGROUND INFORMATION[0003]In order to achieve high efficiency, a high turbine inlet temperature is used in standard gas turbines. As a result, there can arise high NOx emission levels and higher life cycle costs. This can be mitigated with a sequential combustion cycle, wherein the co...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(United States)

IPC IPC(8): F23R3/34F02C7/00F02C7/18

CPCF23R3/20F23R3/12

Inventor SYED, KHAWARPOYYAPAKKAM, MADHAVANWINKLER, ANTONTHEUER, ANDRE

Owner ANSALDO ENERGIA SWITZERLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com