Cured tobacco baking technique capable of improving quality and flavoring

A curing process and tobacco leaf technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems that have not been reported in public, and achieve the effects of good leaf shrinkage, easy operation, and stable yellow color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

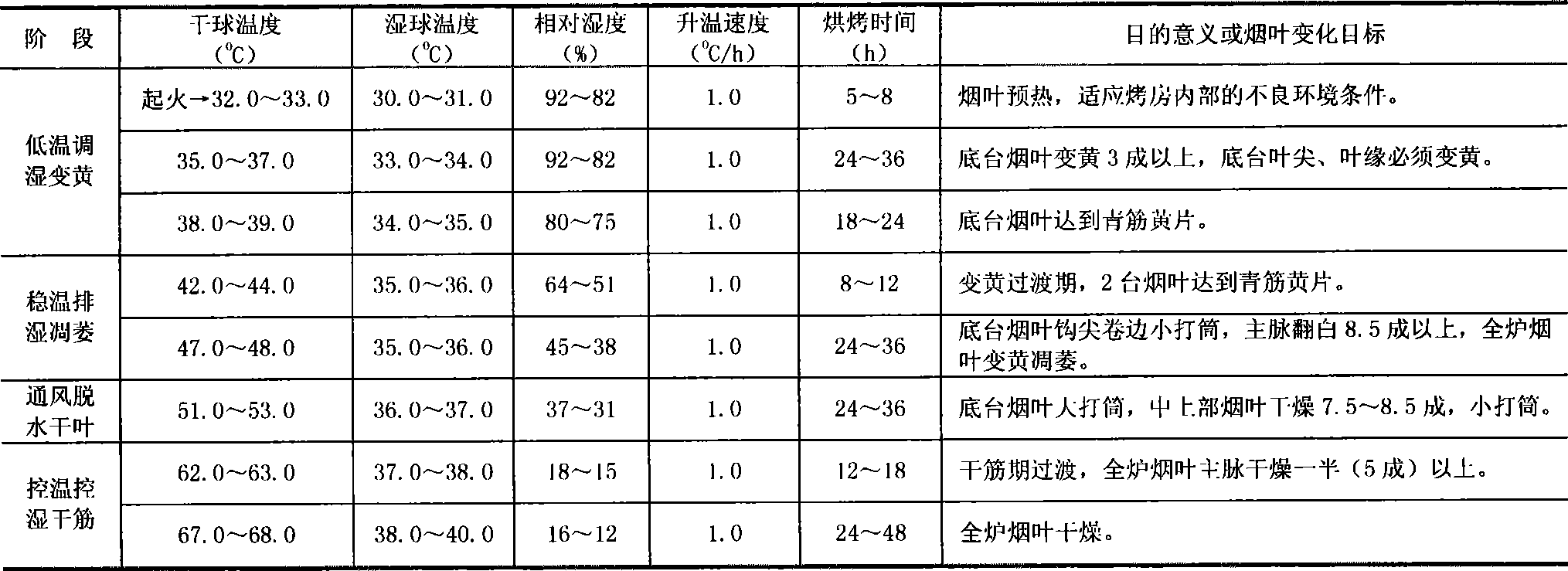

[0017] Embodiment 1: (common air-flow upward type curing barn tobacco leaf curing process)

[0018] ① Low temperature humidity control turns yellow

[0019] In the stage of tobacco leaves turning yellow under low temperature and humidity control, from the appearance of tobacco leaves to the internal physiology and biochemistry, the chemical composition that changes a lot is chlorophyll. The specific measures are: use lower temperature and slightly higher humidity to make the tobacco leaves heated→lose water→soften→collapse→turn yellow. The principle to master is "burning fire should be small and patient". "Loss of water is compatible with yellowing, and it turns yellow while draining moisture."

[0020] Before ignition, the exhaust window and air inlet tunnel are opened by 1 / 3 to 1 / 4. After firing, at an average heating rate of 1°C / h, within 14-17 hours, the dry bulb temperature of the bottom table will rise to 32-33°C, and the wet bulb temperature will reach 30-31°C, keepi...

Embodiment 2

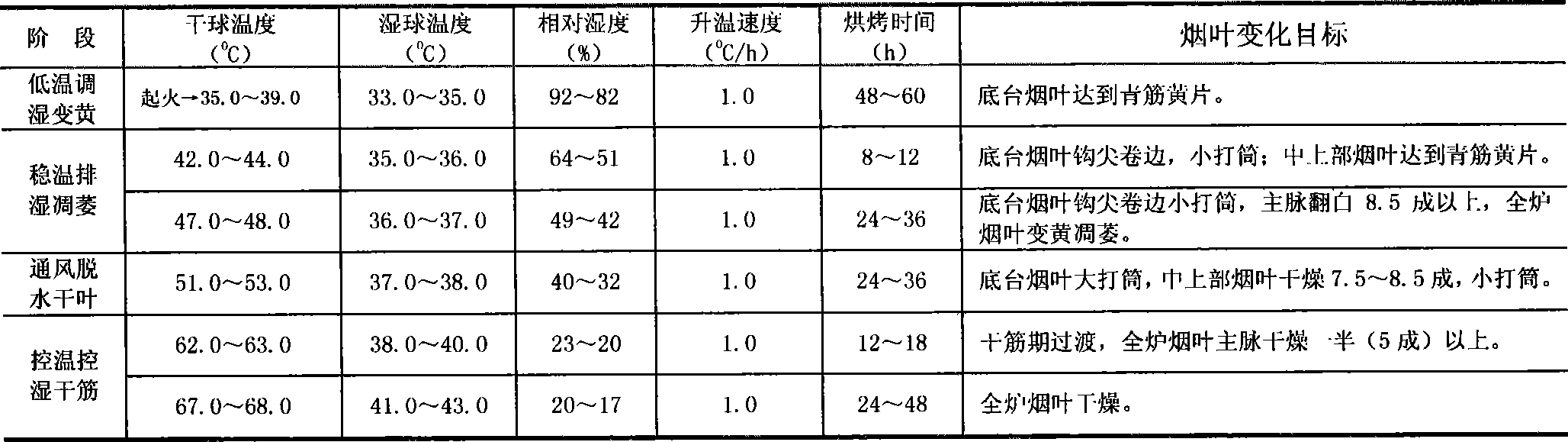

[0031] Embodiment 2: (intensive automated barn tobacco leaf curing process)

[0032] ① Low temperature humidity control turns yellow

[0033] During the yellowing period of tobacco leaves, the degradation of chlorophyll is the most influential factor from the appearance of tobacco leaves to the internal physiology and biochemistry. The specific measures are: under the conditions of appropriate low temperature and low humidity, the tobacco leaves are heated→losing water→softening→collapsing→turning yellow. The principle to master is: "Keep the fire small and patient." "Loss of water is compatible with yellowing, and it turns yellow while draining moisture." The key technology is "controlling humidity with temperature".

[0034] After a fire, with an average heating rate of 1°C / h, within 14-17 hours, the dry bulb temperature of the bottom platform will rise from the natural temperature to 35-39°C, the wet-bulb temperature will reach 33-35°C, and the relative humidity will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com