Patents

Literature

270 results about "Tobacco processor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

After tobacco is cured, it is moved from the curing barn into a storage area for processing. If whole plants were cut, the leaves are removed from the tobacco stalks in a process called stripping. For both cut and pulled tobacco, the leaves are then sorted into different grades.

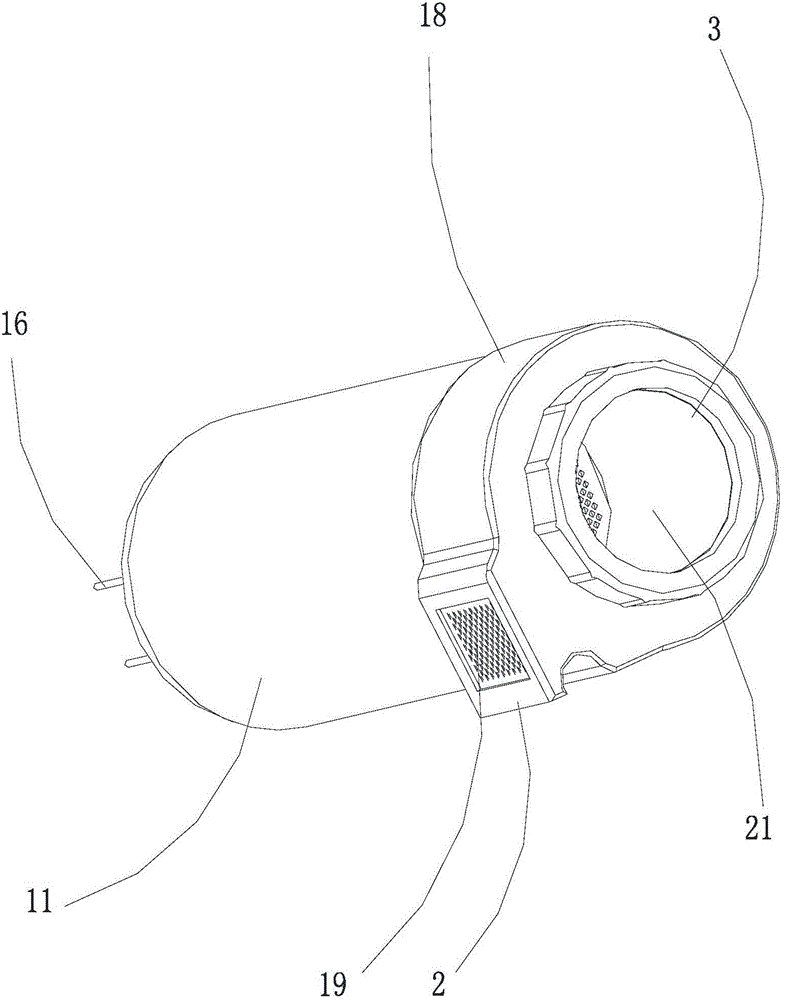

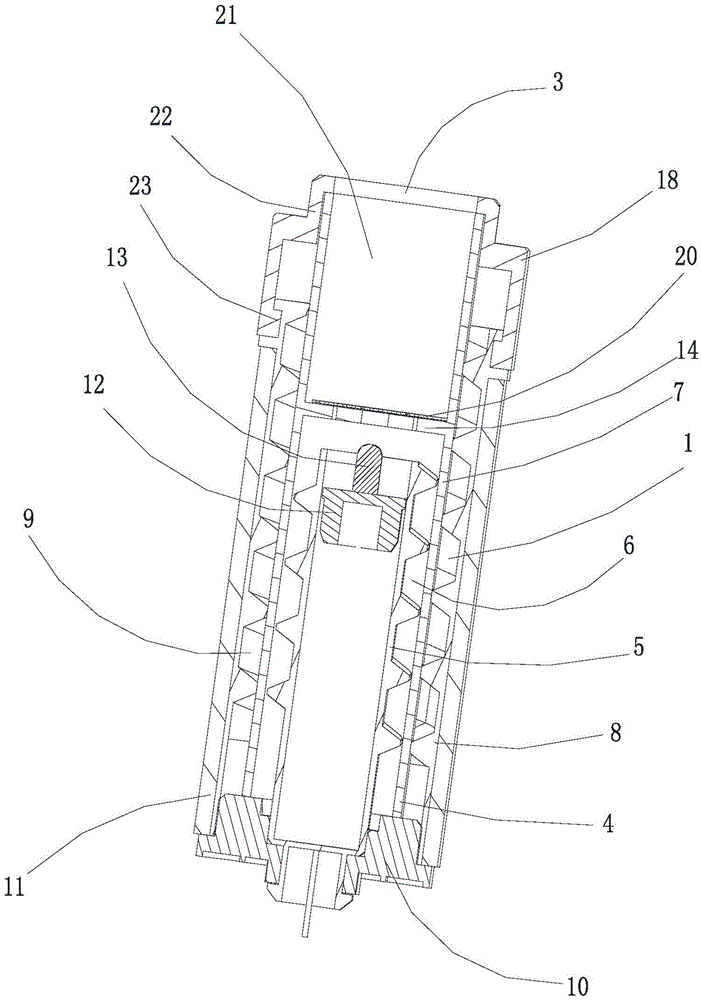

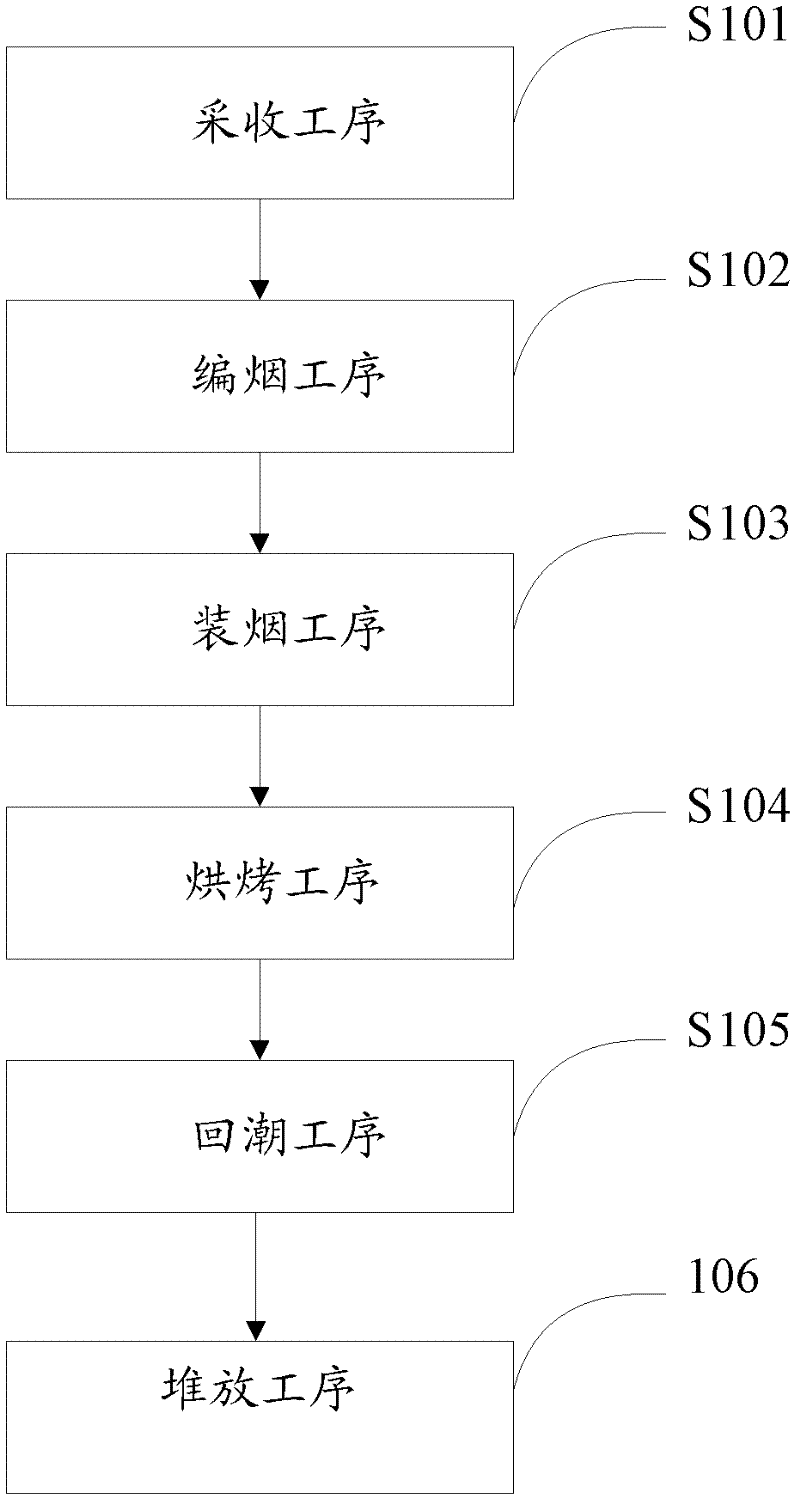

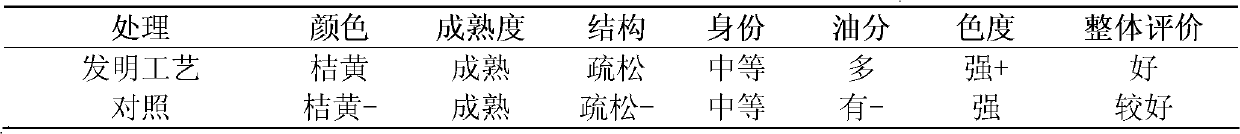

Intensive curing barn precise curing process for flue-cured tobacco

InactiveCN102178335AFully automatedRaise the ratioTobacco preparationAutomatic controlControl system

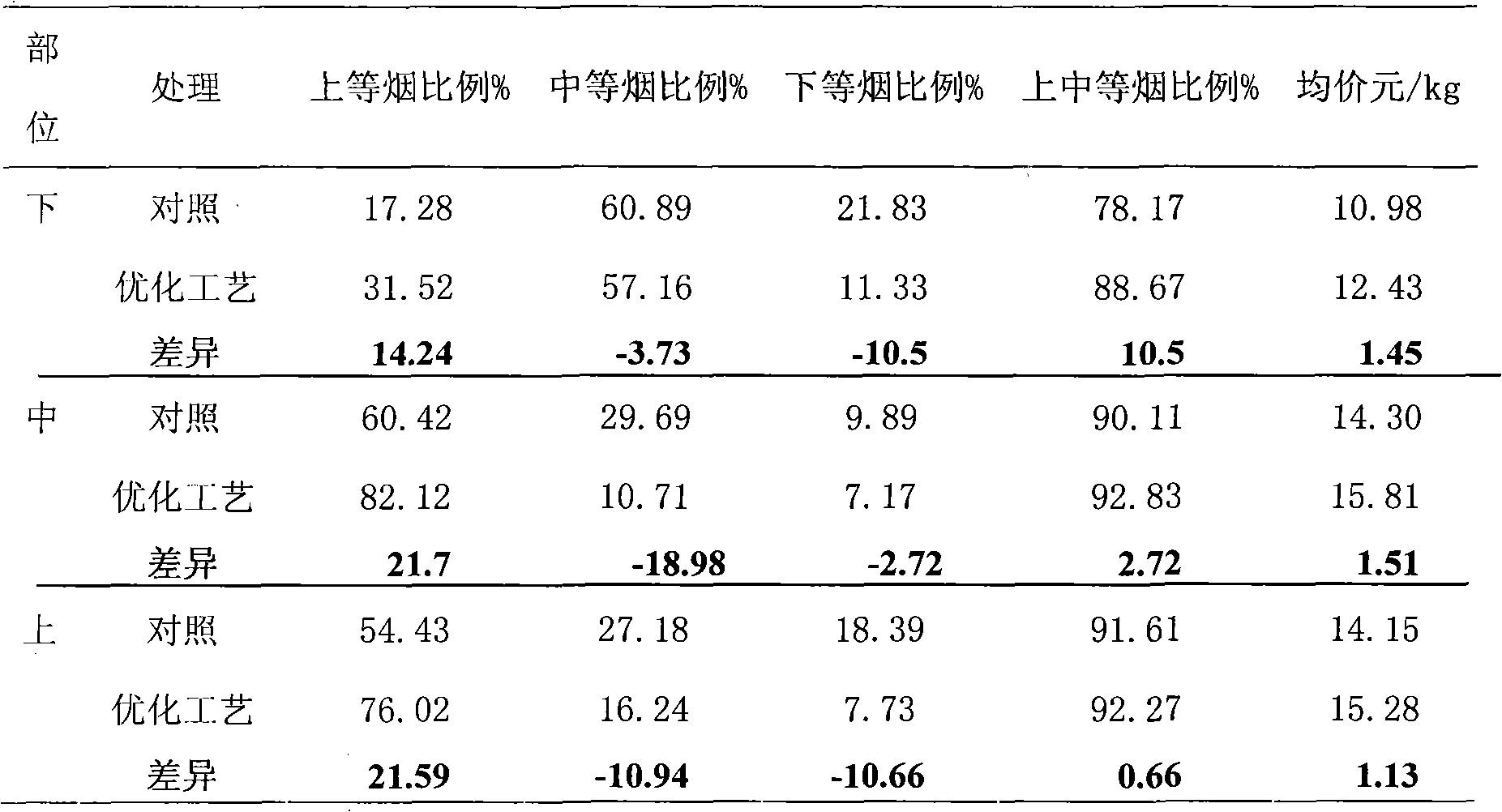

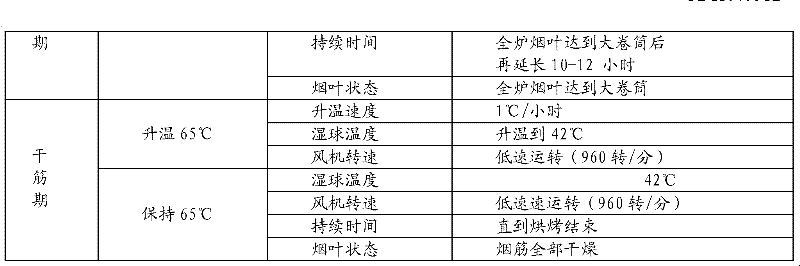

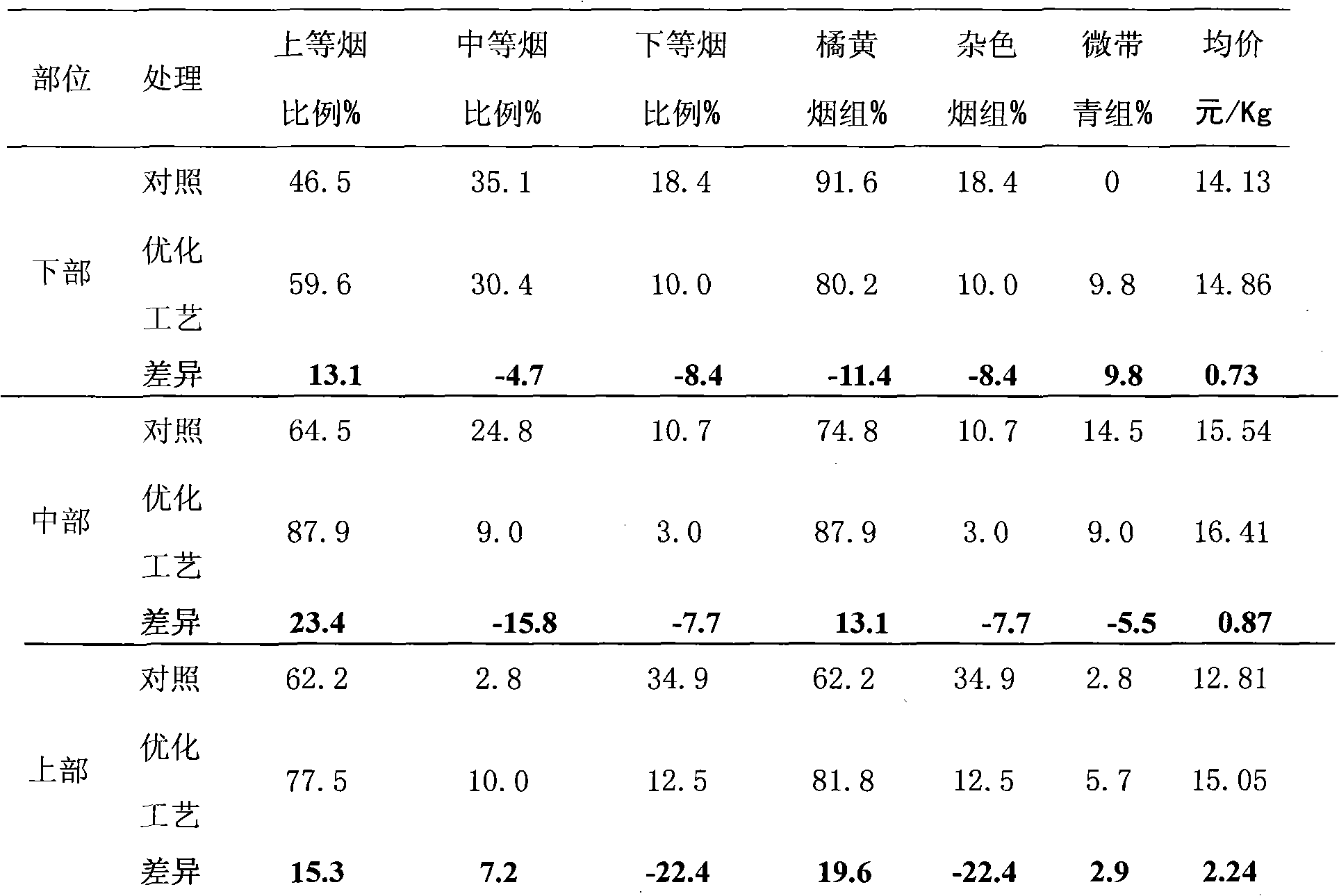

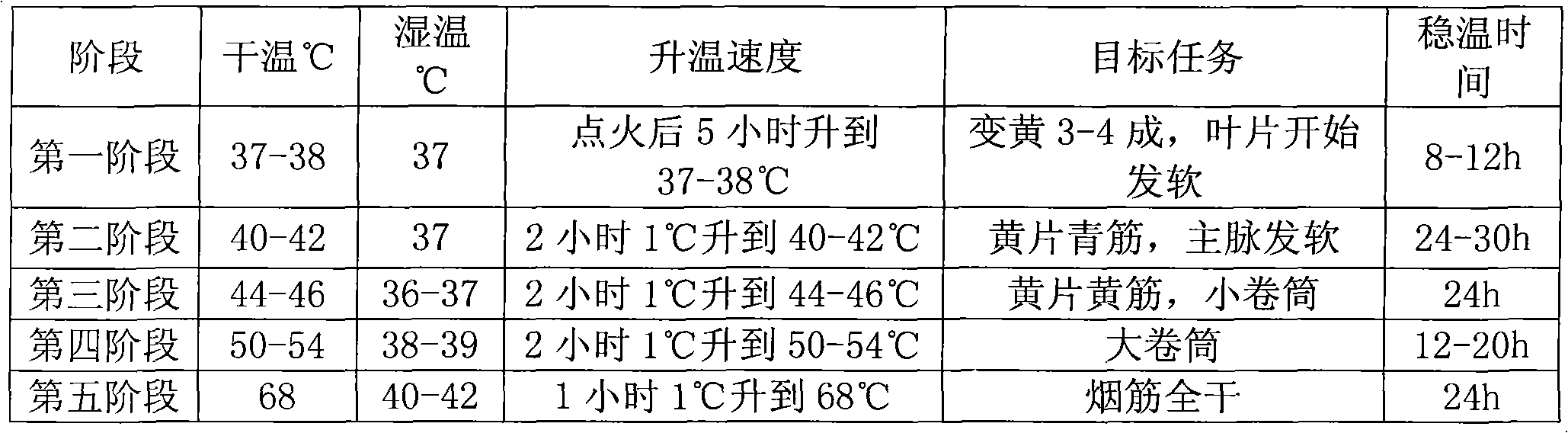

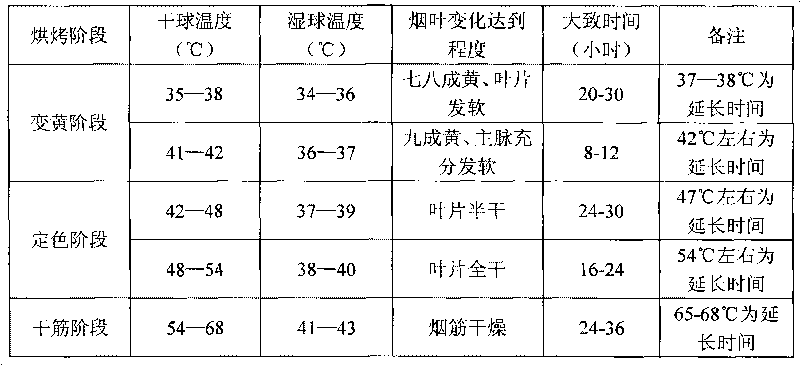

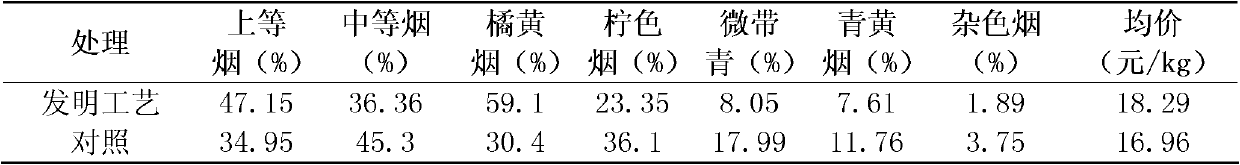

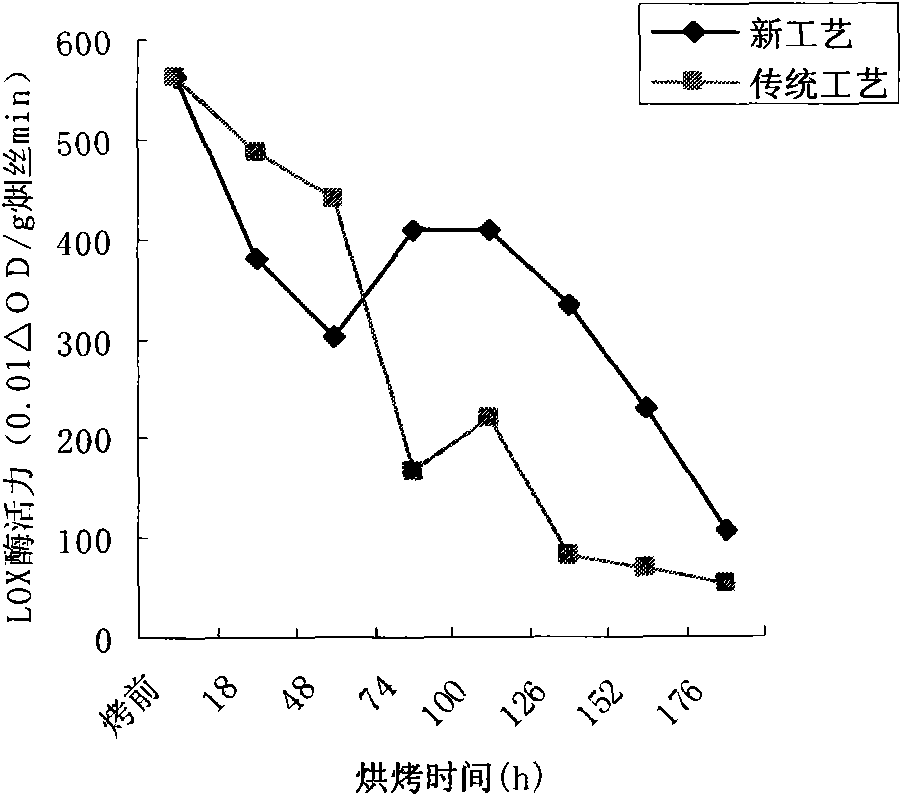

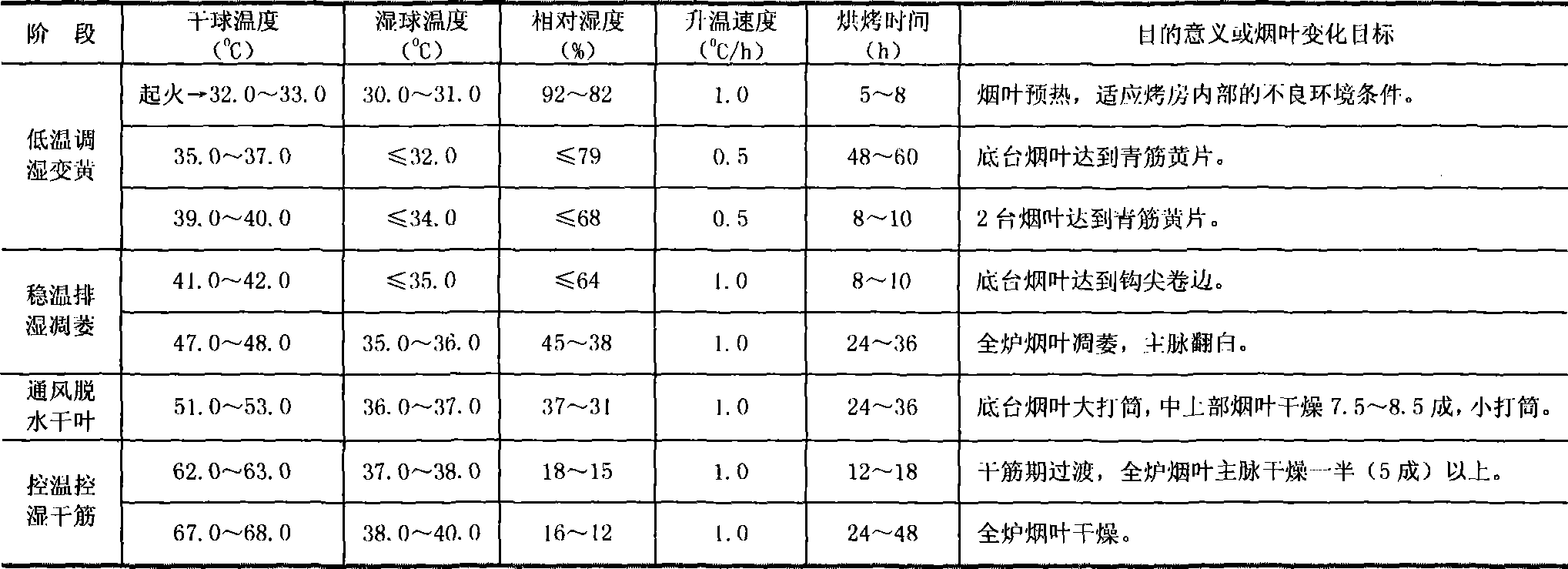

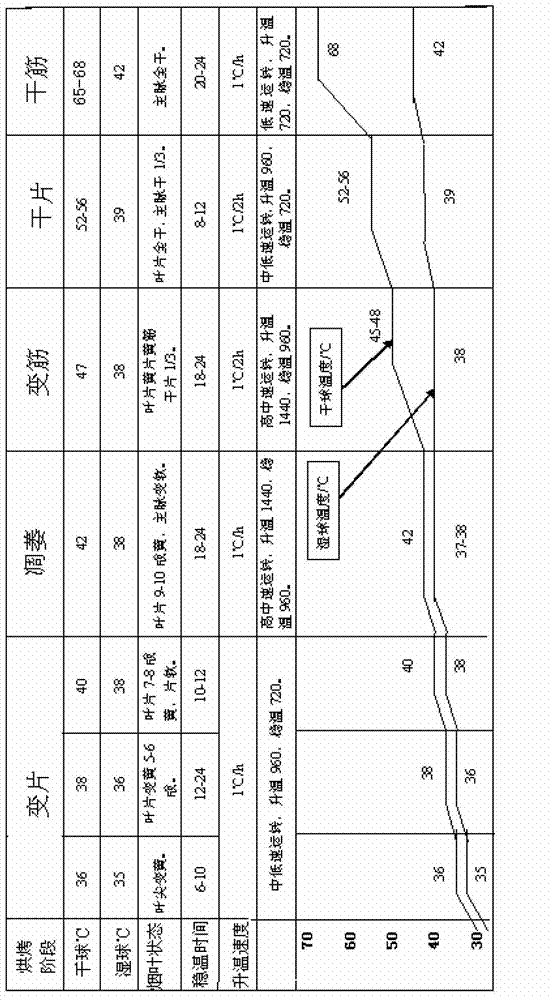

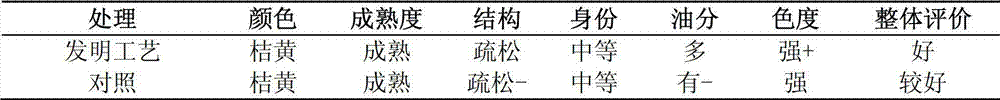

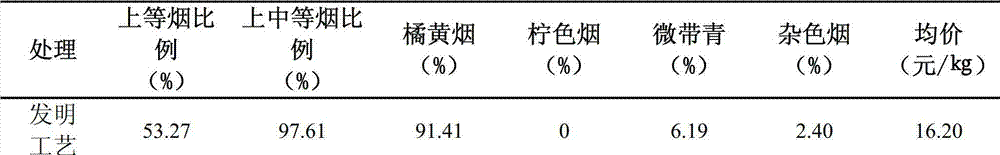

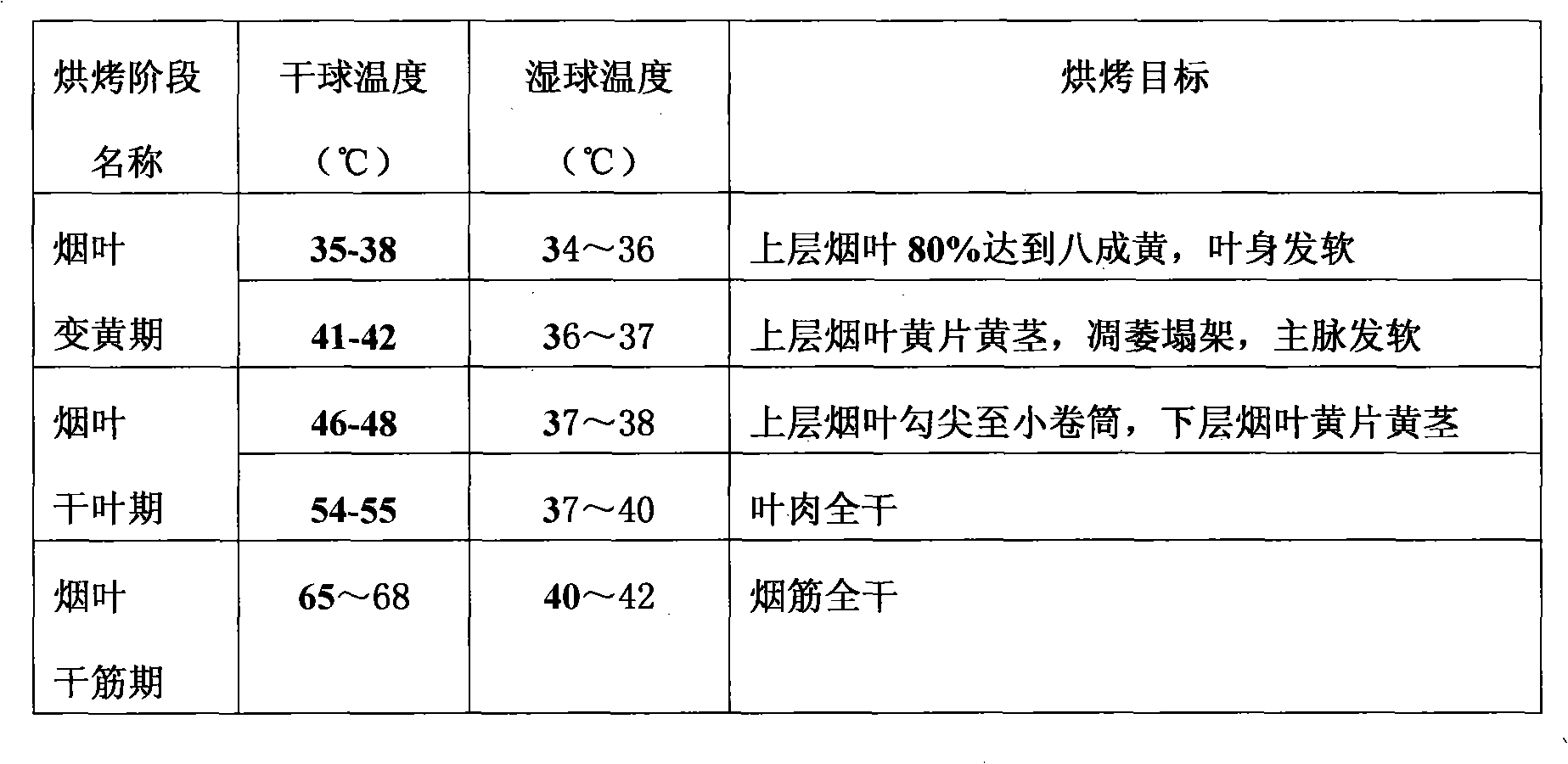

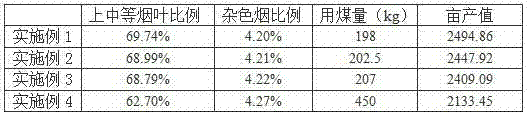

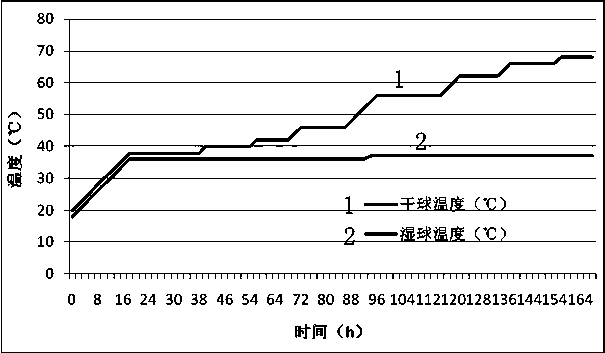

The invention discloses an intensive curing barn precise curing process for flue-cured tobacco. The process mainly comprises three curing stages, namely a yellowing stage, a color fixing stage and a stem drying stage, wherein three key temperature and humidity points are controlled in the yellowing stage; four key temperature and humidity points are controlled in the color fixing stage; one key temperature and humidity point is controlled in the stem drying stage; a flue-cured tobacco temperature and humidity automatic control system is adopted in an entire curing process; and a temperature sensor and a humidity sensor are arranged on the top layer of a down-draft intensive curing barn or the bottom layer of an up-draft bulk curing barn. Through the process, error and loss of manual operation brought by operation by experience are reduced, curing quality of tobacco leaves is improved, curing cost is reduced, and high operability is guaranteed. As proved, badly cured tobacco such as green and miscellaneous tobacco and the like is obviously reduced, proportion of orange tobacco and first-class tobacco is increased, the cured tobacco has a loose structure and increased oil content, and appearance quality inside and outside the tobacco leaves and availability are obviously improved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +1

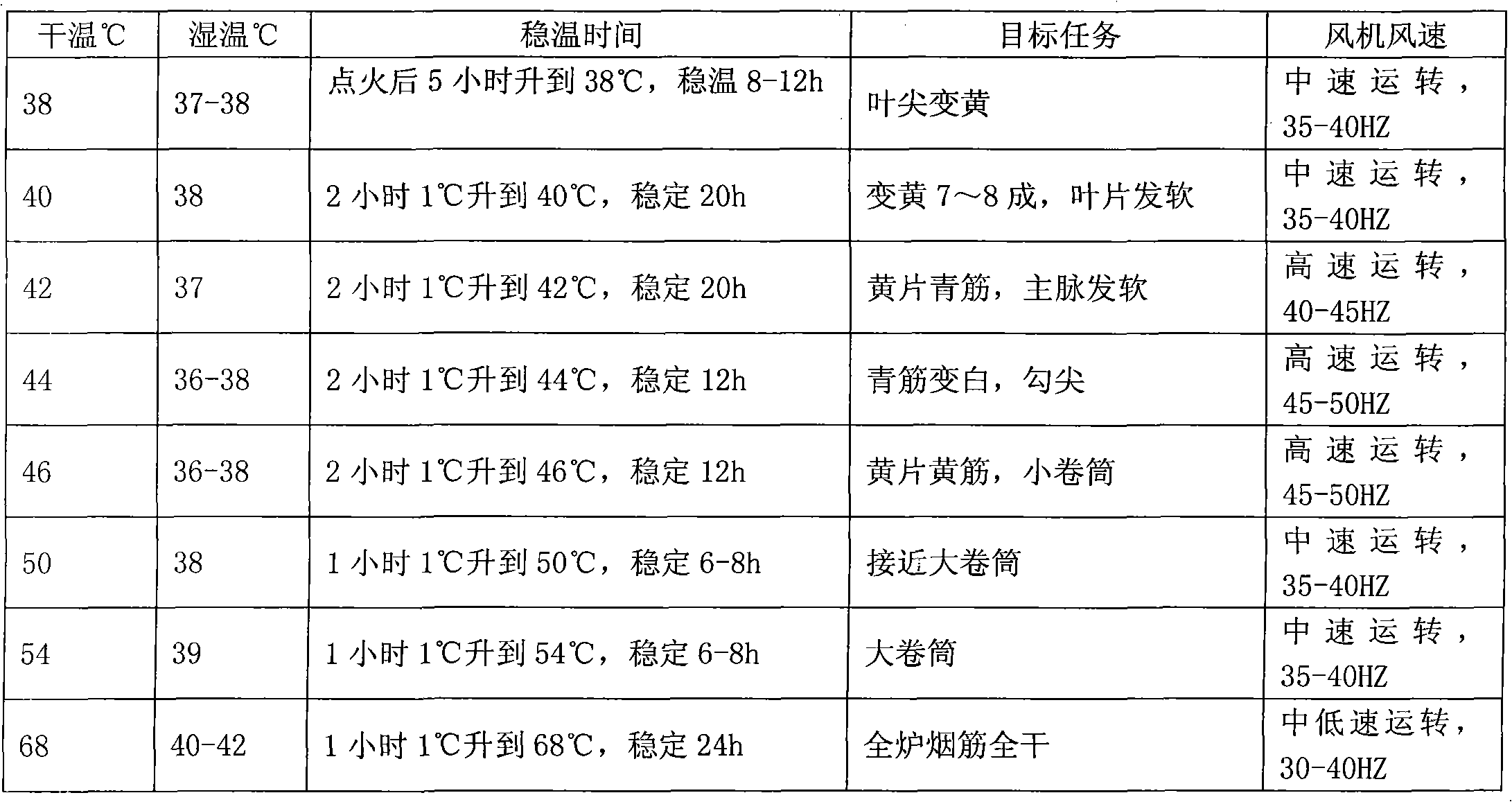

Tobacco flue-curing method for bulk curing barn

The invention relates to the technical field of flue-cured tobacco modulation, in particular to a tobacco flue-curing method for a bulk curing barn. The flue-curing process of the tobacco flue-curing method includes a yellowing period, a withering period, a stem yellowing period, a tobacco leaf drying period and a stem drying period according to factors such as dry-bulb temperature, wet-bulb temperature, drying time, heating rate, variable speed ventilation and tobacco leaf change targets, a color fixing period in the traditional tobacco flue-curing method is prolonged at a fixed point and steady temperature under the condition of hot air circulation, and sufficient decomposition and transformation of amylum, protein and other macromolecular substances in tobacco leaves and forming of aromatic matters are promoted. The tobacco flue-curing method for the bulk curing barn is easy to operate, safe and secure, can keep tobacco leaf yellow to be stable, leaf shrinking degree to be good, oil content to be increased and tobacco leaf aromatic amount to be increased greatly, further can reduce or avoid tobacco leaf roasting damage of green smoke roasting, ash smoke hanging, black bad smoke, lousy smoke roasting and the like, and can obtain high-quality tobacco leaves through roasting.

Owner:四川省烟草公司宜宾市公司

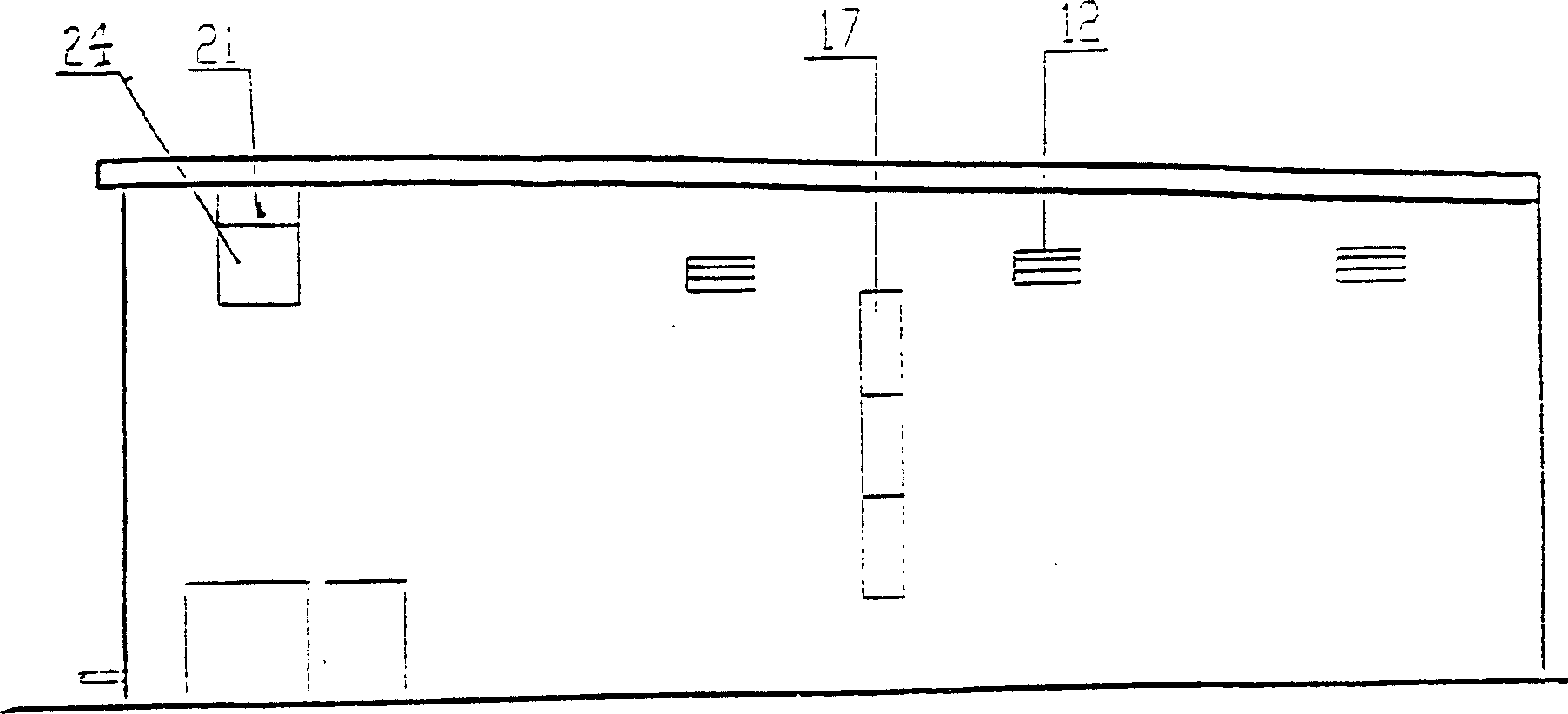

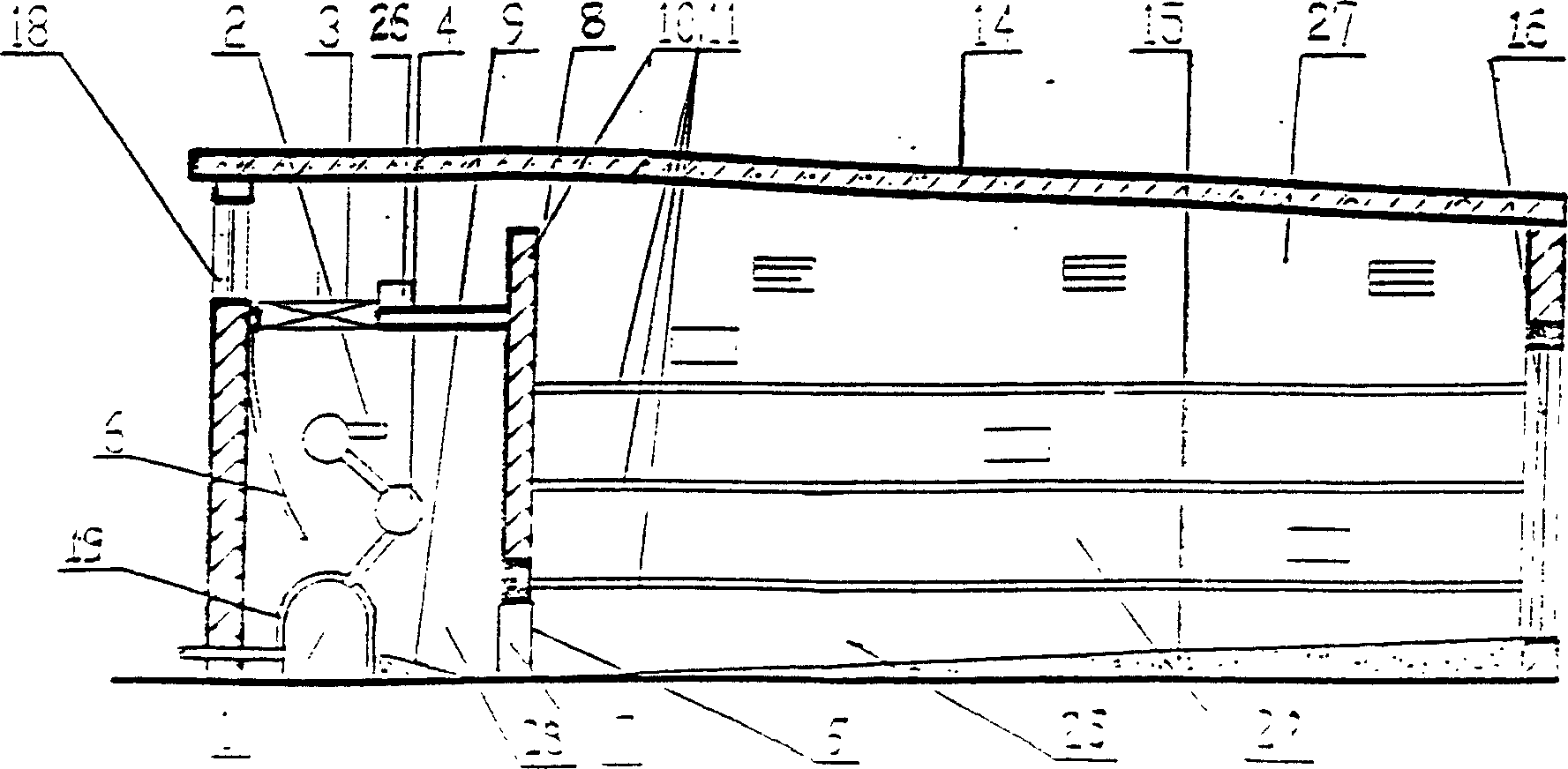

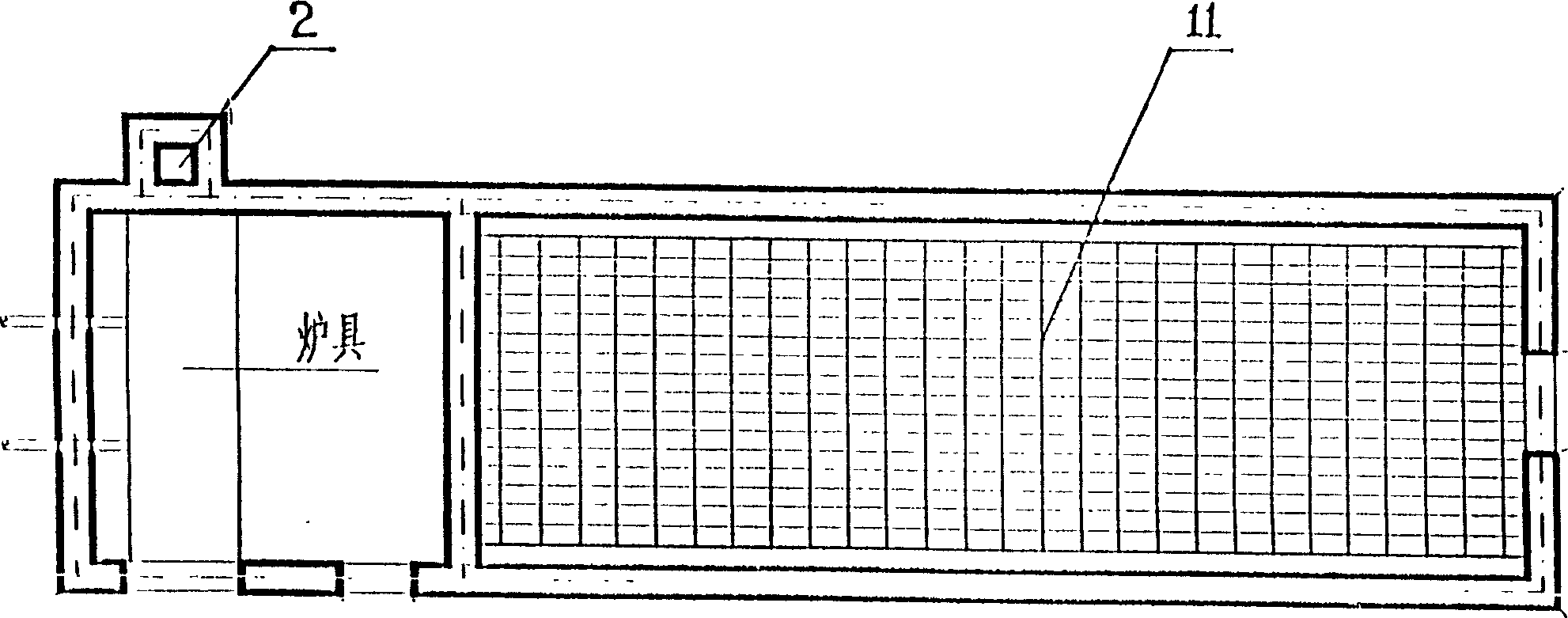

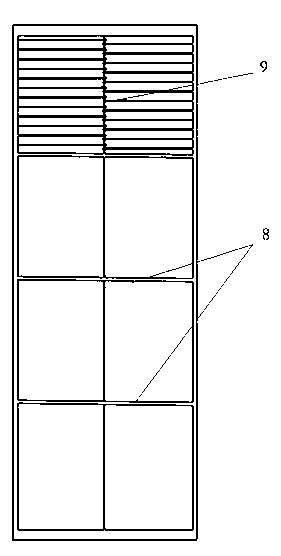

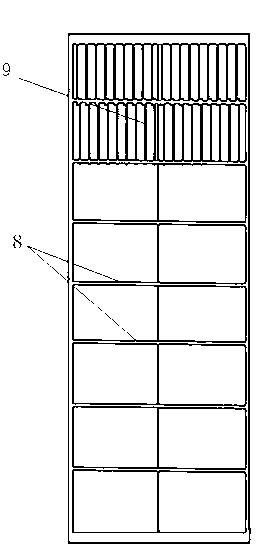

Scattered leaf stacked tobacco-roasting house and its leaf roasting method

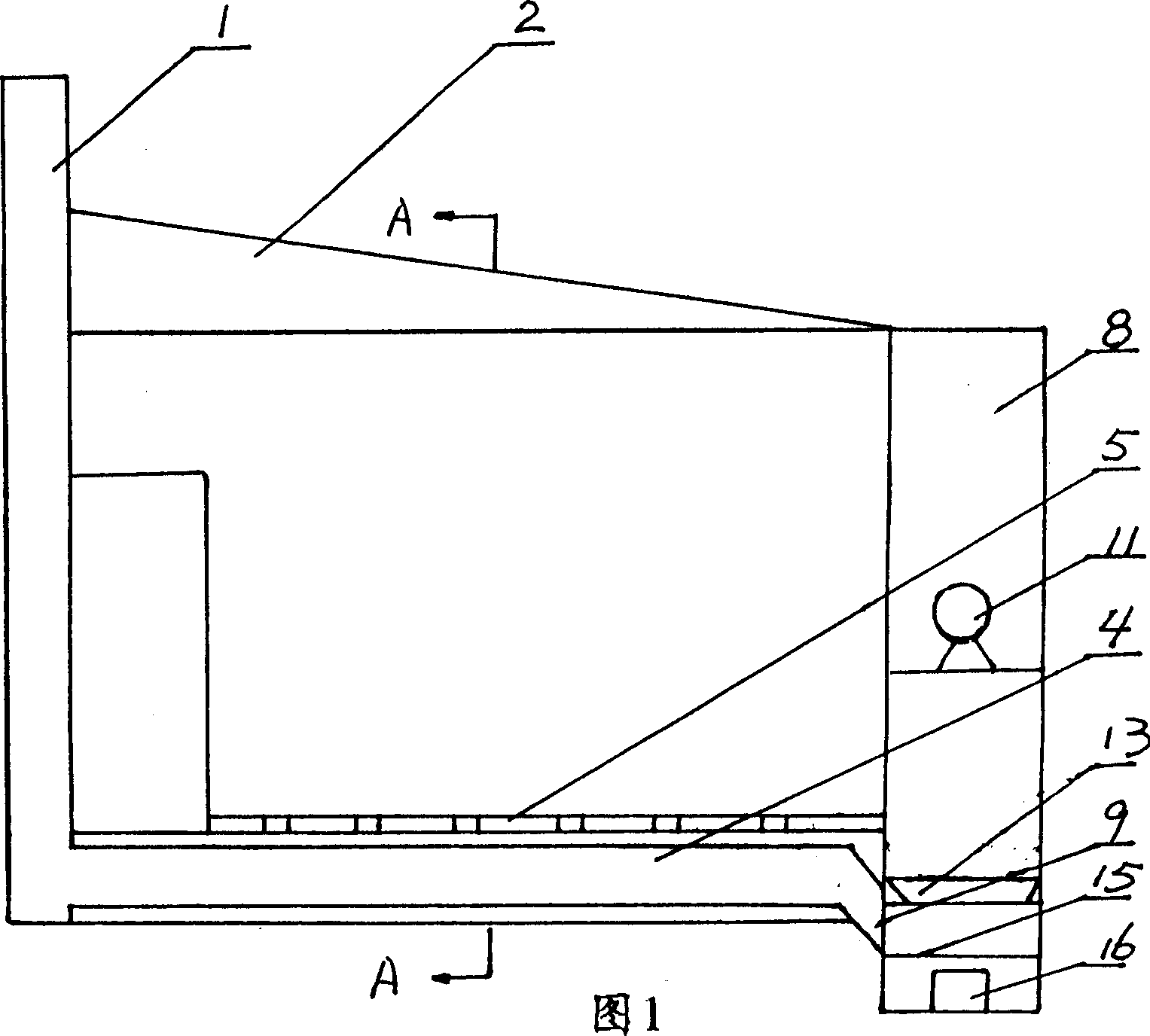

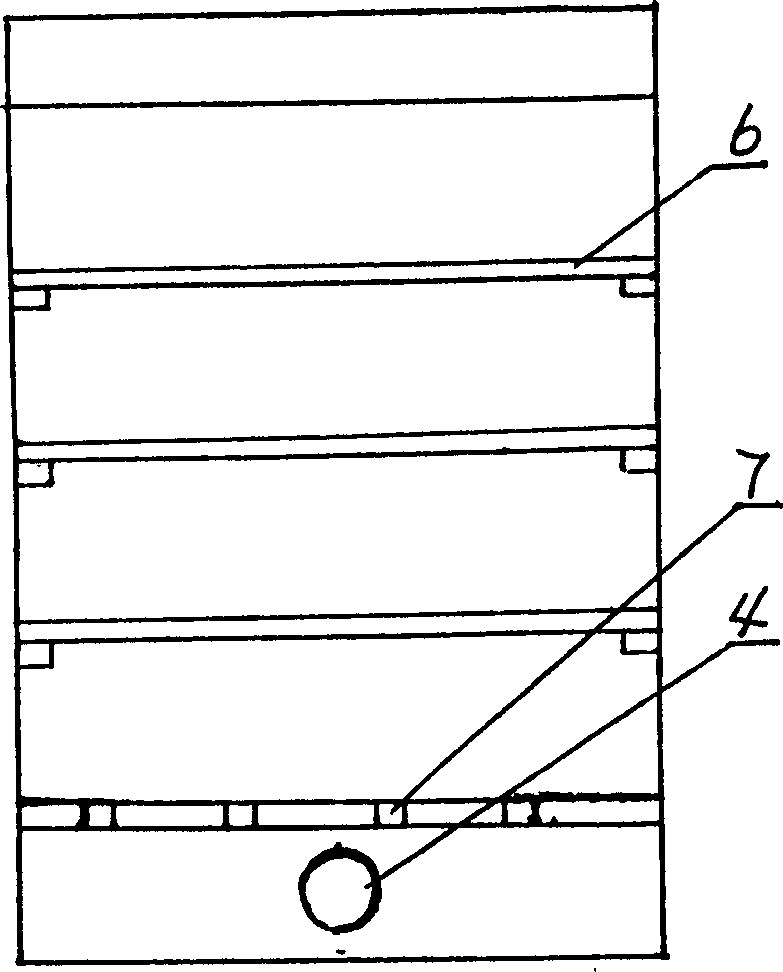

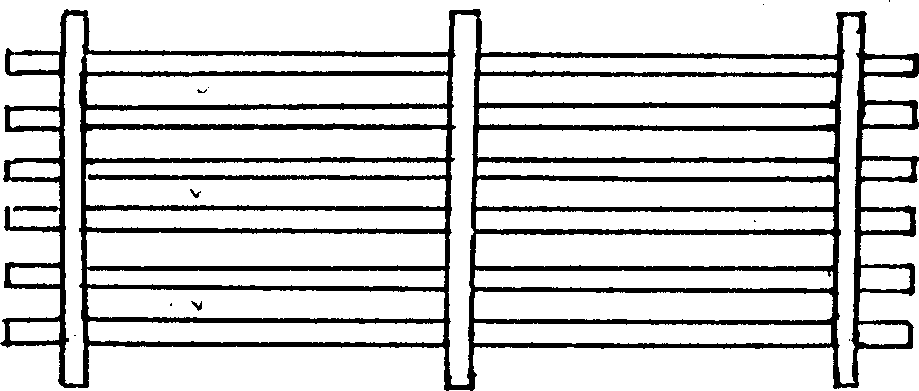

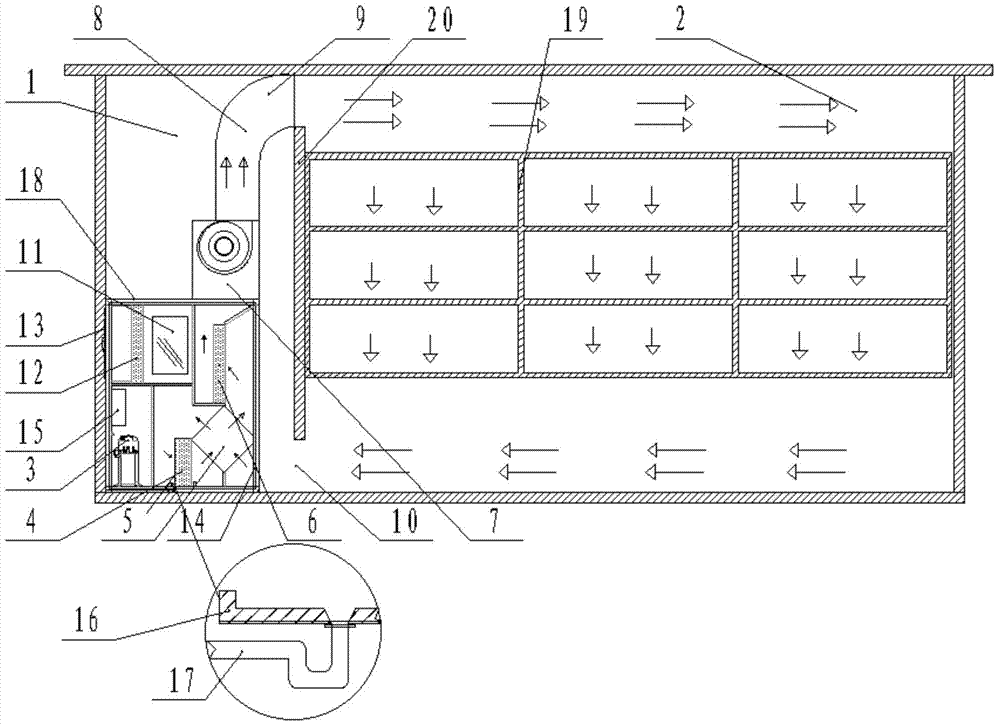

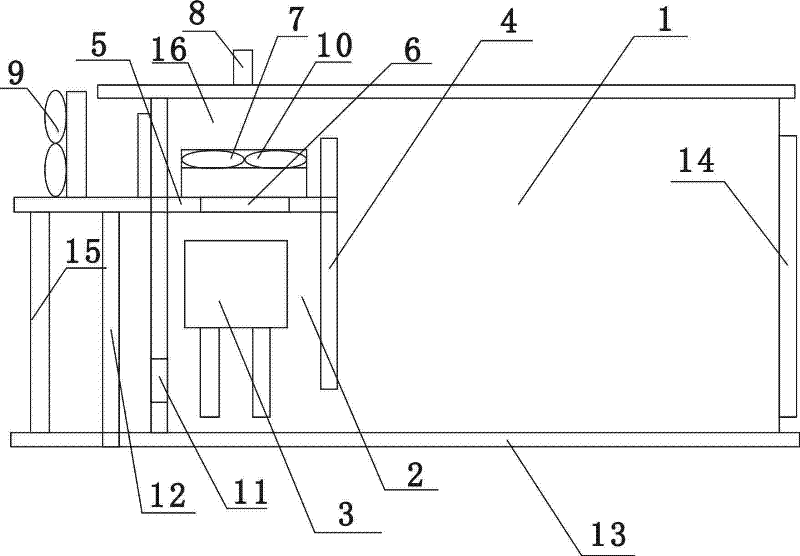

The present invention discloses a scattered leaf stacked tobacco-roasting house and its leaf roasting method, which includes two juxtaposed rooms: a heating room and a tobacco filling room; the said heating system is disposed in the heating room, and a tobacco stacking gate is disposed in the tobacco filling room; the said hot air circulation system which makes the hot air circulate between the heating room and the tobacco filling room is diposed in the heating room and the tobacco filling room and connects the heating room and the tobacco filling room; the layers and the height of the scattered leaf stacked tobacco-roasting house are both lower than that of the conventional roasting house, which avoids the high-altitude operation in the filling house, and the operation being safe and convenient; the scattered leaf stacked tobacco-roasting house adopts that the heating room and the tobacco filling room are mutually isolated with each other, therefore, no fire will occur and it is more secure; the roasting house has a lower-cost, a low vertical temperature, and a uniform surface temperature; and it save labor costs according to the conventional roasting house, thereby improving the quality of tobacco, and increasing the output.

Owner:ZUNYI TOBACCO OF GUIZHOU TOBACCO CORP

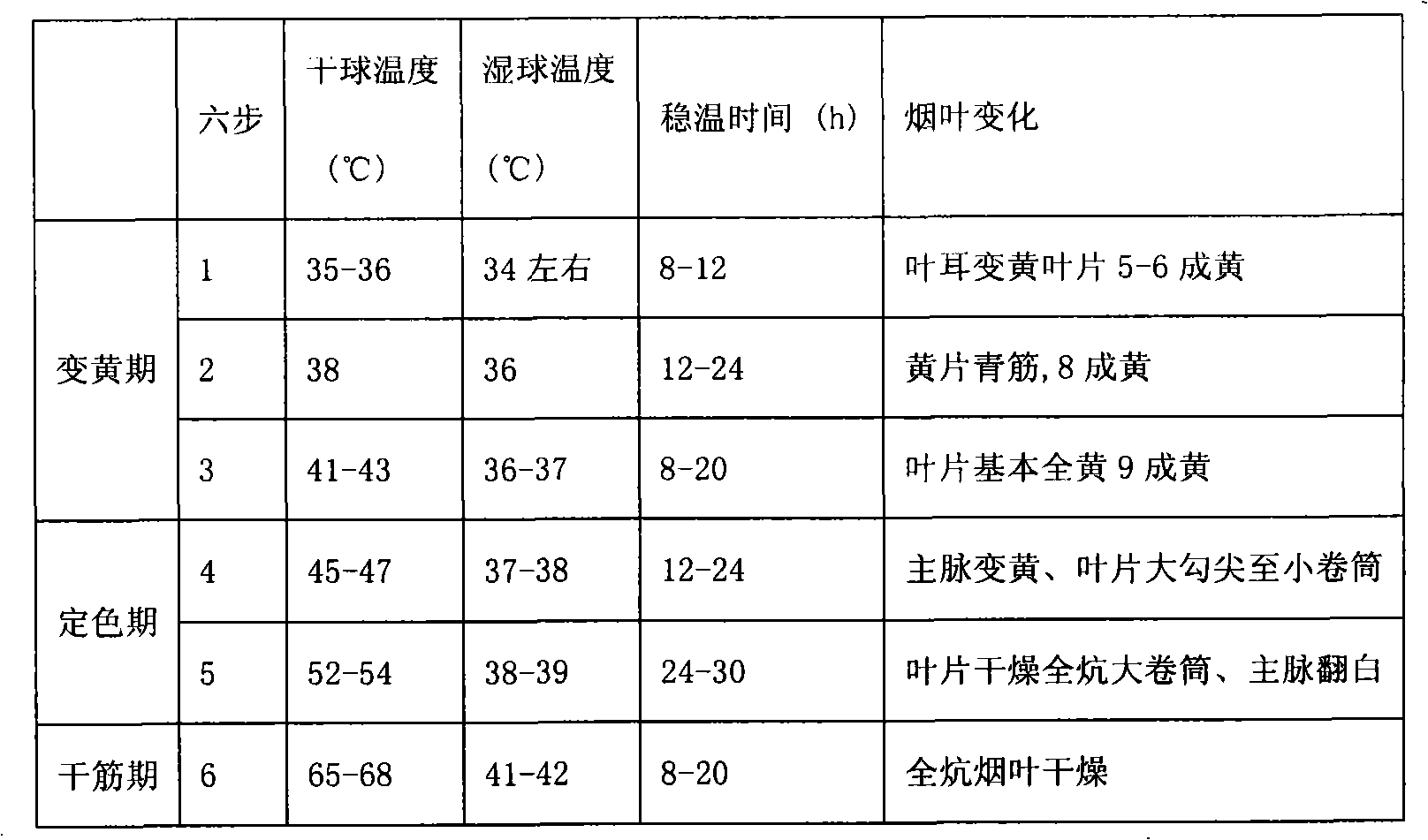

Three-section six-step tobacco baking method

Owner:TOBACCO SCI RES INST CHONGQING CITY COMPANY OF CHINA NAT TOBACCO

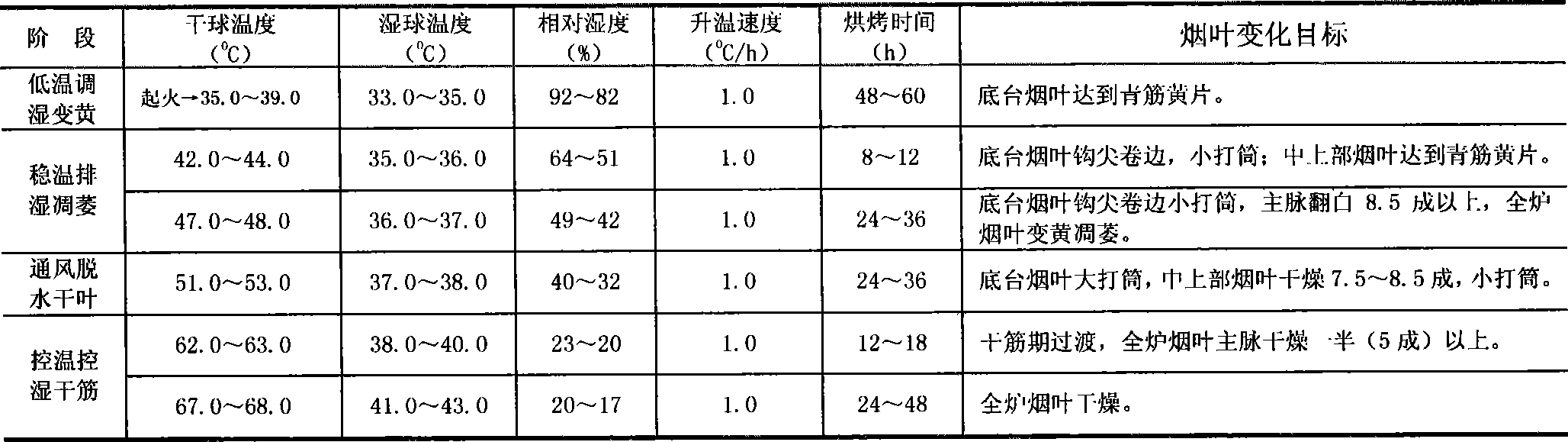

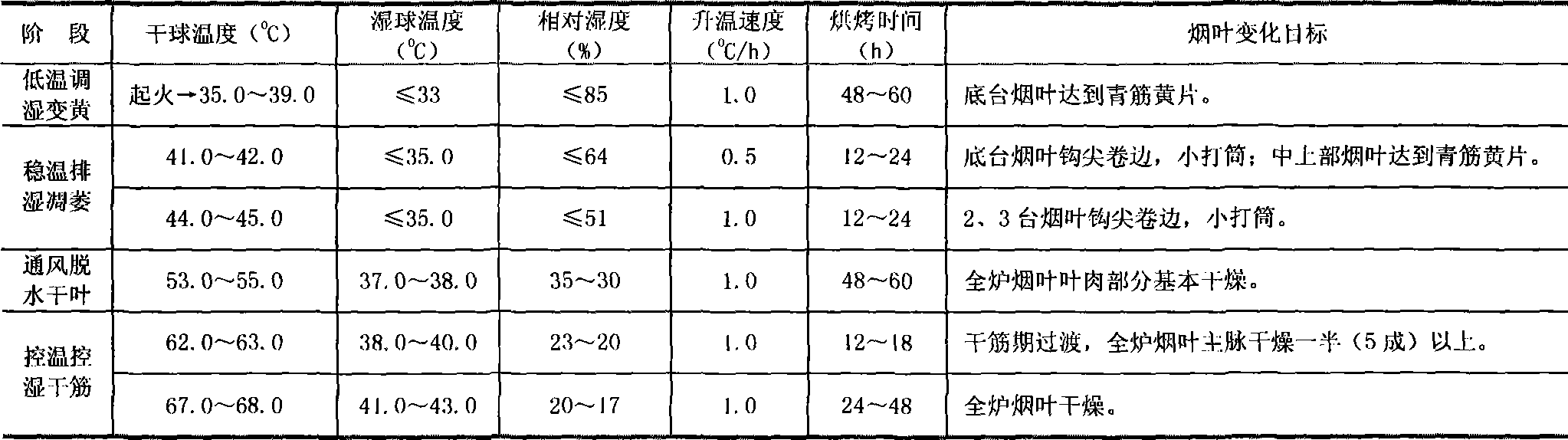

Tobacco leaf curing process capable of improving curing quality of flue-cured tobacco variety KRK26

ActiveCN101991180AMaintain moisture contentImprove roast qualityTobacco preparationDecompositionCell membrane

The invention relates to a tobacco leaf curing process capable of improving the curing quality of a flue-cured tobacco variety KRK26, belonging to the technical field of flue-cured tobacco modulation processes. The curing process comprises the following steps of: regulating the humidity at low temperature to yellow tobacco leaves; stabilizing the temperature and removing moisture for withering; ventilating and dewatering for drying the leaves; and controlling the temperature and the humidity to dry leaf ribs. In the invention, the method of keeping the tobacco leaves at lower temperature to reduce water evaporation in the tobacco leaves and guarantee the water content of the tobacco leaves is adopted to solve the problems of less water and difficult yellowing of the tobacco leaves of the KRK26 variety in the yellowing period; the dry-bulb temperature is between 41 DEG C and 44 DEG C, and the tobacco leaves can be sufficiently dewatered and shrunk to reduce the cell membrane turgor; the tobacco leaf cell membranes cannot be broken between 45 DEG C and 48 DEG C so as to smoothly fix the color; and in the whole process of tobacco leaf curing, the wet bulb temperature is controlled tobe between 34 DEG C and 38 DEG C so as to actively promote the decomposition and the conversion of macromolecular substances and the synthesis of flavoring substances. The invention has the advantages of simple and convenient operation, safety and insurance, can ensure that the tobacco leaves of the variety KRK26 can be smoothly yellowed, timely subjected to color fixing and subjected to rib drying in good time and improves the tobacco leaf curing quality.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

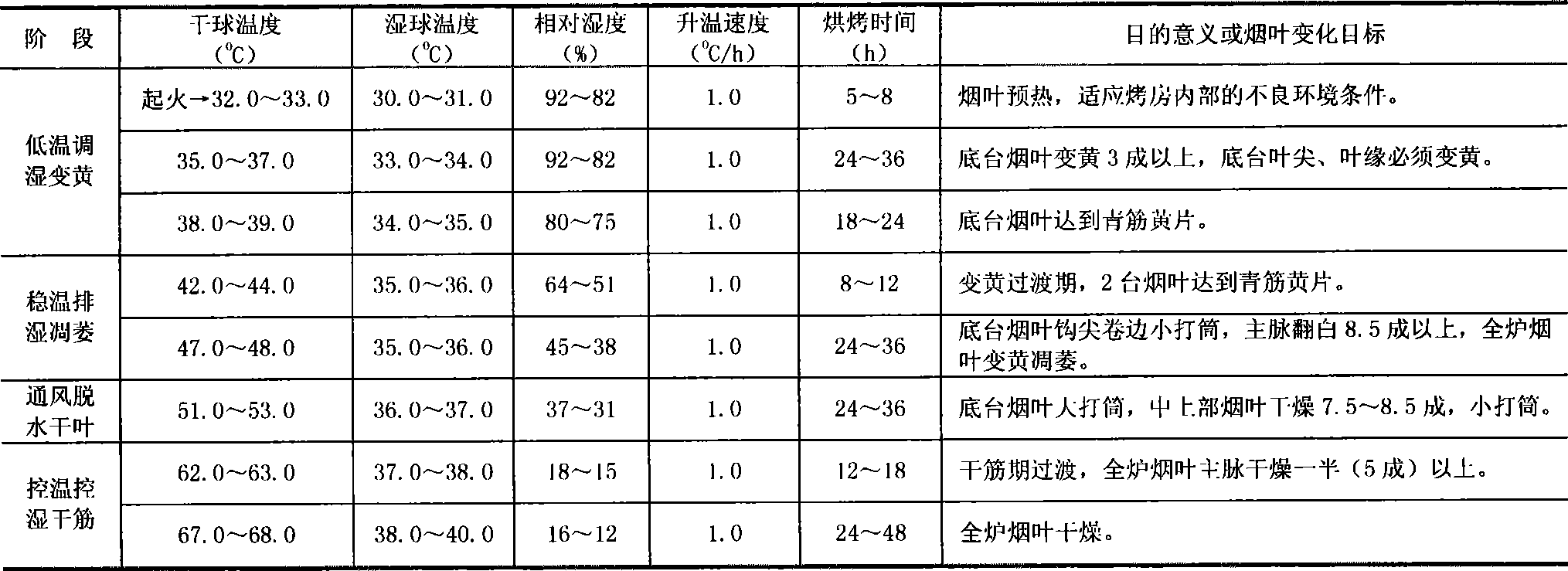

Cured tobacco baking technique capable of improving quality and flavoring

ActiveCN101416767AHigh oil contentIncrease the amount of aromaTobacco preparationEcological environmentMetallurgy

The invention relates to a quality-improving, flavouring, roasting technique of tobacco leaves, belonging to the technical field of roasting tobacco technique. The key technology lies in that: (1) adjusting humidity at a low temperature until turning yellow, roasting the tobacco leaves on the base frame of a roasting room until stems turn green and leaves turn yellow, with the temperature in a furnace less than 39 DEG C, the temperature of a wet bulb less than 35 DEG C and the relative humidity between 92% and 75%; (2) stabilizing the temperatures and discharging moisture until the leaves wilt, roasting until all the tobacco leaves in the furnace fully wilt and diachyma is 7.5-8.5 dried, with the temperature in the furnace between 40 DEG C and 48 DEG C, and the relative humidity in the furnace between 67% and 38%; (3) ventilating and dehydrating until the leaves are dry, roasting until the tobacco leaves on the base frame roll a lot and the upper leaves are 7.5-8.5 dried and roll a little, with the temperature in the furnace between 49 DEG C and 53 DEG C, and the relative humidity in the furnace between 42% and 31%; (4) controlling temperature and humidity until the stems are dry, roasting until all the tobacco leaves in the furnace are dry, with the temperature in the furnace between 54 DEG C and 68 DEG C, and the relative humidity in the furnace between 29% and 12%. The invention has advantages of a simple operation, safety, stable yellow tobacco leaves keeping property, good wrinkling degree of leaves, increased oil, and greatly increased fragrance of leaves; and is applied to roasting tobacco leaves in different ecological environments.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

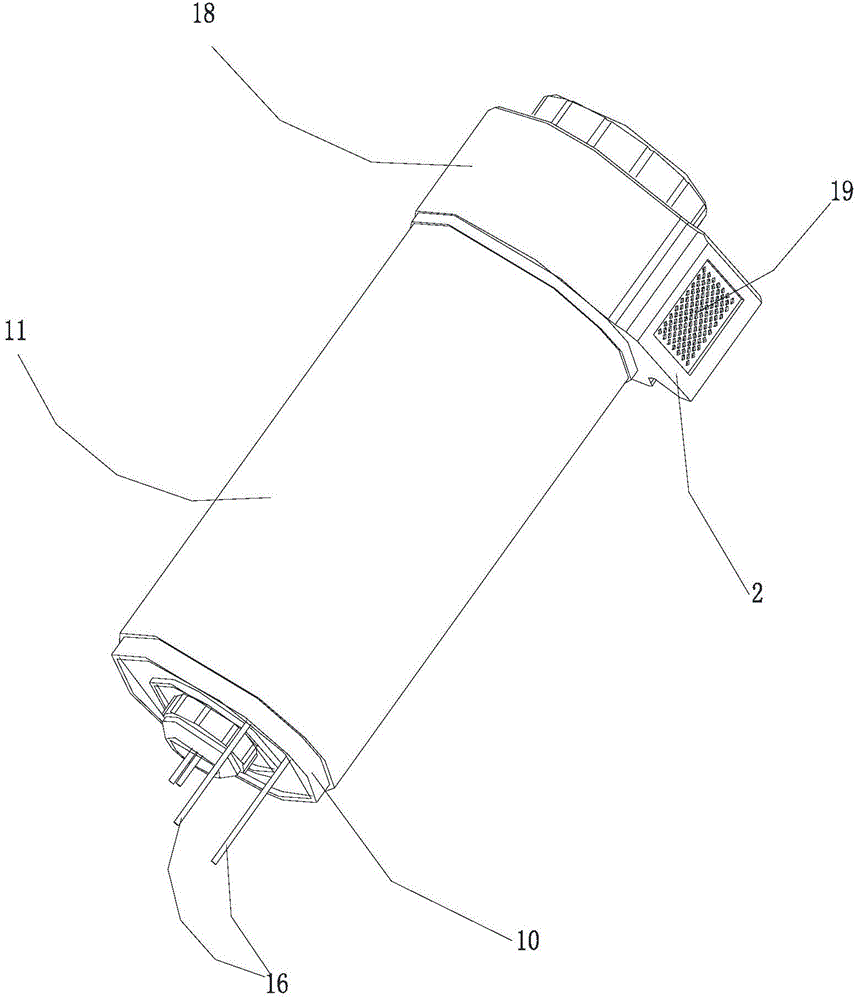

Air preheater

The invention discloses an air preheater, comprising an air passage. One end of the air passage is provided with an air inlet. The other end of the air passage is provided with an air outlet. A heater for heating the air flowing in the air passage is provided within the air passage. The use of the air passage and the heater allows full curing of tobacco shreds, reduction in harmful substances and improvement in taste.

Owner:SMISS TECH

Bulk curing process for cured tobacco K326

The invention discloses a bulk curing process for cured tobacco K326. In the process, on the basis of the traditional three-stage curing, the curing stage is detailed into five stages, wherein the main yellowing temperature in curing is increased by 1 to 2 DEG C, while the wet bulb temperature in a later yellowing stage and an early color fixing stage is reduced by 1 to 2 DEG C. The process combines qualitative description and quantitative index, is scientific and practical, easy and safe to operate and has strong operability, can remarkably reduce rotten tobacco and soot attached tobacco and increase the color and oil content of the tobacco. By the process, the curing quality of the tobacco is remarkably improved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

Tobacco leaf baking method

ActiveCN102499424AGood lookingIncrease the fragranceTobacco preparationTemperature controlEngineering

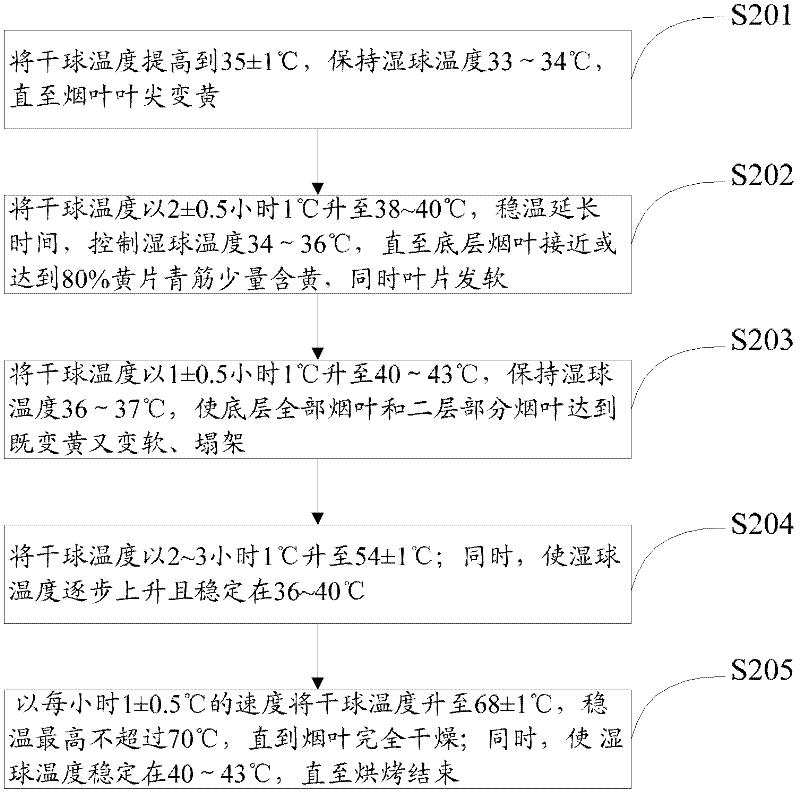

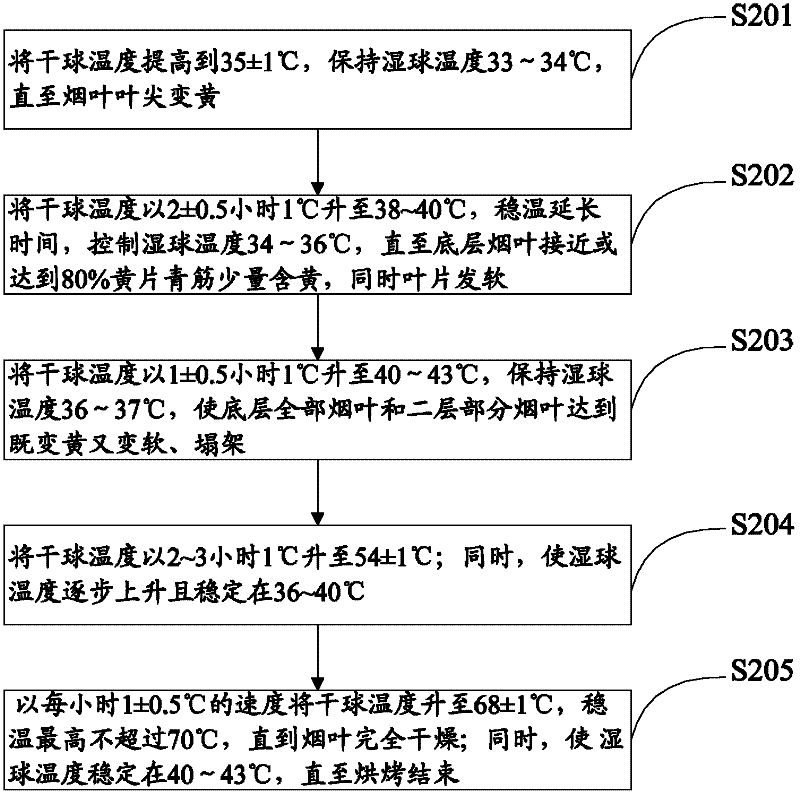

The invention discloses a tobacco leaf baking method, which comprises the following steps of: raising the dry ball temperature to 35+ / -1 DEG C, and maintaining the wet ball temperature at 33 to 34 DEG C until the tobacco leaf tops become yellow; raising the dry ball temperature to 38 to 40 DEG C at a speed being 1 DEG C in 2+ / -0.5 hours, prolonging the time after the temperature is stable, and controlling the wet ball temperature at 34 to 36 DEG C until the bottom layer tobacco leaves approach to or reach the state that yellow leaves account for 80 percent, green ribs become slightly yellow, and simultaneously, the leaves become soft; raising the dry ball temperature to 40 to 43 DEG C at a speed being 1 DEG C in 1+ / -0.5 hour, and maintaining the wet ball temperature being 36 to 37 DEG C so that all tobacco leaves at the bottom and partial tobacco leaves at the second layer become yellow and soft and are collapsed; raising the dry ball temperature to 54+ / -1 DEG C at a speed being 1 DEG C per hour, and simultaneously, gradually raising the wet ball temperature and stabilizing the wet ball temperature at 36 to 40 DEG C; raising the dry ball temperature to 68+ / -1 DEG C at a speed being 1+ / -0.5 DEG C per hour, stabilizing the temperature at the highest temperature not exceeding 70 DEG C until the tobacco leaves are completely dried; and simultaneously, stabilizing the wet bal temperature at 40 to 43 DEG C until the baking is completed. Through optimizing the tobacco leaf baking temperature control scheme, the tobacco baking quality can be improved, and the tobacco leaf baking cost can be reduced.

Owner:CHINA TOBACCO GUANGDONG IND

Curing process of flue-cured tobacco

InactiveCN101983589AStable color fixationStrong baking qualityTobacco preparationEngineeringCuring of tobacco

The invention discloses a curing process of flue-cured tobacco and belongs to the technical field of the curing technology of tobacco leaves. According to the curing characteristic of the leaves of the zhongyan 103, the temperature and the humidity, the curing process of tobacco leaf of the invention divides the whole process of the curing of tobacco leaves into five steps, namely firing-up and temperature control, yellowing of tobacco leaves, transition, colour setting of tobacco leaves and stem-drying of tobacco leaves, wherein the five steps have the three stages of yellowing stage, colour setting stage and stem-dring stage, thus the quality of the cured tobacco leaves is greatly increased. The curing process has high maneuverability and can obviously increase the tobacco leaf quality and high-class leaf ratio of flue-cured tobacco and reduce the rate of green tobacco; the ratios of high-class leaf and middle-class leaf in the cured tobacco leaves are increased by more than 10.65%, the ratio of the tobacco leaf with different colors is reduced by more than 1.67%, the ratio of tobacco leaves of which upper and middle parts are green is reduced by more than 7%; the output value is increased by more than 11.75%; and the cured tobacco leaves are bright-coloured and oily, the chemical composition tends to be coordinated, the sugar-nicotine ratio, the nitrogen-nicotine ratio and the total nicotine all meet the chemical composition quality evaluation standard of the crude tobacco; and the style characteristic of the zhongyan 103 is fully displayed, and the incomes of tobacco farmers are increased.

Owner:张永辉

Intensive barn curing process of safflower mammoth gold tobacco leaves

InactiveCN101692929AReduced rate of blue veinsReduce dust hanging rateTobacco preparationEconomic benefitsEngineering

The invention relates to an intensive barn curing process of safflower mammoth gold tobacco leaves. The intensive barn curing process is characterized in that tobacco leaves of a middle lower part and tobacco leaves of an upper part are separately cured, wherein the curing of the tobacco leaves of the middle lower part has six stages, and the curing of the tobacco leaves of the upper part has eight stages. The intensive barn curing process achieves a better effect through controlling corresponding technical conditions in an intensive barn. After curing, the blue vein rate of the tobacco leaves is reduced, the dust rate of the tobacco leaves is reduced, the volume of aroma of the tobacco leaves is obviously increased, the curing time is shortened, and each furnace saves coal by 11 percent. The invention reduces over-cured tobacco leaves and increases the economic benefits.

Owner:云南省烟草公司大理州公司

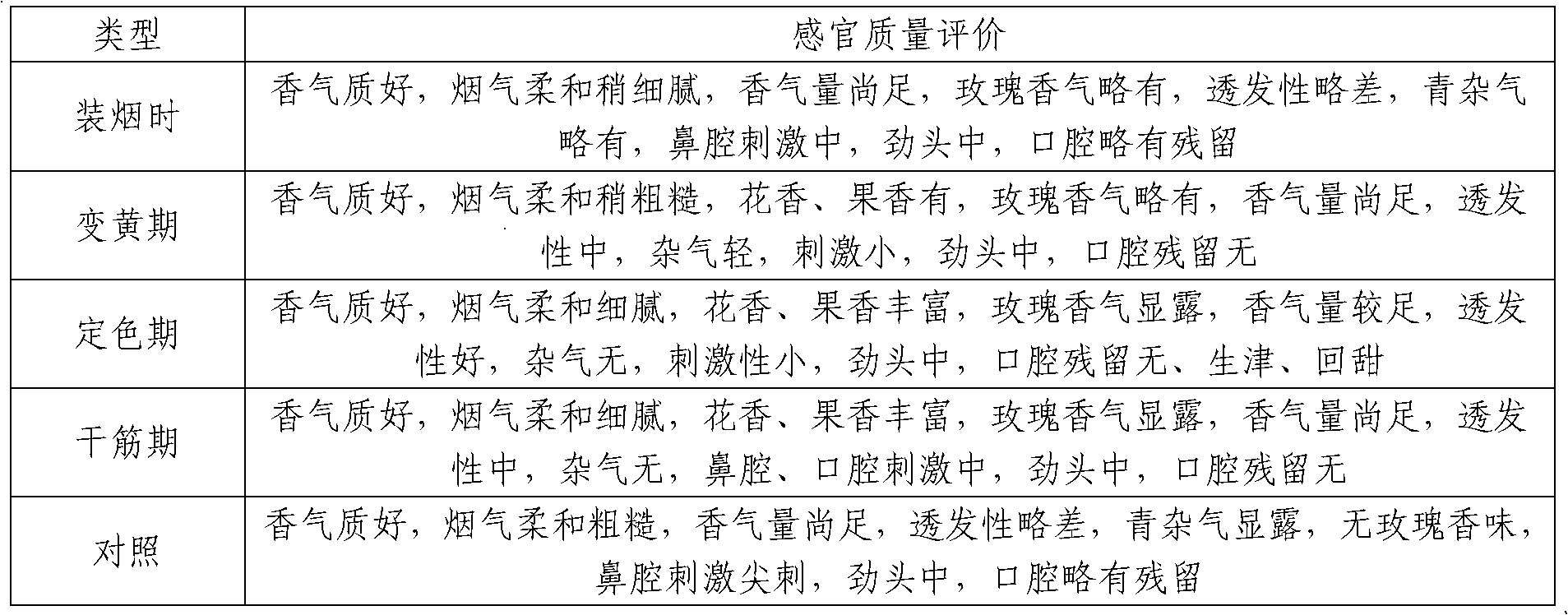

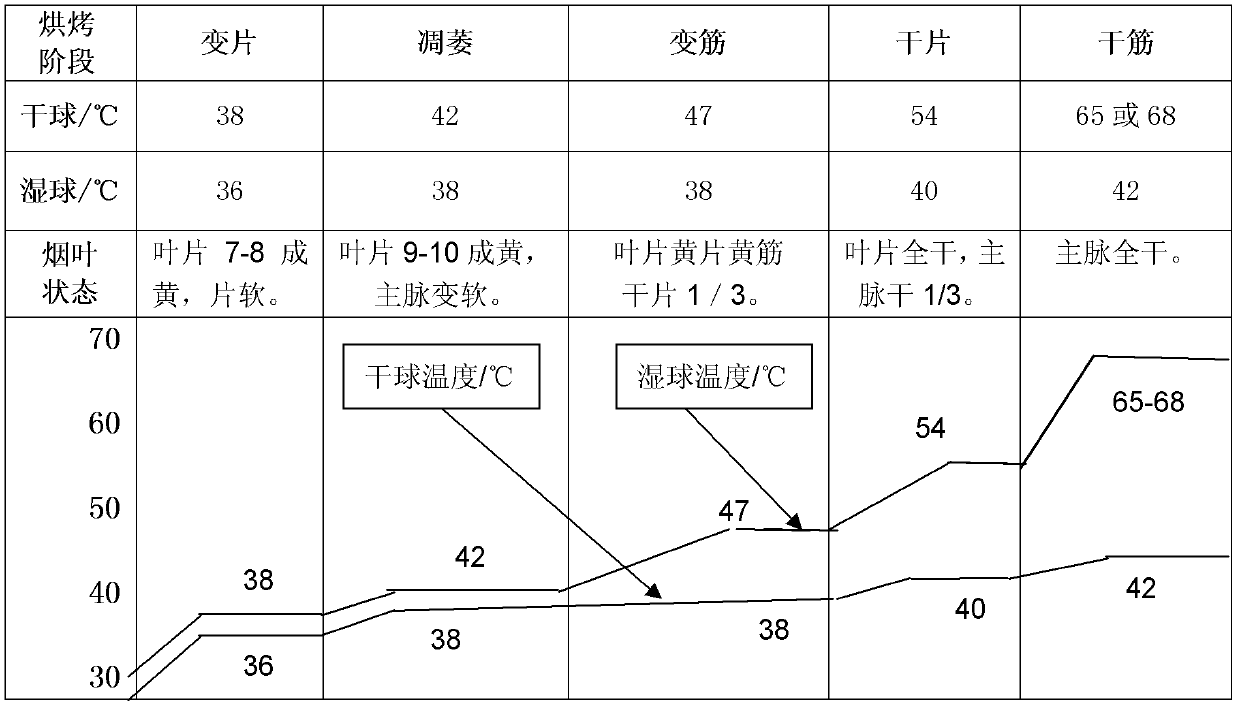

Rose blended tobacco baking and flavoring method

InactiveCN102499428AIncrease sweetnessReduce drynessTobacco preparationCooking & bakingNicotiana tabacum

The invention discloses a rose blended tobacco baking and flavoring method which comprises the following steps of: installing the harvested fresh tobacco on rods, loading the tobacco into a bulk curing barn, separately placing roses in 4-8 ventilated containers during the tobacco flue-curing color curing period, evenly distributing the containers at 3-5 cm away from tobacco, baking the tobacco for 120-140 h, wherein the weight ratio of rose to tobacco is 1:3500. The invention develops a new method, plant rose and tobacco are baked in the same oven, tobacco cells absorb volatile fragrant substances of the rose through breathing under the action of temperature and humidity, so that the purposes of enriching tobacco fragrance, covering miscellaneous smell, improving smoking taste, increasing tobacco sweetness and reducing the dry sensation of smoke are achieve, and the demand of top-grade high-end cigarette brands for high-quality raw material is satisfied. Plant fragrance raw material rose is added before tobacco is industrially used, so that the fragrant ingredients of the rose can be well cured in tobacco. Not only is the use level of rose essence reduced in industrial use, but also the safety of tobacco use is also increased.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Precision five-phase quintuple-correspondence roasting bulk-curing process for tobacco

ActiveCN102599624AImprove qualityNot easy to hang ashTobacco preparationAutomatic controlProcess engineering

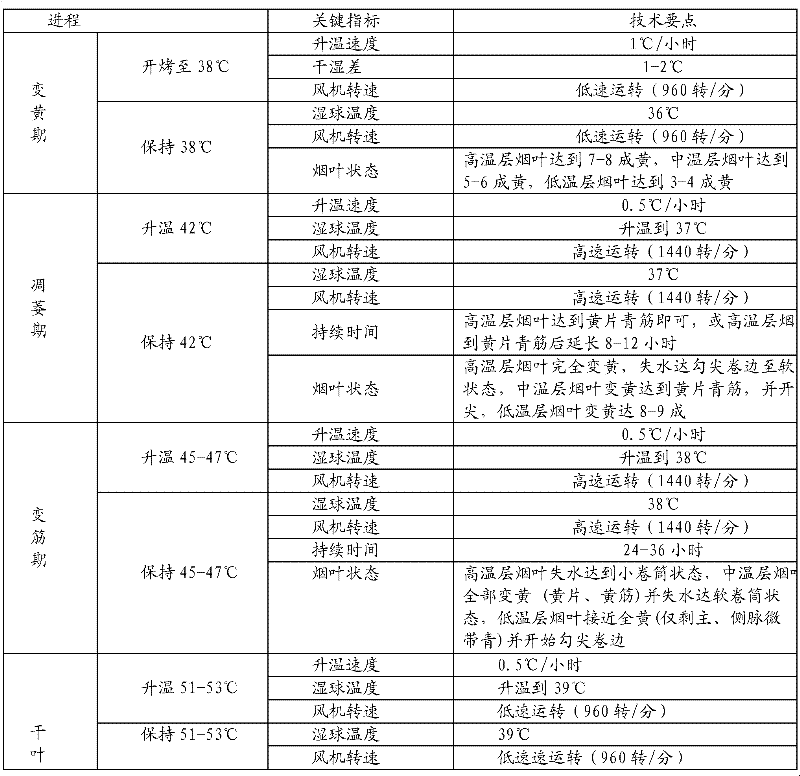

The invention discloses a precision five-phase quintuple-correspondence roasting bulk-curing process for tobacco. According to appearance characteristic change and internal substance transformation characteristics in the process of tobacco flue-curing and by operating automatic control equipment for a bulk curing barn, the process of bulk curing is divided into a tobacco leaf yellowing phase, a tobacco leaf withering phase, a tobacco leaf vein yelling phase, a tobacco leaf drying phase and a tobacco leaf vein drying phase. Each phase includes a process of temperature rise and a process of stable temperature. The formed five phases correspond to dry-wet bulb temperature and tobacco leaf change. Five phases of the dry-wet bulb temperature strictly correspond to indexes of the tobacco leaf change. The time of stable temperature is flexibly adjusted to meet the indexes of the tobacco leaf change. Fire and fan rotation speed are operated and adjusted according to the dry-wet bulb temperature set via a temperature-humidity controller. The leaf appearance change characteristics and the leaf internal transformation degree in the process of bulk curing are combined with the flue-curing operation technique, so that the process of bulk curing is precise in operation, and hierarchical organization, oil content and fragrance quality of tobacco leaves subjected to bulk curing are improved evidently.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

New-type tobacco flue-curing room and the tobacco flue-curing process

InactiveCN1403035ACompatible with growth physiological characteristicsSelection quality improvementTobacco preparationThree stageSmall footprint

Owner:刘志峰

Method for baking tobacco leaves and baking room

InactiveCN101579144AQuality improvementMeet temperature and humidity requirementsTobacco preparationThermal energyCooking & baking

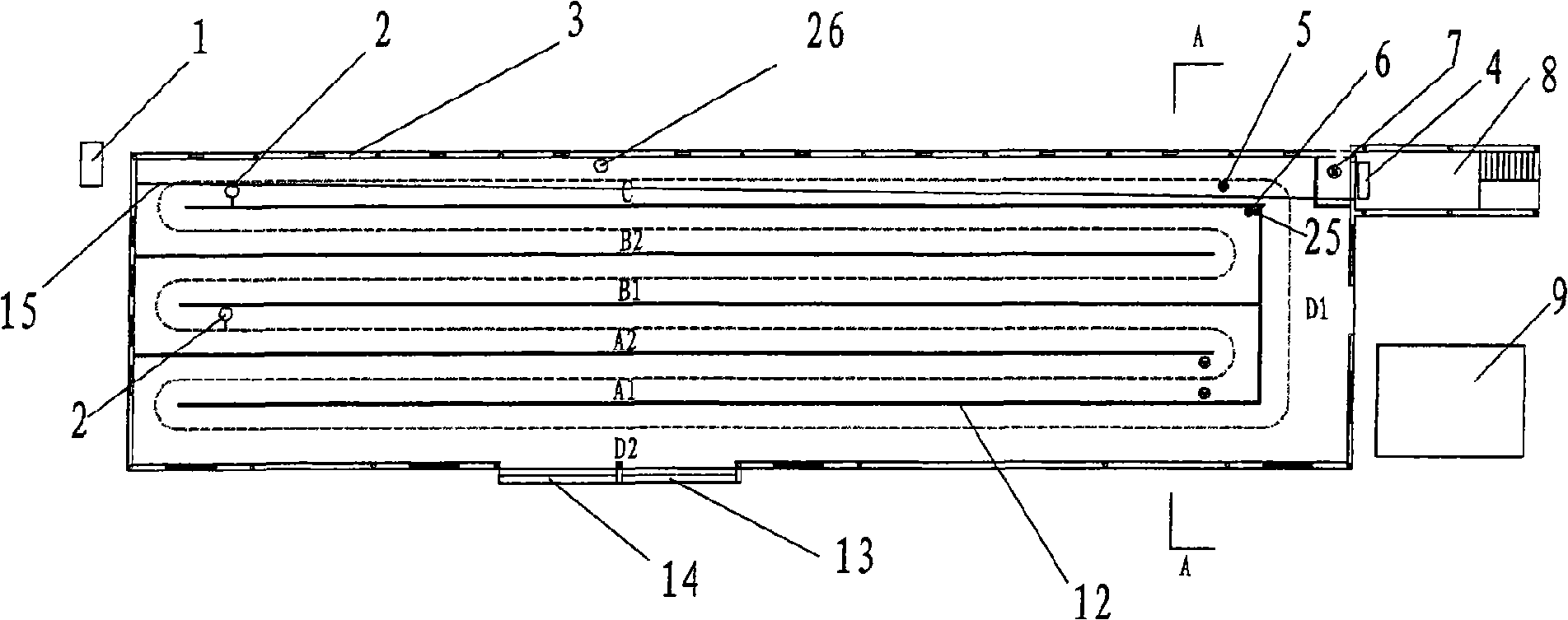

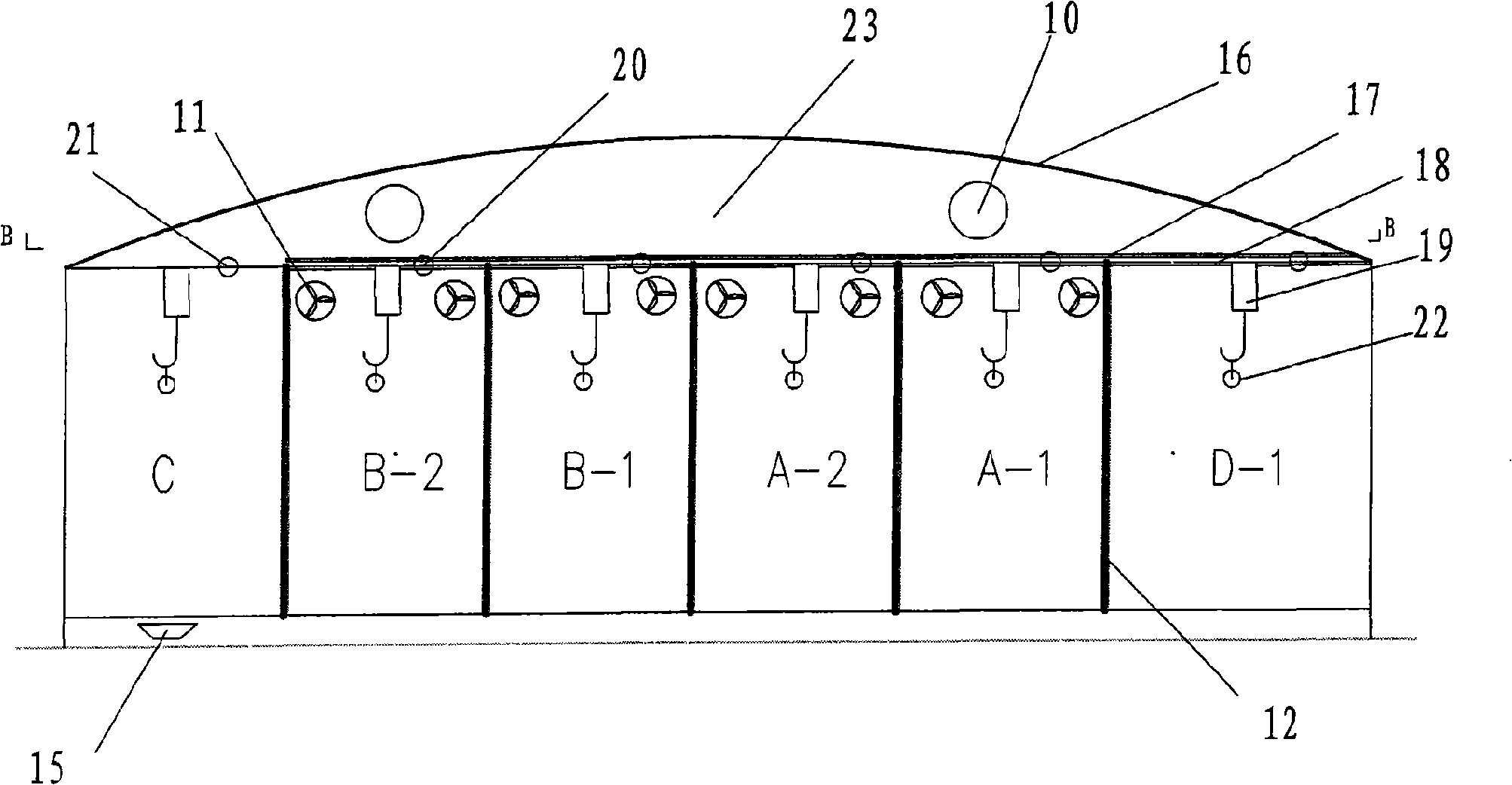

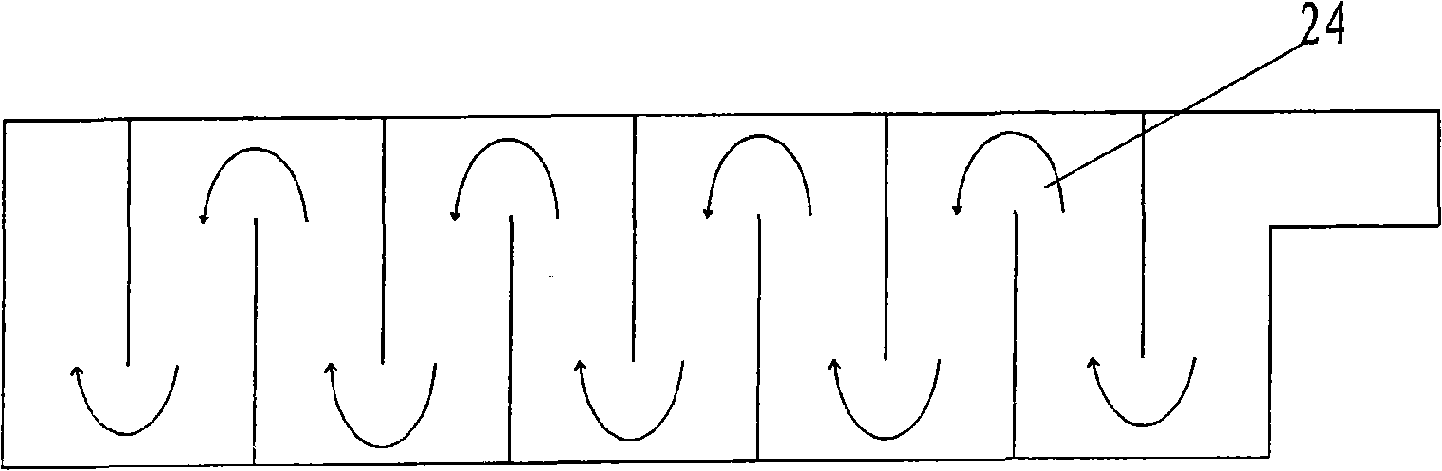

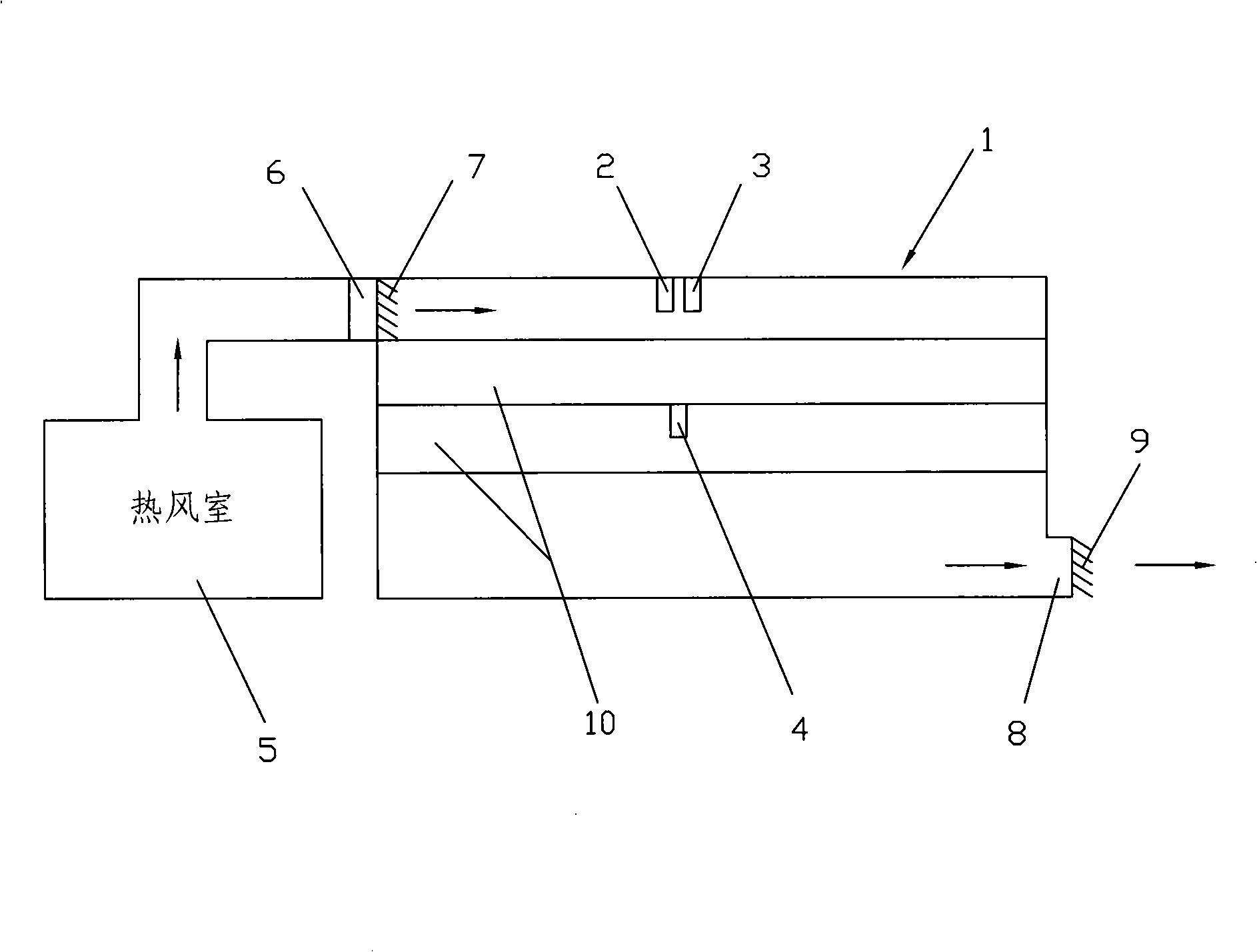

The invention relates to improvement of a method for baking tobacco leaves and a baking room, which are characterized in that the tobacco leaves are baked in the baking room by a forward moving mode and are moved forwards in a reverse direction according to heating and humidifying airflows, and the tobacco leaves are baked at different temperatures and humidity by moving in one baking room. Compared with the prior art, the baking stages are performed according to a time sequence which is then changed into a spatial position sequence so that the tobacco leaves are baked by moving at different temperatures and humidity continuously with gradual changes and without obvious boundaries and time interval divisions, and are dampened at the same time. The method is more accordant with the processes of physiological and biochemical changes and drying gradual changes in the process of baking the tobacco leaves, has good tobacco-baking fragrance-keeping property and quality, reduces the baking energy consumption through sequential usage of hot air, and can achieve continuous operations. The baking room adopts transparent plates to generate auxiliary heat energy so as to have better energy-saving effect. By using a splitter plate movable structure, the multifunctional application of the baking room can be achieved, and the comprehensive utilization value of the baking room is improved.

Owner:江苏科地现代农业有限公司

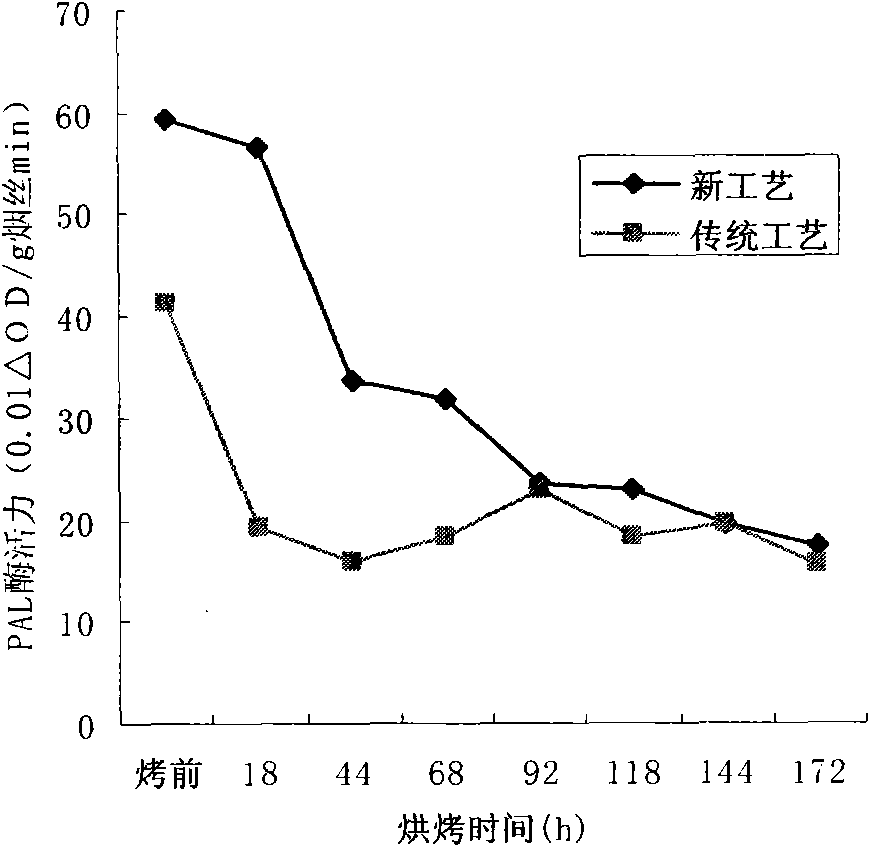

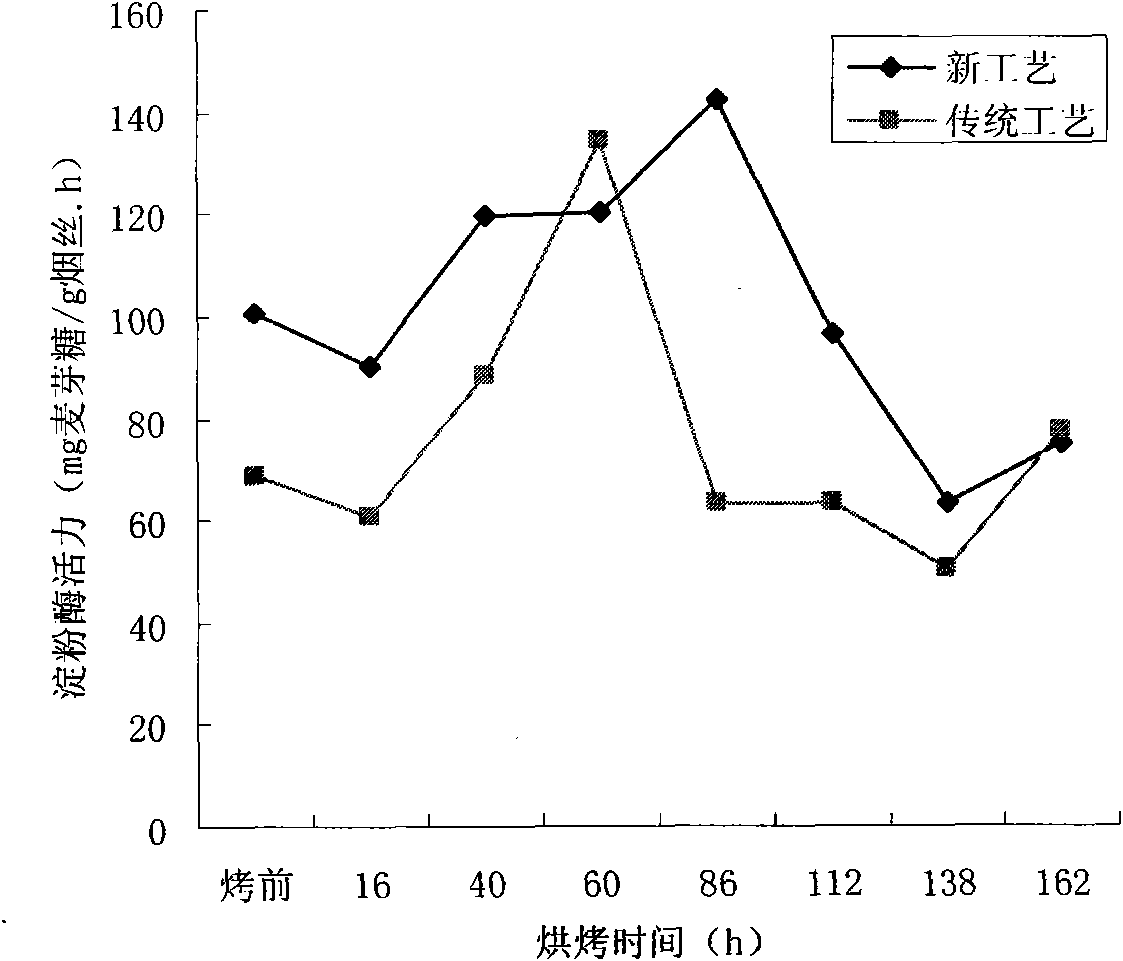

Process for baking Hongda tobacco leaves

The invention relates to a process for baking Hongda tobacco leaves, which belongs to the technical field of tobacco application. The method is an improvement of the traditional baking process and has the main improving points that the total baking time of the tobacco leaves grown at the lower part is shortened to 156 hours from original 168 hours; the total baking time of the tobacco leaves grown at the middle part is shortened to 168 hours from original 180 hours; and the total baking time of the tobacco leaves grown at the upper part is shortened to 170 hours from original 178 hours. The baking temperatures are adjusted by increasing the braking temperature in a yellowing stage to 31-32 DEG C from original 27-29 DEG C, increasing the braking temperature in a withering stage to 40-41 DEG C from original 38-39 DEG C, increasing the braking temperature in a leaf drying stage to 47-49 DEG C from original 43-45 DEG C, and increasing the braking temperature in a leaf ribbing stage to 66-67 DEG C from original 63-65 DEG C. The process for baking Hongda tobacco leaves is favorable for the conversion of chemical substances and the activity of enzymes by improving the baking time and thebaking temperature, the quality of the tobacco leaves is improved obviously, and the Hongda tobacco leaves with the optimum braking quality can be obtained.

Owner:YUNNAN TOBACCO CO LTD KUNMING BRANCH +1

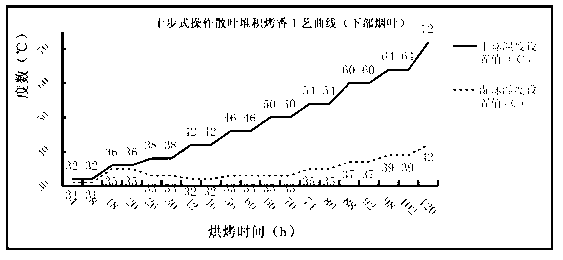

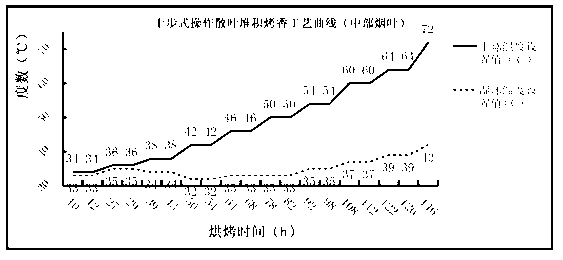

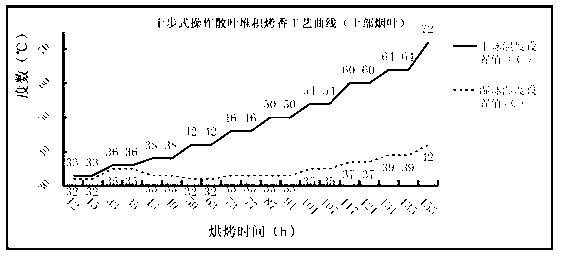

Technology for operating bulk stacking baking fragrance on tobacco baking controller through ten steps

ActiveCN103005657AImprove the level ofImprove appearance qualityTobacco preparationCooking & bakingDecomposition

The invention provides a technology for operating bulk stacking baking fragrance on a tobacco baking controller through ten steps. The technology comprises the following steps of: performing baking fragrance verifying and fine tuning in the baking changing process of the tobaccos on the tobaccos at the lower, middle and upper parts and formed under special weather conditions, respectively setting figures on the tobacco baking controller, and combining into a baking fragrance technological curve; baking, so that the tobaccos form prime matters of aroma components in the yellowing stage through biochemistry and complete decomposition; enabling the fragrance prime matters to form abundant aroma components at the later period of the color fixing stage; and rapidly drying tobacco leaves at the drying period, reducing the decomposition of the aroma components, and keeping the quality and the quantity of aroma of the tobaccos. By the technology, the level and the appearance quality of the tobaccos are greatly improved; the technology is suitable for bulk stacking baking, and is also suitable for baking the tobaccos in other compact modes; and the technology is easy to popularize.

Owner:贵州省烟草公司遵义市公司绥阳分公司

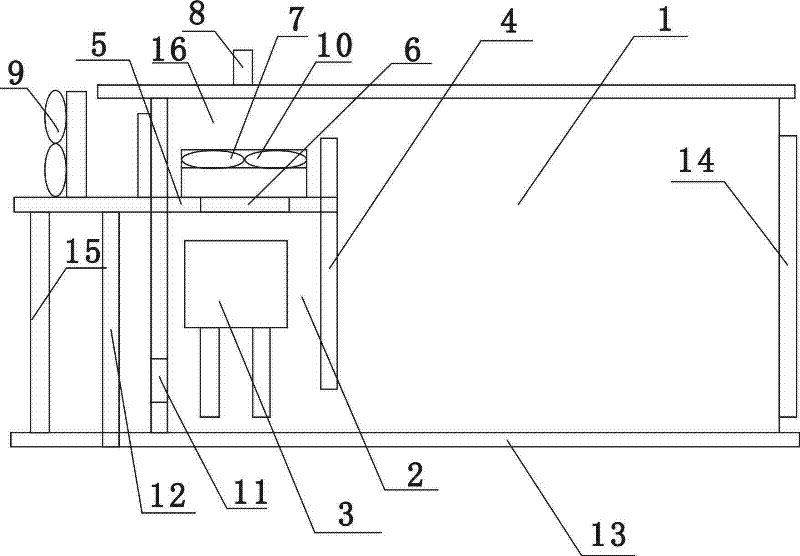

Tobacco leaf baking equipment

InactiveCN105520185AShort cycleSimple structureTobacco preparationBiomass combustionProcess engineering

The invention aims to provide tobacco leaf baking equipment. The tobacco leaf baking equipment comprises a heating apparatus, a humidity discharging apparatus and a controller, wherein the heating apparatus comprises a biomass combustion furnace, a heat exchanger connected with an exhaust gas outlet pipe of the biomass combustion furnace, a circulating fan used for conveying hot air, and a feeding apparatus used for feeding to the biomass combustion furnace; the feeding apparatus comprises a hopper and a helical conveying part for conveying the material in the outlet of the hopper to the material inlet of the biomass combustion furnace; the humidity discharging apparatus comprises a humidity discharging opening and a humidity discharging window formed in the humidity discharging opening; and an oxygen supplying device, the circulating fan and the helical conveying part in the biomass combustion furnace are all connected with the controller. By adoption of the technical scheme, the tobacco leaf baking equipment has the advantages as follows: the overall tobacco leaf baking equipment is simple in structure; due to the integrated design of the heating apparatus, the humidity discharging apparatus and the controller, the tobacco leaf baking equipment is high in practicability; and the biomass combustion furnace is adopted for providing heat energy, so that the tobacco leaf baking equipment is green and environment friendly.

Owner:CHANGSHA XINDI ELECTRONICS TECH

De-stem flue-cured tobacco one-step baking technique

The invention relates to the processing way of baking tobacco without stalks by one time baking. Nowadays, most of the tobacco leaves are primarily baked by farmers before they are transferred to the tobacco re-baking factories to bake again and remove the stalks to provide materials for cigarette factories. There are several disadvantages in present technologies such as high cost, long processing time and low efficiency etc. The way mentioned in the invention can solve the previous problems. The procedures go as follows: remove the stalks of tobacco leaves; bake the tobacco leaves at low temperature until the water content of the tobacco leaves reduce to 2% or less; re-damping the tobacco leaves to the water content of 11-13%; the baked tobacco leaves can serve as the cigarette materials.

Owner:彭惠滨

Simulating guide system for fire-curing or flue-curing tobacco leaves

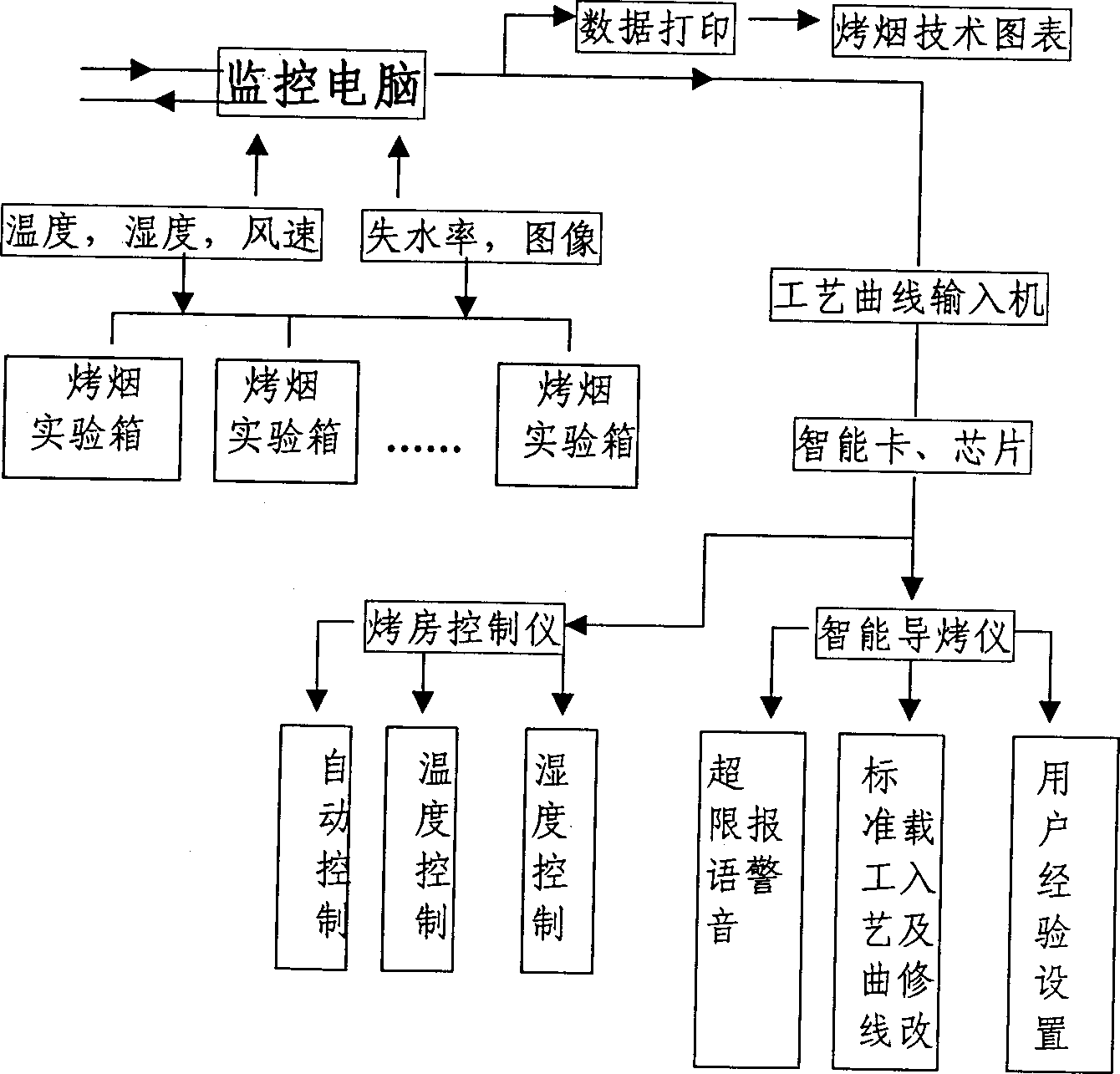

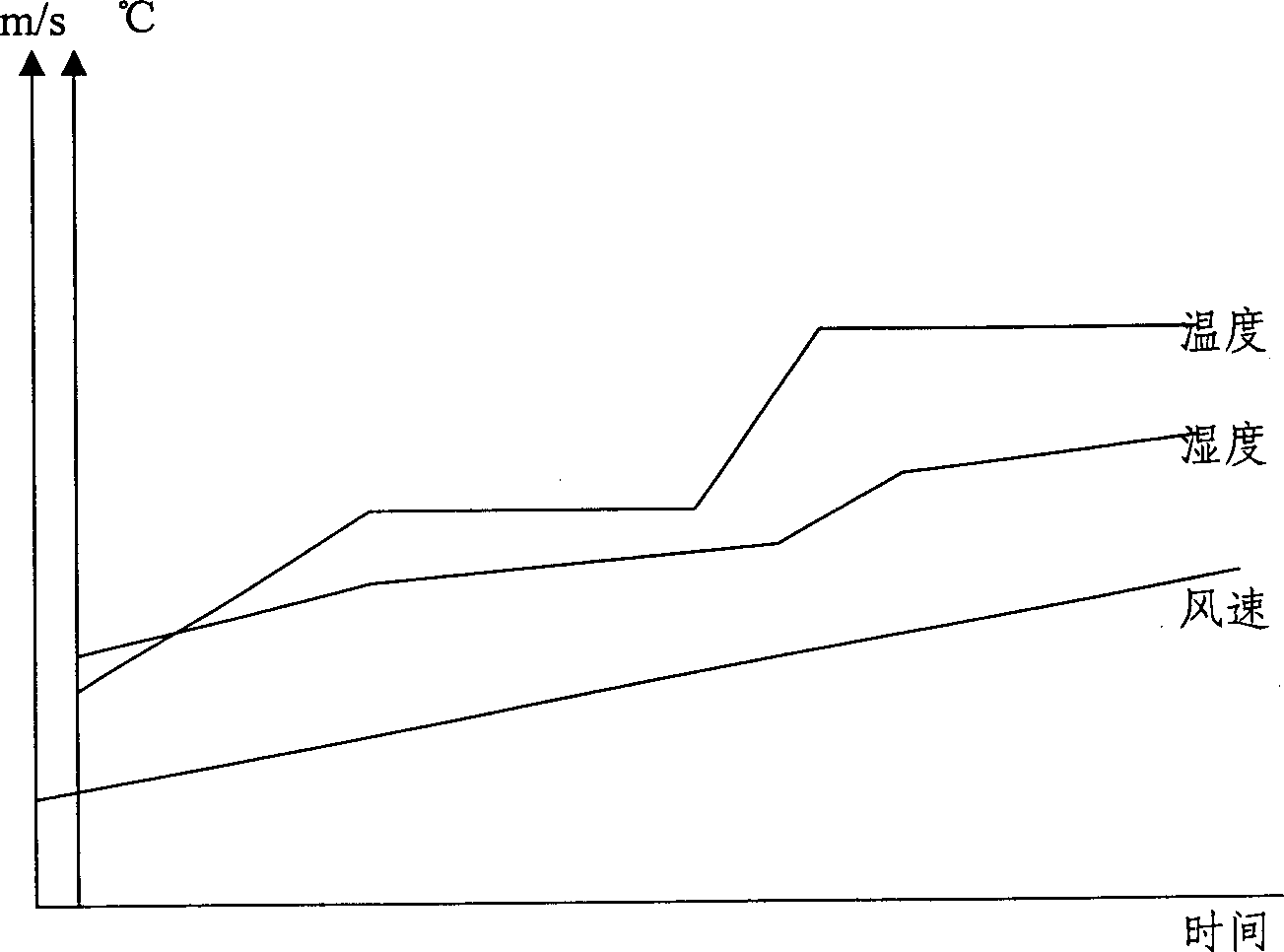

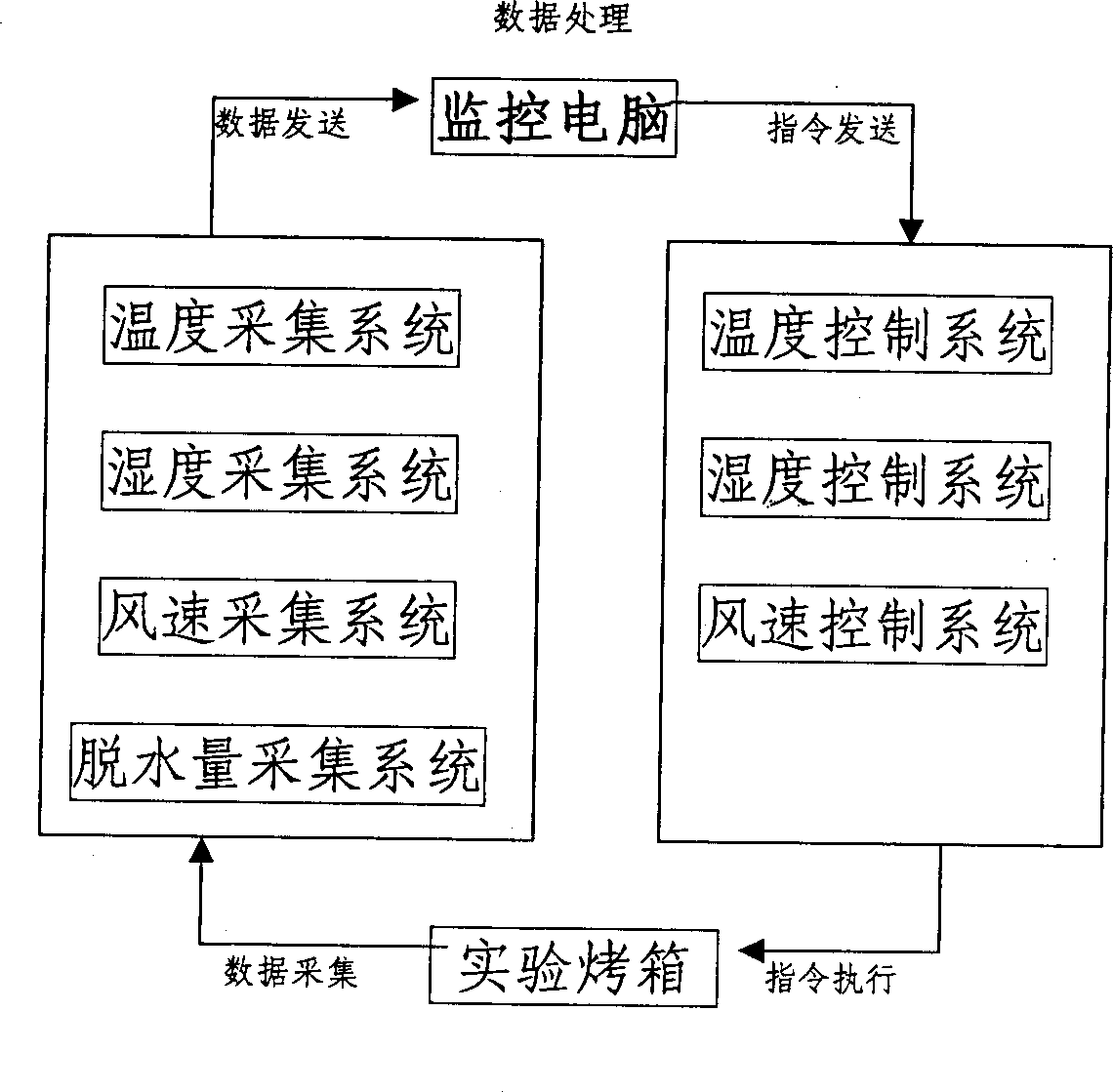

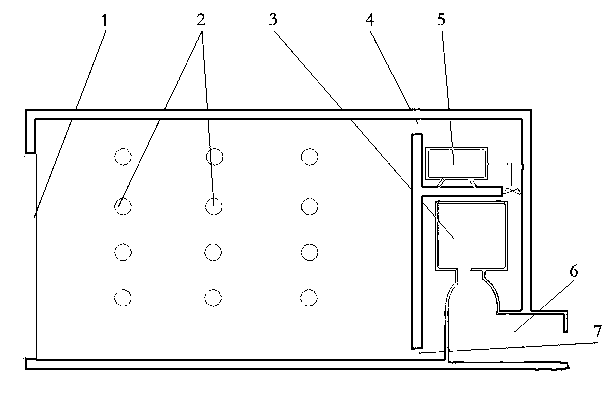

A simulation system for instructing the fire- and flue-curing of tobacco leaves features that an experimental oven is autocontrolled by a monitor computer in which a technological fire- and flue-curing curve is preloaded, the data about the flue-curing process is collected and used to define optimal technological curve, said optimal technological curve is stored in intelligent card or chip, and said card or chip is installed to the controller for fire- and flue-curing tobacco leaves.

Owner:李盎

Bulk-curing-bam curing method for improving curing quality of K326 tobacco

InactiveCN102934835AImprove uniformityReduce temperature differenceTobacco preparationEngineeringTemperature difference

The invention relates to a bulk-curing-bam curing method for improving curing quality of K326 tobacco. According to the method, the tobacco placing mode is changed in an airflow downdraft type bulk curing bam, the temperature is gradually increased, and the humidity is controlled, so that the temperature and the humidity can be precisely controlled, the uniformity of the tobacco in placing can be improved as well as the flowing smoothness of the airflow, the temperature difference in each position in the curing bam is reduced, the yellowing time of the tobacco in the whole curing bam is reduced, the dehydration rate of the tobacco in the color fixing stage is increased, the time of curing the tobacco is reduced on the whole, the ratio of dreg lamina generating, dust sticking and green tobacco lamina can be reduced, and as a result, the curing quality of the whole K326 tobacco in curing can be improved.

Owner:HONGTA TOBACCO GRP +1

Cured tobacco baking technique capable of preventing 'black ant peel' symptom during baking tobacco leaf

ActiveCN101416770AImprove roast qualitySimple and fast operationTobacco preparationEngineeringTobacco processor

The invention relates to a tobacco roasting technique preventing and treating a Heimapi symptom (a symptom that the tobacco leaves turn black and have flecks or blocks partially or whole) in a tobacco roasting process, belonging to the technical field of tobacco preparation. The technique is as follows: after filling the tobacco leaves in a furnace, keeping the temperature less than 40 DEG C and the relative humidity at 92%-82% to <=79% or to <=68%, with the change curve sharply dropped; keeping balancing the relative humidity of an intensive roasting room to less than or equal to 85%; (1) adjusting humidity at a low temperature until turning yellow, roasting the tobacco leaves on the base frame until stems turn green and leaves turn yellow, with the temperature in the furnace between 40 DEG C and 48 DEG C and the relative humidity of the common roasting room changed from less than or equal to 68% to less than or equal to 64% to less than or equal to 45%-38%, also with the change curve sharply dropped; stabilizing the temperatures and discharging moisture until the leaves wilt, all the tobacco leaves in the furnace turn white and the tips turn up; go on roasting according to the normal method until all the tobacco leaves are dry after the temperature in the furnace is 49 DEG C. The invention has advantages of a simple operation, overcomes over 85% of tobacco leaves with the Heimapi symptom and obviously improves roasted tobacco leaves, and is applied to roasting tobacco leaves in cold areas and upper tobacco leaves.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Accurate NC55 tobacco variety bulk curing process

ActiveCN102960844AIn line with the principle of physiological and biochemical changesImprove roast maturityTobacco preparationAutomatic controlEngineering

The invention discloses an accurate NC55 tobacco variety bulk curing process. According to the change characteristics of the appearance trait and inherent physiology and biochemistry of tobacco in the process of curing and in combination with the operation of the automatic control equipment of an intensive curing barn, bulk curing is divided into a tobacco yellowing stage, a tobacco wilting stage, a tobacco vein yellowing stage, a tobacco drying stage and a tobacco vein drying stage. The tobacco yellowing stage includes three temperature-increasing and temperature-keeping processes, each of the other stages includes a temperature-increasing and temperature-keeping process, seven steps corresponding to dry and wet bulb temperatures and the change in tobacco are formed, the dry and wet bulb temperatures need to strictly correspond to the change indexes of the tobacco, the temperature-keeping time is flexibly regulated in order to reach the change indexes of the tobacco, and the power of fire and the rotational speed of a fan are controlled according to the dry and wet bulb temperatures set by a temperature-humidity controller. The tobacco yellowing stage of the accurate NC55 tobacco variety bulk curing process adopts step-by-step temperature rise for yellowing, which accords with the physiological and biochemical change principle of tobacco curing, consequently, the maturity of cured tobacco can be effectively increased, the tobacco cannot be easily cured to turn green, and is rich in oil, aroma is remarkably increased, and the quality of tobacco is good.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

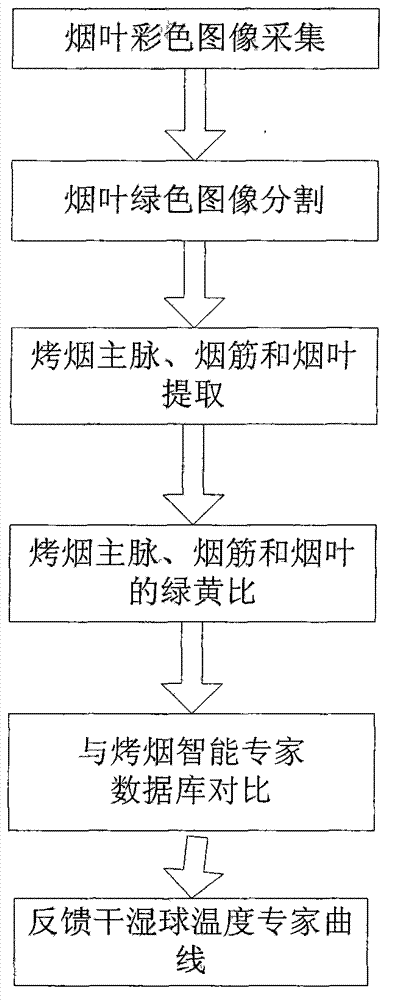

Densification tobacco flue-cure dry-wet bulb temperature automatic control technique based on tobacco image processing

The invention provides a densification tobacco flue-cure dry-wet bulb temperature automatic control technique based on tobacco image processing. The technique includes: building an intelligent expert database of the green-yellow ratio of the tobacco, the tobacco stem and the main vein parts of tobacco flue-cure and the dry-wet bulb temperature curve; using a color video camera to collect the color images of tobacco in a standard flue-cure room in real time; performing binarization on the green component images of the color tobacco images, extracting the tobacco, the tobacco stem and the main vein parts and the like, and calculating the green-yellow ratio of corresponding parts; performing Bayesian crosscheck on the green-yellow ratio of the tobacco, the tobacco stem and the main vein parts and the like and the corresponding features in the intelligent expert database, and estimating current tobacco flue-cure state in real time; feeding the current tobacco flue-cure state to a dry-wet bulb temperature automatic control system of the flue-cure room, calling corresponding dry-wet bulb temperature expert curves to automatically control dry-wet bulb temperature. The technique has the advantages that the constantly changed tobacco flue-cure image features during tobacco flue-cure are utilized to monitor densification tobacco flue-cure quality online in real time, tobacco flue-cure dry-wet bulb temperature is controlled automatically, quality of flue-cured tobacco can be increased effectively, and labor cost of tobacco flue-cure workers can be reduced.

Owner:CHONGQING UNIV +2

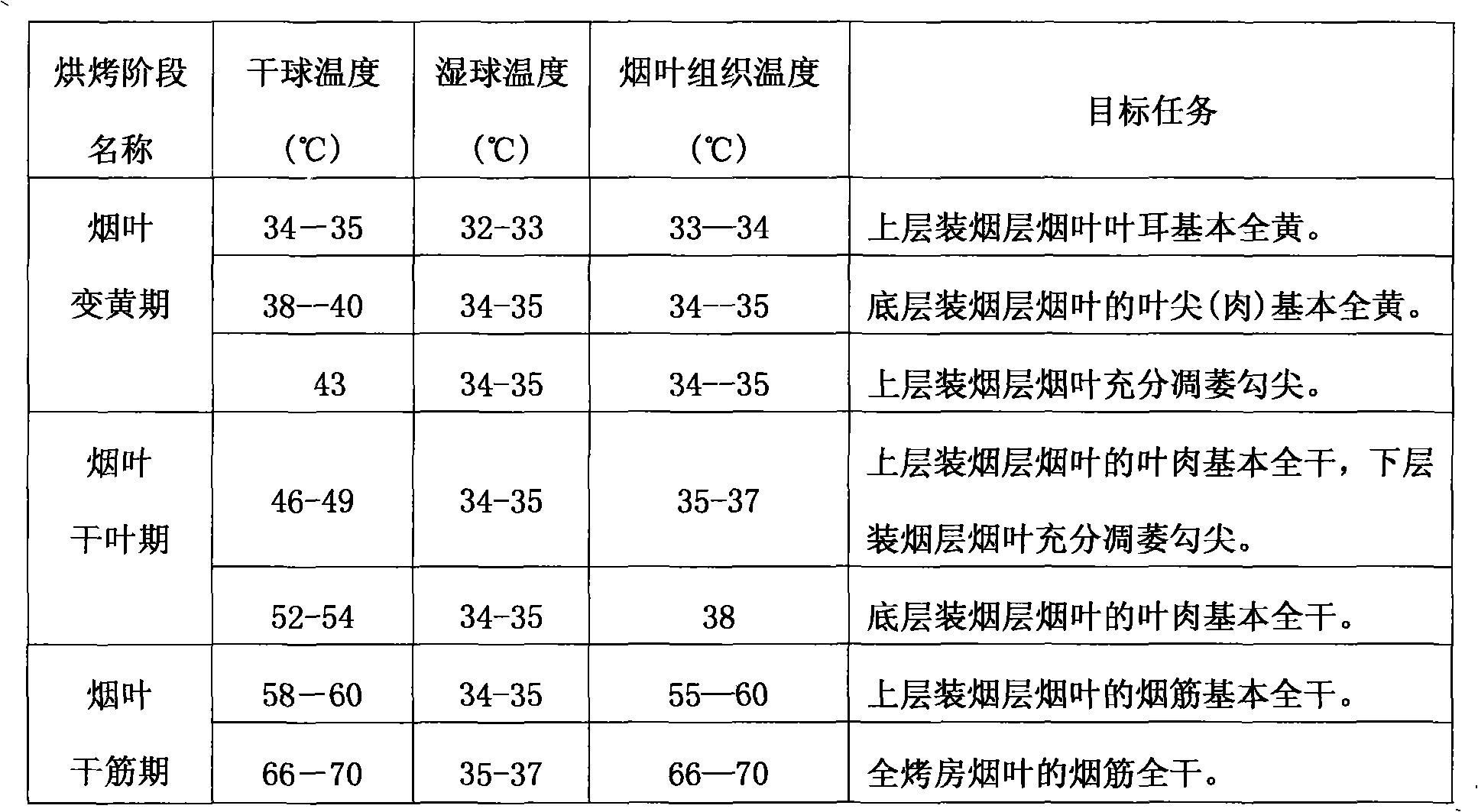

Tobacco roasting process of intensive hothouse

The invention discloses a tobacco curing method for intensive flue-curing barns, which comprises curing step of three stages: a yellowing stage, a leaf drying stage and a stem drying stage. The difference between the method and the conventional curing method is that a second dry bulb thermometer is arranged in a tobacco loading layer for detecting the tissue temperature of tobacco leaves besides a dry bulb thermometer and a wet bulb thermometer arranged in the curing room. Fully considering the problem of heat generated by breathing of wet tobacco tissue, the tobacco curing method can control the temperature and the humidity in the flue-curing barn as well as the tissue temperature of the tobacco leaves. Specifically, the temperature of the wet tobacco tissue in the yellowing stage must be controlled within a change range of physiological and biochemical temperature of the wet tobacco leaves, which is the key for preventing the tobacco leaves from curing bad, thus ensuring the curing quality of intensive flue-curing barns.

Owner:杨树勋

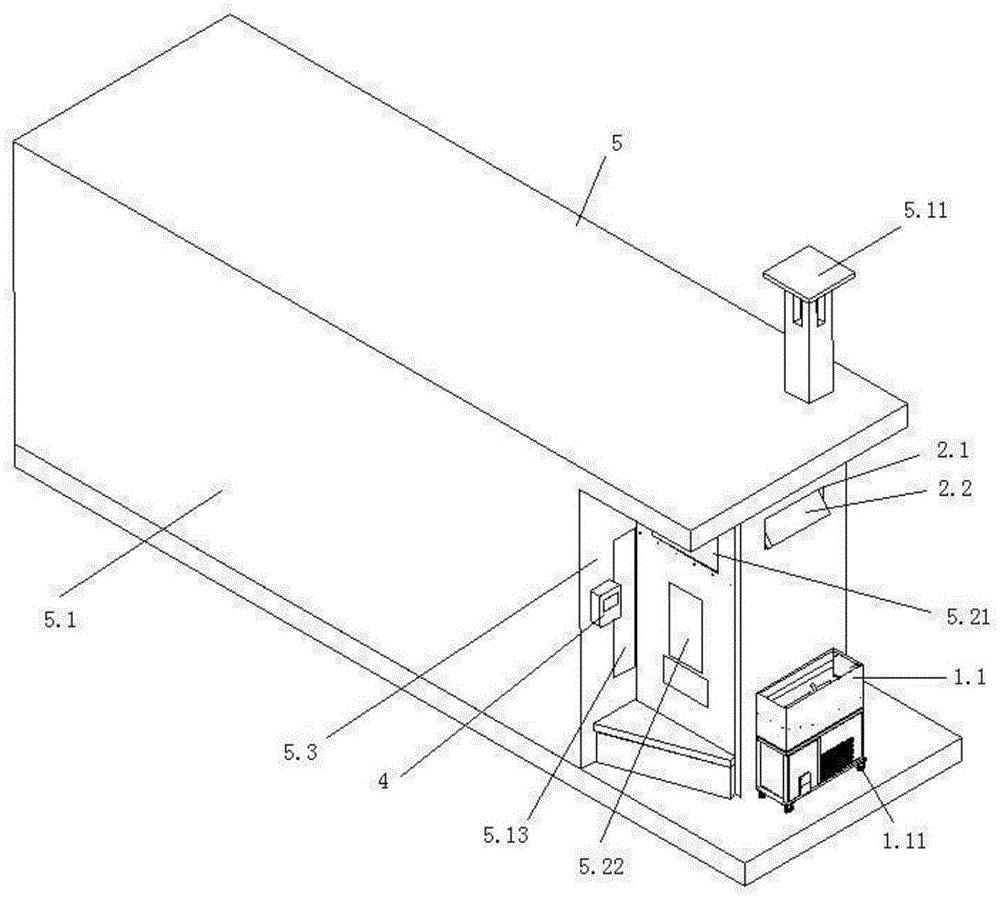

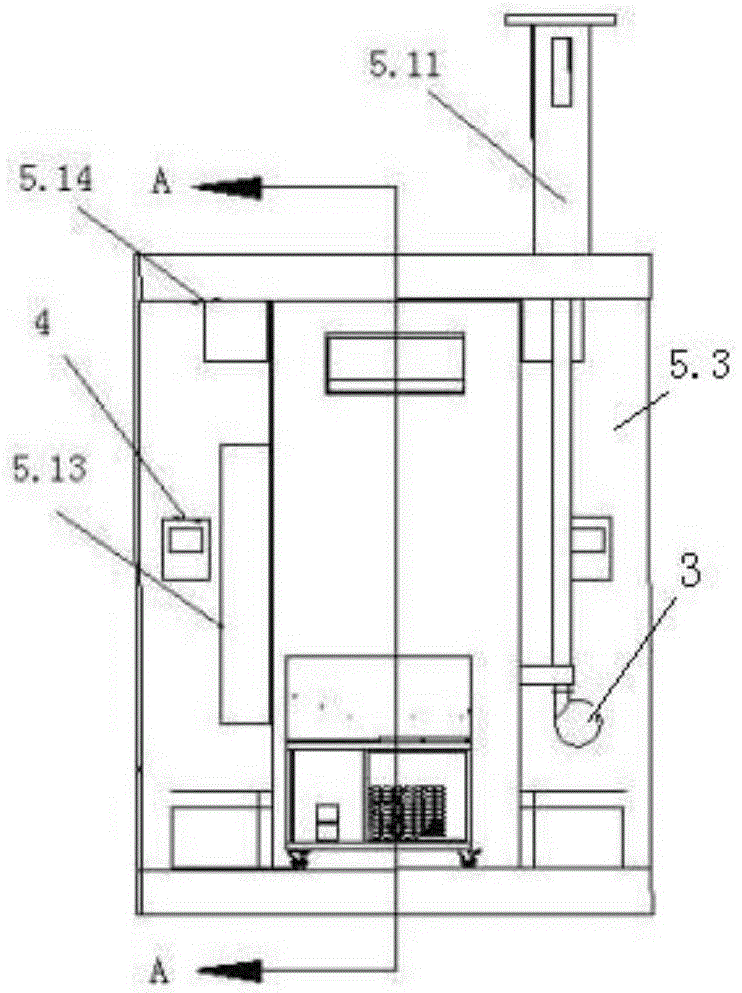

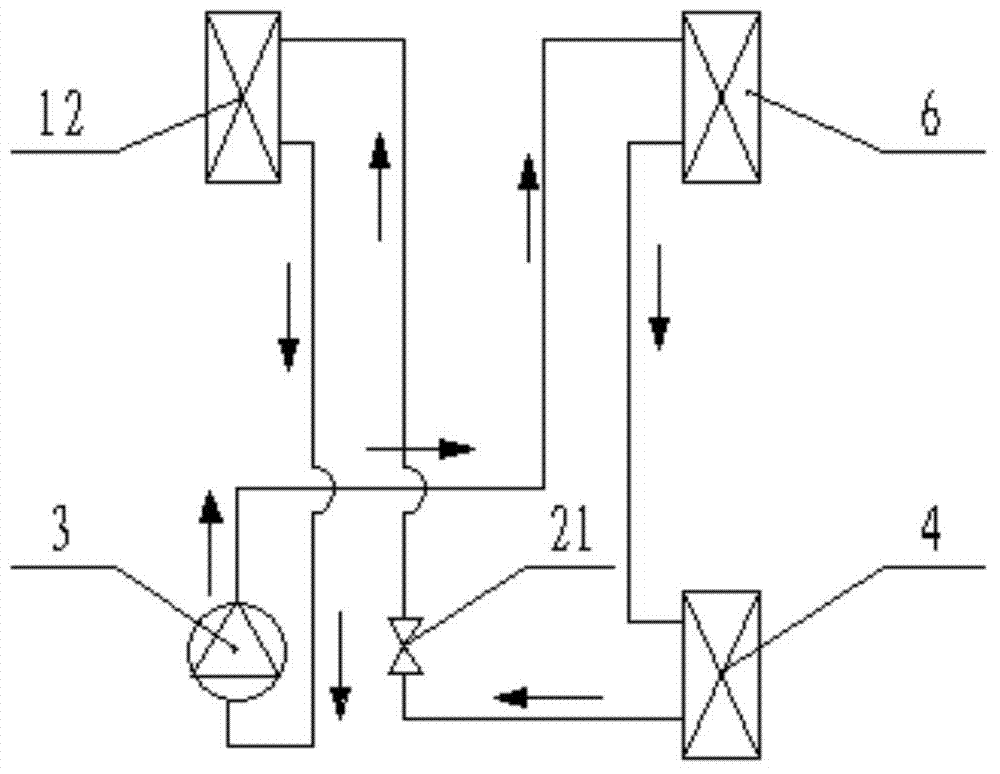

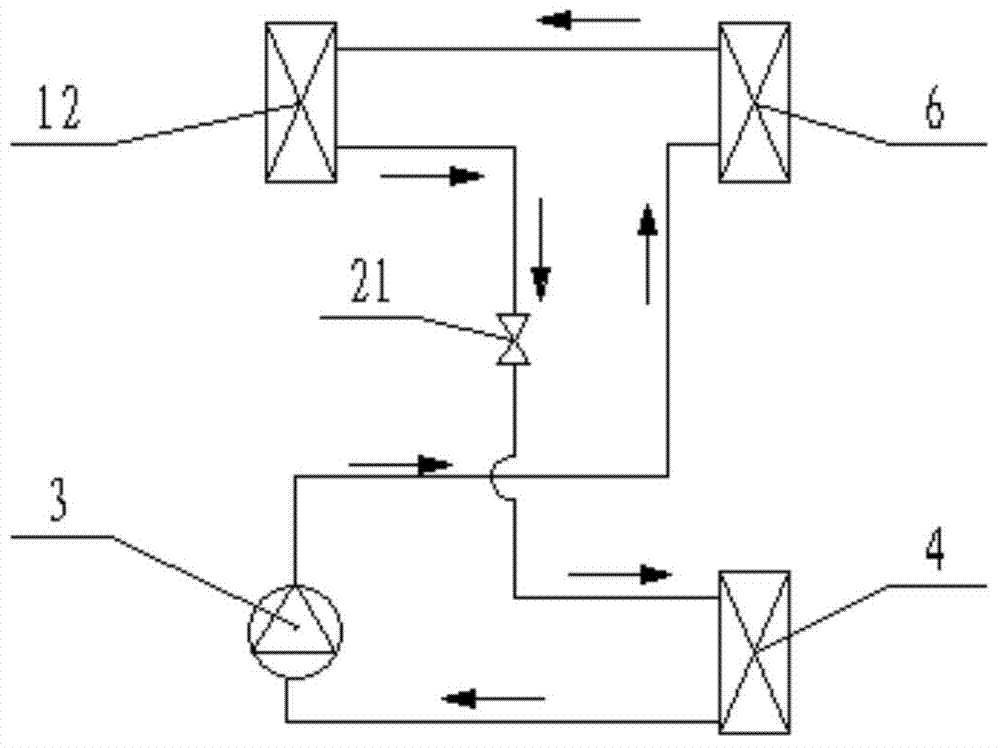

Intensive curing barn baking process for airflow alternate-operation flue-cured tobacco

ActiveCN102068028AReduce the plane temperature differenceReduce vertical temperature differenceTobacco preparationTobacco treatmentEcological environmentOperation mode

The invention relates to an intensive curing barn baking process for airflow alternate-operation flue-cured tobacco, belonging to the technical field of flue-cured tobacco preparation process. The intensive curing barn baking process for airflow alternate-operation flue-cured tobacco is the improvement on the existing intensive curing barn baking process. The improvement point is characterized inthat interval time for the alternate operation of airflow rise and airflow descending is as follows: in the low-temperature humidifying and yellowing stage: two airflow operation modes are provided, the time interval is 0.50 hour, and alternation is carried out once; in the stable-temperature dehumidifying and withering stage: two airflow operation modes are provided, the time interval is 0.50 hour, and alternation is carried out once; in the ventilating, dewatering and leaf-drying stage: two airflow operation modes are provided, the time interval is 0.75 hour, and alternation is carried out once; and in the temperature and moisture controlling and tendon drying stage: two airflow operation modes are provided, the time interval is 1.00 hour, and alternation is carried out once. Other baking operation technologies of the process are same with the conventional baking process. The intensive curing barn baking process can obviously improve the baking property of the tobacco loading chamber of the intensive curing barn, improve tobacco leaf baking quality, and improve the safety for baking the tobacco leaf. The intensive curing barn baking process is suitable for intensive baking underdifferent ecological environment conditions in the tobacco area in China.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

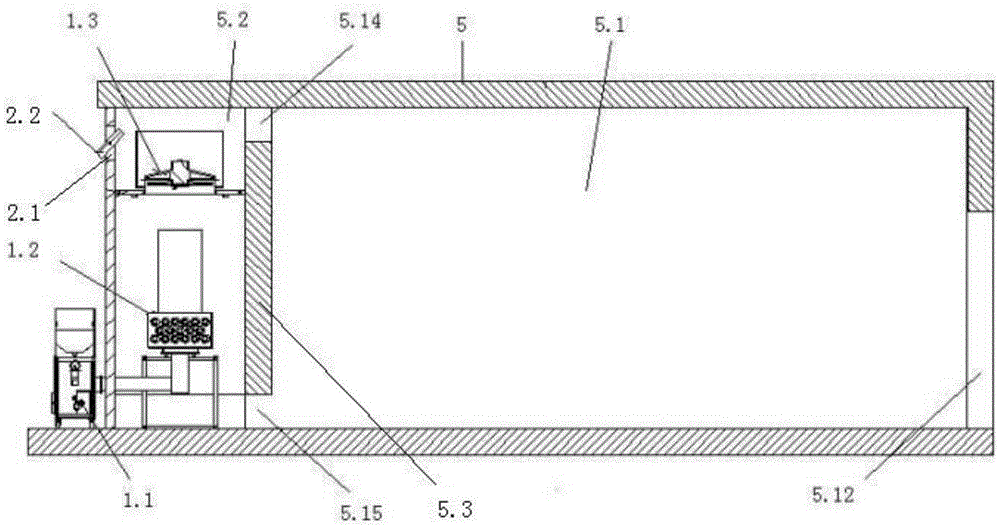

Sealed curing barn for tobacco leaf curing

The invention belongs to the technical field of tobacco leaf curing and particularly relates to a sealed curing barn for tobacco leaf curing. The sealed curing barn for the tobacco leaf curing comprises an equipment room and a tobacco containing room, the equipment room and the tobacco containing room are sealed, the whole tobacco leaf curing process is conducted in the sealed curing barn with no open window, the tobacco leaf aroma compositions and other gas compositions beneficial to improving the tobacco leaf curing quality volatilized in the tobacco leaf curing process are maintained in the sealed curing barn, therefore, the tobacco leaf curing quality is improved, and losses of curing barn dehumidification airflow waste heat are avoided to achieve the energy conservation and the emission reduction of the tobacco leaf curing.

Owner:云南中海路德清洁技术有限公司

Curing process of flue-curing barn

InactiveCN102499431AEffective reflection of qualityStable color fixationTobacco preparationOperabilityDry-bulb temperature

The invention discloses a curing process of a flue-curing barn, and belongs to the technical field of a tobacco curing. The process comprises the following steps: an ignition and temperature control stage: heating and roasting by utilizing an air source heat pump unit independently; tobacco leaf yellowing stage: heating and roasting by utilizing the air source heat pump unit independently; tobacco leaf color fixing stage: heating by utilizing the air source heat pump unit independently when a dry-bulb temperature is between 44 and 50 DEG C, and heating by using a coal burning boiler independently when the dry-bulb temperature rises to over 50 DEG C; and a tobacco leaf stem drying stage: heating by using the coal burning boiler independently. The curing process has the advantages of safetyand insurance, strong operability, stability of tobacco leaf color fixation, good leaf shrinkage, great improvement of flavor quantity of tar and tobacco leaves, is simple to operate; and the technical scheme of the roasting process has strong operability, so that the tobacco leaf curing quality and superior leaf ratio can be remarkably improved, the tobacco leaf dry matter consumption is reduced, and the roasting effects of saving energy, reducing emission, increasing quality and improving efficiency can be achieved.

Owner:LUZHOU CO LTD SICHUAN TOBACCO

Humidity stabilizing and temperature increasing bulk curing method for flue-cured tobaccos

The invention discloses a humidity stabilizing and temperature increasing bulk curing method for flue-cured tobaccos. The humidity stabilizing and temperature increasing bulk curing method for the flue-cured tobaccos includes humidity stabilizing and temperature increasing yellowing stages and humidity stabilizing and temperature increasing drying stages. The humidity stabilizing and temperature increasing bulk curing method has the advantages that the stability of the suitable tobacco leaf yellowing, color fixing and killing-out temperatures of wet bulbs can be maintained, the temperatures ofdry bulbs can be increased at different steps according to tobacco leaf curing target requirements, stability maintaining and slight increasing effects can be realized, tobacco leaf yellowing and dehydrating are coordinated with each other, drying and aroma enhancing are connected with each other, the curing failure rate can be reduced, and the curing quality can be improved; the humidity stabilizing and temperature increasing bulk curing method is simple and is easy to control during operation; the humidity stabilizing and temperature increasing bulk curing method is wide in application range and can be used for curing optional variety of tobacco leaves of excellent varieties which are popularized and applied in current flue-cured tobacco production.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

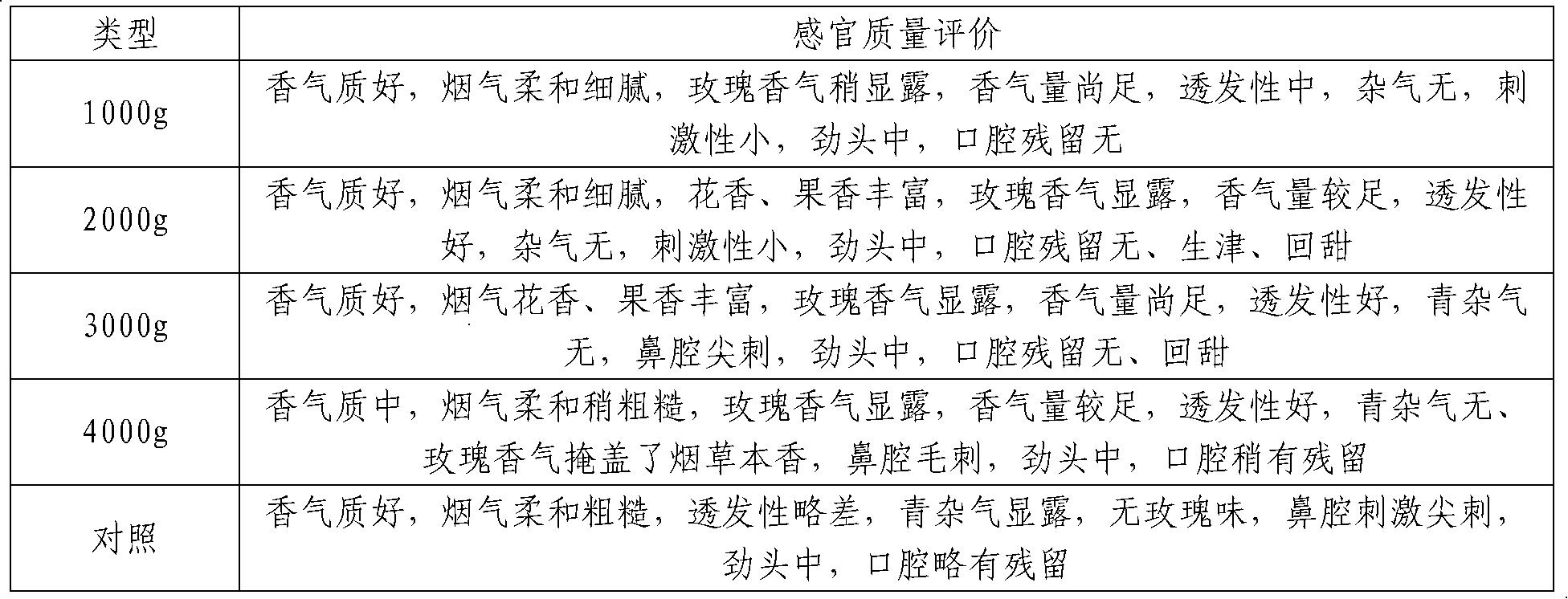

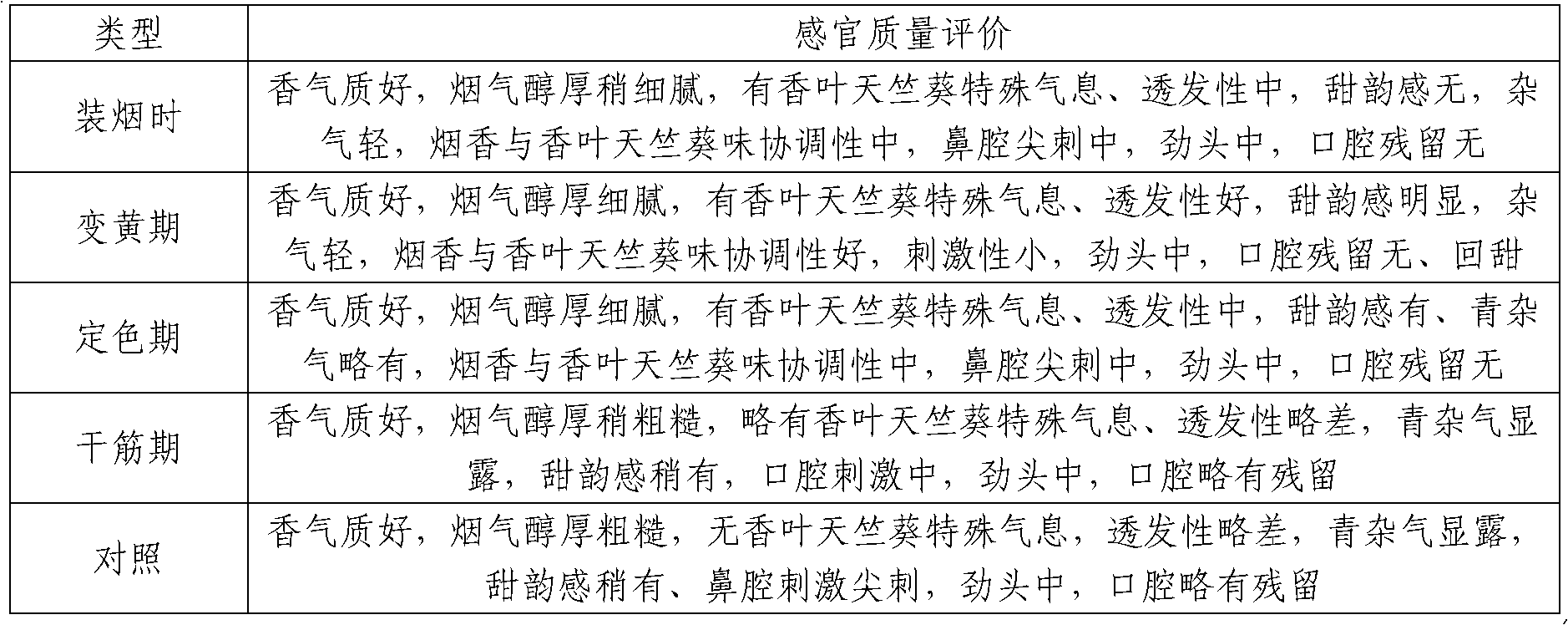

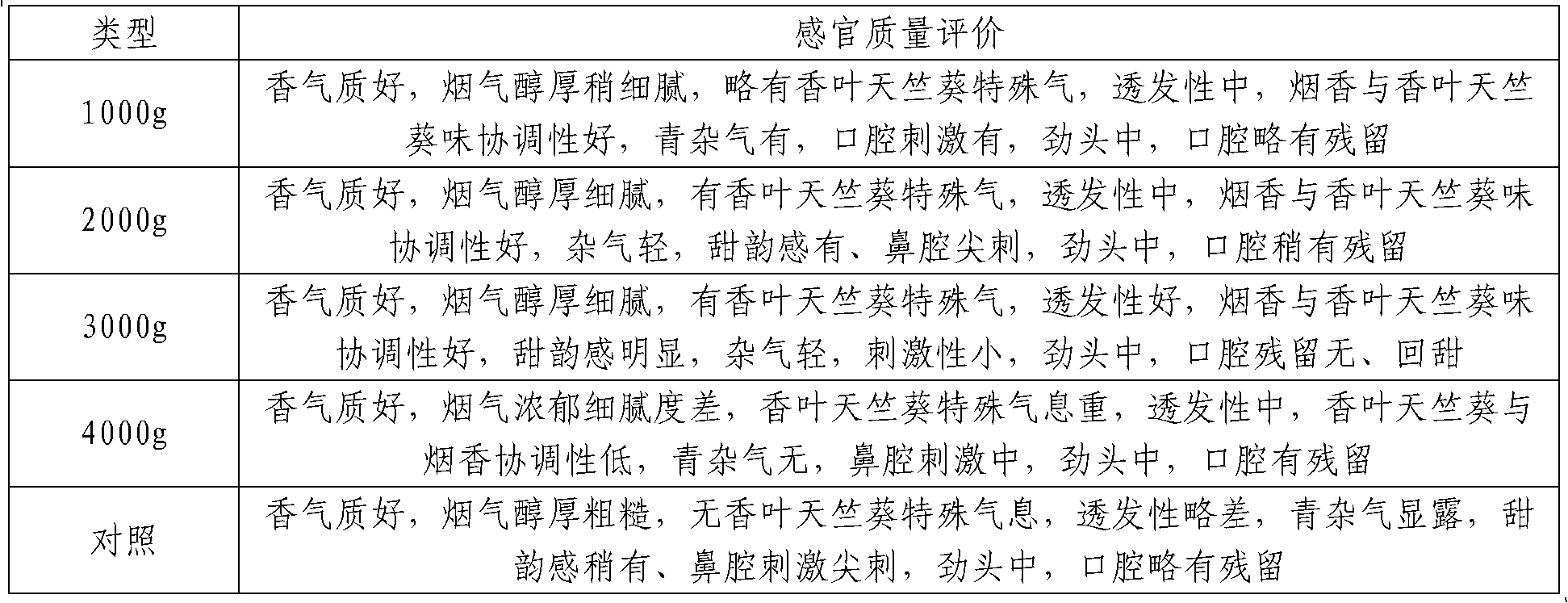

Method for flue-curing and perfuming tobacco by blending rose geranium in tobacco

The invention discloses a method for flue-curing and perfuming tobacco by blending rose geranium in tobacco. Fresh harvested tobacco leaves are numbered by poles and then loaded into dense curing barns; afterwards, rose geranium leaves are respectively placed in 4 to 8 breathable containers in the flue-curing and yellowing period of the tobacco leaves, distributed in positions at distances of 3 to 5 cm from the tobacco leaves on a bottom platform, and flue-cured for 120 to 140 hours; and the weight proportion of the rose geranium leaves to the tobacco leaves is 1: 2667. The method developing a new style has the advantages that the rose geranium is utilized to be baked with the tobacco leaves in the same barn; under the effects of humidity and temperature, volatile aromatic matters of the rose geranium are absorbed by cells of the tobacco leaves in a respiratory manner, so that aroma-active components of the rose geranium can be well solidified in the tobacco leaves, aromas of the tobacco leaf fragrance are richened, miscellaneous odor is concealed, the smoking taste is improved, the tobacco leaves are enabled to have full aromas and be rich in sweet sensation and special pleasant flavor of the rose geranium and the simulation of smoke gas is reduced, so that the tobacco leaves are enabled to have a particular smoking taste style and can satisfy the requirement of high-grade cigarette bands for high-quality raw materials.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com