Spinning solution containing silicon acrylonitrile copolymer and preparation method thereof

A technology for spinning dope and acrylonitrile is applied in the field of polyacrylonitrile-based high-performance carbon fiber spinning dope and its preparation to achieve the effect of improving compact structure and large bond energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

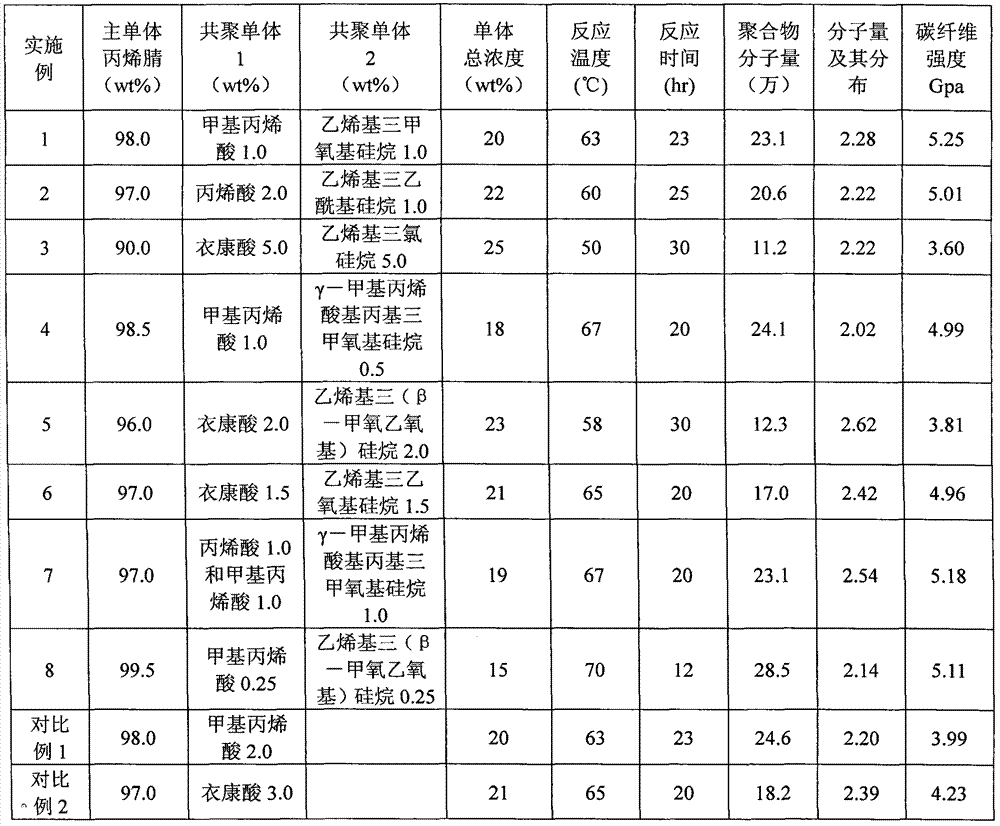

Examples

Embodiment 1

[0025] Using dimethyl sulfoxide as a solvent, azobisisobutyronitrile as an initiator, acrylonitrile as the main monomer, methacrylic acid as comonomer 1, and vinyltrimethoxysilane as comonomer 2 to carry out acrylonitrile solution copolymerization Polymerization. Solvent dimethyl sulfoxide, main monomer acrylonitrile, comonomer 1 methacrylic acid, comonomer 2 vinyltrimethoxysilane and azobisisobutyronitrile are added respectively in the polymerization kettle. The weight ratio of added raw material is acrylonitrile: methacrylic acid: vinyltrimethoxysilane=98: 1: 1, and the consumption of azobisisobutyronitrile accounts for 0.8% of total monomer weight, controls monomer to account for total solution. 20% by weight. The mixture was stirred uniformly at room temperature, then bubbled with nitrogen for 20 minutes, and reacted at 63° C. for 25 hours. At a reaction temperature of 65°C and a vacuum of 0.090 MPa, the singlets are removed by a wiper-type singlet removal device, and af...

Embodiment 2

[0027] The solvent dimethyl sulfoxide, the main monomer acrylonitrile, the comonomer 1 acrylic acid, the comonomer 2 vinyltriacetylsilane and the initiator azobisisobutyronitrile are sequentially added to the polymerization kettle, and the added raw materials The weight ratio is acrylonitrile:acrylic acid:vinyltriacetylsilane=97:2:1, the amount of azobisisobutyronitrile accounts for 1.2% of the total weight of the monomers, and the monomers account for 22% of the total weight of the solution. The mixture was stirred uniformly at room temperature, then bubbled with nitrogen gas for 20 minutes, and reacted at 60° C. for 25 hours. At a reaction temperature of 60°C and a vacuum of 0.098 MPa, the singlets are removed by a wiper-type singlet removal device, and after static defoaming at 40°C, a silicon-containing acrylonitrile copolymer spinning stock solution is obtained. The molecular weight of the copolymer measured by gel permeation chromatography (GPC) is 206,000, and the molec...

Embodiment 3

[0029]The solvent dimethyl sulfoxide, main monomer acrylonitrile, comonomer 1 itaconic acid, comonomer 2 vinyltrichlorosilane and azobisisobutyronitrile are sequentially added to the polymerization kettle, and the weight ratio of the raw materials added is It is: acrylonitrile: itaconic acid: vinyltrichlorosilane = 90:5:5, the amount of azobisisobutyronitrile accounts for 2.0% of the total weight of the monomer, and the control monomer accounts for 25% of the total weight of the solution. The mixture was stirred and mixed at room temperature, followed by bubbling nitrogen gas for 20 minutes, and reacted at a temperature of 50° C. for 30 hours. At a reaction temperature of 68°C and a vacuum of 0.085 MPa, the singlets are removed by a wiper-type singlet removal device, and after static defoaming at 48°C, a silicon-containing acrylonitrile copolymer spinning stock solution is obtained. The molecular weight of the copolymer measured by gel permeation chromatography (GPC) is 112,00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com