Self-compacting concrete prepared from recycled aggregate and preparation method thereof

A self-compacting concrete and recycled aggregate technology, applied in the field of building materials, can solve the problems of reduced mechanical properties of concrete materials, poor compactness of recycled aggregates, and increased water-cement ratio in the interface transition zone of new cement mortar, etc., to achieve improvement Mechanical strength, good dispersion effect, effect of improving dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

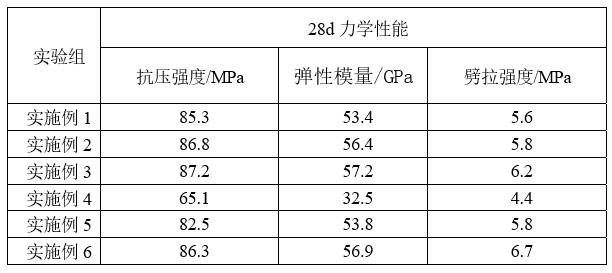

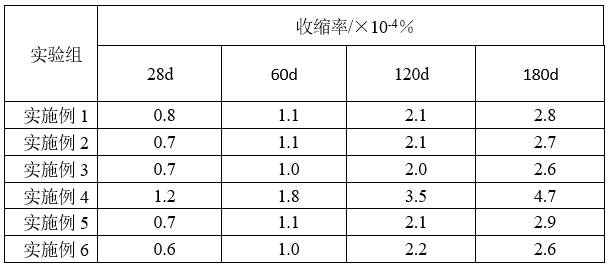

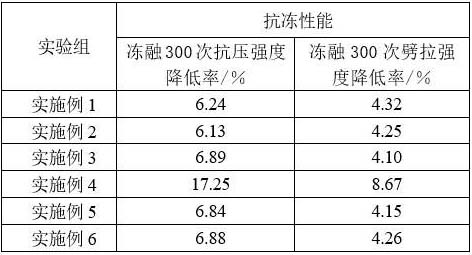

Examples

Embodiment 1

[0031] Parts by weight basis, 45 parts of acetone were weighed, and 10 parts of 3 parts of silicon carbide nanometers silane coupling agent KH-560 was placed in a stirring device, stirring and mixing using triethylamine adjusted to pH 4.5, and collecting the mixture 200W was placed at an ultrasonic dispersion 10min, dispersed suspension were collected and placed at 200 ℃ dried 3h, left to cool to room temperature and grind to obtain modified nano silicon carbide particles;

[0032] Mass ratio of 1: 3: 15, modified nano silicon carbide particles, fly ash is added to a solids content of 28% water glass, mixed by stirring and placed under 200W ultrasonic dispersion 10min, collected liquid coating modification; after 5, was added to the recycled aggregate cOATED liquid, after pressure to 3MPa, pressure treatment after soaking 25min, 25min and then treated in the ultrasonic vibration 200W, soaking taken: taking recycled aggregate mass ratio of 1 press aggregate and placed to dry at roo...

Embodiment 2

[0034] According to the weight of the weight, 47 parts of acetone, 12 parts of nanocarbium carbide and 4 parts of silane coupling KH-560, respectively, were placed in a stirring device, stirred and mixed with triethylamine and adjusted pH to 4.7, collecting mixed liquid parallel The ultrasonic dispersion was dispersed at 250w, and the dispersion suspension was collected and dried at 210 ° C for 4 h, and the sedation was allowed to cool to room temperature and crushed, and the nano silicon carbide particles were changed.

[0035] According to the mass ratio 1: 3: 15, the modified nano silicon carbide particles, fly ash addition to a water glass having a solid content of 28%, stirred and mixed with ultrasonic dispersion of 250W, and the coated modified liquid is collected; Reproduced aggregates and by mass 1: 5, the regenerated aggregate was added to the coated modified solution, pressurized to 4 MPa, after pressure soaking treatment 27min, then the ultrasonic vibration treatment of 2...

Embodiment 3

[0038] According to the weight of the weight, 50 parts of acetone, 15 parts of nanocarbium carbide and 5 parts of the coupling agent were weighed, and the mixture was stirred and mixed with triethylamine and mixed with mixed liquid and placed under 300W. Ultrasonic dispersion 15min, collects the dispersion suspension and dried at 220 ° C for 5 h, and allows for cooling to room temperature and ground pulverization, modified nano silicon carbide particles;

[0039] According to the mass ratio of 1: 3: 15, the modified nanocarbium carbide particles, the fly ash addition to a solid content of 28%, stirred mixed and placed at 300W, ultrasonic dispersion 15min, and collectively modified liquid; Reproduced aggregates and add the regenerated aggregate to the coated modified liquid, pressurized to 5 MPa, pressurized to 5 MPa, and then the ultrasonic vibration of 30 min at 300 w, after removing soaking The aggregate is placed at room temperature, and the concrete after drying is placed in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com