Single-crystal lithium nickel cobalt manganate precursor and preparation method thereof and single-crystal lithium nickel cobalt manganate

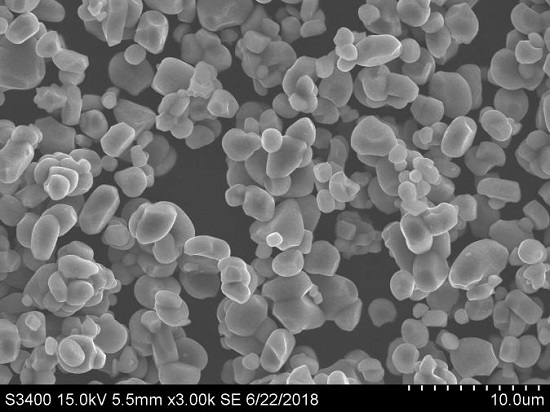

A technology of nickel-cobalt lithium manganese oxide and precursors, which is applied in the field of cathode materials for lithium-ion batteries, and can solve the problems of large median particle size of secondary particles, low electrical energy density, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

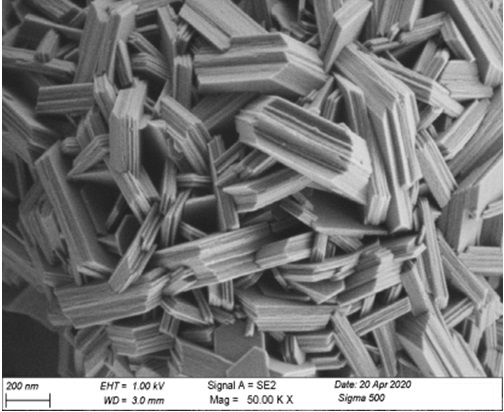

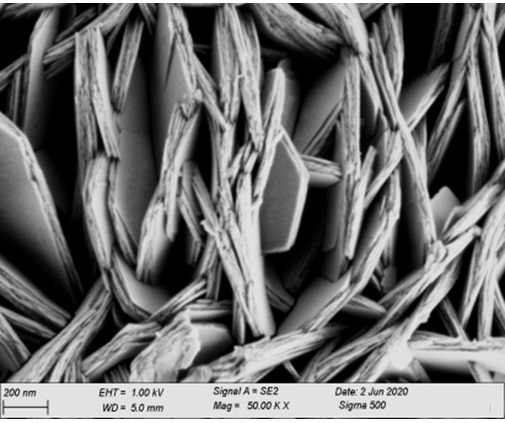

Image

Examples

Embodiment 1

[0034] 1. Prepare a single crystal nickel cobalt lithium manganate precursor, the steps are as follows:

[0035] Step 1, according to Ni:Co:Mn:Zr molar ratio 0.65:0.15:0.19:0.01 is mixed with the nickel, cobalt, manganese, zirconium mixed salt solution that total metal ion concentration is 1.5mol / L; Preparation concentration is 6mol / L NaOH aqueous solution; the preparation concentration is 8mol / L ammonia solution.

[0036] Step 2: Add the above-mentioned NaOH aqueous solution and ammonia solution to the sealed reaction kettle to form a bottom liquid, adjust its pH to 10.0-11.0, and make the bottom liquid account for 40% of the volume of the reaction kettle.

[0037] Step 3, continue to feed the mixed gas into the reaction kettle, the volume ratio of oxygen and non-oxygen in the mixed gas is 1:19, the flow rate of the mixed gas is 12L / min, turn on the stirring device, the stirring speed is 400rpm, and continuously add the Prepared mixed salt solution, NaOH aqueous solution and...

Embodiment 2

[0084] 1. Prepare a single crystal nickel cobalt lithium manganate precursor, the steps are as follows:

[0085] Step 1, press Ni:Co:Mn:Ca molar ratio 0.70:0.10:0.19:0.01 to be mixed with the nickel, cobalt, manganese, calcium mixed salt solution that total metal ion concentration is 1.5mol / L; Preparation concentration is 6mol / L NaOH aqueous solution; the preparation concentration is 8mol / L ammonia solution.

[0086] Step 2: Add the above-mentioned NaOH aqueous solution and ammonia solution to the sealed reaction kettle to form a bottom liquid, adjust its pH to 10.0-11.0, and make the bottom liquid account for 60% of the volume of the reaction kettle.

[0087] Step 3, continue to feed the mixed gas into the reaction kettle, the volume ratio of oxygen and non-oxygen in the mixed gas is 1:23, the flow rate of the mixed gas is 7L / min, turn on the stirring device, the stirring speed is 100rpm, and continuously add the Mixed salt solution, NaOH aqueous solution and ammonia solutio...

Embodiment 3

[0096] 1. Prepare a single crystal nickel cobalt lithium manganate precursor, the steps are as follows:

[0097] Step 1, press Ni:Co:Mn:Mg molar ratio 0.75:0.12:0.12:0.01 to be mixed with the nickel, cobalt, manganese, calcium mixed salt solution that total metal ion concentration is 1.5mol / L; Preparation concentration is 6mol / L NaOH aqueous solution; the preparation concentration is 8mol / L ammonia solution.

[0098] Step 2: Add the above-mentioned NaOH aqueous solution and ammonia solution to the sealed reaction kettle to form a bottom liquid, adjust its pH to 10.0-11.0, and make the bottom liquid account for 90% of the volume of the reaction kettle.

[0099] Step 3, continue to feed the mixed gas into the reaction kettle, the volume ratio of oxygen and non-oxygen in the mixed gas is 1:29, the flow rate of the mixed gas is 20L / min, turn on the stirring device, the stirring speed is 500rpm, and continuously add the Prepared mixed salt solution, NaOH aqueous solution and ammon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com