Tobacco leaf baking equipment

A technology of curing equipment and tobacco leaves, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve problems such as aroma weakening, environmental and people's health hazards, and leaf stiffness, so as to facilitate loading and unloading of tobacco, improve safety performance, and overall The effect of streamlining the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

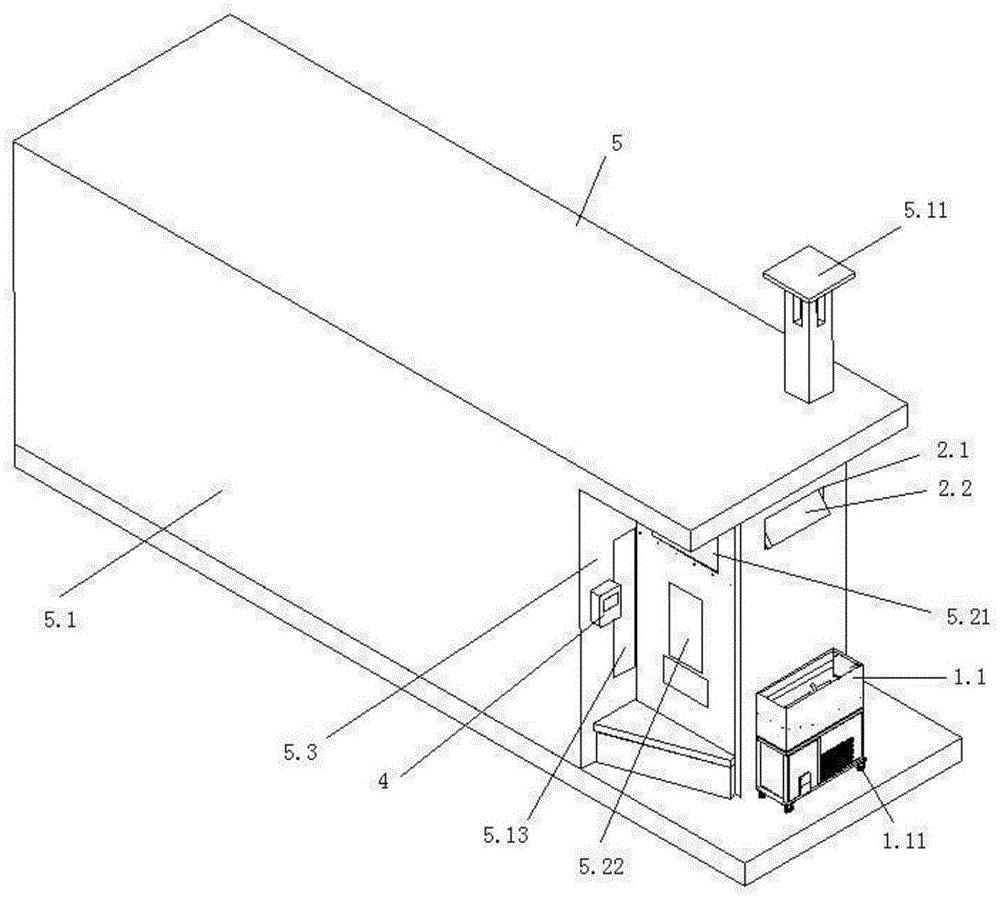

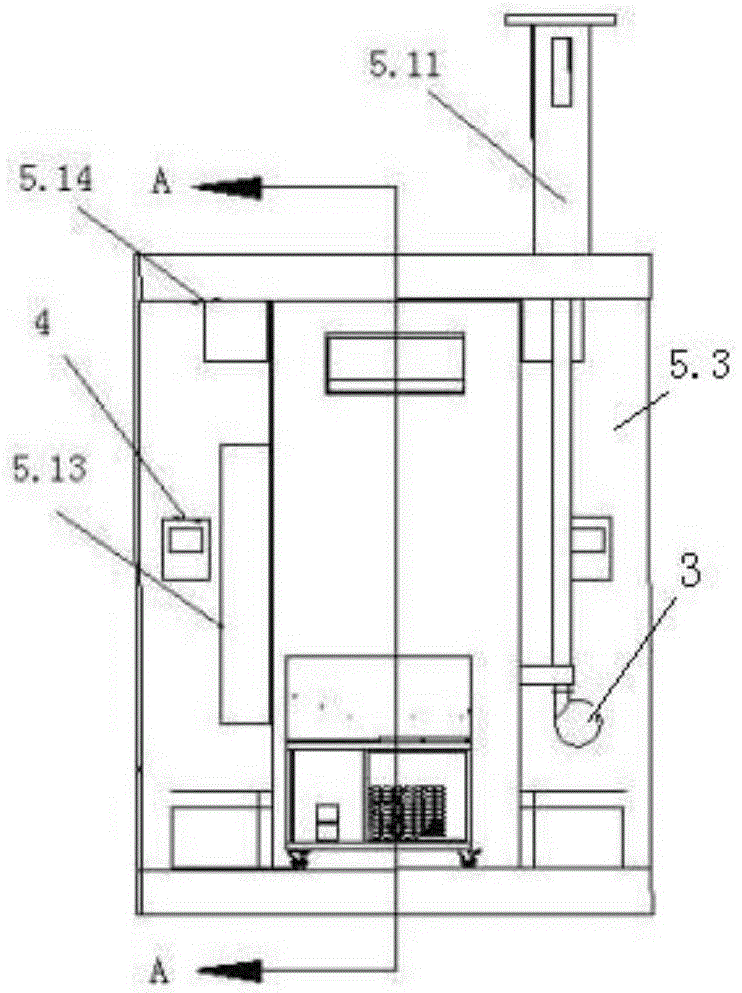

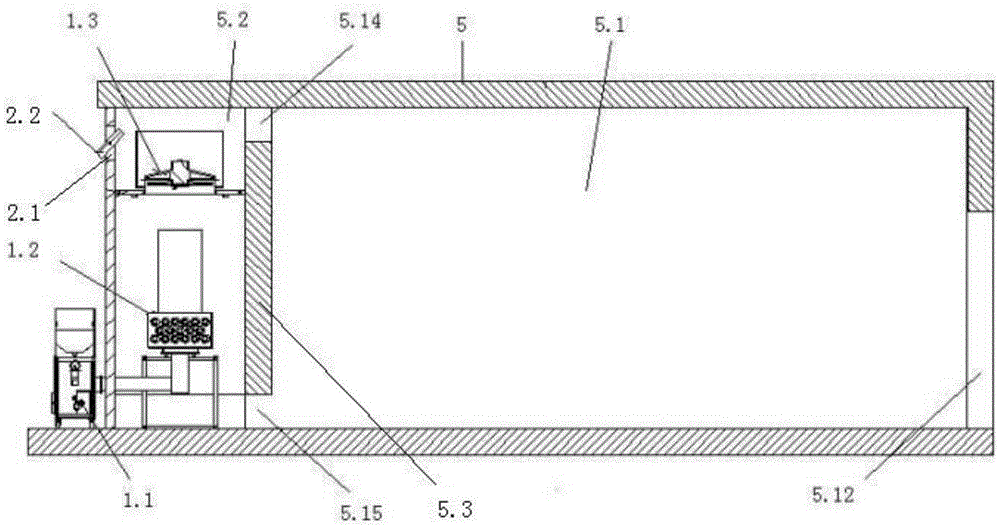

[0041] see Figure 1-Figure 7 , a tobacco leaf curing equipment, the design air volume is 18000m 3 / h, the design wind speed between leaves is 0.1-0.2m / s, including heating device, dehumidification device, feeding device, controller and oven 5.

[0042] The heating device includes a biomass combustion furnace 1.1, a heat exchanger 1.2 connected to the flue gas outlet pipe of the biomass combustion furnace 1.1, and a circulation fan 1.3 for conveying hot or cold air, details are as follows:

[0043] The structure of the biomass combustion furnace 1.1 is detailed in figure 1 , figure 2 , image 3 with Figure 5 , specifically including three parts: the combustion furnace body 1.12, the air supply system 1.13 and the control system. machine and ignition port e, the furnace chamber volume of combustion chamber b increases a lot (volume increases about 3-5 times) compared with similar coal-fired boilers, to adapt to the highly volatile characteristics of biomass fuel; describ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com