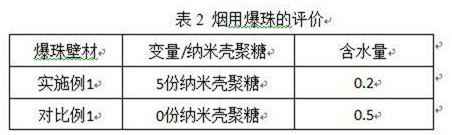

Patents

Literature

32results about How to "Improve dense structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

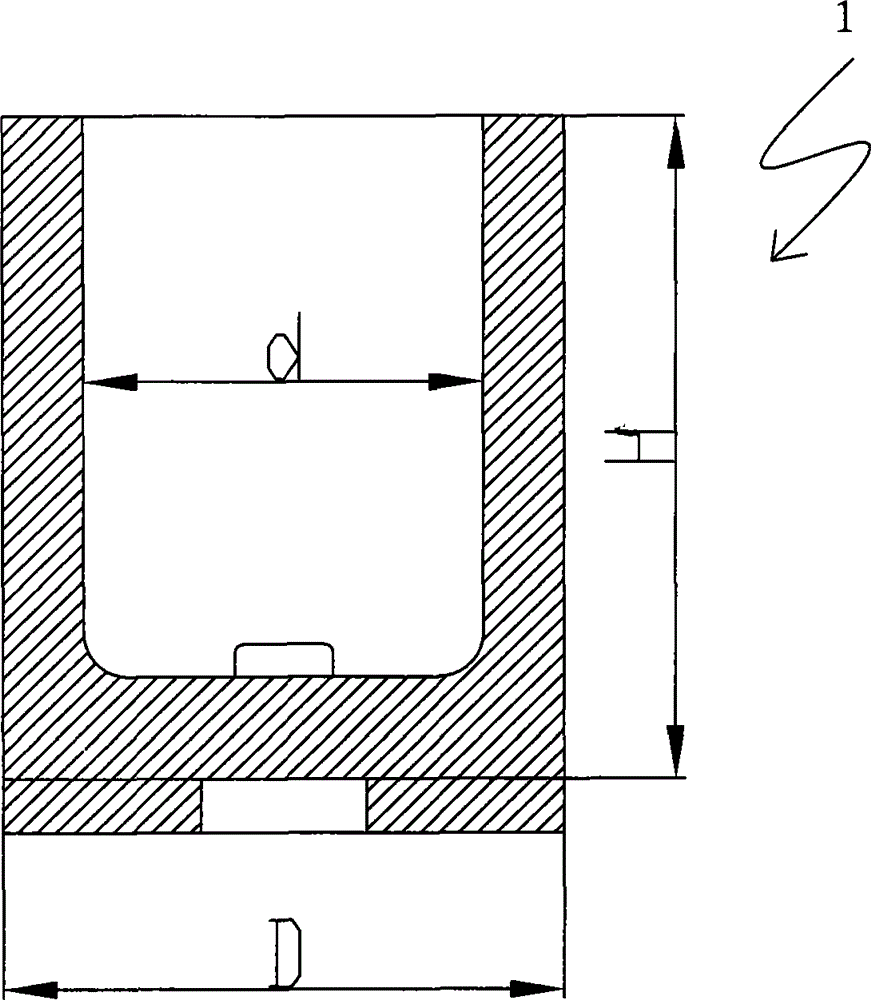

Differential-speed extrusion forming method of magnesium alloy high performance cup-shaped piece

ActiveCN106607468AIncrease the number of deformationsIncrease the amount of plastic deformationExtrusion diesChinese charactersHigh density

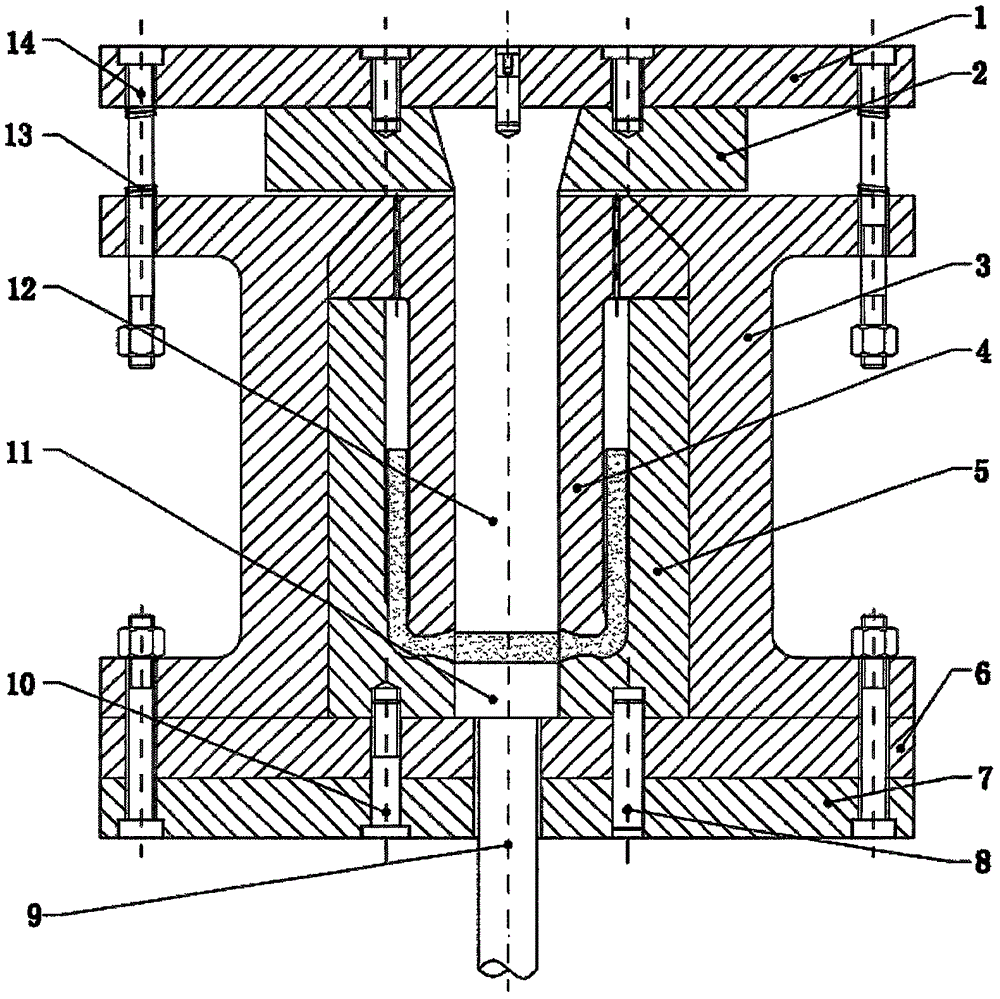

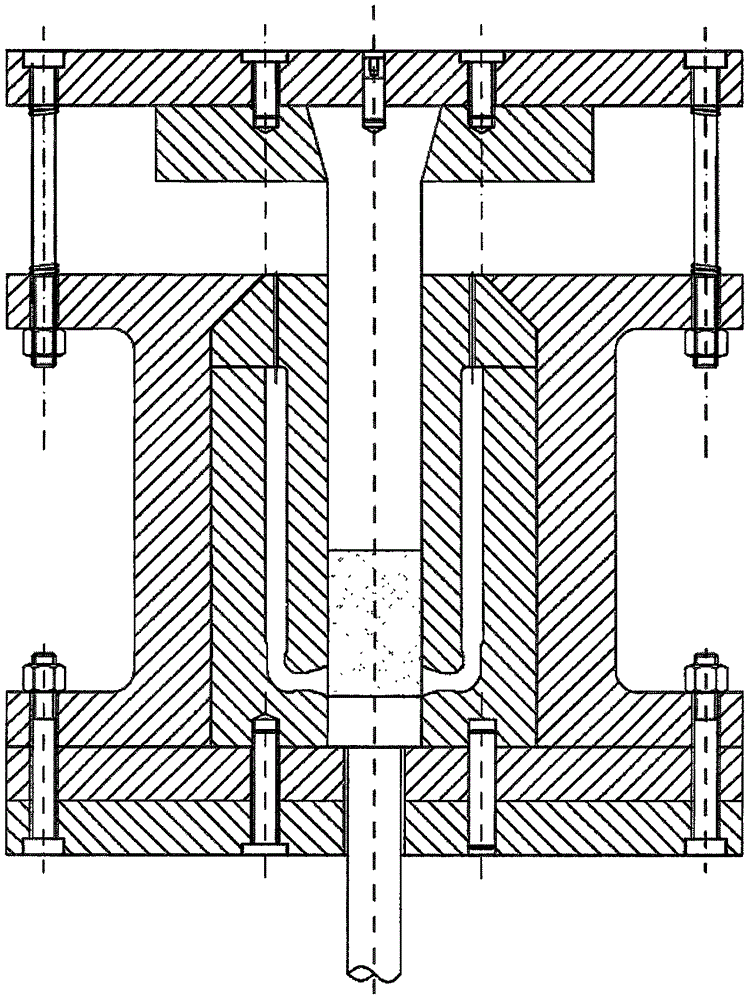

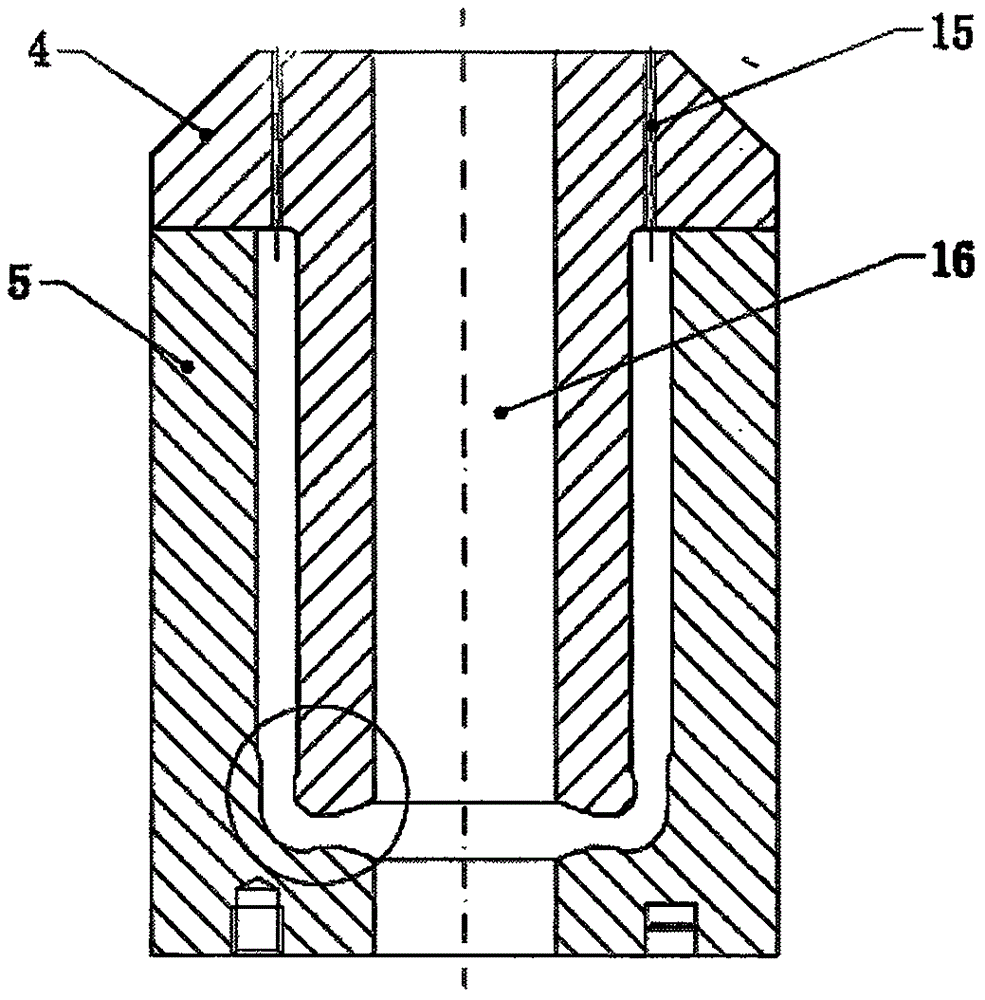

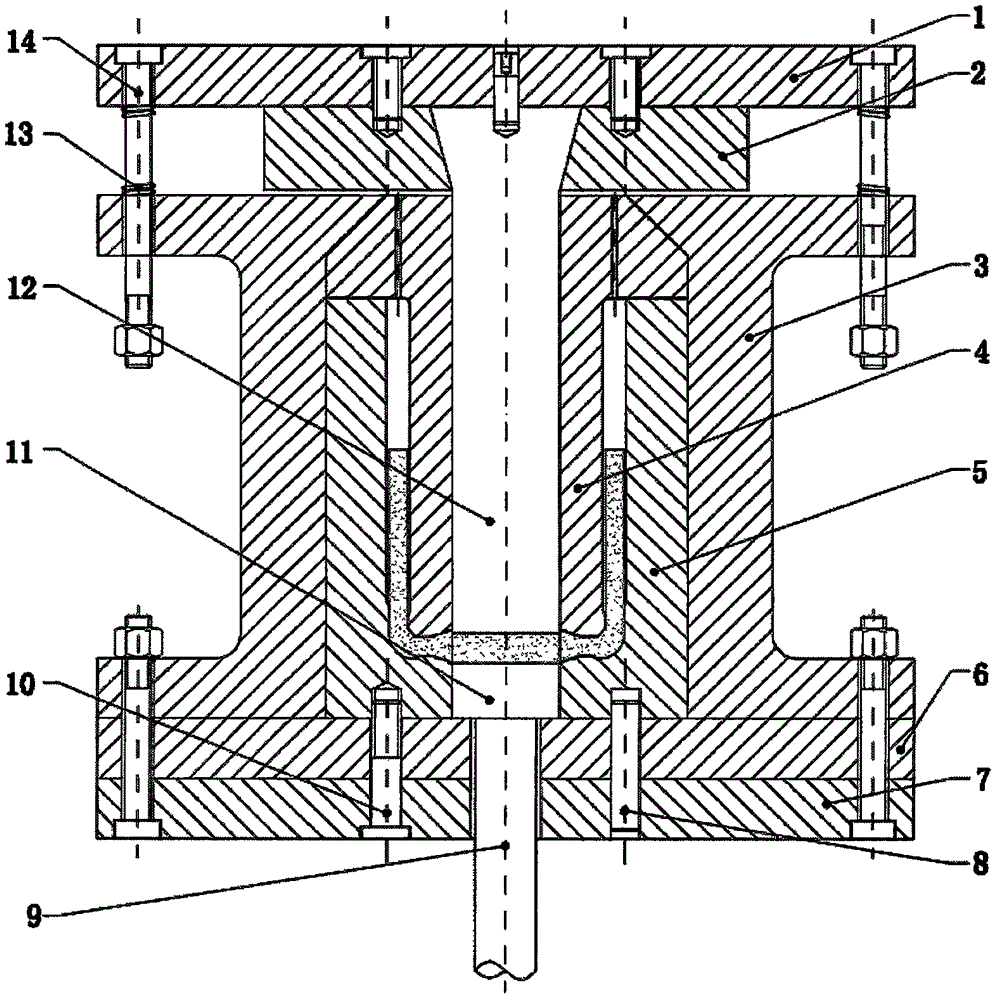

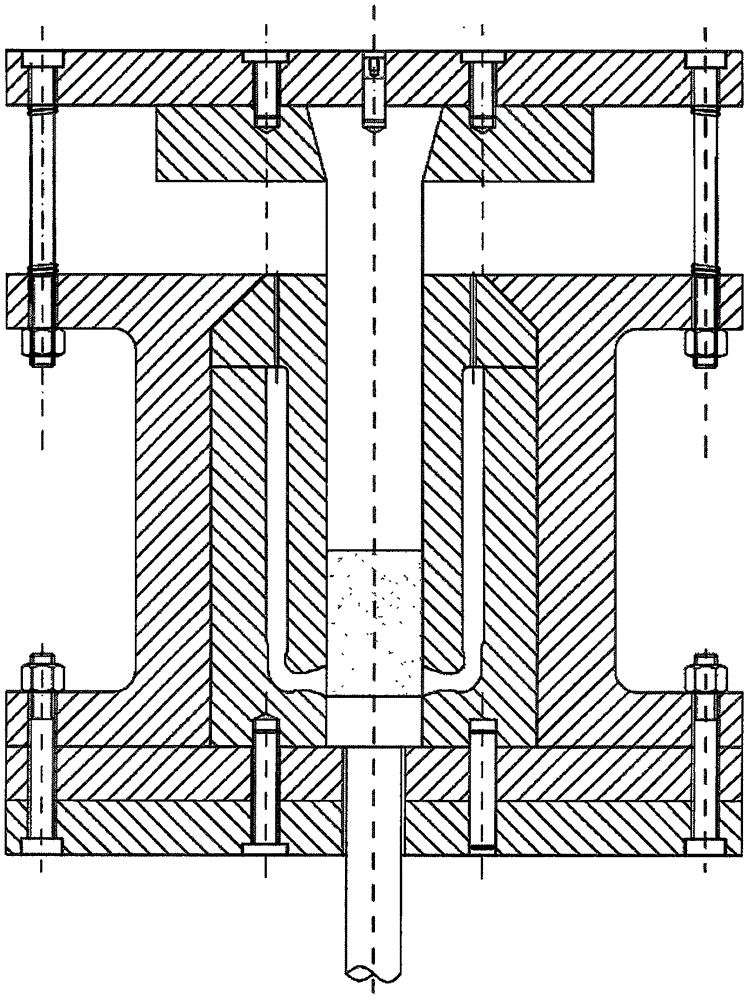

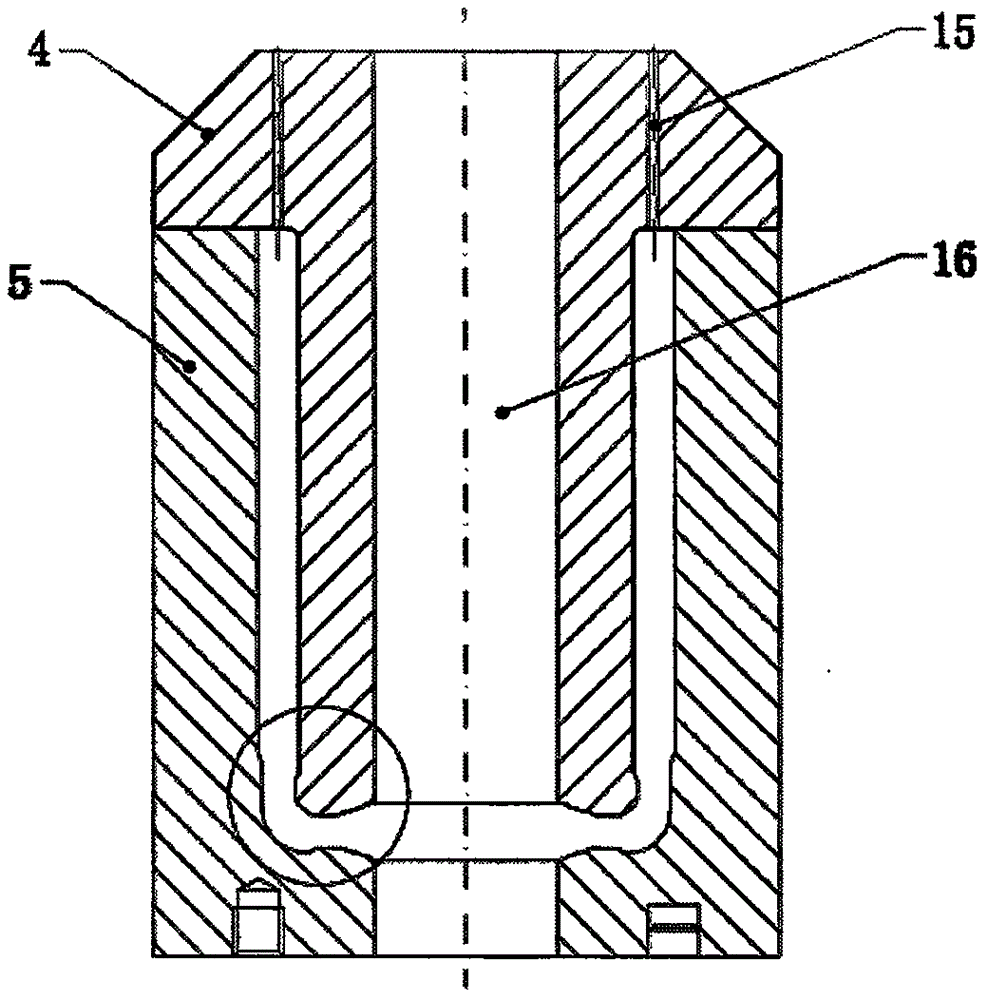

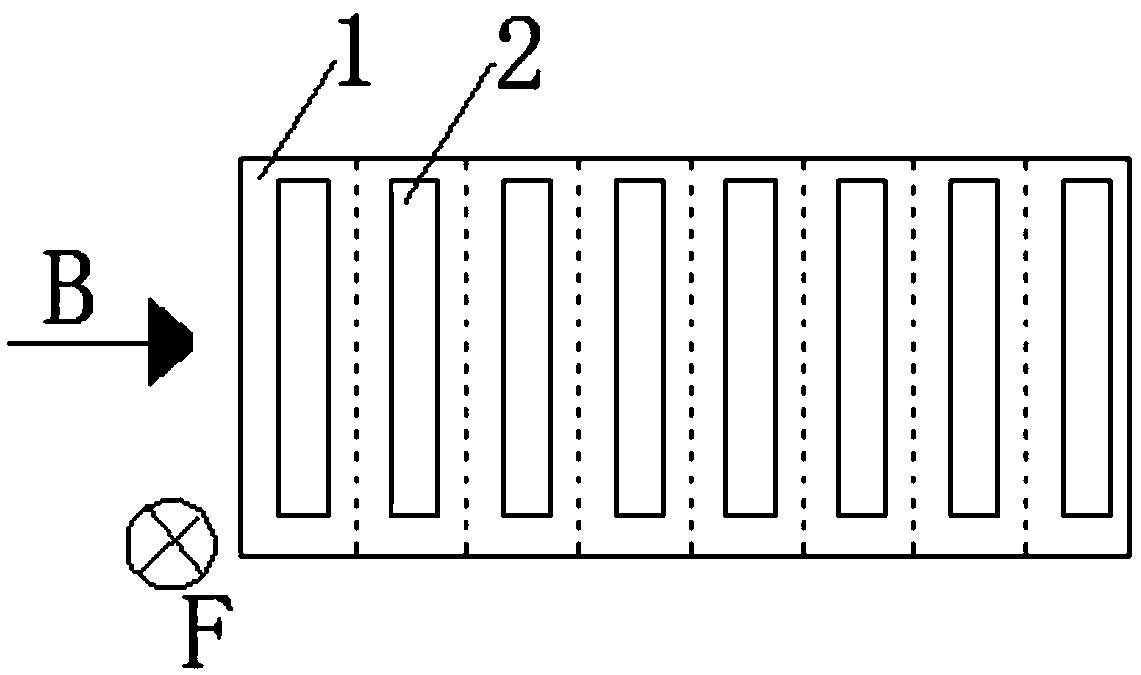

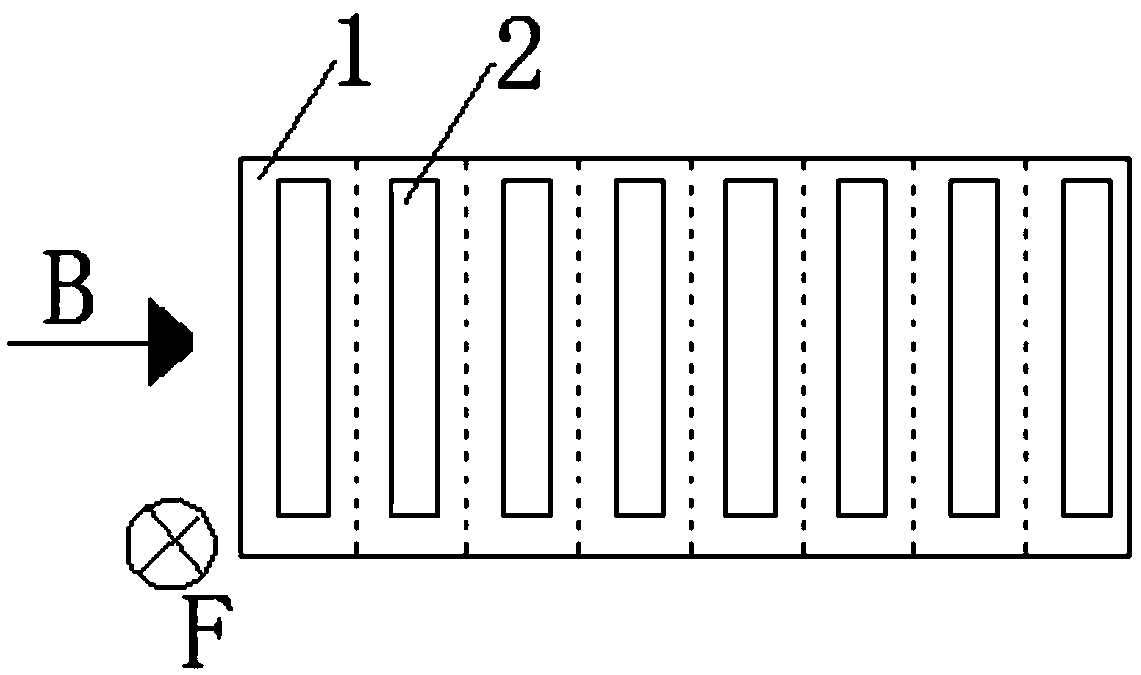

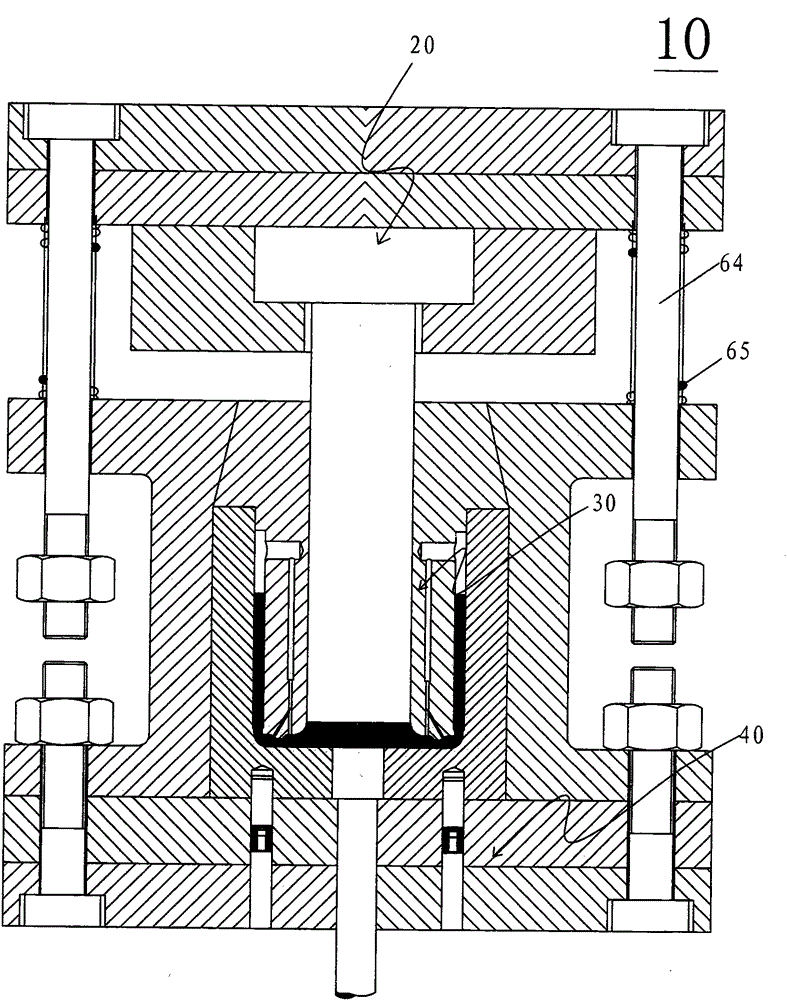

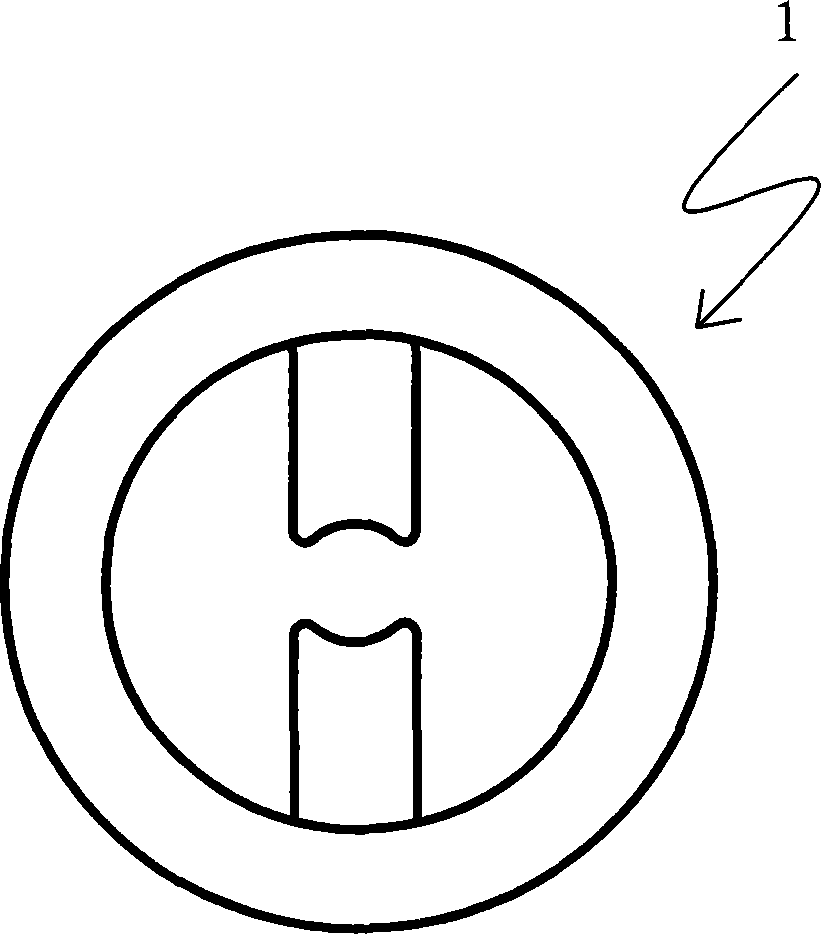

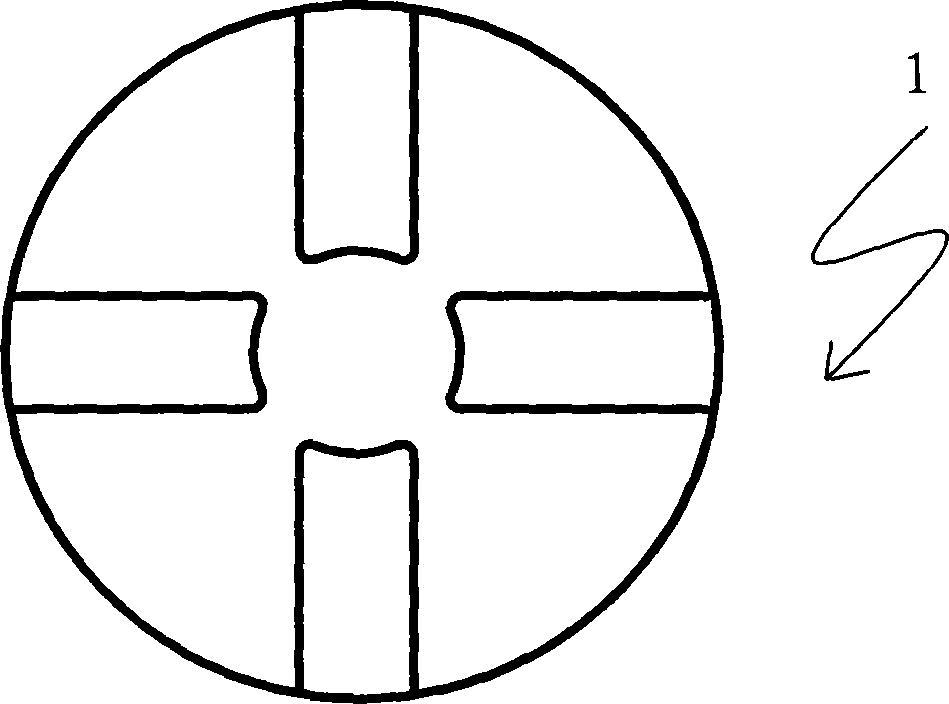

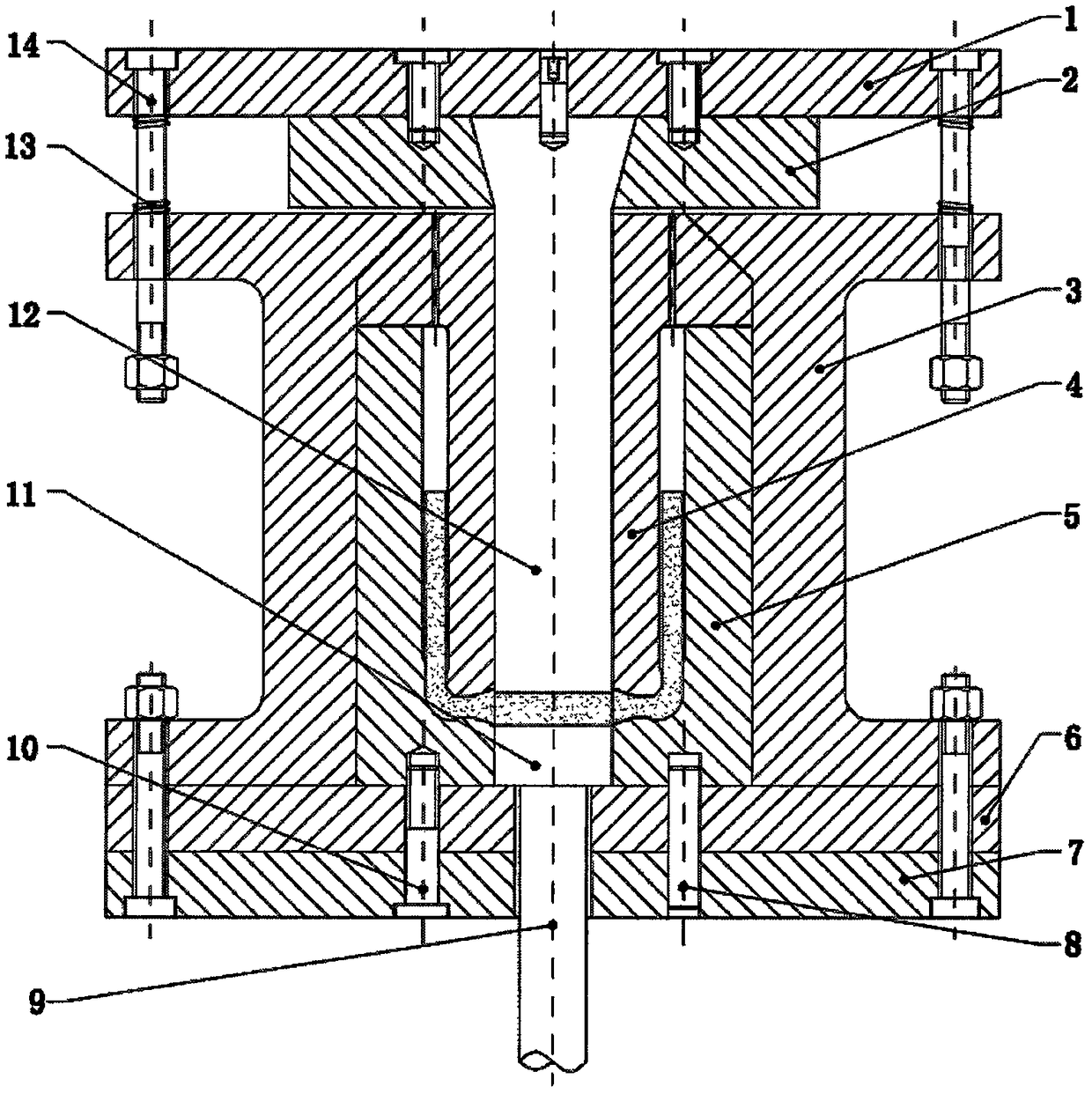

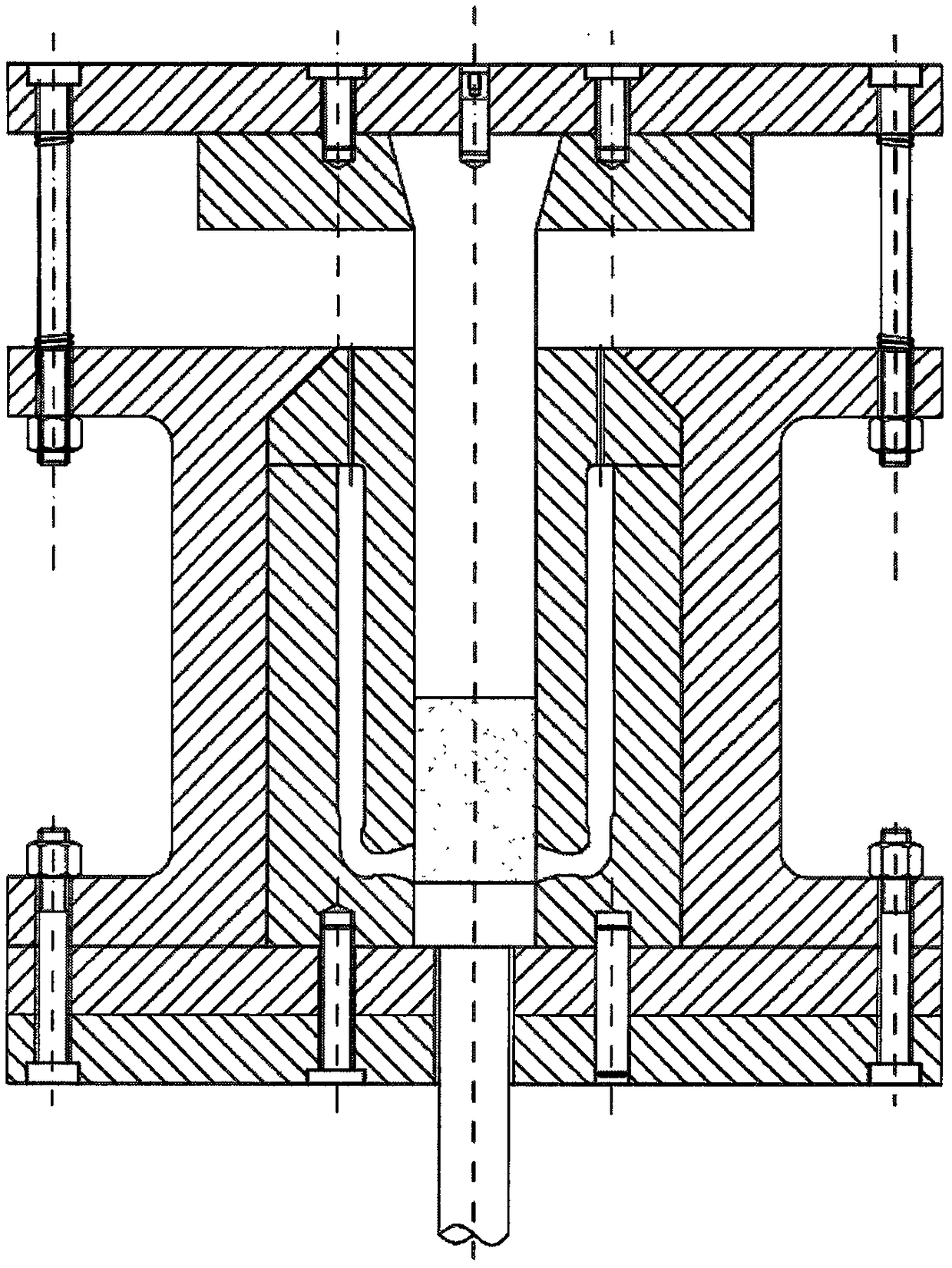

The invention provides a differential-speed extrusion forming method of a magnesium alloy high performance cup-shaped piece and relates to the technical field of metal and plastic machining and forming. A combined concave die is adopted and comprises a T-shaped upper concave die body and a U-shaped lower concave die body. The T-shaped upper concave die body is internally provided with a cylindrical cavity and installed on the U-shaped lower concave die body, and the section of a formed revolved cavity is shaped like a Chinese character 'shan'. Staggered 'ladder' type differential-speed extrusion steps are adopted for the bottom of the extrusion cavity shaped like the Chinese character 'shan'. Three stages of deformation are conducted, the first stage is the axial similar cylinder pier coarse deformation stage, the second stage is the radial extrusion large deformation stage, and the third stage is the corner extrusion and shearing deformation stage. The extrusion cavity shaped like the Chinese character 'shan' and the staggered 'ladder' type differential-speed extrusion steps at the cavity bottom are adopted for extruding the magnesium alloy high performance cup-shaped piece, the magnesium alloy material forming capacity is greatly improved, a high-density structure is obtained, great plastic deformation is obtained, the grain refining effect is remarkable, the effect of eliminating grain dual-mode distribution of the barrel wall of the cup-shaped piece is obvious, and the fabrication procedure of the high performance magnesium alloy cup-shaped piece is shortened.

Owner:ZHONGBEI UNIV

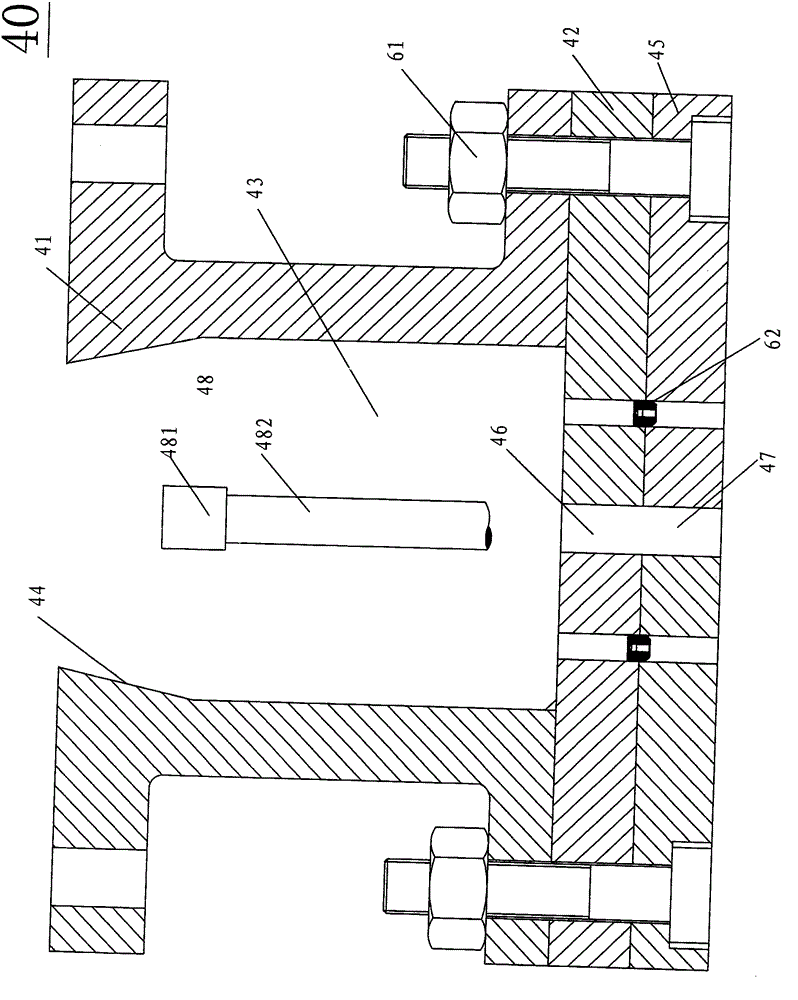

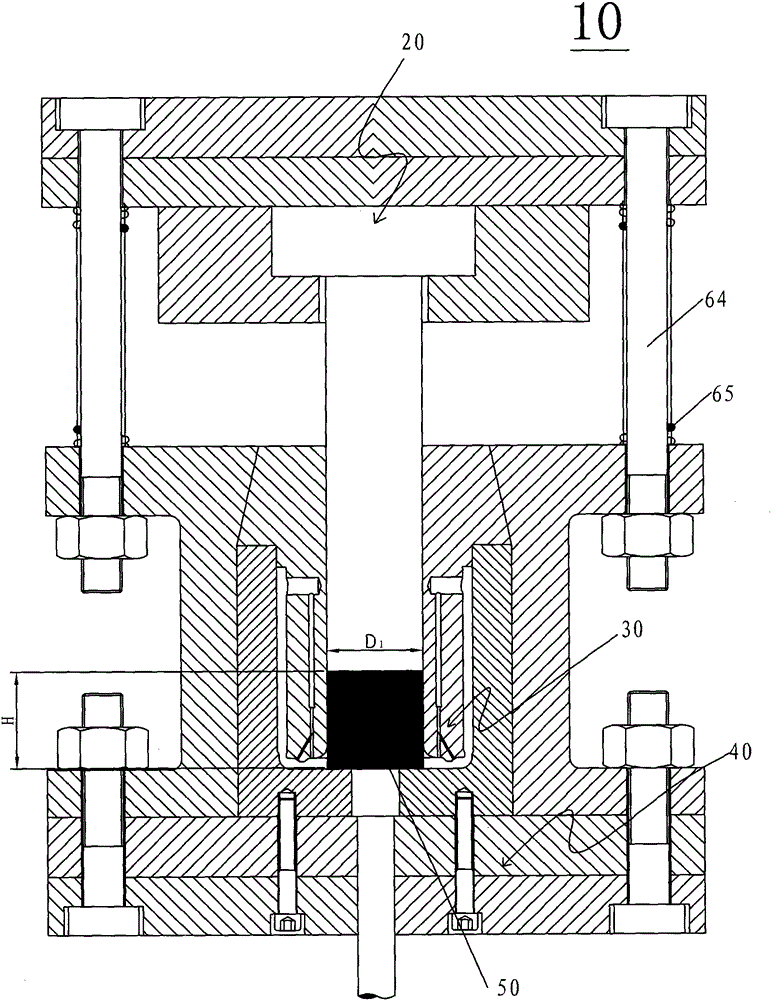

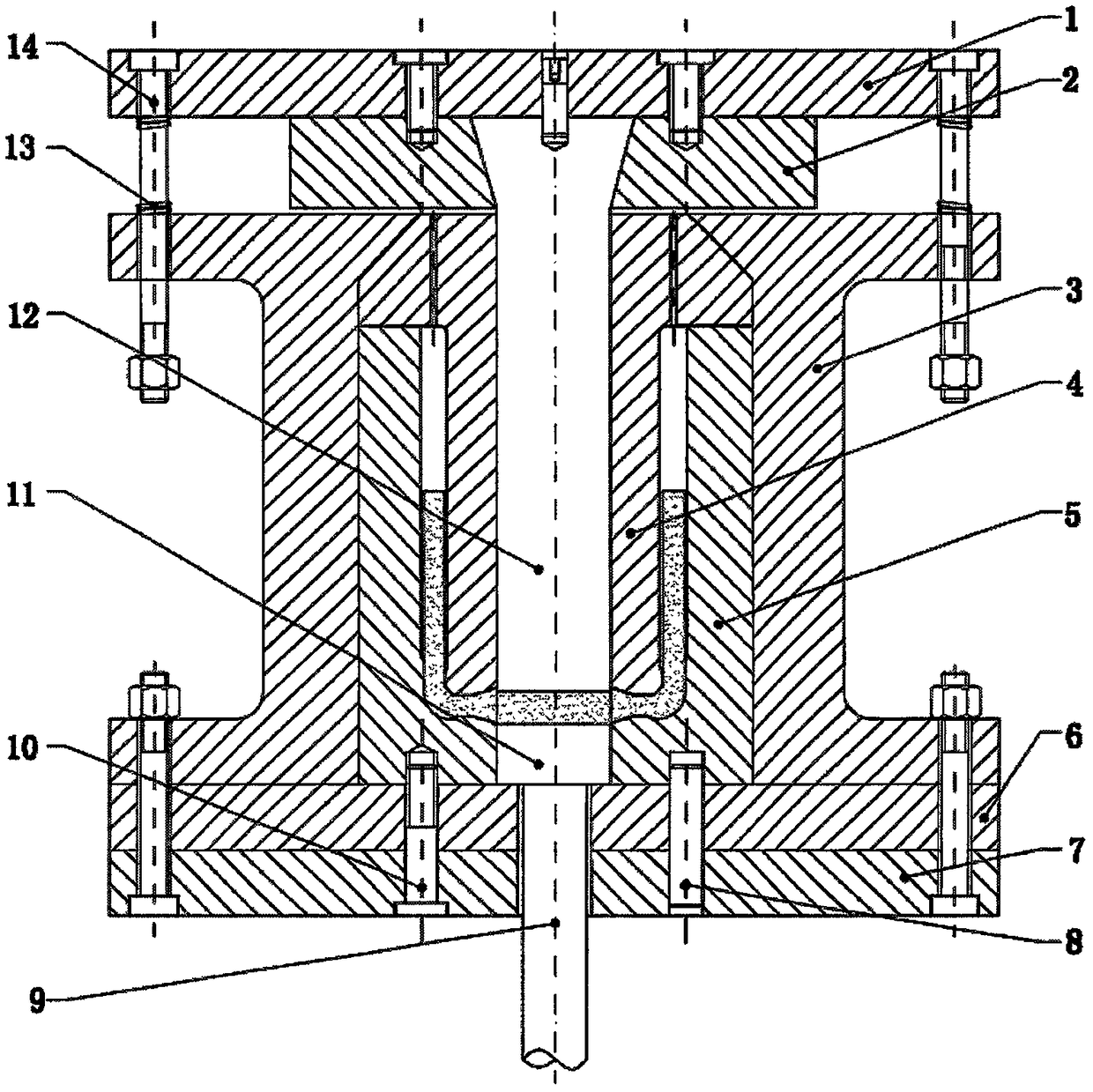

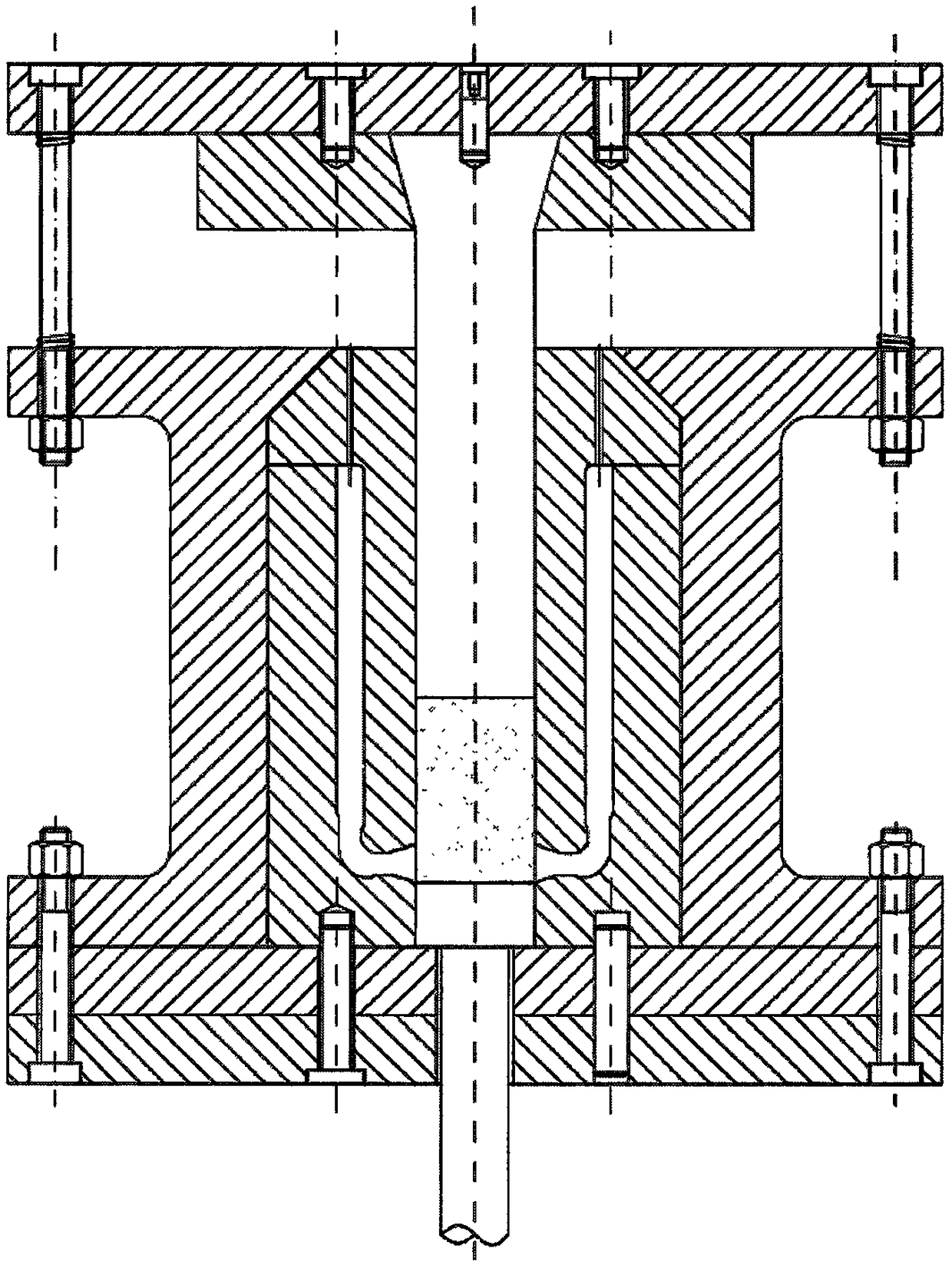

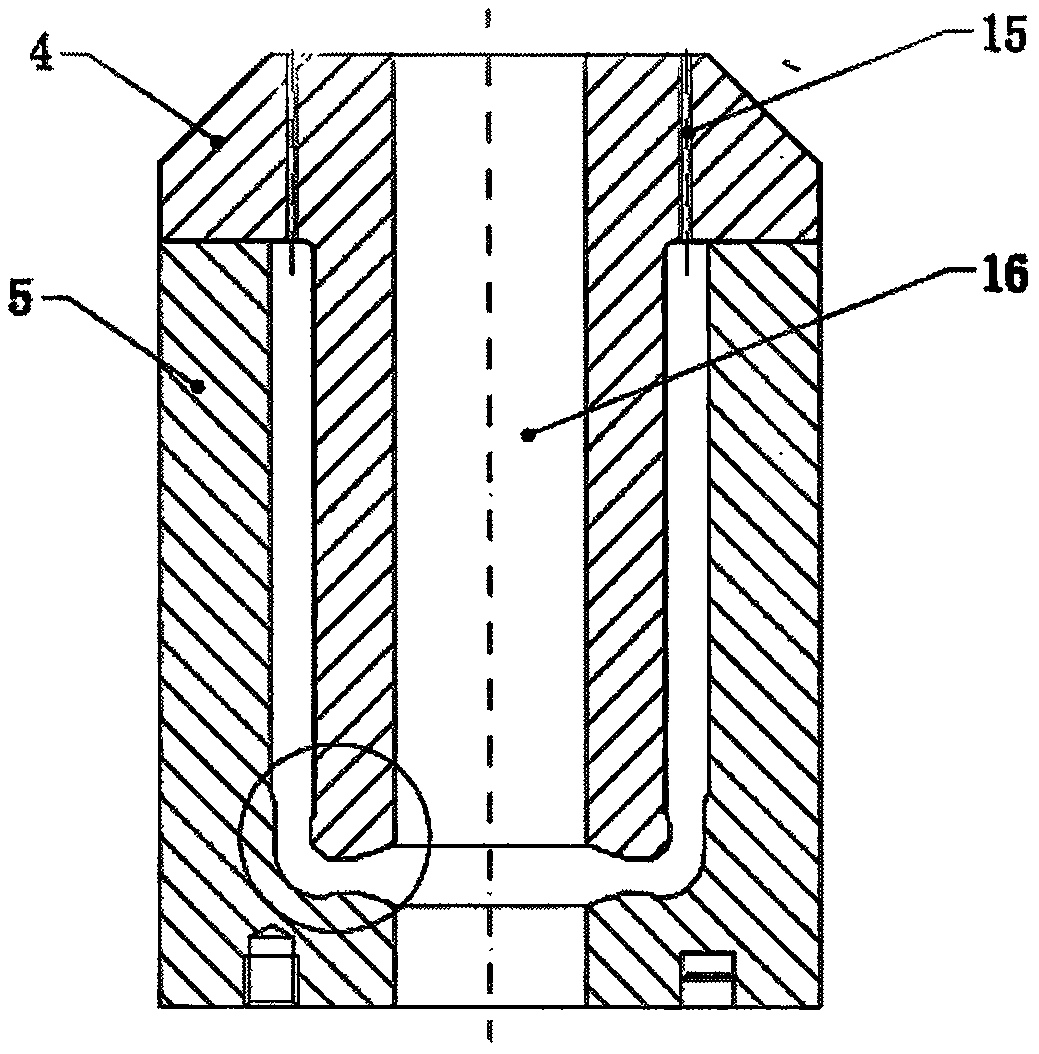

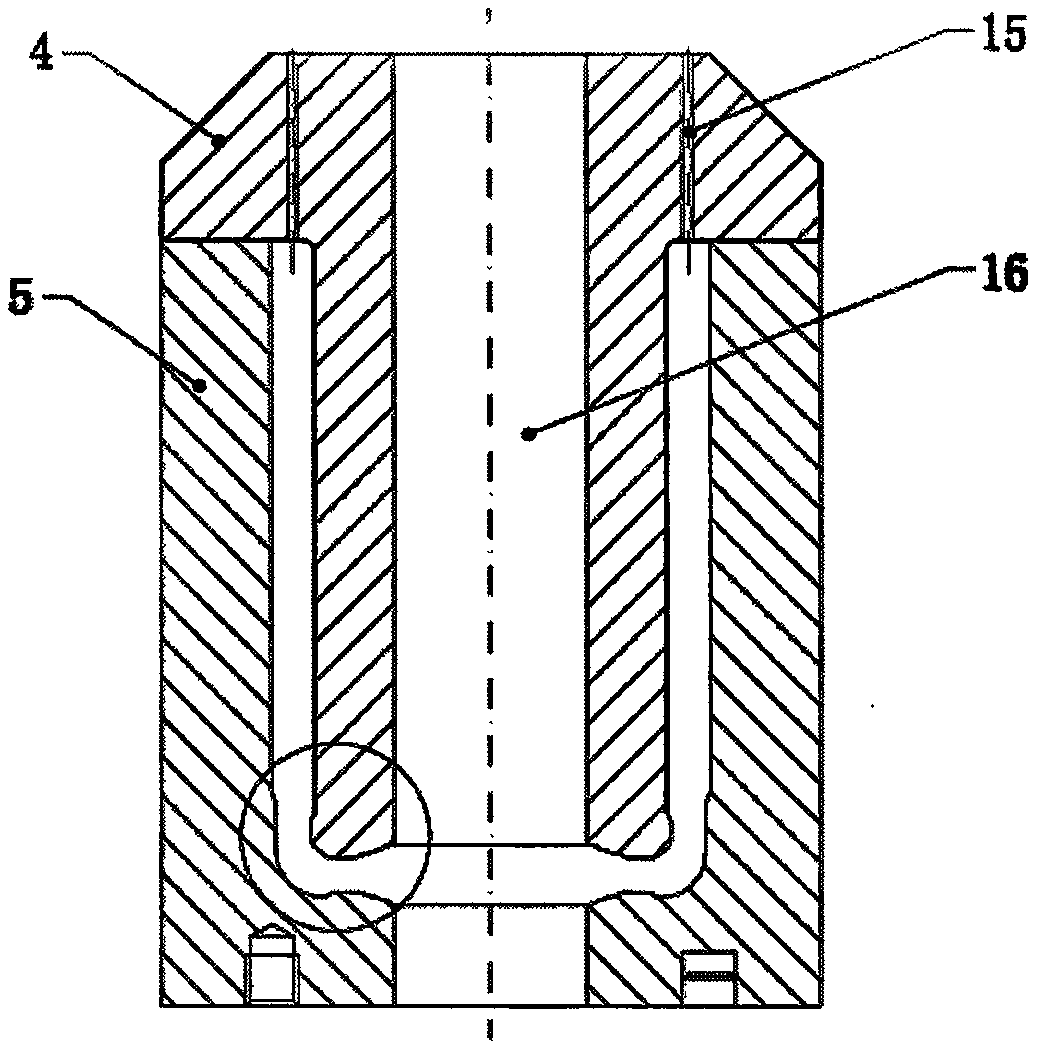

Differential extrusion forming die of high-performance magnesium alloy cup-shaped part

ActiveCN106825098AIncrease the number of deformationsIncrease the amount of plastic deformationExtrusion diesExtrusion mandrelsChinese charactersMachining process

The invention discloses a differential extrusion forming die of a high-performance magnesium alloy cup-shaped part and relates to the technical field of metal plastic machining processes and forming. A combined type female die comprising a T-shaped upper female die body and a U-shaped lower female die body is adopted. A cylindrical cavity is formed inside the T-shaped upper concave die body mounted on the U-shaped lower concave die body, and the cross section of a formed revolution body cavity is shaped like the Chinese character 'shan'. Staggered ladder type differential extrusion steps are arranged at the bottom of the extrusion cavity shaped like the Chinese character 'shan'. The magnesium alloy cup-shaped part is extruded through the extrusion cavity shaped like the Chinese character 'shan' and the staggered ladder type differential extrusion steps at the bottom of the cavity, so that the forming capacity of a magnesium alloy material is improved greatly, a high compact structure and large plastic deformation are obtained, the grain refining effect is significant, the effect of removing grain dual modality distribution of the cylinder wall of the cup-shaped part is obvious, and the manufacturing process of the high-performance magnesium alloy cup-shaped part is accelerated.

Owner:ZHONGBEI UNIV

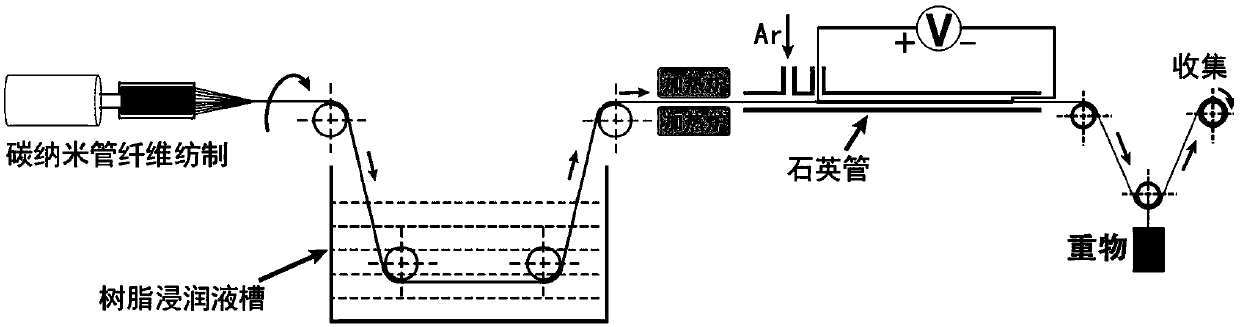

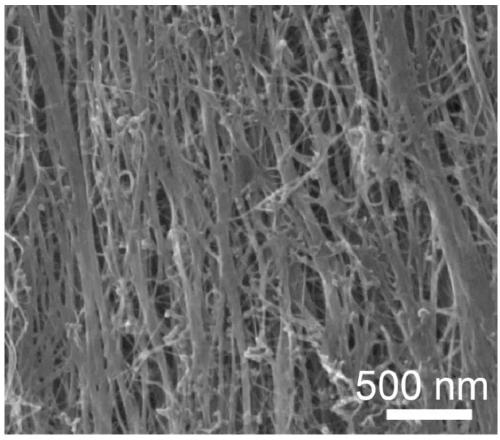

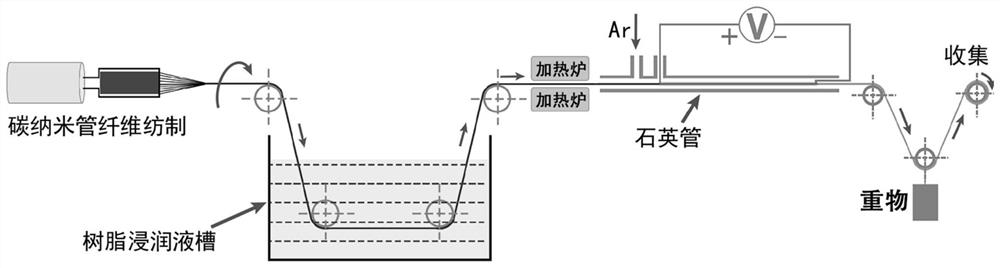

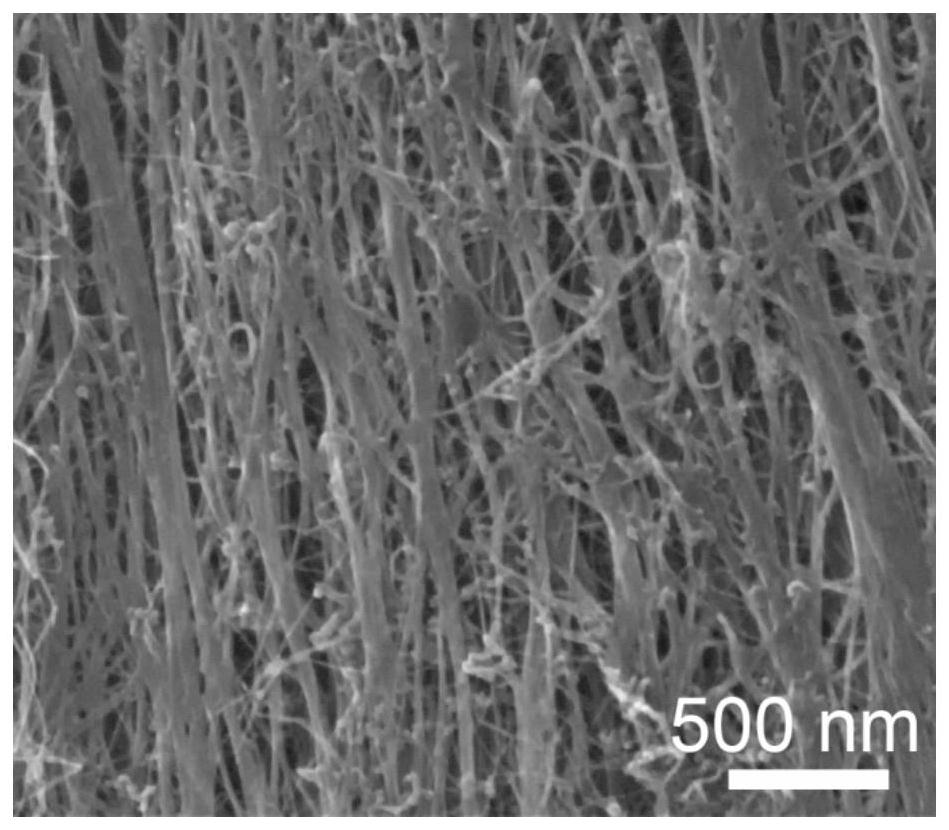

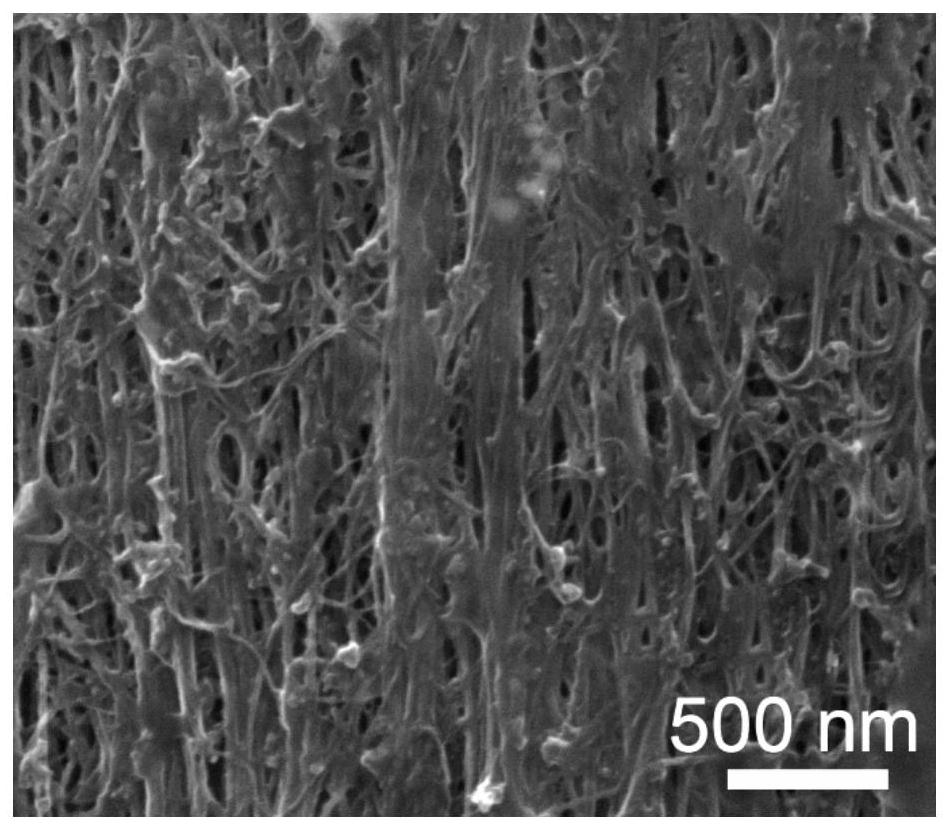

High-performance carbon nanotube/carbon composite fiber and rapid preparation method thereof

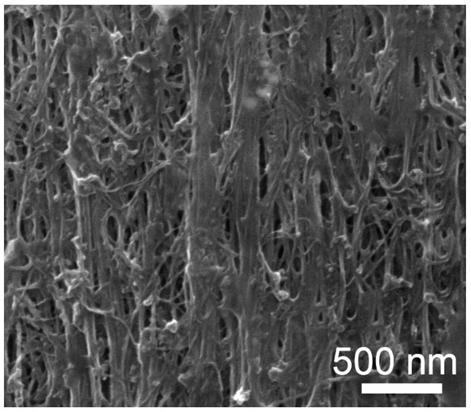

ActiveCN111101371AIncrease the force between the tubesHigh strengthCarbon fibresCarbon compositesCarbon nanotube

The invention discloses a high-performance carbon nanotube / carbon composite fiber and a rapid preparation method thereof. The preparation method comprises the following steps of during the carbon nanotube fiber spinning process and / or after the spinning is completed, fully infiltrating a precursor solution of a polymer with a high residual carbon rate and twisting the carbon nanotube fiber, and then removing a solvent on the surface of the carbon nanotube fiber; and applying a drafting force to the obtained carbon nanotube composite fiber, introducing current into the carbon nanotube compositefiber, so that a precursor of the polymer with the high residual carbon rate in the carbon nanotube composite fiber is crosslinked and cured, and then the formed polymer is carbonized to obtain the high-performance carbon nanotube / carbon composite fiber. The preparation method of the invention is fast and efficient, and the carbon nanotube / carbon composite fiber with high orientation and a compact structure can be prepared in only 10 seconds, which not only can greatly improve the mechanical property and the electrical property of the carbon nanotube fiber, but also enable the carbon nanotubefiber to have excellent resistance to extreme environment.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

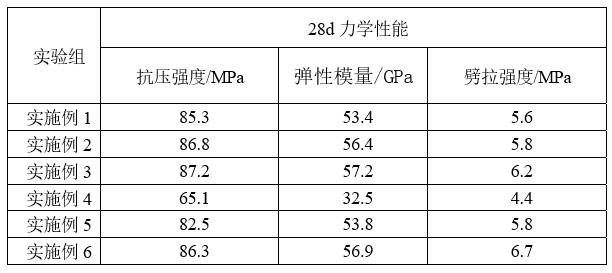

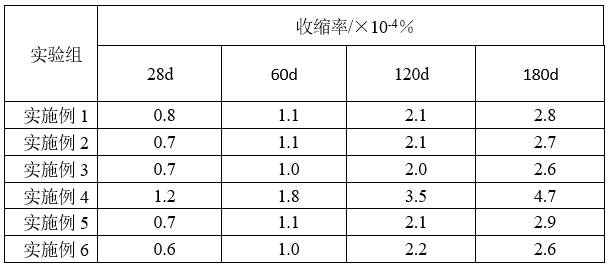

Self-compacting concrete prepared from recycled aggregate and preparation method thereof

The invention relates to the field of dimming films, and particularly discloses self-compacting concrete prepared from recycled aggregate, and the self-compacting concrete prepared from the recycled aggregate comprises 40-50 parts of heat-resistant coarse aggregate, 10-15 parts of modified recycled aggregate, 30-40 parts of fine aggregate, 8-10 parts of cement, 6-10 parts of water, 4-8 parts of mineral powder and 2-5 parts of fly ash. According to the invention, the structure of the recycled aggregate in the self-compacting concrete prepared from the recycled aggregate is optimized, the compactness of the material is improved and capillary pores and microscopic cracks in the recycled aggregate are filled by coating the recycled aggregate with slurry, meanwhile, the structure of the slurry-coated recycled aggregate is round and smooth, pores formed between actually filled materials are small, and thus the compact structure of the self-compacting concrete is further improved, and the mechanical strength of the self-compacting concrete prepared from the recycled aggregate is effectively improved.

Owner:靖江市恒生混凝土制造有限公司

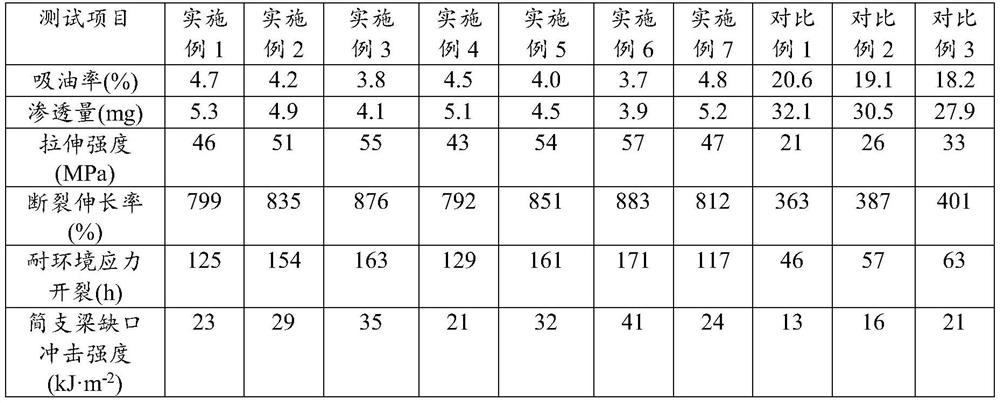

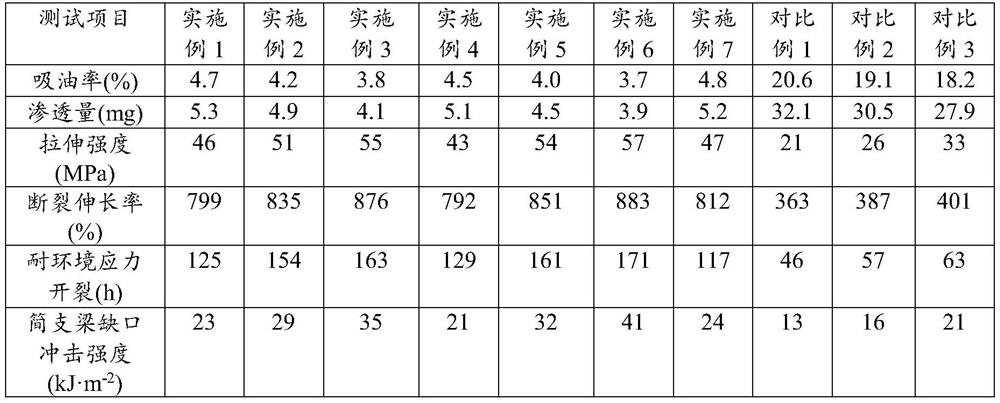

Chemical-resistant high-density polyethylene resin and preparation method thereof

The invention belongs to the field of polymer chemistry, and particularly relates to chemical-resistant high-density polyethylene resin and a preparation method thereof. The chemical-resistant high-density polyethylene resin is prepared from, by weight, 65 to 85 parts of high-density polyethylene resin, 8 to 18 parts of xanthan gum, 0.8 to 8 parts of polyarylethynyl resin, 0.2 to 0.8 part of a cross-linking agent, 0.3 to 0.8 part of a cross-linking auxiliary agent, 0.04 to 0.1 part of a main antioxidant, 0.08 to 0.20 part of an auxiliary antioxidant and 0.5 to 8 parts of an inorganic auxiliaryagent through a reaction. The chemical-resistant high-density polyethylene resin provided by the invention has excellent comprehensive properties, especially excellent high-temperature chemical resistance, has tolerance to complex chemical corrosion environments, can be widely applied to packaging materials, geomembranes and the like of bottles, barrels and the like, and widens the application field of the packaging materials, geomembranes and the like.

Owner:WANHUA CHEM GRP CO LTD +2

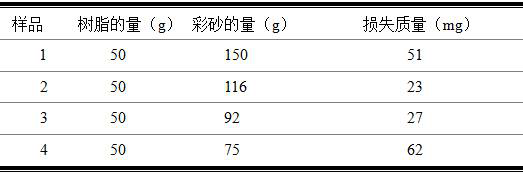

Anti-crack non-sticky precoated sand for forging

The invention discloses anti-crack non-sticky precoated sand for forging. Raw materials of the anti-crack non-sticky precoated sand comprise quartz sand, marble, talcum powder, pyrophyllite, coal ash, gypsum powder, a refractory material, sodium fluosilicate, magnesium oxide, microelements, synergists, modified phenolic resin, urotropine and water. A preparation method of the modified phenolic resin comprises the steps that phenol, lignin and p-Toluene sulfonic acid are mixed and then reacted, formaldehyde and potassium hydrox are added, a viscous material is obtained through a reaction, dewatering, drying and crushing are conducted after washing, and the modified phenolic resin is obtained. The anti-crack non-sticky precoated sand for forging has the characteristics that high temperature resistance is achieved, the compactness is good, and the sand is not prone to adhering to a casting; and the defects that according to traditional precoated sand molding, the number of blow holes of a casting is large, and demolding is difficult are overcome.

Owner:蚌埠市北晨微型机床厂

Method for preparing high-strength high-conductivity carbon nanometer material film

ActiveCN108172319AImprove conductivityEasy to prepareFullerenesCarbon nanotubesLubricationDual effect

Provided in the invention is a method for preparing a high-strength high-conductivity carbon nanometer material film. The preparation method comprises the following steps that: a thin film is preparedby using a suction filtration method; a carbon nano-material solution is added to a piece of filter paper for suction filtration and a film with the thickness of30 to 800 microns is prepared; the obtained film is immersed into a lubricating agent, pressurization is carried out during the immersion process and the film is kept to be in a wet state during the pressurization process to obtain a high-strength high-conductivity carbon nanometer material film, wherein the pressure intensity is controlled to be 0.5-3 MPa and the temperature is at 30-70 DEG C during the pressurization process and thepressurization effect time is 0.1 to 10 hours. According to the invention, under the dual effects of the pressure and the lubrication effect of the lubricating agent, densification of the carbon nanometer material film is realized and the high-strength high-conductivity conductive film is obtained; and the specific intensity is 100-500 MPa and the conductivity is 1000-10000 S / m. The method havingcharacteristics of low cost, simplicity, and obvious effect has borad application prospects in the industrial field.

Owner:绍兴兆丽新材料科技有限公司

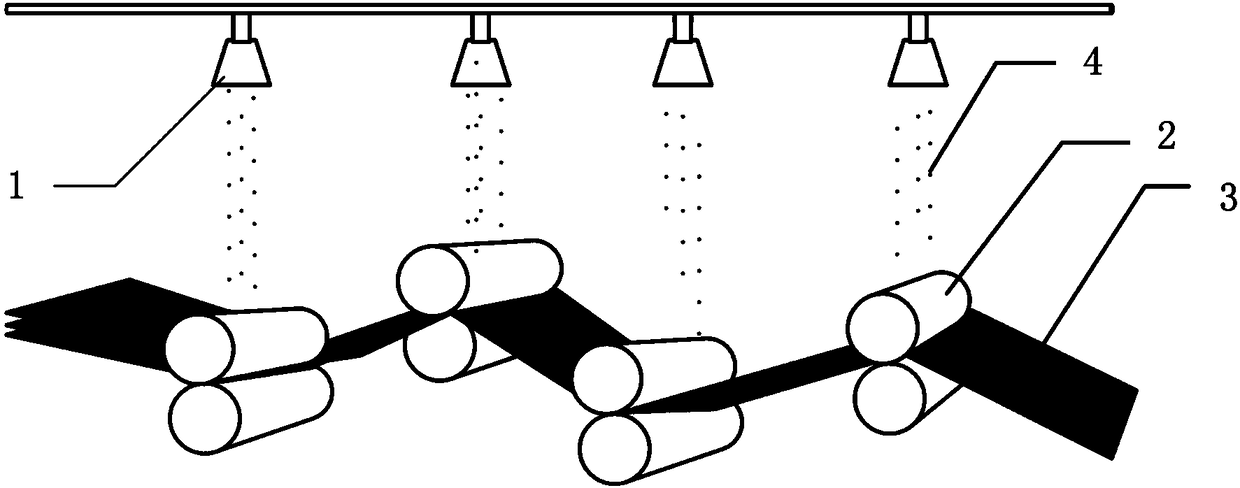

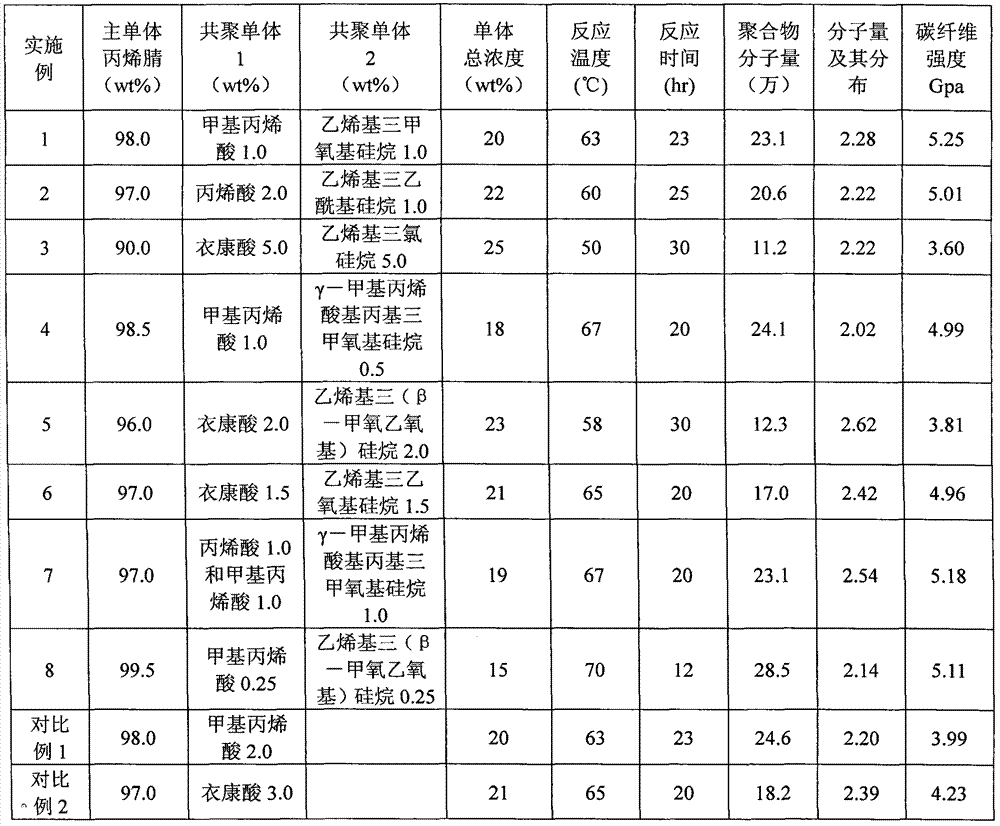

Spinning solution containing silicon acrylonitrile copolymer and preparation method thereof

ActiveCN102102235BSmooth rotationImprove dense structureMonocomponent synthetic polymer artificial filamentSpinning solutions preparationFiberYarn

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

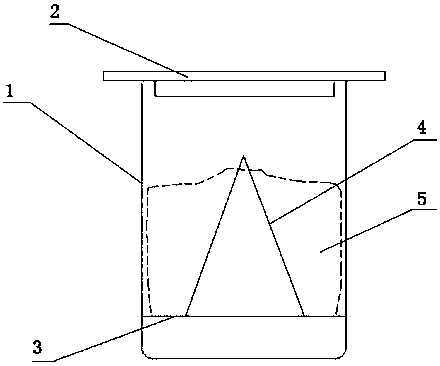

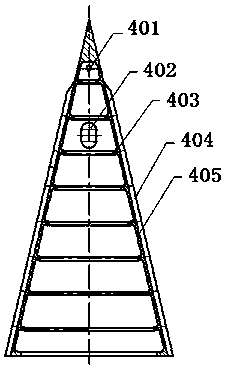

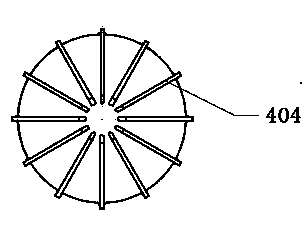

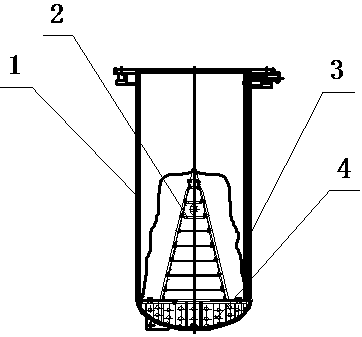

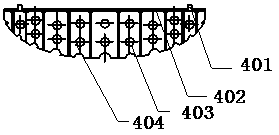

Reaction unit for reduction distillation of titanium sponge

The invention discloses a reaction unit for reduction distillation of titanium sponge. The reaction unit is mainly composed of a reactor and a big cover. The bottom of the reactor is provided with a screen plate. A conical tower is arranged on the screen plate and welded to the center of the screen plate. The height of the conical tower is greater than that of a titanium lump. The conical tower is of a circular conical structure. The diameter of the tower bottom of the conical tower is greater than or equal to one-second of the diameter of the screen plate. By adopting the reaction unit, the distillation efficiency and the compact structure of products can be improved; moreover, a central tube in an existing reaction unit can be omitted; and the reaction unit is simple in structure and low in manufacturing cost.

Owner:ZUNYI TITANIUM

Reduction distillation reaction device for sponge titanium production

The invention discloses a reduction distillation reaction device for sponge titanium production. The reduction distillation reaction device mainly consists of a reactor, a conical tower frame, a magnesium chloride pipe and a sieving plate. The magnesium chloride pipe is arranged on one side in the reactor. The sieving plate is arranged at the bottom of the reactor. The conical tower frame is welded to the sieving plate. The sieving plate is composed of a supporting panel and a supporting frame which is in the shape like a Chinese character 'jing' and connected with the lower portion of the supporting panel. A plurality of holes are formed in the supporting panel. The supporting frame which is in the shape like a Chinese character 'jing' is composed of a plurality of vertical plates in a crossed and staggered mode. A through hole is formed in each vertical plate. The lower part of the supporting frame which is in the shape like a Chinese character 'jing' is in a nearly hemispherical shape. By means of the reduction distillation reaction device, distillation channels can be formed in the interior of a sponge titanium heap and the bottom of the reactor, the distillation efficiency isimproved, the distillation time of sponge titanium is decreased, the sponge titanium production cycle is shortened, and energy consumption is reduced.

Owner:ZUNYI TITANIUM

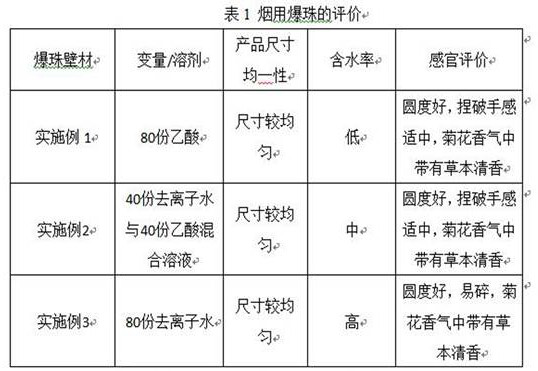

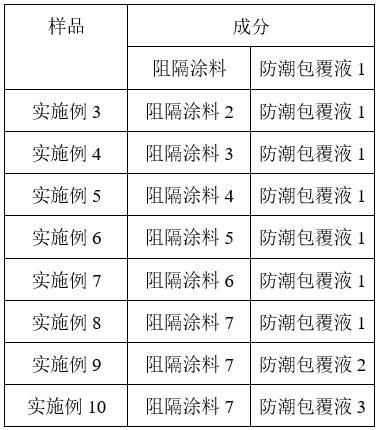

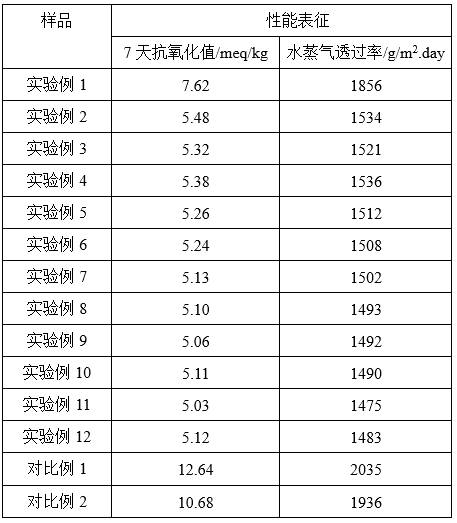

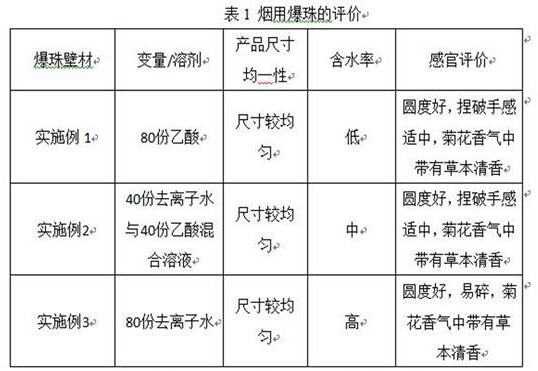

Cigarette filter capsule wall material and preparation method thereof

ActiveCN113647669AAdd flavorEnhanced inhibitory effectTobacco treatmentTobacco devicesPolymer sciencePolymer chemistry

The invention discloses a cigarette filter capsule wall material and a preparation method thereof. Mesona chinensis gum, nano chitosan and starch are used as main raw materials for preparing the wall material, formation of a composite gel network structure is dominated based on the hydrogen-bond interaction of the starch and the mesona chinensis gum, and an electrostatic compound is formed through the electrostatic attraction effect generated between the positively charged chitosan and the negatively charged mesona chinensis gum; the ternary composite system enhances the crosslinking degree of the network structure, the mesona chinensis gum and the starch interact to form the gel network structure to constrain movement of free water, and meanwhile after the nano chitosan is added, the nano chitosan forms a highly-oriented crystal domain in the ternary composite system, so that the transmission path of water vapor and oxygen is prolonged, the permeation amount of oxygen and water vapor per unit time is reduced, and the prepared wall material not only has good stability, but also has good water resistance.

Owner:HUBEI CHINA TOBACCO IND

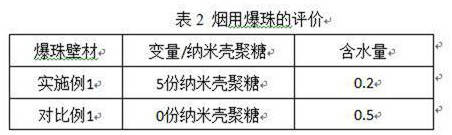

Preparation method of alcohol resisting type polyarylether electrolyte film material

InactiveCN108470921AGood alcohol resistanceThe synthesis method is simpleCell seperators/membranes/diaphragms/spacersFuel cell detailsCross-linkKetone

The invention relates to a preparation method of an alcohol resisting type polyarylether electrolyte film material, and belongs to the technical field of an electrolytic film material. Collagen and polyvinyl alcohol are mixed to be subjected to hydrolysis to form amino acid to be grafted to the surface of a polyvinyl alcohol material; by virtue of amino modification of polyvinyl alcohol and sulfonic acid group modification processing, a macromolecule crosslinking agent with the sulfonic acid group is introduced; next, through thermal treatment, the sulfonic acid group and amino are subjected to a cross-linking reaction to prepare an amino-containing sulfonated polyarylether ketone sulfone / sulfonated polyvinyl alcohol crosslinking film; sulfonated polyvinyl alcohol has high alcohol resisting performance, and meanwhile, the sulfonic acid group and amino can exist in an acid alkali pair form by virtue of an acid alkali effect therebetween, so that proton transmission sites are provided for protons and proton conduction is promoted; and in addition, by virtue of the formed crosslinking network structure, permeation of methyl alcohol can be suppressed effectively, and the prepared electrolyte film material can be excellent in compact structure.

Owner:CHANGZHOU DAAO NEW MATERIAL TECH CO LTD

Novel ternary thermal composite material and preparation method thereof

The invention discloses a novel ternary thermal composite material and a preparation method thereof. The material comprises the following components in volume ratio: at least 15vol% and at most 30vol% of Cu, at least 70vol% and at most 85vol% of W+diamond, at least 70vol% (W+diamond) and less than 100vol% (W+diamond) of W, and more than 0vol% (W+diamond) and at most 30vol% (W+diamond) of diamond. The preparation method comprises the following steps: selecting the raw materials including W, Cu and diamonds, weighing in proportion, mixing by using planetary ball milling, and then sintering by using vacuum hot-pressing to obtain a compact W-Cu-Diamond ternary thermal composite material. The novel ternary thermal composite material has the advantages of high compactness, uniform and stable texture structure, light weight, excellent mechanical property and thermal property and adjustable thermal expansion coefficient; the preparation process is simple and good in repeatability.

Owner:WUHAN UNIV OF TECH

Magnet parallel pressing forming method and forming equipment thereof

InactiveCN106424719AIncrease compaction densityGood and stable product qualityInductances/transformers/magnets manufactureMagnetizationMagnet

The invention discloses a magnet parallel pressing forming method. A mold for pressing has a die pressing structure; a magnetic block is formed in the die pressing structure, and is suffered from pressure in a magnetic field to realize pressing formation; and the direction of the magnetic field is parallel to the direction of the pressure. The magnet parallel pressing forming method can enable the stress extrusion to adapt to magnetization of magnetic powder in the magnetic pressing process through a mode of parallel the magnetic direction of the magnetic field to the direction of the pressure, so that the excellent magnet compact structure is obtained, the magnetic field configuration with excellent magnetization form is obtained, the magnet machining forming efficiency is improved, and the magnet product quality is promoted.

Owner:NINGBO XINFENG MAGNET IND

Preparation method of nutritional digestible corn grit porridge

PendingCN114586931AImprove dense structurePromote digestion and absorptionFood thermal treatmentFood processingNutritionMouthfeel

The invention discloses a preparation method of nutritional digestible corn grit porridge, and relates to a method for preparing the nutritional digestible corn grit porridge by using corn grit as a raw material. The invention solves the problems of difficulty in cooking, poor taste, low digestibility and easiness in aging and retrogradation of the traditional large-dreg porridge. The preparation method of the nutritional digestible corn grit porridge comprises the following steps: 1, pretreating a corn grit raw material; 2, heating and soaking the raw materials; 3, gelatinizing and cooking by a constant-temperature cooking method; and 4, performing biological enzymolysis on the corn grit porridge. The nutritional digestible corn grit porridge disclosed by the invention has the advantages that firstly, the porridge is easy to digest and absorb and high in nutritional value; 2, the storage performance of the large-dreg porridge is improved, and the aging and retrogradation of the corn porridge are reduced; 3, the process is advanced, and industrial production is easy; and fourthly, the food is convenient to eat and suitable for wide crowds. According to the preparation method of the corn grit porridge, the digestibility and the nutritional value of the corn porridge are improved by improving the corn particle structure.

Owner:QIQIHAR UNIVERSITY

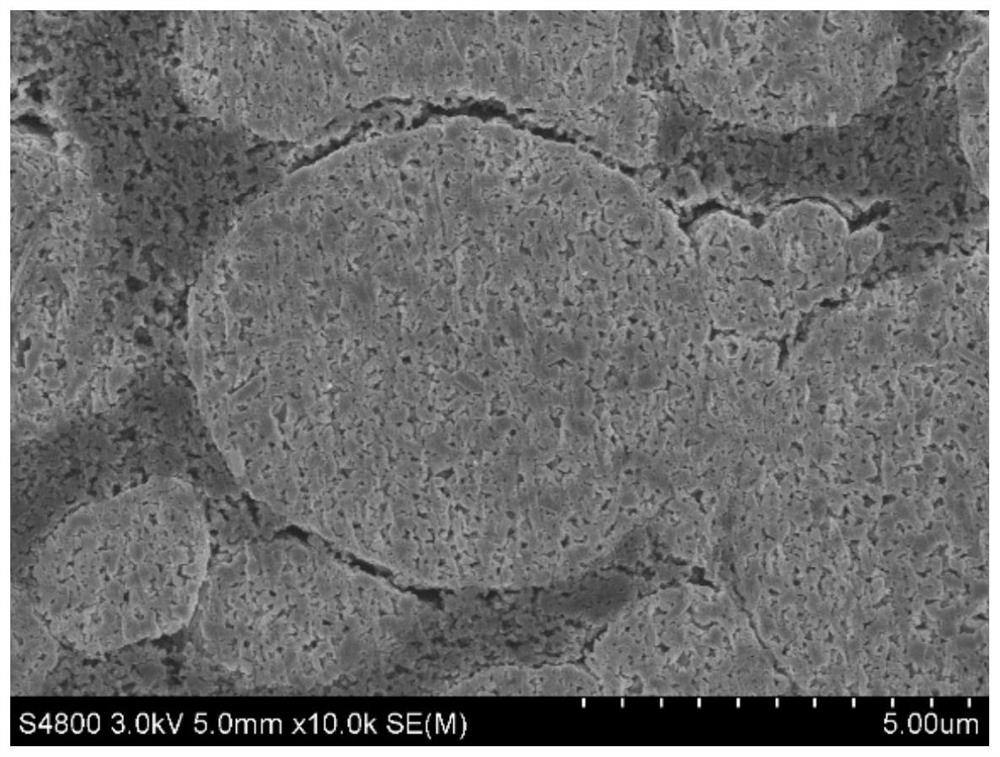

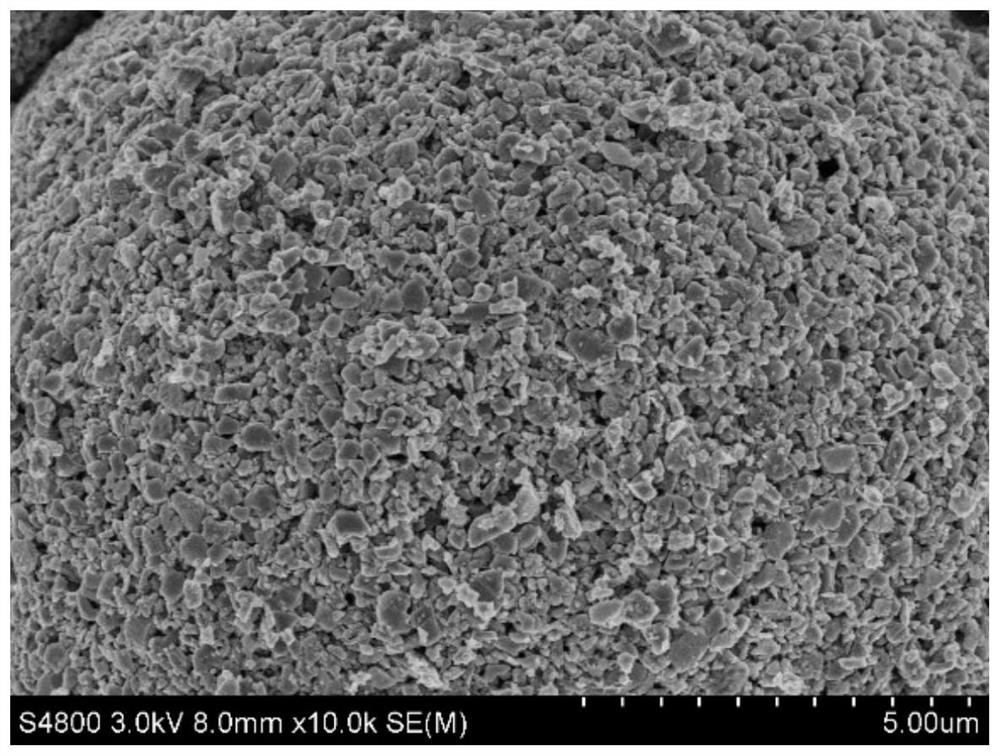

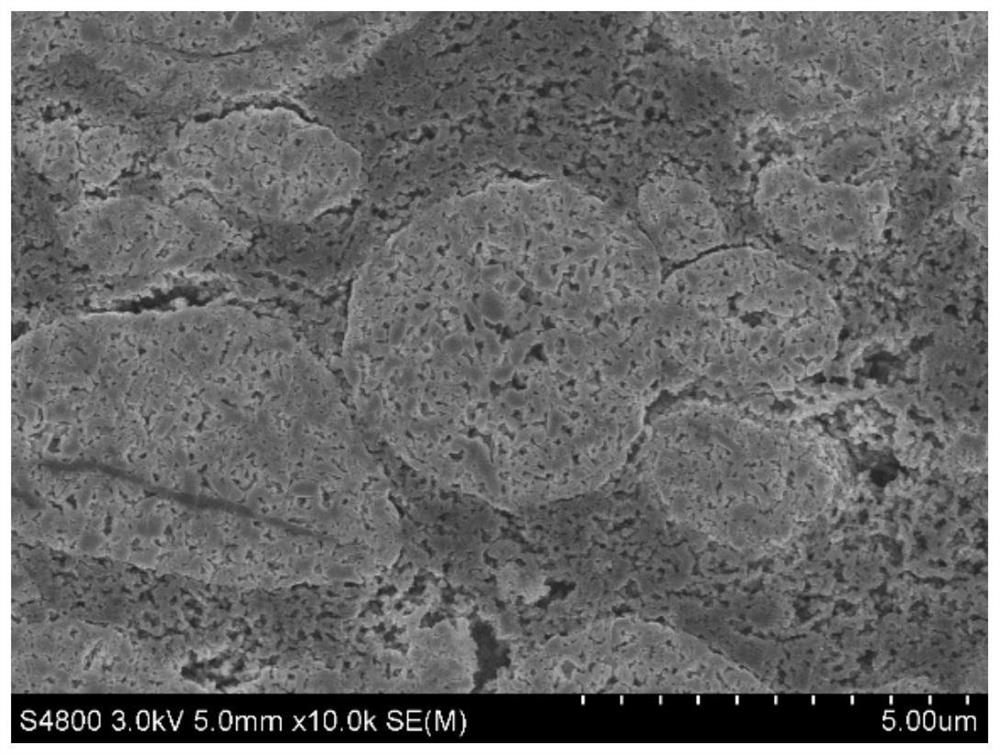

Nano lithium titanate material with high-density structure and preparation method of nano lithium titanate material

PendingCN114314647AControllable particle size and shapeCompact internal structureCell electrodesSecondary cellsLithium electrodeSpray dried

The invention relates to a nano lithium titanate material with a high-density structure and a preparation method thereof, and belongs to the technical field of lithium ion batteries. The invention discloses a nano lithium titanate material with a high-density structure. The nano lithium titanate material is prepared from the following raw materials: a titanium source, a lithium source, a surface and bulk phase modifier and a macromolecular modifier, wherein the addition amount of the surface and bulk phase modifier accounts for 0.05%-0.5% of the total weight of the titanium source and the lithium source, and the addition amount of the polymer modifier accounts for 1%-5% of the total weight of the titanium source and the lithium source. The invention also discloses a preparation method of the nano lithium titanate material with the high-density structure, and the preparation method comprises the following steps: sequentially dispersing a titanium source and a lithium source in a mixed solution containing the surface and bulk phase modifier and the high-molecular modifier, and then carrying out grinding and ultrasonic dispersion treatment to obtain the nano lithium titanate material with the high-density structure. Then carrying out spray drying granulation on the nano precursor slurry to obtain nano lithium titanate precursor powder; and calcining to obtain the nano lithium titanate material.

Owner:台州闪能科技有限公司

A kind of chemical-resistant high-density polyethylene resin and preparation method thereof

The invention belongs to the field of polymer chemistry, in particular to a chemical-resistant high-density polyethylene resin and a preparation method thereof. The chemical-resistant high-density polyethylene resin is prepared by reacting raw materials comprising the following components: 65-85 parts by weight of high-density polyethylene resin, 8-18 parts by weight of xanthan gum, and 0.8-18 parts by weight of polyarylacetylene-based resin 8 parts by weight, 0.2-0.8 part by weight of cross-linking agent, 0.3-0.8 part by weight of cross-linking auxiliary, 0.04-0.1 part by weight of main antioxidant, 0.08-0.20 part by weight of auxiliary antioxidant, and 0.5-8 part by weight of inorganic auxiliary share. The chemical-resistant high-density polyethylene resin of the invention has excellent comprehensive properties, especially high-temperature chemical resistance, has resistance to complex chemical corrosion environments, and can be widely used in packaging materials such as bottles, barrels, and geomembranes and so on, broadening its application field.

Owner:WANHUA CHEM GRP CO LTD +2

A kind of magnet vertical press molding method and its molding equipment

ActiveCN106670456BIncrease compaction densityGood and stable product qualityInductances/transformers/magnets manufactureMagnetizationMaterials science

The invention discloses a magnet vertical press forming method. A mold adopted for pressing is of a mold pressing structure, a magnet blank is formed in the mold pressing structure, and press forming is realized as the pressure is applied to the magnet blank in a magnetic field, wherein the direction of the magnetic field is perpendicular to that of the pressure. According to the magnet vertical press forming method, with adoption of a mode that the direction of the magnetic field is perpendicular to that of the pressure, stress extrusion and magnetic powder magnetization can be mutually adapted in the magnetization pressing process, so that a magnetic field configuration with good magnetization configuration is obtained when a good magnet dense structure is acquired, and the efficiency of magnet processing forming and the quality of a magnet product are improved.

Owner:NINGBO XINFENG MAGNET IND

Die and method for angular extrusion forming of annular channel of magnesium alloy cup-shaped component

ActiveCN104588428BGood formabilityReduce performance anisotropyExtrusion diesExtrusion mandrelsChinese charactersMetal

Owner:ZHONGBEI UNIV

Moisture-proof oxygen-barrier packaging paper and preparation method thereof

ActiveCN114108382AEasy to processImprove barrier propertiesFlexible coversWrappersPolymer sciencePaper based

The invention relates to the technical field of packaging materials, and particularly discloses moisture-proof oxygen-barrier packaging paper which comprises a packaging paper base layer. The barrier layer is arranged on one side of the packaging paper base layer and is formed by coating and curing the barrier coating; the barrier coating comprises the following substances in parts by weight: 3-8 parts of polylactic acid; 45 to 50 parts of a hexafluoroisopropanol solution; and 1-2 parts of a silane coupling agent. The preparation method comprises the following preparation steps: S1, preparing the barrier layer; s2, preparing a damp-proof layer; and S3, drying treatment. The polylactic acid film is selected as the barrier layer to coat and modify the packaging paper base layer, a good barrier effect can be formed on the packaging paper base layer through the polylactic acid film, and the moisture-proof and oxygen-barrier properties of the packaging paper base layer are further improved.

Owner:JIANGSU DAYA NEW PACKAGING MATERIALS

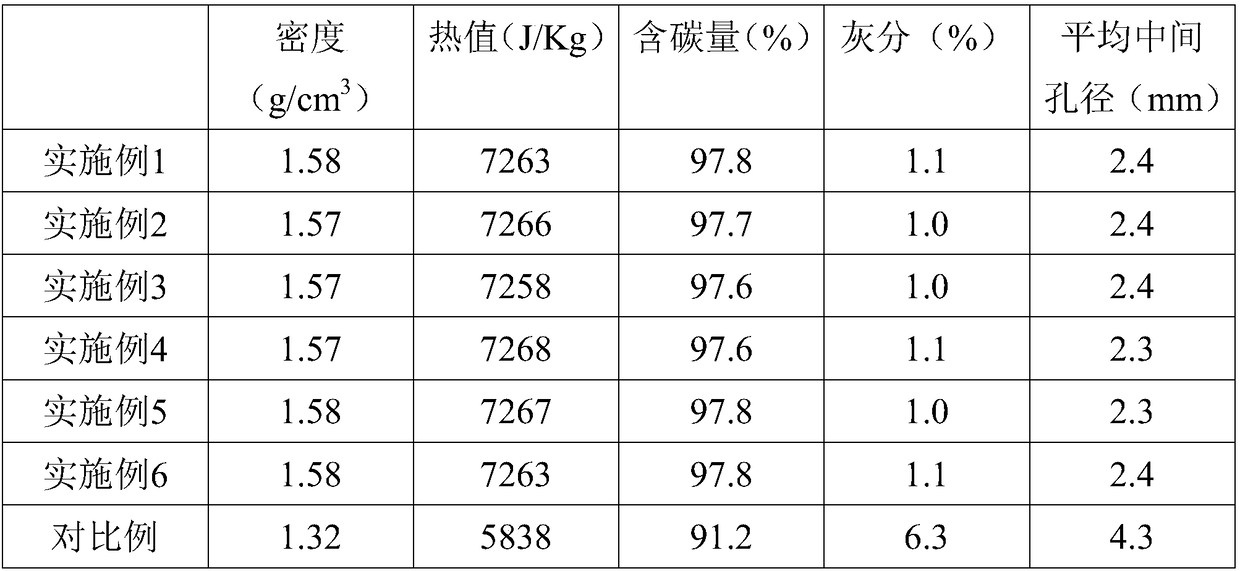

Method for preparing machine-made charcoal from waste wood and bamboo

The invention discloses a method for preparing machine-made charcoal from waste wood and bamboo and relates to the field of waste bamboo and wood product recycling. The method comprises the followingsteps: (1) smashing the waste wood and bamboo, dissolving into an alkali solution, performing ultrasonic stirring and utilizing deionized water to clean a solution into a neutral state; (2) evenly mixing the waste wood and bamboo powder processed by the alkali solution and cellulase of 0.3% of the weight of the powder and reacting under 32 to 34 DEG C; (3) evenly mixing a reaction product with sorghum straw powder, corn straw powder, glycerol and urea-formaldehyde resin and putting into a high-speed stirring machine to be stirred; (4) utilizing a punching type rod making machine to punch a mixture which is stirred at a high speed into carbon rods; (5) sending the carbon rods into a carbonizing furnace to be carbonized to obtain the machine-made charcoal. By means of the method disclosed bythe invention, the waste wood and bamboo is turned into wealth, and resource reutilization is achieved; not only are resources saved, and waste is avoided, but also environmental friendliness is achieved; the environment is prevented from being polluted by particles generated in a waste bamboo and wood burning process.

Owner:和县伊迈炭业有限责任公司

A Differential Speed Extrusion Forming Method of Magnesium Alloy High Performance Cup

ActiveCN106607468BIncrease the number of deformationsIncrease the amount of plastic deformationExtrusion diesHigh densityChinese characters

The invention provides a differential-speed extrusion forming method of a magnesium alloy high performance cup-shaped piece and relates to the technical field of metal and plastic machining and forming. A combined concave die is adopted and comprises a T-shaped upper concave die body and a U-shaped lower concave die body. The T-shaped upper concave die body is internally provided with a cylindrical cavity and installed on the U-shaped lower concave die body, and the section of a formed revolved cavity is shaped like a Chinese character 'shan'. Staggered 'ladder' type differential-speed extrusion steps are adopted for the bottom of the extrusion cavity shaped like the Chinese character 'shan'. Three stages of deformation are conducted, the first stage is the axial similar cylinder pier coarse deformation stage, the second stage is the radial extrusion large deformation stage, and the third stage is the corner extrusion and shearing deformation stage. The extrusion cavity shaped like the Chinese character 'shan' and the staggered 'ladder' type differential-speed extrusion steps at the cavity bottom are adopted for extruding the magnesium alloy high performance cup-shaped piece, the magnesium alloy material forming capacity is greatly improved, a high-density structure is obtained, great plastic deformation is obtained, the grain refining effect is remarkable, the effect of eliminating grain dual-mode distribution of the barrel wall of the cup-shaped piece is obvious, and the fabrication procedure of the high performance magnesium alloy cup-shaped piece is shortened.

Owner:ZHONGBEI UNIV

A homogeneous high-strength and toughening magnesium alloy cup-shaped member rotary extrusion method

The invention discloses a rotary extrusion method of a homogenous high-toughness magnesium alloy cup-shaped component. The rotary extrusion method of the homogenous high-toughness magnesium alloy cup-shaped component comprises the following steps: (1) blanking a bar material; (2) carrying out homogenizing thermal treatment; (3) heating the whole rotary extrusion mold, wherein the rotary extrusion mold mainly comprises a punch and a forming concave mold for the rotary extrusion cup-shaped component, the punch is connected with an upper rotary workbench of a hydraulic machine with the upper rotary workbench, the surface of a conical body of the end part of the punch in contact with an extrusion billet is provided with non-communicated grooves with certain widths and depths, and a groove is formed in the plane of the bottom of a mold cavity of the forming concave mold; spraying oiling agent graphitic lubricant for a punch operating belt, the non-communicated grooves, the mold cavity and the blank; installing the blank for extrusion into the mold cavity; (4) moving the upper rotary workbench of the hydraulic machine around a rotary axis, loading the blank around the rotary axis, and filling metal extruded into the non-communicated grooves by the punch when the punch moves around the rotary axis continuously in a smoothing-raising-smoothing-raising mode; (5) processing an extrusion element so as to form the magnesium alloy cup-shaped component.

Owner:ZHONGBEI UNIV

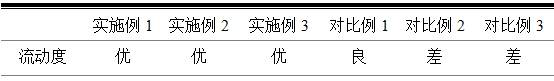

Preparation method of zero-water-absorption colored road marking material

PendingCN114836988AImprove wear resistanceImprove durabilityTextiles and paperGarment beltsEpoxyAcrylic resin

The invention relates to a preparation method of a road marking material, in particular to a preparation method of a zero-water-absorption colored road marking material, which adopts a matched curing effect among glass particles, acrylic resin and polyurethane resin to form a compact chemical structure. The surface of the material is coated with the curing film through the hydroxyl action on the surface of the material, and the purpose of zero water absorption of the filler is achieved. And the colored sand with zero water absorption enables the water-borne epoxy resin to have more excellent fluidity, so that the road marking belt can adapt to various road conditions. Based on the characteristic that epoxy groups in water-borne epoxy resin can be located at multiple positions in a molecular chain, the epoxy groups can be subjected to a cross-linking reaction with multiple groups, then a stable core-shell structure is formed and combined with colored sand, and the colored sand has an excellent compact structure, heat stability and hardness; and the wear resistance, water resistance, acid resistance, alkali resistance and aging resistance of the road marking belt are improved, namely the service life is prolonged.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +2

A kind of preparation method of peppermint instant tea

The invention relates to the technical field of instant tea processing, in particular to a preparation method of mint instant tea, which is prepared by the steps of fixing, pulverizing, extracting, concentrating, saccharifying, vacuuming, and spray-drying mint, and in the extracting process Carry out a magnetization treatment at an interval of 30-45min. The peppermint instant tea prepared by the present invention has mint fragrance and green tea fragrance, high dissolution rate, and has the effects of relieving fatigue, refreshing the mind, and enhancing immunity. It has a sweet smell, strong tea fragrance, good sensory quality and storage effect, and has no toxic and side effects.

Owner:贵州省普定县黔龙茶业有限公司

Explosive bead wall material for cigarette and preparation method thereof

ActiveCN113647669BAdd flavorEnhanced inhibitory effectTobacco treatmentTobacco devicesPolymer sciencePolymer chemistry

The invention discloses an explosive bead wall material for cigarettes and a preparation method thereof. The invention uses curcuma gum, nano-chitosan and starch as the main raw materials for preparing the wall material, and the formation of the composite gel network structure is dominated by the hydrogen bond between starch and curcumin, and the positively charged chitosan and the negatively charged chitosan The electrostatic attraction between the charged grass gums forms an electrostatic complex. The ternary composite system strengthens the cross-linking degree of the network structure. The interaction between the grass gum and starch forms a gel network structure, which binds the movement of free water. After nanochitosan, nanochitosan forms highly oriented crystalline domains in the ternary composite system, which prolongs the transmission path of water vapor and oxygen, thereby reducing the permeation amount of oxygen and water vapor per unit time. The prepared wall material not only has good stability, but also has good water resistance.

Owner:HUBEI CHINA TOBACCO IND

A Differential Extrusion Die for Magnesium Alloy High Performance Cup

ActiveCN106825098BIncrease the number of deformationsIncrease the amount of plastic deformationExtrusion diesExtrusion mandrelsChinese charactersMachining process

Owner:ZHONGBEI UNIV

A kind of high-performance carbon nanotube/carbon composite fiber and its rapid preparation method

ActiveCN111101371BIncrease the force between the tubesHigh strengthCarbon fibresCarbon compositesFiber

The invention discloses a high-performance carbon nanotube / carbon composite fiber and a rapid preparation method thereof. The preparation method includes: fully infiltrating and twisting the carbon nanotube fibers with a precursor solution of a polymer with a high carbon residue rate during and / or after the spinning of the carbon nanotube fibers, and then removing the surface of the carbon nanotube fibers. a solvent; and, applying a drawing force to the obtained carbon nanotube composite fiber, while passing an electric current into the carbon nanotube composite fiber, so as to make the precursor of the polymer with high carbon residue rate in the carbon nanotube composite fiber The body is cross-linked and solidified, and then the formed polymer is carbonized to prepare high-performance carbon nanotube / carbon composite fibers. The preparation method of the invention is fast and efficient, and the carbon nanotube / carbon composite fiber with high orientation and high density can be prepared in only 10 seconds, which can not only greatly improve the mechanical properties and electrical properties of the carbon nanotube fiber, but also make it have Excellent resistance to extreme environments.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

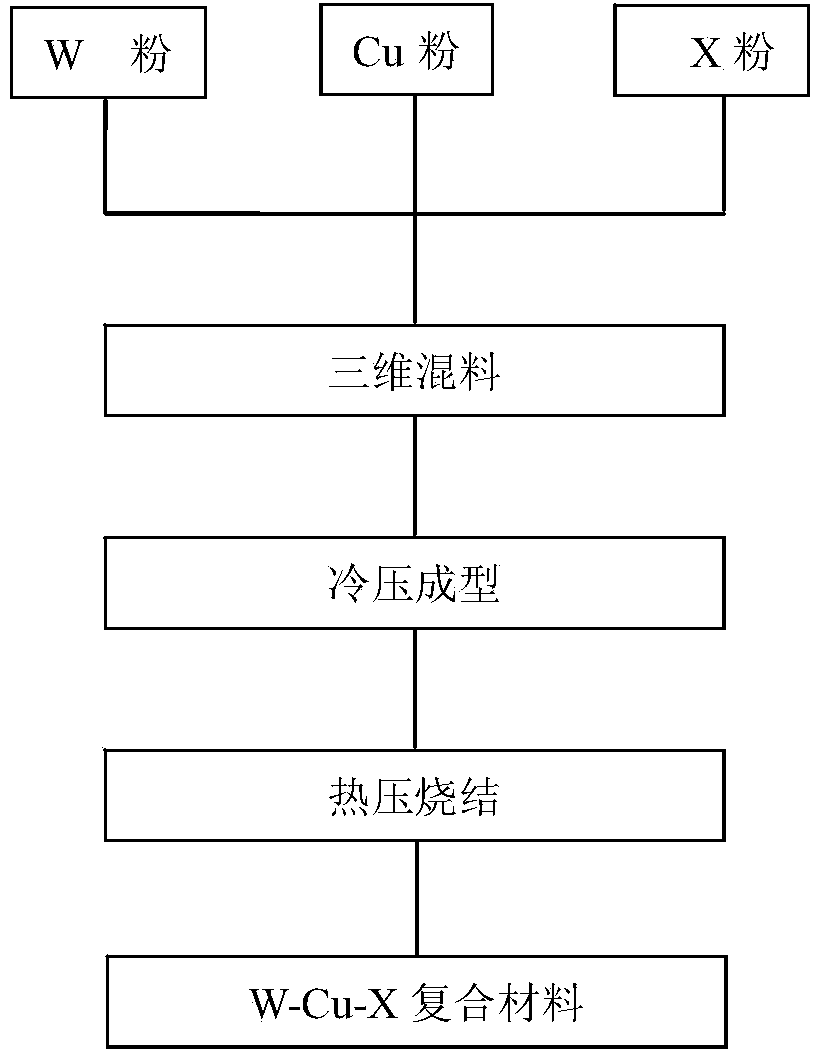

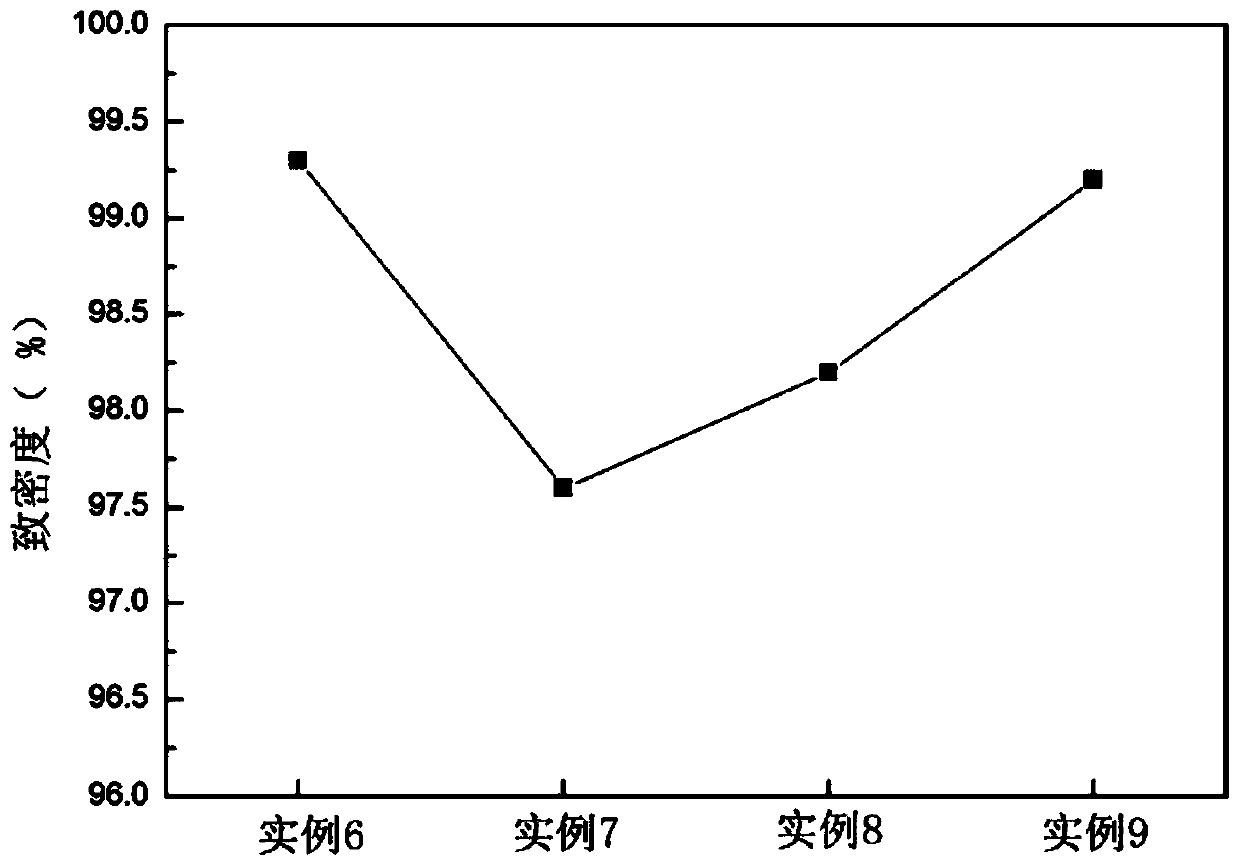

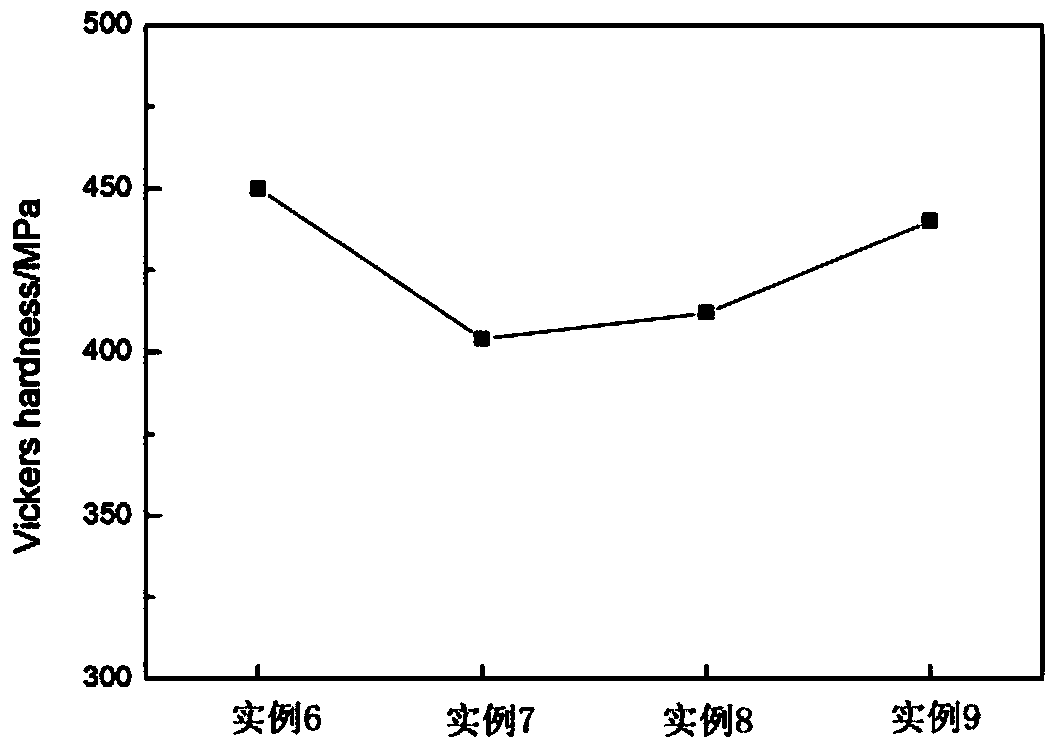

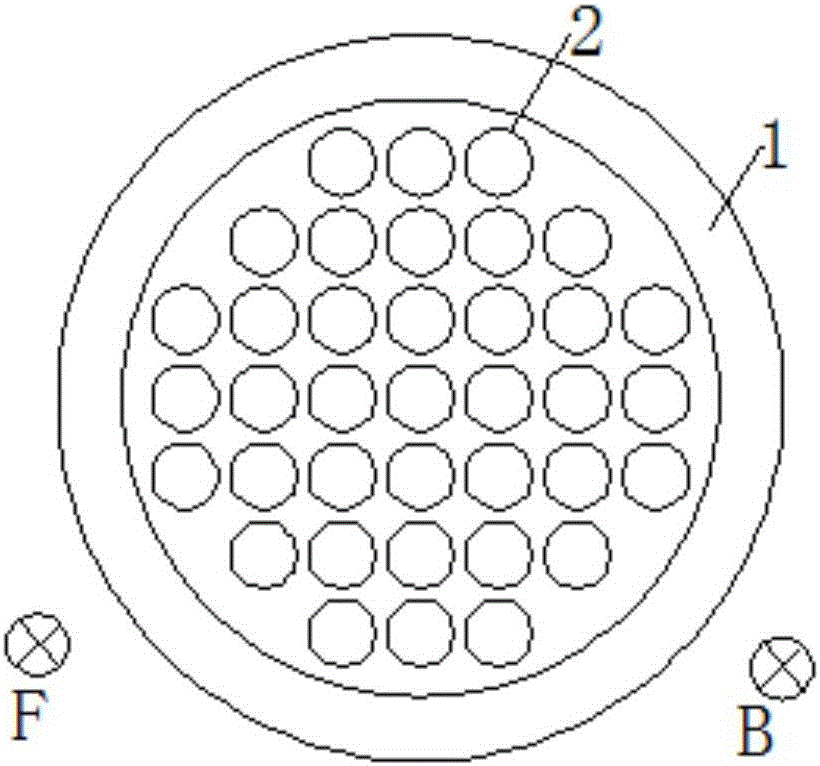

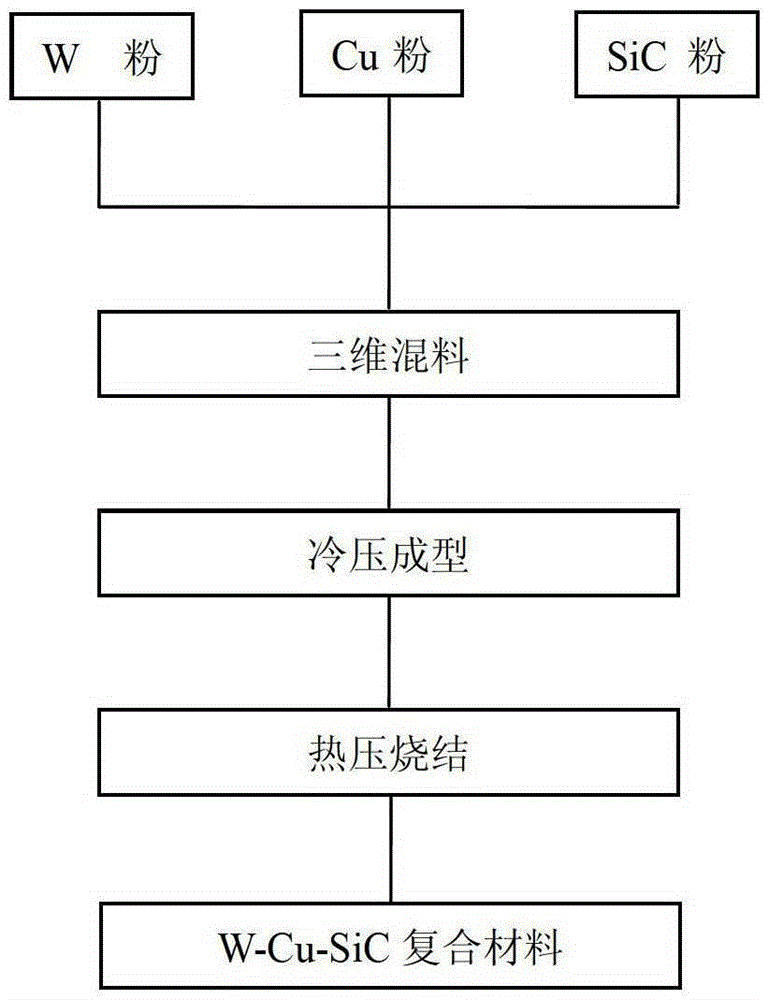

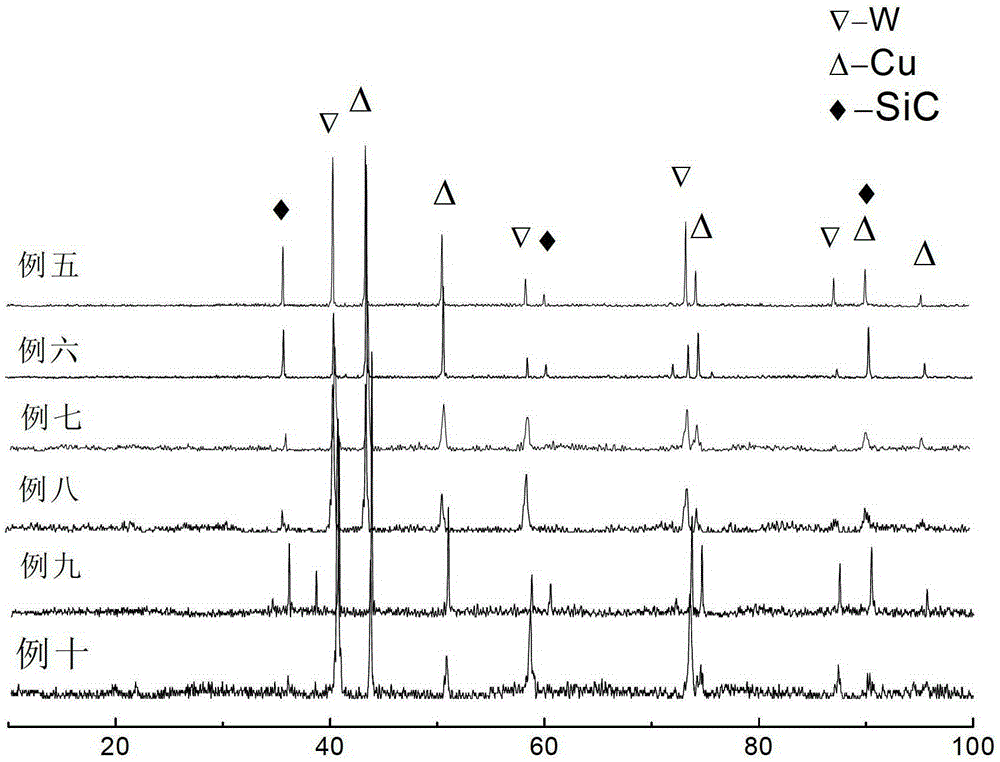

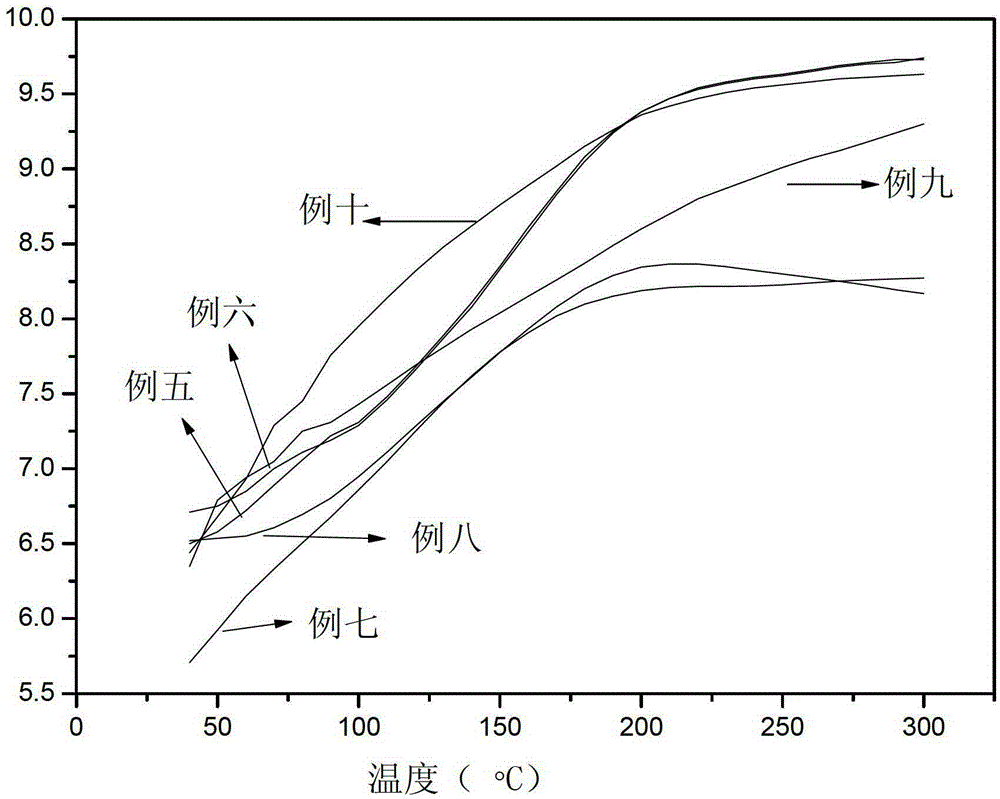

w-cu-sic ternary composite material and preparation method thereof

The invention is a novel W-Cu-SiC ternary thermal control composite material having a high density structure and a preparation method thereof. The W-Cu-SiC ternary composite material is prepared by mixing a W powder, an SiC powder and a Cu powder in a proportion and then carrying out hot pressing sintering. The composite material contains 30 to 50 vol% of Cu, 50 to 70 vol% of W and SiC, wherein the volume fraction range of SiC is 20 to 80%, and the corresponding volume fraction range of the W powder is 80 to 20%; the density degrees of the W-Cu-SiC composite material are all up to 98% or more in different proportions, and the thermal expansion coefficients of the composite material are all stable between 5.7*10<-6> to 9.74*10<-6> / K in a temperature range of 40 to 300 DEG C. The composite material is the novel composite material having convenient molding, low cost and high performance, and has wide application prospects in electronic packaging, semiconductor cooling fins and the like.

Owner:WUHAN UNIV OF TECH

Self-compacting concrete prepared from recycled aggregate and preparation method thereof

This application relates to the field of light-adjusting films, and specifically discloses a self-compacting concrete prepared from recycled aggregates. The self-compacted concrete prepared from recycled aggregates includes: 40-50 parts of heat-resistant coarse aggregate, 10-15 parts of modified Recycled aggregate, 30-40 parts of fine aggregate, 8-10 parts of cement, 6-10 parts of water, 4-8 parts of mineral powder and 2-5 parts of fly ash. This application optimizes the structure of recycled aggregate in self-compacting concrete with recycled aggregate configuration. By coating it with grout, the compactness of the material is improved, and the capillary pores and microscopic cracks in the recycled aggregate are filled, and at the same time, it is coated with grout The post-recycled aggregate structure is round, and the pores formed between the actual filled material and the material are small, thereby further improving the compact structure of self-compacting concrete, and effectively improving the mechanical strength of self-compacting concrete prepared with recycled aggregate.

Owner:靖江市恒生混凝土制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com