Method for preparing high-strength high-conductivity carbon nanometer material film

A technology of carbon nanomaterials and material films, which is applied in the field of multifunctional material preparation, can solve the problems of poor orientation of carbon nanotubes, high production costs, and low performance, and achieve simple and easy preparation methods, industrialization, and high electrical conductivity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 prepares carbon nanotube / graphene composite film, comprises the steps:

[0032] (1) 0.1wt% uniformly dispersed graphene suspension (Weihai Power High-Tech Carbon Material Co., Ltd.) and 0.1wt% uniformly dispersed carbon nanotube dispersion (Suzhou Jiedi Nano Technology Co., Ltd.) according to the mass ratio = 5 : 5 mixed, deposited by Buchner funnel suction filtration, the suction filtration process control pressure is 0.5MPa, at room temperature to dry naturally, to obtain a carbon nanotube / graphene composite film with a thickness of 100.61 microns.

[0033] (2) Using a flat vulcanizer to pressurize

[0034] S1: Use PE film to prepare a 15cm×15cm transparent square container, place the square container in the middle of the upper and lower platens of the flat vulcanizer, and put 30ml of acetone solution into the square container.

[0035] S2: Cut the carbon nanotube graphene composite film obtained in step (1) to a size of 5 cm long × 5 cm wide, and cut A4...

Embodiment 2

[0039] Embodiment 2 prepares carbon nanotube / graphene composite film, comprises the steps:

[0040] (1) Mix the uniformly dispersed graphene suspension (Weihai Weili Gaoke Carbon Material Co., Ltd.) with the uniformly dispersed carbon nanotube dispersion (Suzhou Jiedi Nano Technology Co., Ltd.) according to the mass ratio = 5:5, and pass through the cloth The deposition was carried out by suction filtration through a Scherner funnel at a pressure of 1 MPa, and dried naturally at room temperature to obtain a carbon nanotube / graphene composite film with a thickness of 100.61 microns. Wherein, the concentrations of the graphene suspension and the carbon nanotube dispersion are respectively 0.5 wt % and 0.5 wt %.

[0041] (2) Pressurization by rolling method

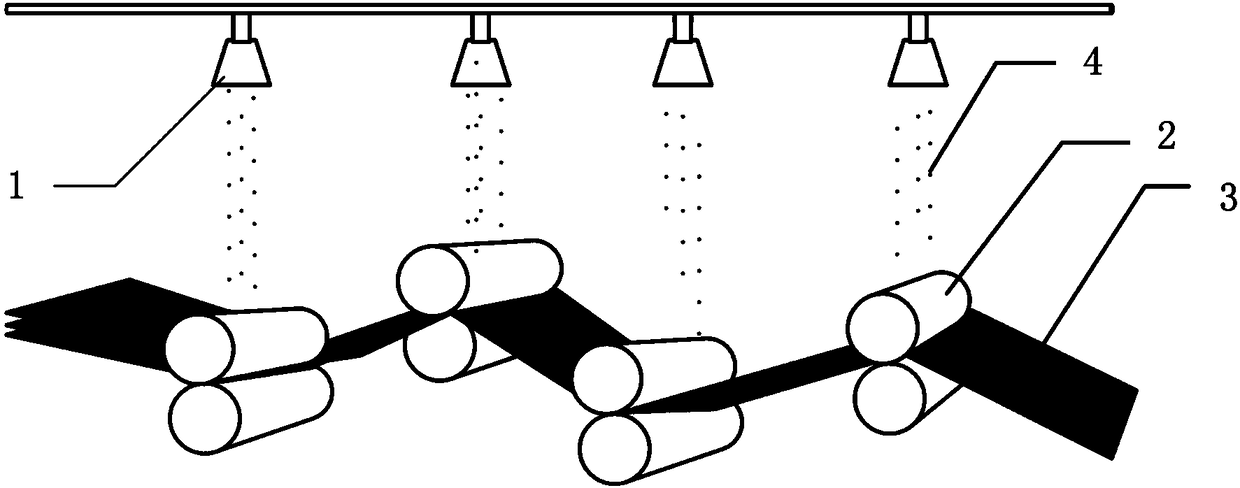

[0042] The schematic diagram of the pressurization process is shown in figure 1 shown.

[0043] S1: Use an electronic balance to weigh out 30 g of acetone solution, and place it in the spray container 1 .

[0044] S2: maki...

Embodiment 3

[0048] Embodiment 3 prepares carbon nanotube / graphene composite film, comprises the steps:

[0049] (1) Mix the uniformly dispersed graphene suspension (Weihai Weili Gaoke Carbon Material Co., Ltd.) with the uniformly dispersed carbon nanotube dispersion (Suzhou Jiedi Nano Technology Co., Ltd.) according to the mass ratio = 1:10, and pass through the cloth Deposit by funnel suction filtration, the pressure is 1MPa, and dry naturally at room temperature to obtain a carbon nanotube / graphene composite film with a thickness of 130.6 microns; wherein, the concentrations of the graphene suspension and the carbon nanotube dispersion are respectively 0.5wt% , 1 wt%.

[0050] (2) Using a flat vulcanizer to pressurize

[0051] S1: Use PE film to prepare a transparent square container of 15cm×15cm, place the square container in the middle of the upper and lower platens of the flat vulcanizer, and put 30ml of ethanol solution in the square container.

[0052] S2: Cut the carbon nanotube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com