Reaction unit for reduction distillation of titanium sponge

The technology of a reaction device and titanium sponge is applied in the field of reaction devices for reductive distillation, which can solve the problems affecting the quality of titanium sponge and the self-weight of titanium sponge, and achieve the effects of reducing structure densification, low processing cost and improving distillation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

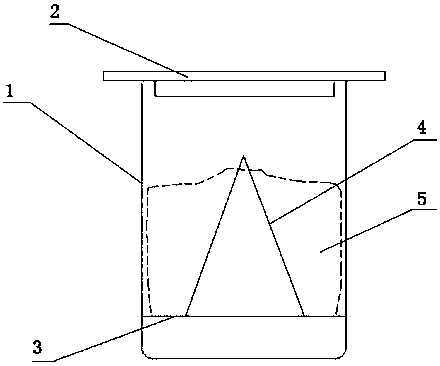

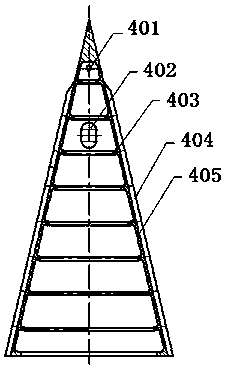

[0020] Such as figure 1 , figure 2 , image 3 As shown, a reaction device for the reduction and distillation of sponge titanium is mainly composed of a reactor 1 and a large cover 2. The bottom of the reactor 1 is provided with a sieve plate 3, and a cone-shaped tower 4 is provided on the sieve plate 3. The type tower 4 is welded to the center of the screen plate 3. The height of the cone type tower 4 is greater than the height of the titanium tuo 5. The cone type tower 4 is a circular cone structure, and the bottom diameter of the cone type tower 4 Diameter of sieve plate.

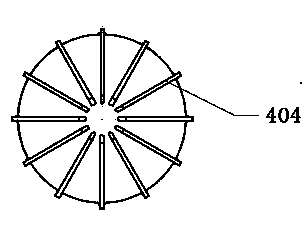

[0021] The cone-shaped tower 4 is mainly composed of a frame body 405 and an inner ring rib 403 arranged inside. The frame body 405 is provided with an outer reinforcing rib plate 404, and the middle and upper parts of the frame body 405 are respectively provided with lifting holes 402. The breathing hole 401. The lifting hole 402 is a pipeline structure.

[0022] The cone-shaped tower 4 is made of low-carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com