Method for preparing hydrocarbons matter with biological oil and fat

A bio-oil and substance technology, applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, petroleum industry, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

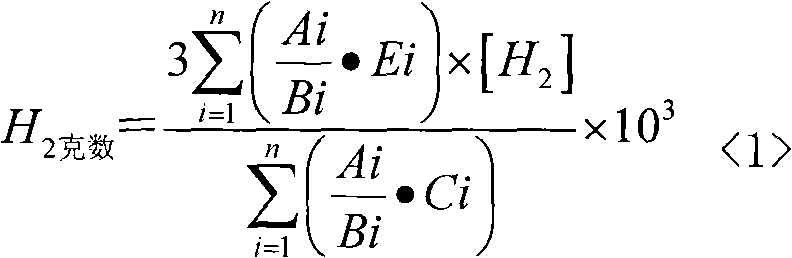

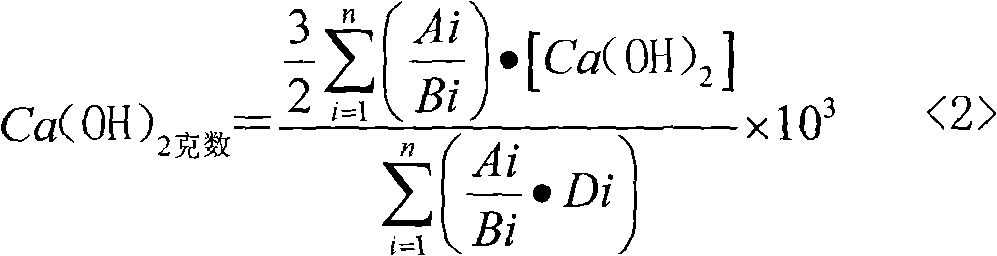

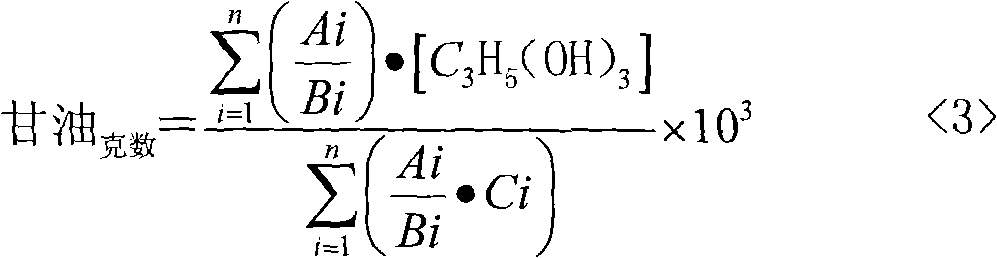

Method used

Image

Examples

Embodiment 1

[0214] Preparation of hydrocarbon components from tallow

[0215] 1) Steps to obtain tallow tallow by hot pressing: peel off the outer wax layer of tallow tallow seeds, dry and heat the tallow tallow by hot pressing at about 73°C, and obtain tallow tallow by suction filtration. The product is pure tallow tallow, and at the same time press the cake into Honeycomb coal shape, for the energy required for the whole process;

[0216] 2) Full hydrogenation step: add 23.487 grams of hydrogen to 1 kg of tallow tallow obtained in step 1) to make tallow tallow full hydrogenated. Process conditions: continuous catalytic hydrogenation process device, catalyst: fixed bed nickel catalyst, temperature control 200 ℃, pressure control 1.2MPa, the product is fully saturated tallow;

[0217] 3) Total calcium saponification step: add 133.0995 grams of anhydrous calcium hydride to 1 kg of fully saturated tallow tallow obtained in step 2) to saponify fatty acid total calcium. Process conditions: ...

Embodiment 2

[0224] Preparation of hydrocarbon components from camphor resin

[0225] 1) Steps to obtain camphor resin by hot pressing: peel off the seed core of camphor seed, heat it through hot pressing after drying at about 60°C, filter to obtain camphor resin, remove impurities by vacuum filtration while it is hot, and press the cake into Honeycomb briquettes for the energy needed for the whole process: the product is pure camphor;

[0226] 2) Full hydrogenation step: add 0.785 g of hydrogen to 1 kg of camphor obtained in step 1) to fully hydrogenate the camphor. Process conditions: continuous catalytic hydrogenation process device, catalyst: fixed bed nickel catalyst. The temperature is controlled at 240°C, the pressure is controlled at 0.8MPa, and the product is fully saturated camphor;

[0227] 3) Total calcium saponification step: 1 kg of fully saturated camphor fat obtained in step 2) is added to 182.2920 grams of anhydrous calcium hydroxide to saponify fatty acid total calcium....

Embodiment 3

[0232] Preparation of hydrocarbons from canola oil

[0233] High erucic acid rapeseed oil is rich in a fatty acid called erucic acid. Its molecule is docos-one-enoic acid, and its saturation degree is higher than that of small-molecular-weight mono-enoic acid. Therefore, the whole oil The degree of saturation is relatively high, which seems to be suitable for making fuel oil with the present invention.

[0234] "821" is a famous high-erucic acid rapeseed variety in my country. It is resistant to insects, diseases and stresses, and its yield per mu and oil content are not low. However, because its oil is rich in erucic acid, it is not good for human health. Therefore, high erucic acid rapeseed varieties including "821" have been eliminated in my country. However, due to their extensive cultivation, disease resistance and stress resistance, the production conditions are not high, and they can be propagated in large numbers in rice fallow fields for other uses. Now, an example o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com