Patents

Literature

324results about How to "Achieve densification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for achieving high-melting-point material 3D printing through nanometer ink together with laser melting

InactiveCN103407296AWide range of choicesLarge specific surface areaOther printing apparatusDevice formInk printer

The invention discloses a method for preparing the nanometer ink through ceramics, metal, semiconductors, glass and other high-melting-point materials, carrying out 3D printing and utilizing the laser heating sintering in the process of printing to obtain 3D devices formed by combining the ceramics, the metal, the semiconductors and other composite. The method comprises the first step of processing raw materials needed to prepare the device into nanometer particles of 1-500nm, the second step of preparing the particles into ink jet printing ink, the third step of carrying out 3D printing by utilizing an improved ordinary ink printer and adopting the laser heating sintering in the process of printing, and the fourth step of achieving the melting and sintering molding of the nanometer particles. According to the method, micron-level precision devices with any complex shape can be directly prepared, the high surface energy of the nanometer particles is utilized, the sintering temperature is lowered, high density is achieved, and a superior property is obtained. The method can be used for manufacturing automobile metal ceramic composite pistons, aviation engine tail pipes, and ceramic bearings and ceramal composite precise components of watches and other precision instruments and for directly printing a circuit board.

Owner:南京鼎科纳米技术研究所有限公司

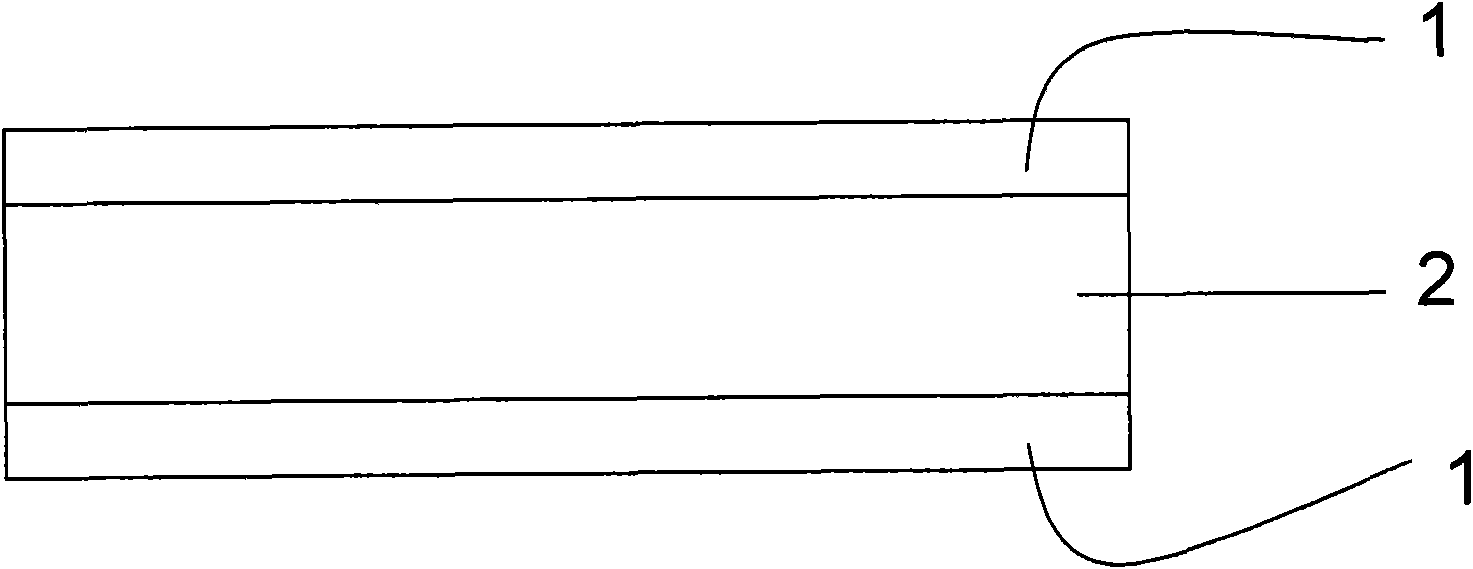

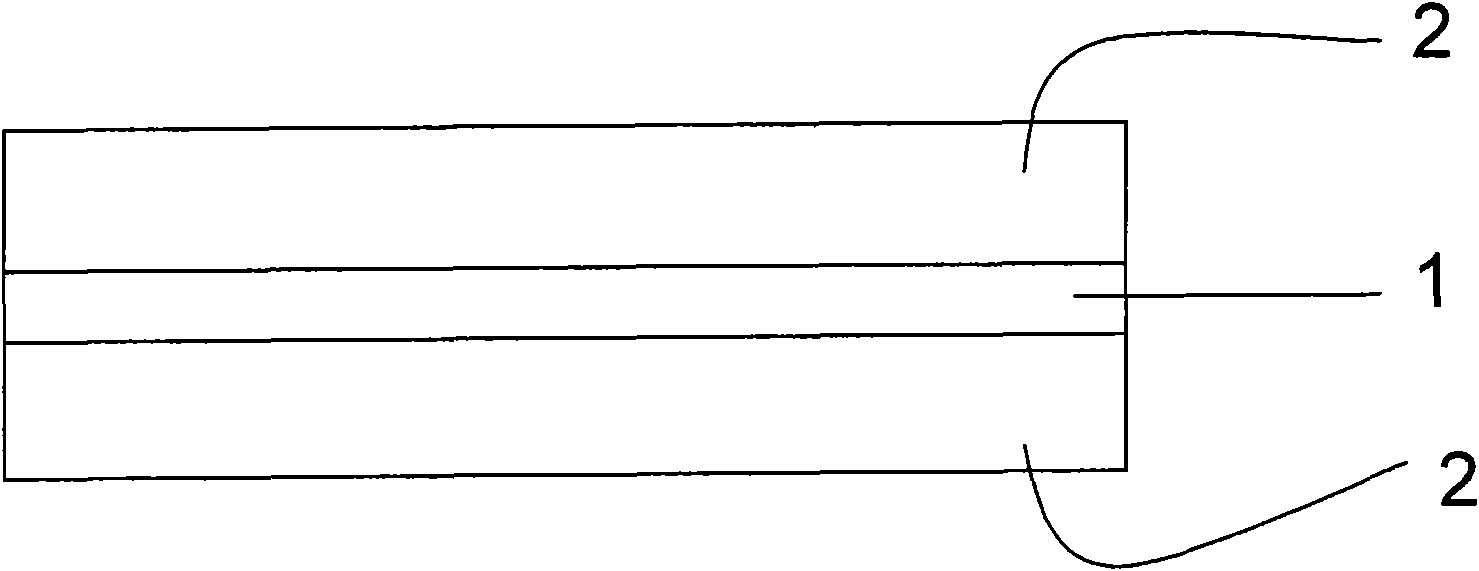

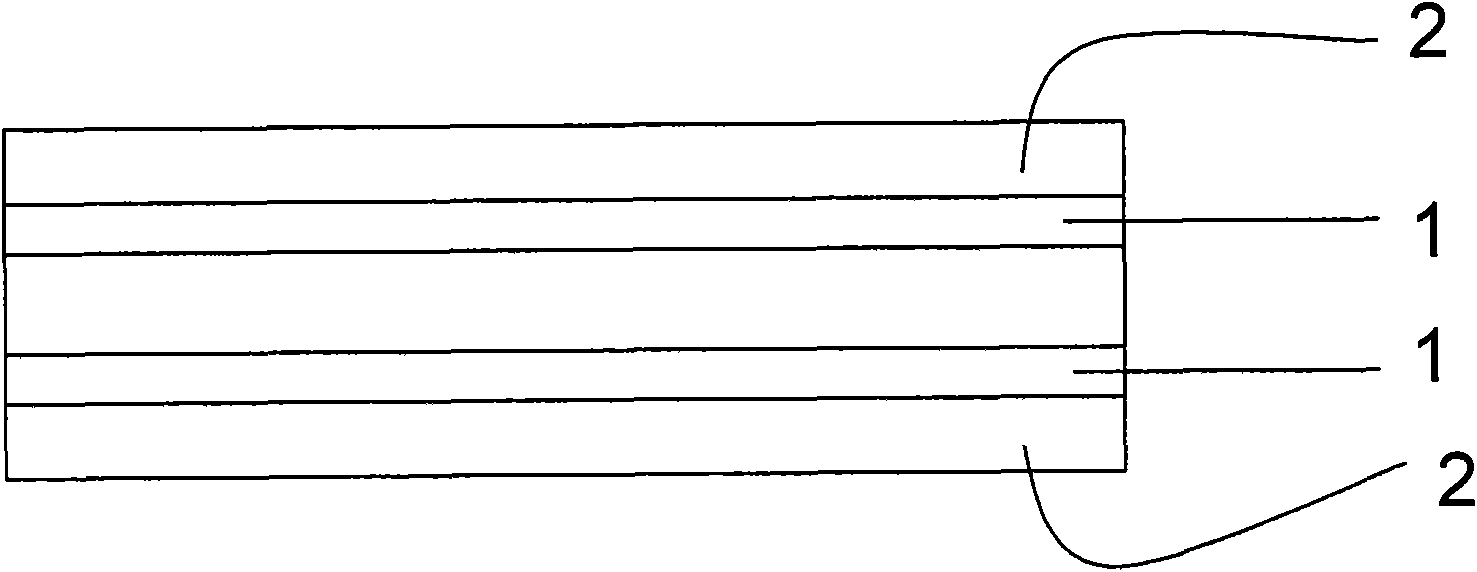

Method for densifying wood and densified wood

The invention discloses a method for densifying wood and densified wood manufactured by the same. The method comprises: sealing the cross section of wood by using a hydrophobic material, wherein the water content of the wood is less than 12 weight percent; coating softener on the surface and / or shallow layer of the sealed wood; and performing the hot pressing of the wood of which the cross section is sealed and which is coated with the softener at a temperature above the boiling point of the softener to densify the wood. The method for densifying wood can compress the wood to different extent according to needs. The method is simple and easy to operate, requires short time and simple equipment and makes product cost low. The densified wood manufactured by the method of the invention is greatly improved in surface density, hardness and wear resistance.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

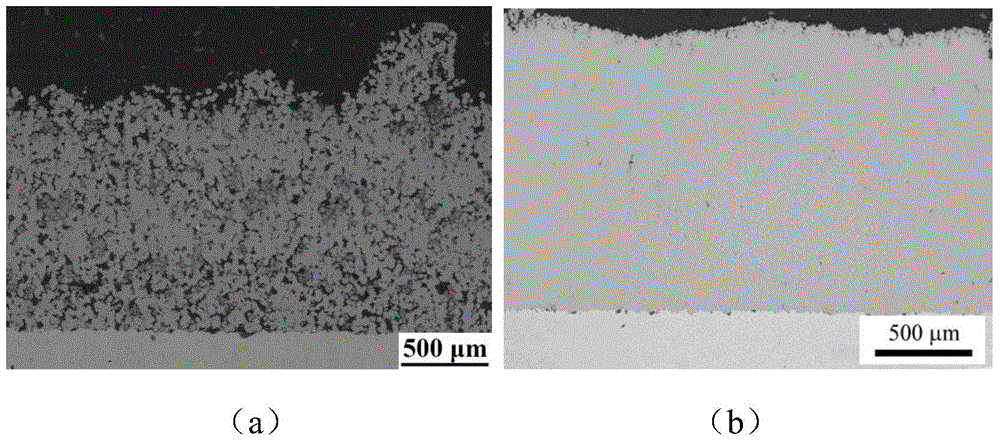

Preparation method of high density cold spraying metal/metal-based sedimentary body and application thereof

ActiveCN104894554AAchieve densificationImprove conductivityHeat inorganic powder coatingMaterials processingPeening

The invention discloses a preparation method of a high density cold spraying metal / metal-based sedimentary body and an application thereof, which belongs to the technical field of material processing. The method comprises the following steps: 1)taking ceramic particles, cermet particles, fine metal or an alloy as shot blast particles; taking fine metal with a single component, the alloy, metal and a metal-based composite material, or, taking a mixture of two or more than two of fine metal, the alloy or an intermetallic compound as deposition material powder; and 2)employing a cold spraying technology for spraying a mixture of the shot blast particles and the deposition material powder on the surface of the matrix to prepare the high density cold spraying metal / metal-based sedimentary body. According to the method, obvious increasing of particle speed and deposition temperature is not required, operation is simple, the deposition body has more excellent conductivity, thermal conductivity, higher corrosion resistance, wear resistance and higher mechanical property, so that the deposition body can be used for preparing the coating with high conductivity, high heat conduction, high corrosion resistance and high wear resistance as well as high mechanical property workpiece.

Owner:XI AN JIAOTONG UNIV

Sintering preparation method of boron carbide ceramic

The invention discloses a sintering preparation method of boron carbide ceramic, which comprises the following steps: 1. sintering: carrying out mixing and ball milling on boron carbide powder, carbon powder, metal powder, a dispersant, an adhesive and deionized water to make a slurry, carrying out spray granulation, pressing into a biscuit, presintering for debonding, and carrying out thermal-insulation sintering at lower sintering temperature (slightly higher than the melting point of metal), thereby implementing primary shrinkage sintering of the product by utilizing the surface tension of the molten metal in the system; and 2. sintering: continuing enhancing the sintering temperature, carrying out in-situ reaction to generate metal carbide, metal boride or metal boro-carbide and nano B4C which have higher sintering activity, and forming a solid solution with boron carbide granules by using the metal carbide, metal boride or metal boro-carbide and nano B4C as sintering assistants to promote the further shrinkage sintering of the system, thereby obtaining the high-performance boron carbide ceramic. The method has the advantages of both the normal-pressure sintering technique and the reactive sintering technique.

Owner:NINGBO VULCAN TECH CO LTD

High-strength high-conductivity oxidation-resisting low-silver copper-base alloy and preparation thereof

A copper base alloy, which possesses high-strength, high conductivity, oxidation resistance and contains silver of low content, is characterized in that said high-strength high-conductivity oxidation-resistance low-silver copper base alloy is composed of low-silver copper base alloy powder, diamond powder of 0.2-1.0% and graphitized nanometer carbon fibre and is prepared through a powder metallurgy technological process, wherein said low-silver copper base alloy powder contains Ag of 0.08 -0.12%, Y, La and Ce of 0.05 -0.5% or one of misch metal or mixture of several misch metal. Said alloy in accordance with the present invention possesses higher intensity and hardness, stronger anti-crackle forming and stomatic expandability, and exhibits definite puddle welding resistance and better electroconductive performances at the same time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

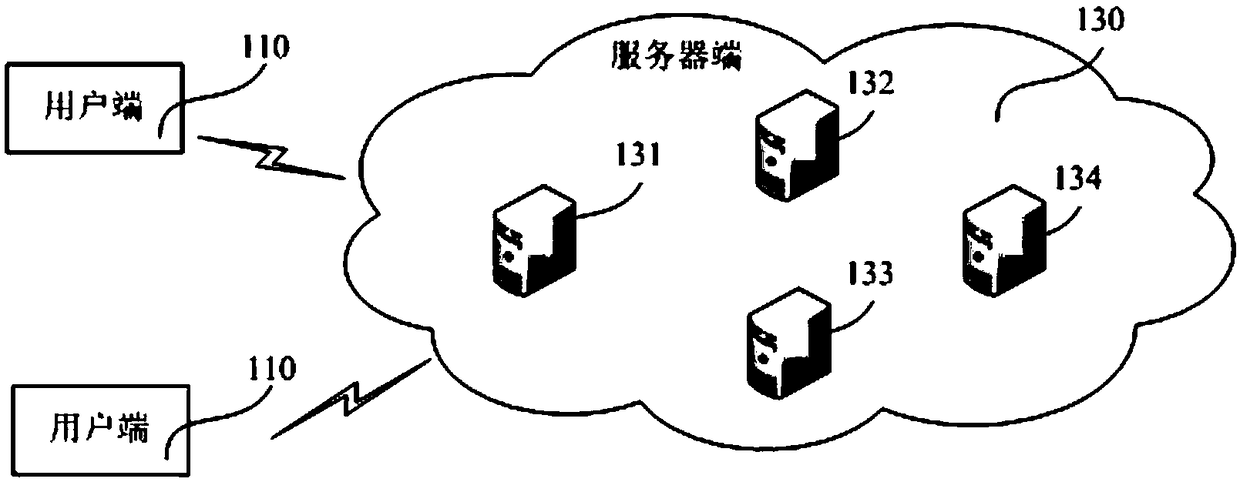

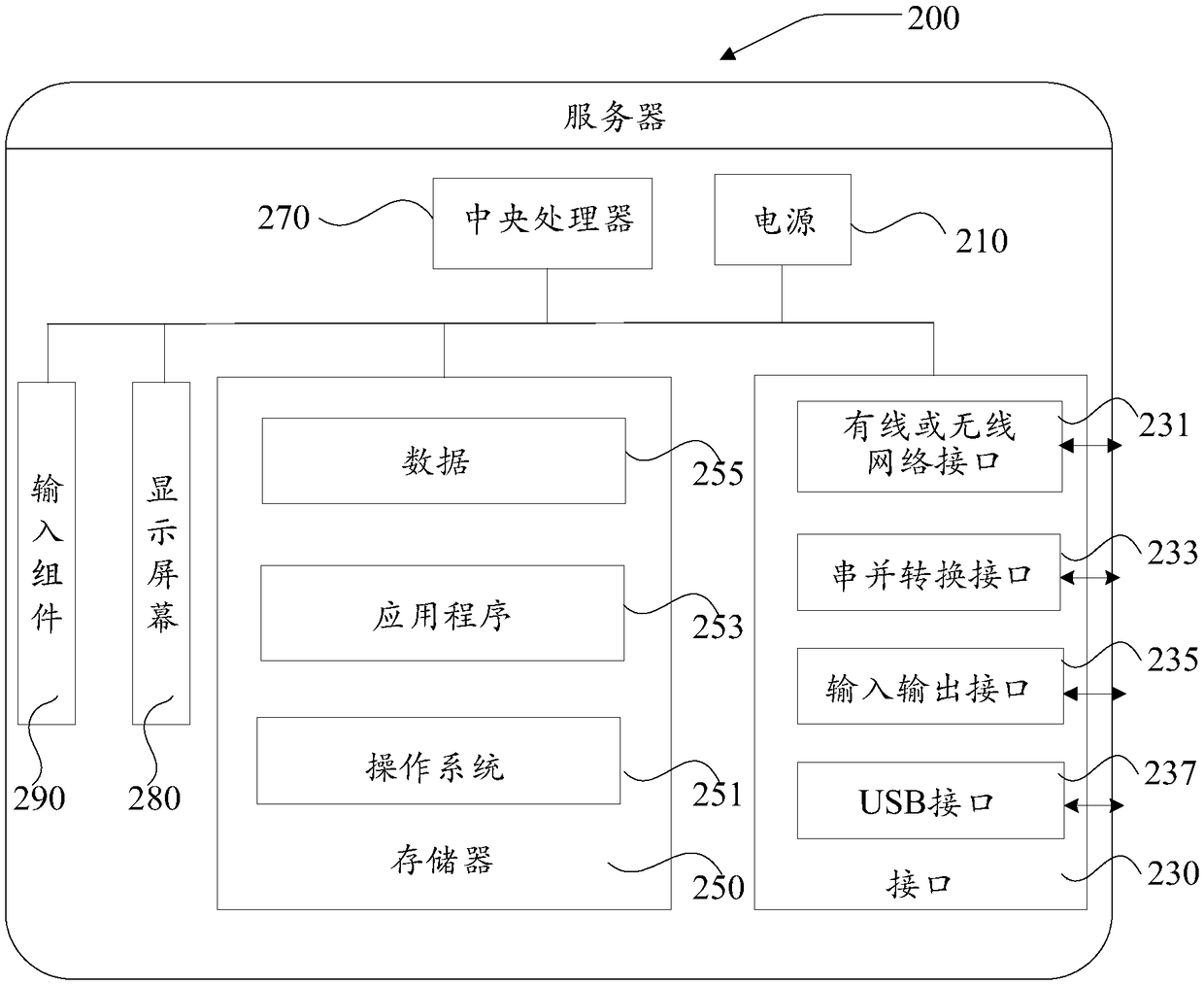

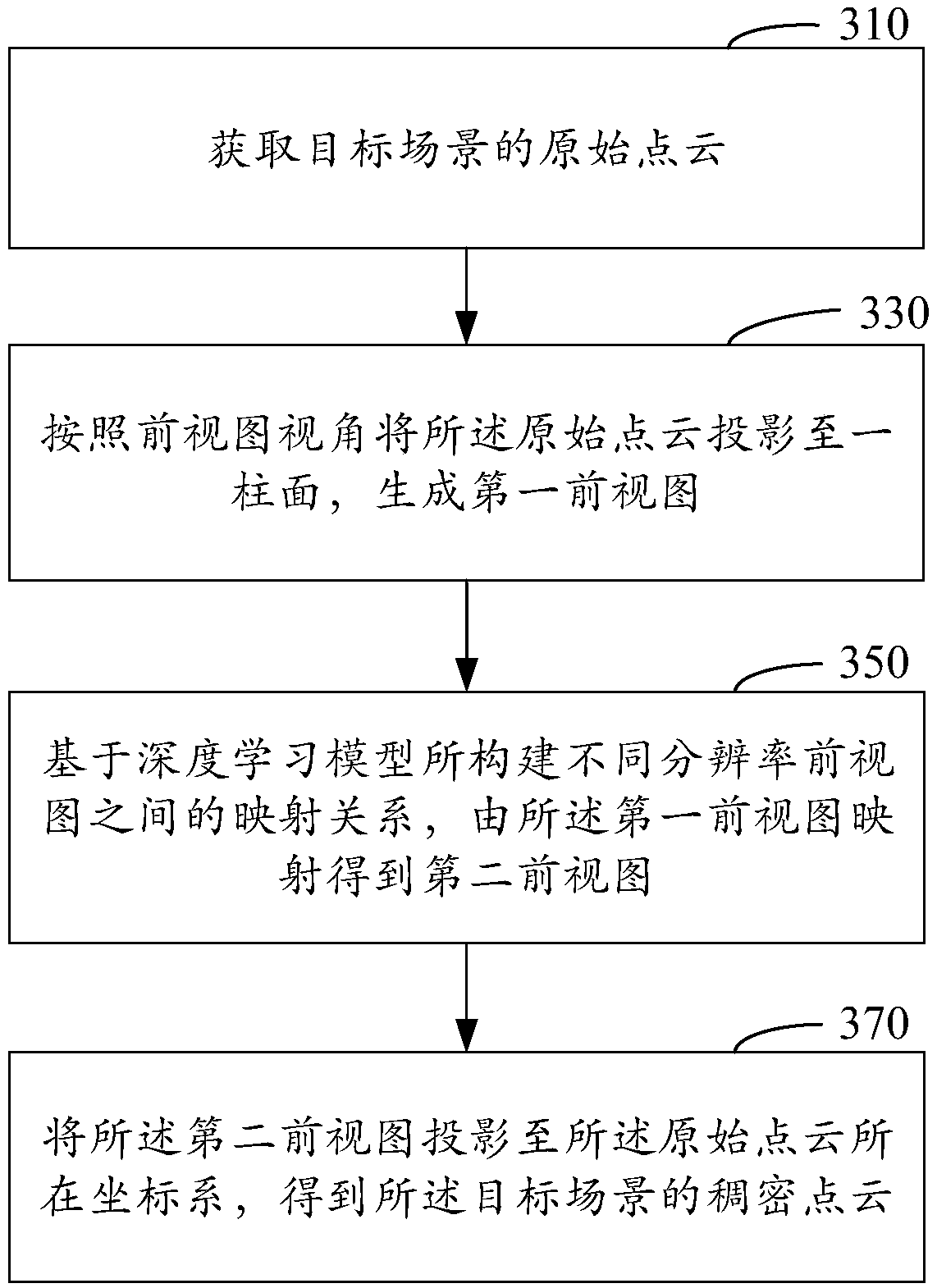

Method and device for realizing laser point cloud densification and computer equipment

ActiveCN109493407AAchieve densificationSolve the problem of relatively poor densification effectImage enhancementImage analysisPoint cloudRadar

The invention discloses a method and device for realizing laser point cloud densification and computer equipment. The method for achieving laser point cloud densification comprises the steps that original point cloud of a target scene is obtained; projecting the original point cloud to a cylindrical surface according to a front view angle, generating a first front view, the front view angle beingrelated to an azimuth angle when the laser radar collects the original point cloud; based on a mapping relation between different resolution front views constructed by a deep learning model, mapping the first front view to obtain a second front view, the resolution of the second front view being higher than the resolution of the first front view; and projecting the second front view to a coordinate system where the original point cloud is located to obtain dense point cloud of the target scene. By adopting the method and the device for realizing laser point cloud densification and the computerequipment provided by the invention, the problem of relatively poor densification effect of the laser point cloud in the prior art is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

A kind of preparation method of pseudo-boehmite and microcrystalline corundum abrasive

ActiveCN102295304AParticle size is smallHigh purityOther chemical processesAluminium oxides/hydroxidesBoehmiteAluminium isopropoxide

The invention relates to a preparation method of pseudo-boehmite and a microcrystalline corundum abrasive. The method comprises the steps of: hydrolyzing aluminium isopropoxide under a hydrothermal condition so as to obtain the pseudo-boehmite with a particle diameter of 3-20nm, then preparing, drying, calcinating and sintering a pseudo-boehmite gel, thus obtaining the microcrystalline corundum abrasive. With controllable technical conditions, the method of the invention is suitable for large scale production, and the obtained microcrystalline abrasive has a particle size of 50-300nm, and a compact structure, with a density of 3.9-4.0g / cm<3> and hardness of 19-23GPa. Besides used as a wear resistant material, the obtained microcrystalline corundum abrasive can also be used in high temperature materials, matrials for electronic devices, high frequency insulating materials, aerospace materials, information materials and the like.

Owner:SHANDONG UNIV

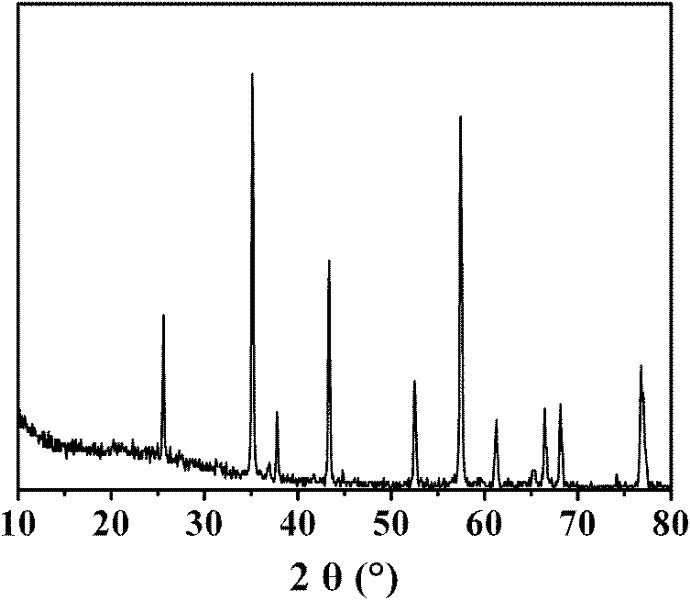

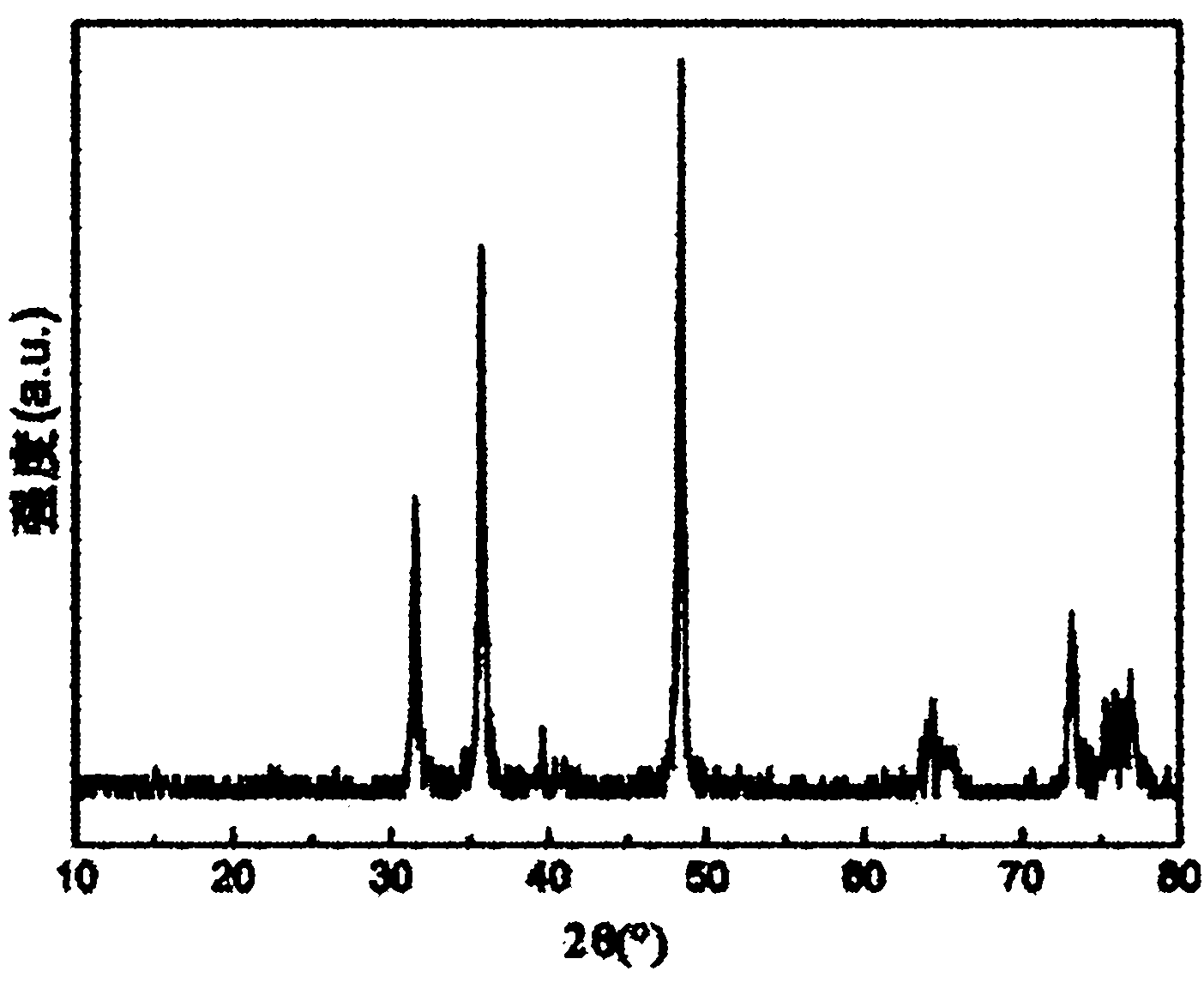

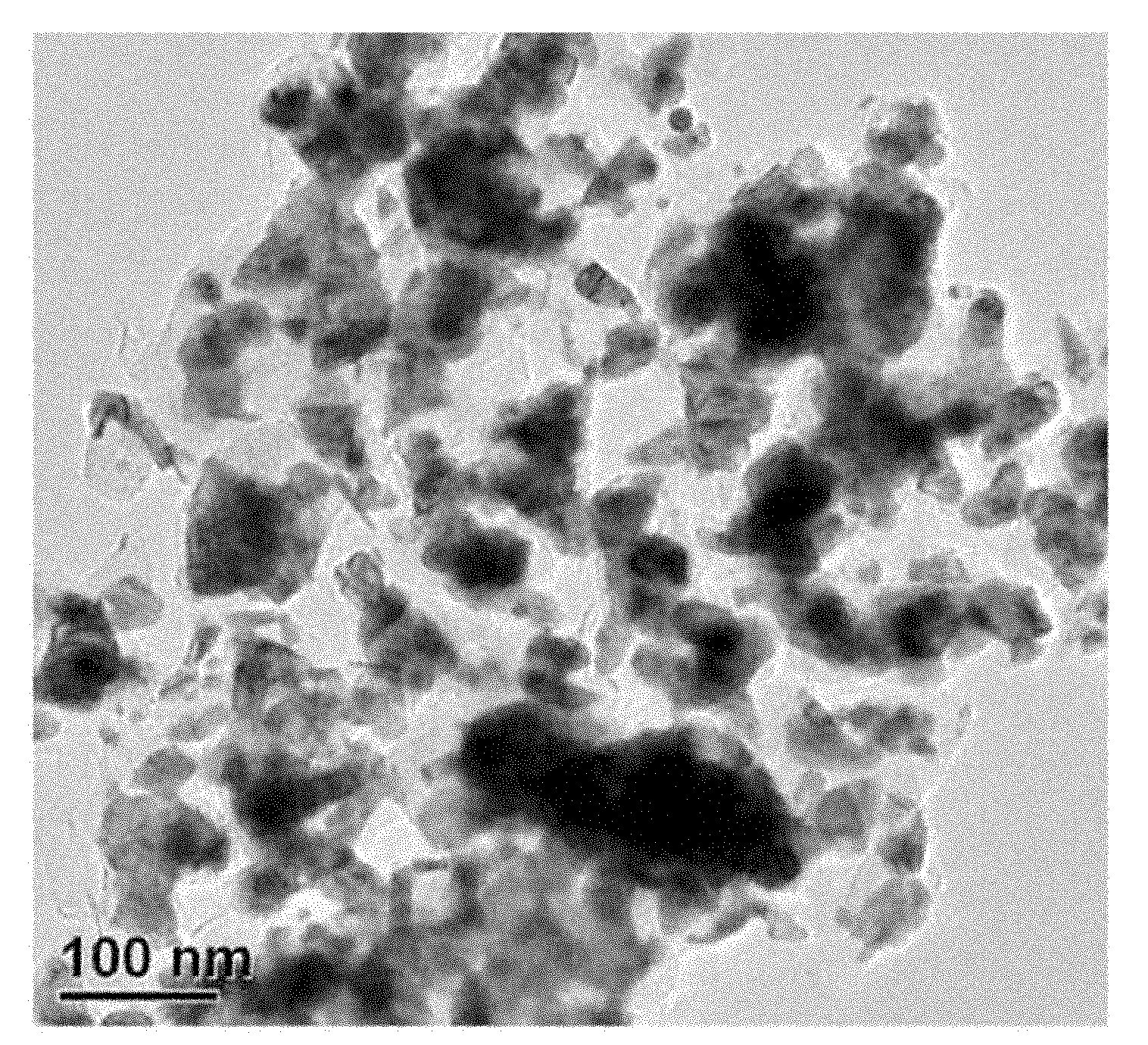

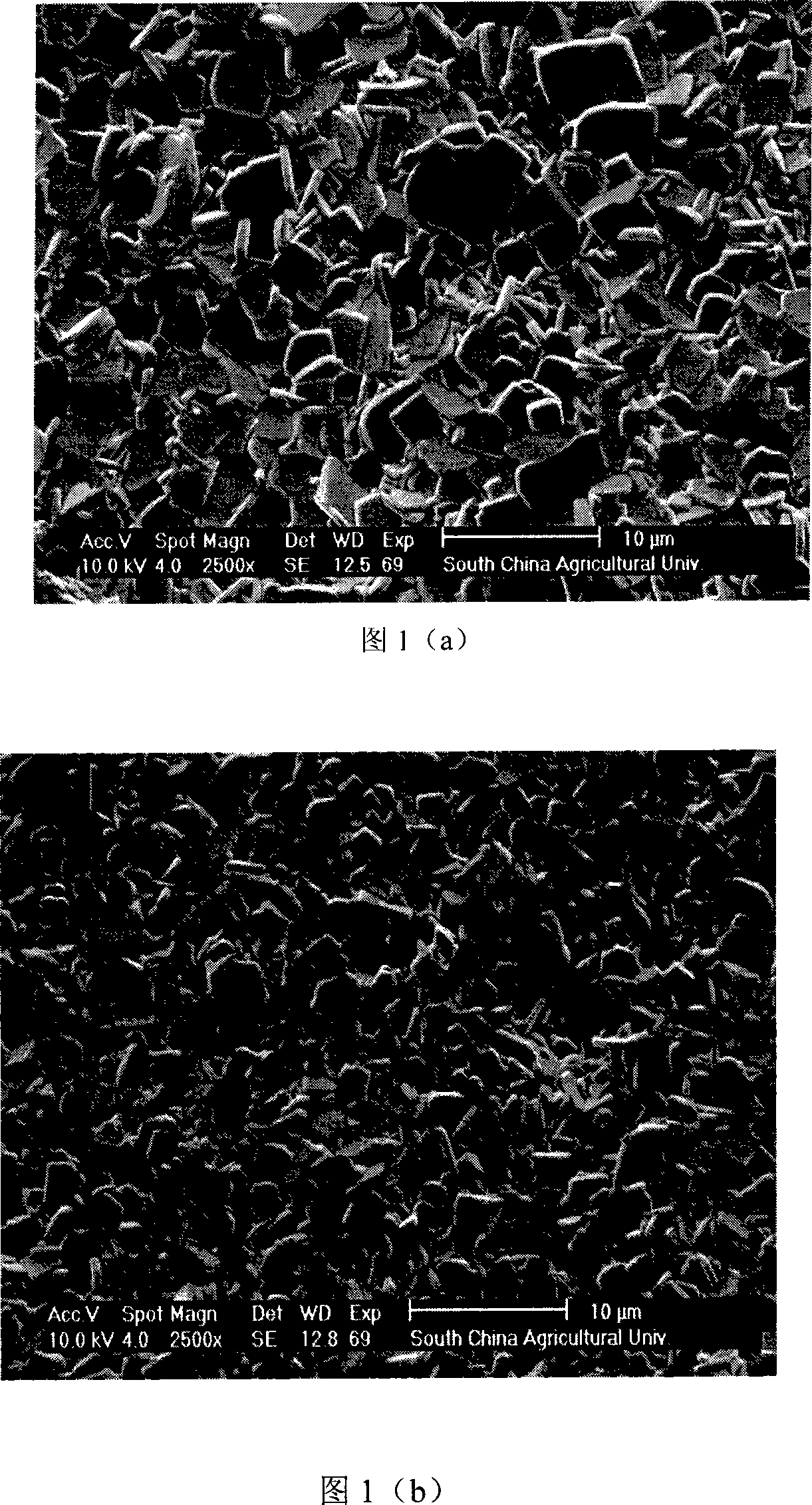

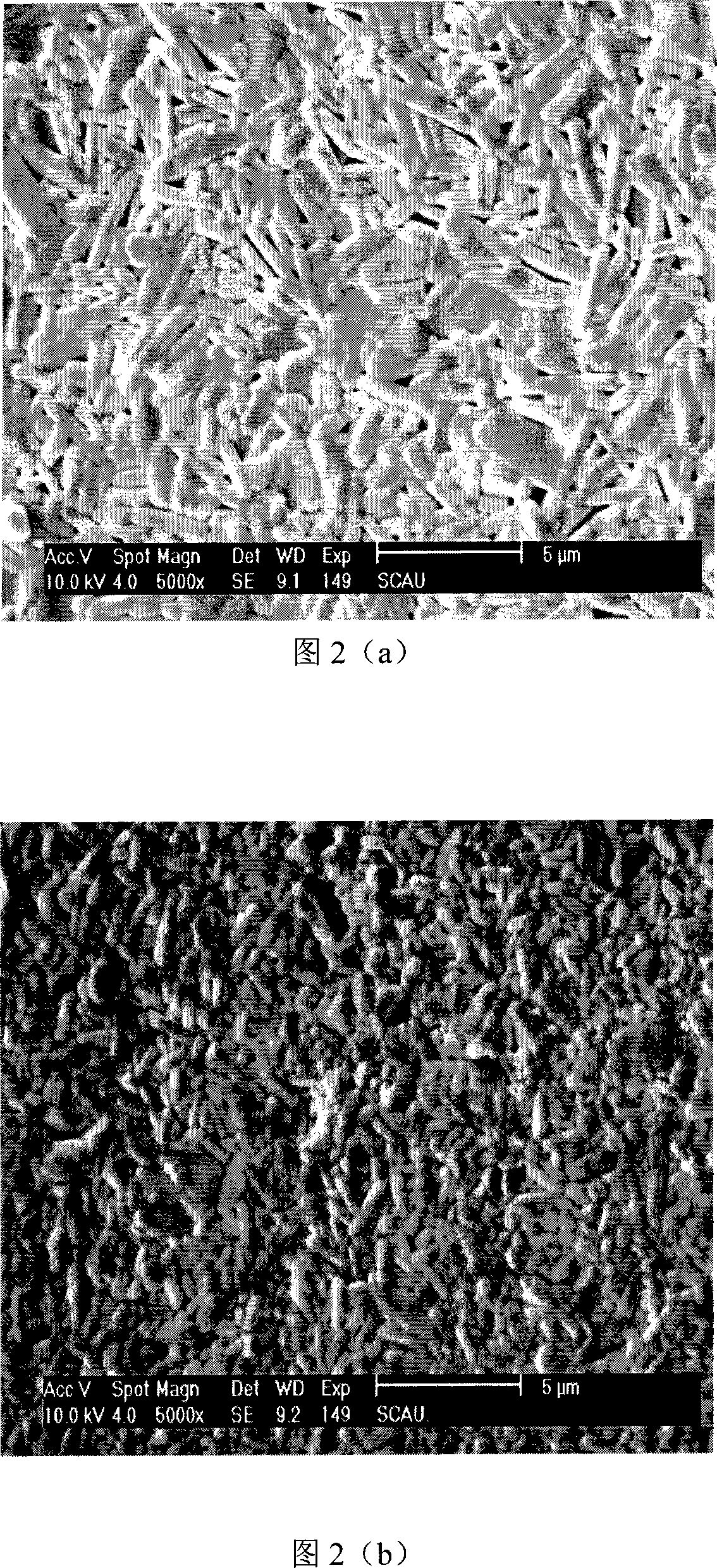

Preparation method for high-performance WC-Co nanocrystal cemented carbide

A disclosed preparation method for high-performance WC-Co nanocrystal cemented carbide comprises: taking nanometer tungsten carbide (WC) powder, ultrafine cobalt (Co) powder and ultrafine vanadium carbide (Cr2C3) powder as raw material powders, employing an alcohol wet grinding technology, and performing vacuum sintering and hot isostatic pressing sintering to prepare the WC-Co nanocrystal cemented carbide. By employing the above method for preparing nanocrystal cemented carbide, WC crystal grain structure is complete and clearly visible, by employing a method prescribed in ISO4499-2 for calculating two hundred or more WC crystal grains and averaging, the WC average crystal grain is less than 150 nm, the hardness HV30 is 1900 or more, the strength TRS is 4000 MPa or more and the metallographic structure is A02B00C00. The technology is simple, the process control is convenient, the production cost is low, and the prepared nanocrystal cemented carbide has the advantages of high densification degree and excellent performances.

Owner:XIAMEN TUNGSTEN

Manufacturing method for high-copper-silicon magnesium powder metallurgy aluminum alloy

The invention relates to a manufacturing method for a high-copper-silicon magnesium powder metallurgy aluminum alloy, and belongs to the field of material forming with a traditional powder metallurgy forming-sintering process combined with aluminum alloy machining. The manufacturing method includes the steps that an aluminum alloy ingot blank is manufactured through indoor temperature pressing-sintering; then, the aluminum alloy ingot blank is subjected to hot extrusion to obtain an aluminum alloy section; the aluminum alloy section is subjected to solid-solution quenching treatment; and finally, the aluminum alloy section obtained after quenching treatment is subjected to aging treatment. The performance of the material is significantly improved through proper low-temperature sintering assisted by heat machining and heat treatment matched with the temperature of low-temperature sintering, and particularly, an unexpected effect on increase of elongation is achieved. The manufacturing process is simple, the obtained product is excellent in performance, and large-scale industrialized application is facilitated.

Owner:CENT SOUTH UNIV

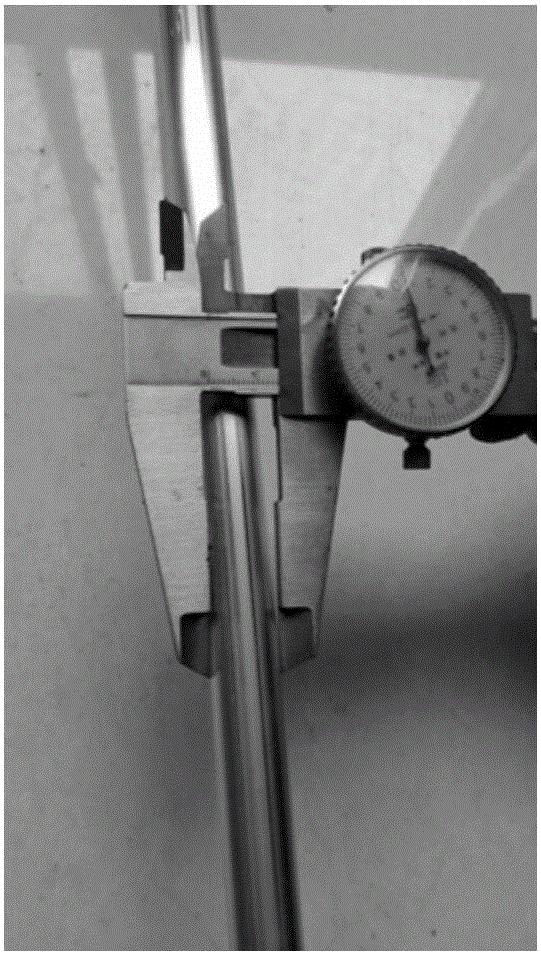

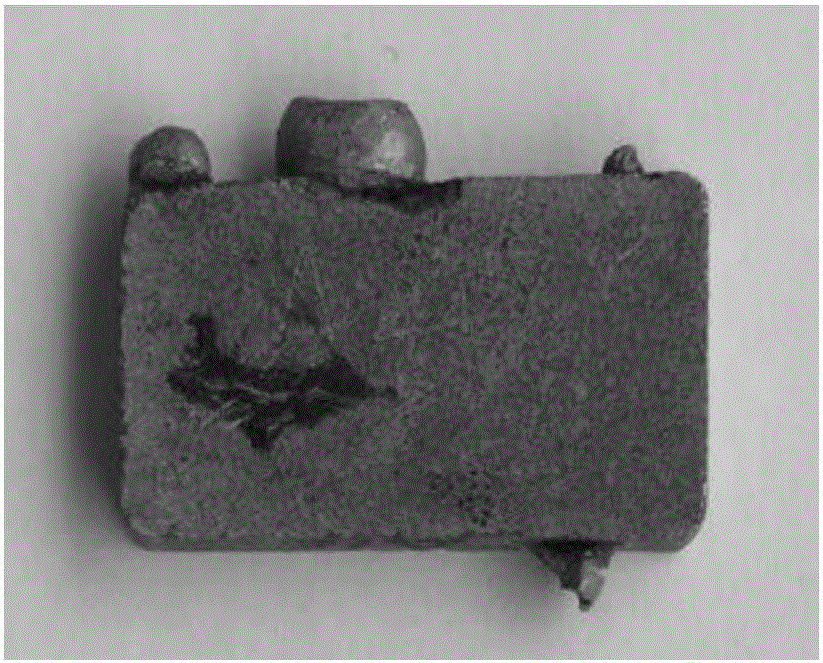

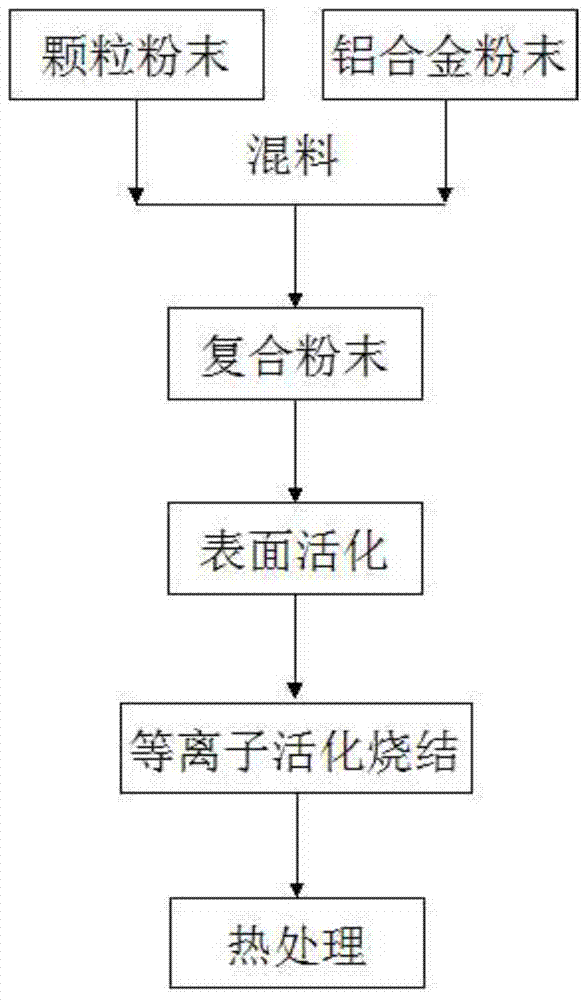

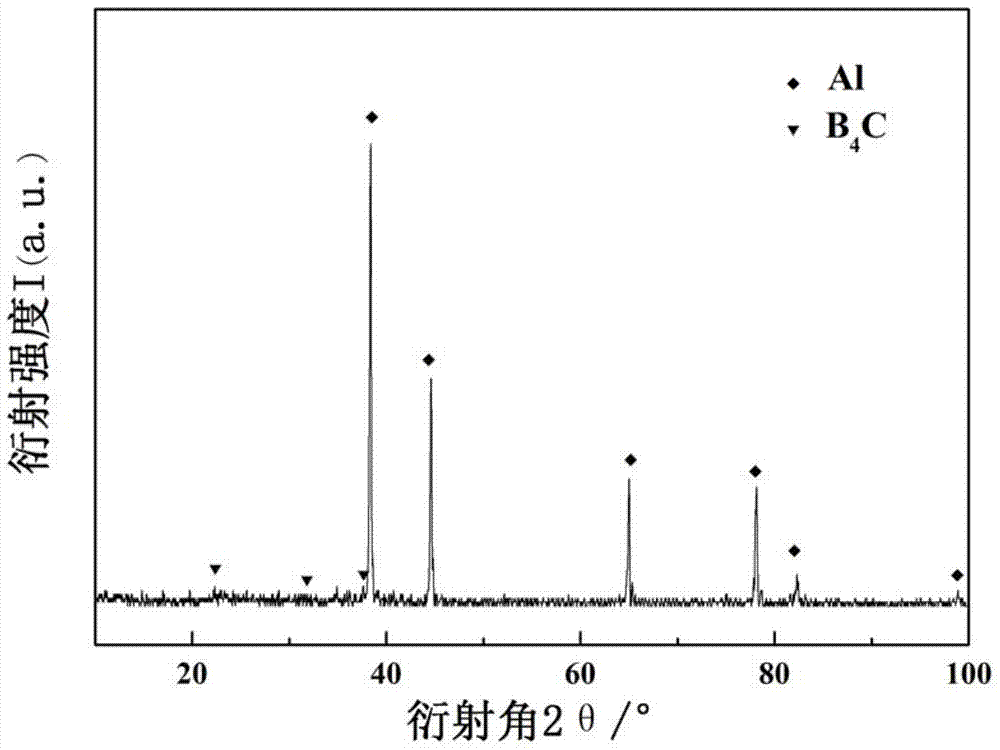

Preparation method of boron carbide particle enhanced aluminum-based composite material

The invention relates to the technical fields of aluminum-based composite materials and preparation thereof, in particular to a boron carbide particle enhanced aluminum-based composite material and a preparation method thereof. According to the composite material, aluminum alloy is used as a matrix; the mass percentage of boron carbide used as a wild phase is 2.5 to 30%; the boron carbide particles are distributed in the matrix uniformly. The specific preparation method comprises the following steps: mixing boron carbide powder and aluminum alloy powder; performing surface activation, plasma activated sintering and heat treatment to prepare a sintering test sample close to full density. The aluminum-based composite material prepared by the method has low sintering temperature, high density, small crystal particles and an excellent mechanical property, is simple to operate and high in controllability, and is a lightweight high-performance aluminum-based composite material.

Owner:WUHAN UNIV OF TECH

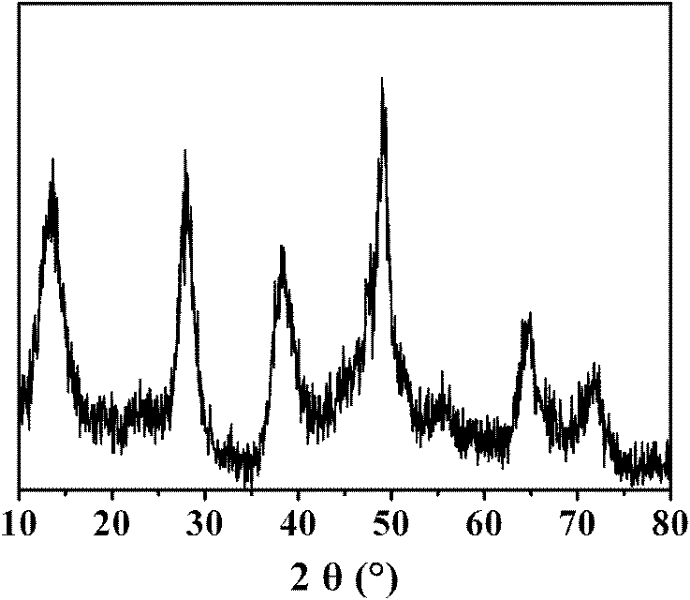

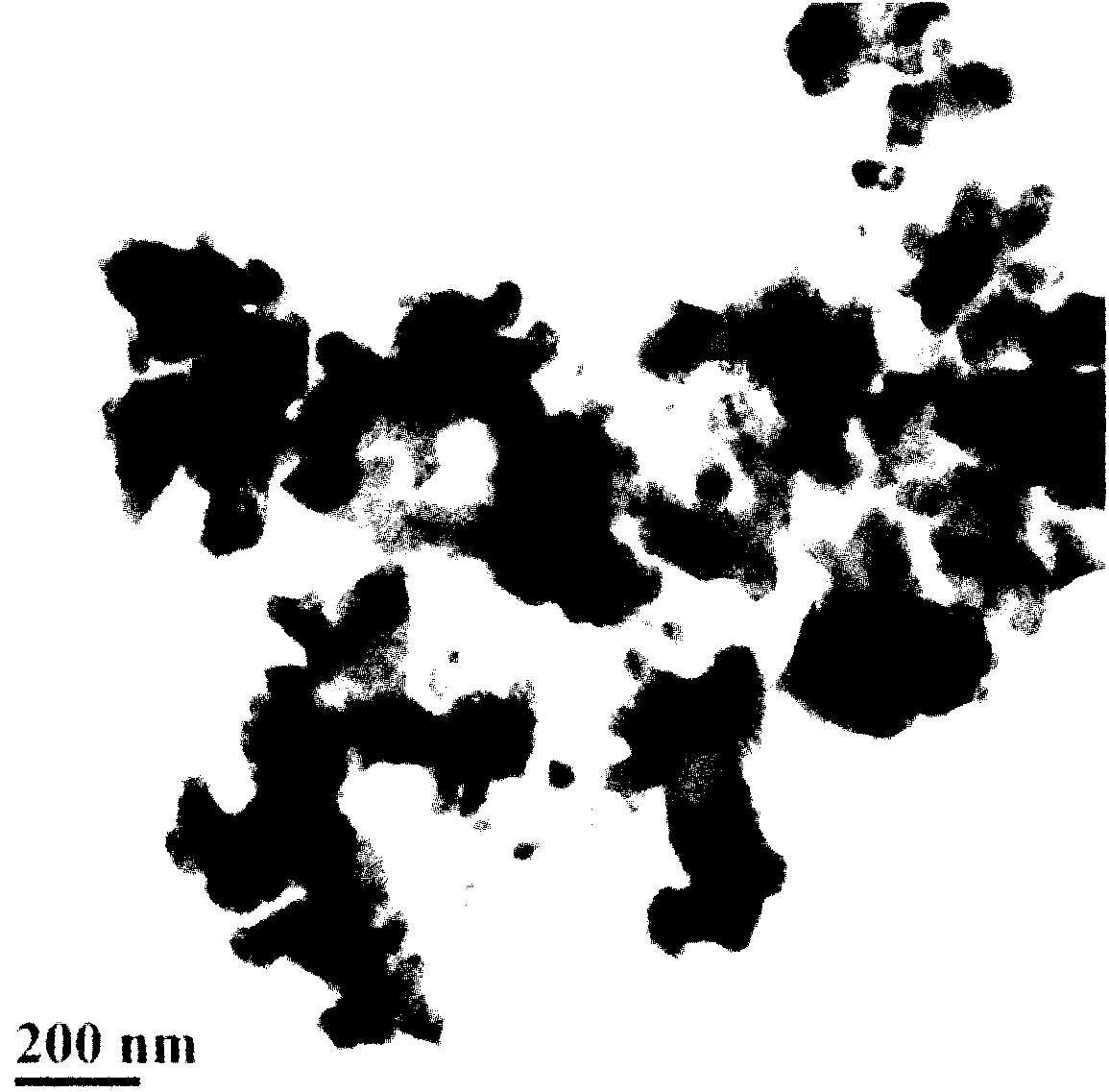

Method for preparing tungsten carbide nano-powder

InactiveCN101985356ASimple preparation processStrong maneuverabilityTungsten/molybdenum carbideAir atmosphereIon

The invention discloses a method for preparing tungsten carbide nano-powder. The method comprises the following steps of: dissolving ammonium paratungstate and citric acid in deionized water, and performing complexation in water bath; filtering and drying to obtain a precursor of tungsten oxide, and calcining under air atmosphere to obtain tungsten oxide powder; putting the obtained tungsten oxide powder in a tube furnace, introducing ammonia and nitriding to obtain tungsten nitride powder; mixing the obtained tungsten nitride powder and carbon black, performing ball milling, performing rotary evaporation drying and performing heat treatment under the air pressure of less than 200 Pa or inert atmosphere; or putting the obtained tungsten nitride powder in the tube furnace, and introducing the mixed gas of methane and hydrogen and carbonizing to obtain the tungsten carbide nano-powder. The preparation process of the method is simple, practical, and high in controllability and can easily realize large-scale production; the particle size of the prepared powder is small, the particle size distribution is uniform and the aggregation degree is low; and the method has high sintering activity, and densification can be realized by performing hot pressing sintering at the temperature of 1,700 DEG C.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

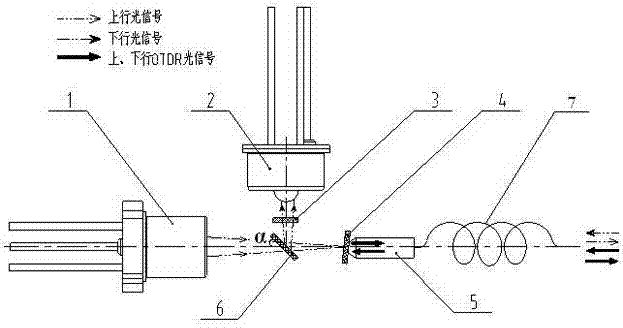

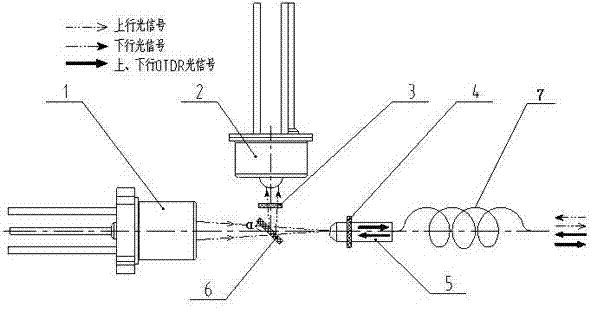

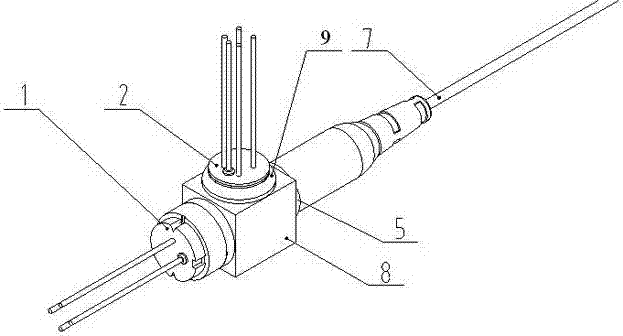

Optical network unit photoelectric device with optical time domain reflection function

ActiveCN102412902AReal-time and accurate online monitoringAchieve densificationCoupling light guidesElectromagnetic transmissionTime domainOperational costs

The invention discloses an optical network unit (ONU) photoelectric device with an optical time domain reflection function. The photoelectric device comprises a laser used for emitting up light, a photoelectric detector used for receiving an optical signal, and an optical interface used for external connection with a fiber. Along an optical axis direction of the optical interface, the photoelectric device is provided with a first wavelength division multiplexing element inside. The up light and down light can fully penetrate through the first wavelength division multiplexing element, an optical time domain detection signal used for optical time domain reflection is fully or partly reflected, and an optical time domain detection signal which penetrates through the first wavelength division multiplexing element returns to a fiber through the optical interface. According to the invention, a reflection function to the optical time domain detection signal is integrated in the ONU photoelectric device used in an optical network, real-time accurate on-line monitoring of each path of ONU by an OLT (optical line terminal) of a PON (passive optical network) system local side is realized, fault diagnosis of an optical network line by a service provider and positioning and detection of an ONU user are facilitated, and operation cost is greatly reduced.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

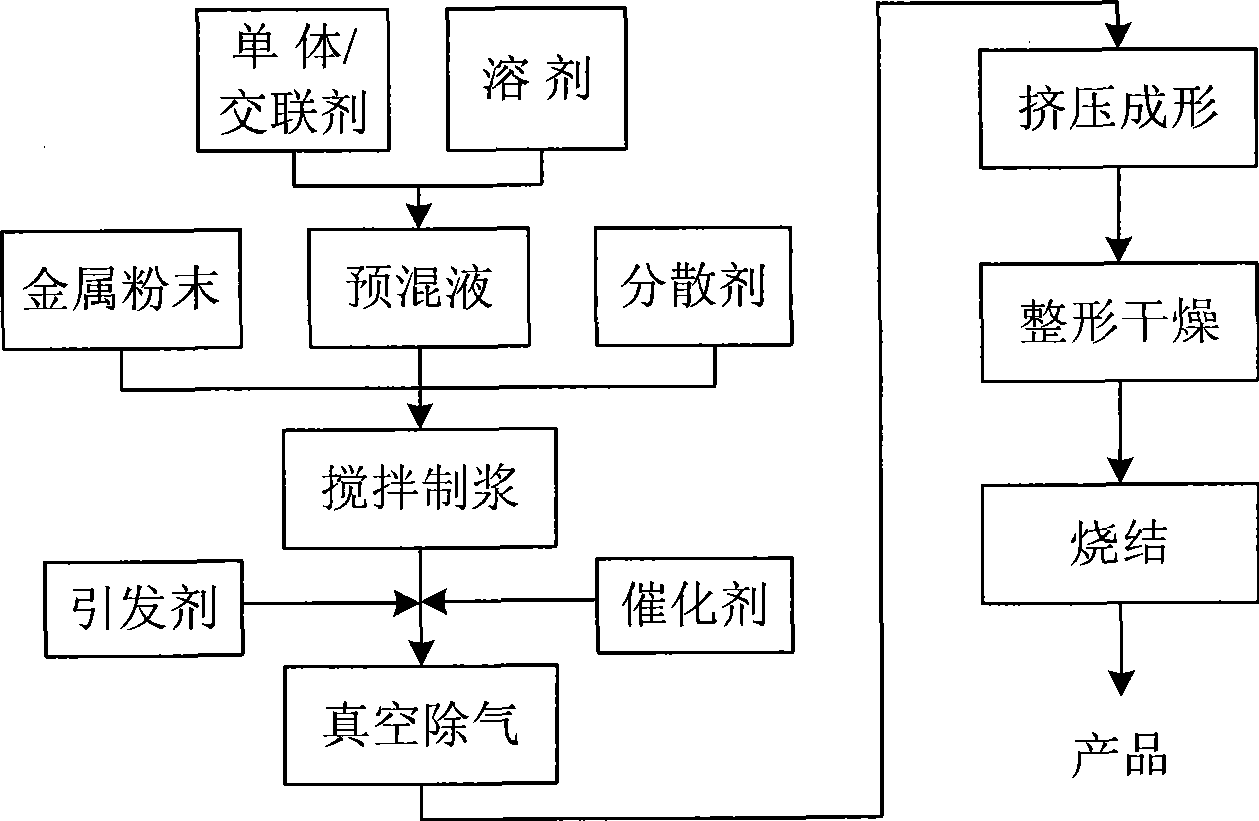

Method for extruding and molding metal powder gelatin

The invention relates to a method for extruding and molding metal powder gelatin, which belongs to the field of metal part preparation in powder metallurgic production technology. The method is characterized by comprising the steps: firstly, premixed liquid with finite concentration is prepared; then, metal powder is added into the premixed liquid to prepare a stable gelatin system; the stable gelatin system is extruded and molded to prepare a blank body; and finally, the blank body is sintered into a part. The invention breaks through the traditional molding technology and can prepare metal products with large sizes and complicated shapes. Compared with the pressure molding, the invention solves the problems of complicated shape limitation and energy consumption caused by overlarge pressure needed by molding, and greatly improves the molding condition. Compared with the injection molding and the hot pressure casting molding which need to be added with a lot of organic binding agents, the method does not need a special degreasing step, has simple technology and can greatly reduce the production cost.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing dense fluoride ceramic films on magnesium surface and magnesium alloy surface

InactiveCN101845636AUniform thicknessImprove bindingAnodisationMetallic material coating processesPhosphatePotassium fluoride

The invention relates to a method for preparing dense fluoride ceramic films on a magnesium surface and a magnesium alloy surface and belongs to the technical field of metal surface treatment. The method comprises the following steps of: chemically passivating a magnesium alloy; preparing a single-pulse ceramic film; and preparing a double-pulse ceramic film. In a chemically passivating process, solution such as hydrofluoric acid, phosphoric acid, hydrogen fluoride amine and the like are used; the preparations of the single-pulse ceramic film and the double-pulse ceramic film are mainly performed in a fluoride electrolyte-containing system, wherein potassium fluoride (sodium) is taken as a main salt; phosphate is taken as an additive; and citrate or tartrate is taken as a main stabilizing agent. The fluoride ceramic film obtained by the method is complete and dense, has high hardness, is firmly combined with a substrate, can be separately used as a protective layer and can be prepared into a composite surface functional layer which has higher corrosion resistance, higher wearing resistance and high hardness after subsequent processing treatment. The overall process of the method has the advantages of simple flow, low equipment cost, environment friendliness and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

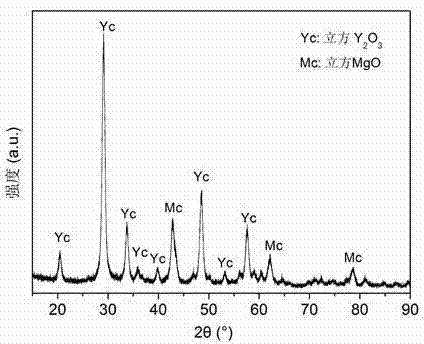

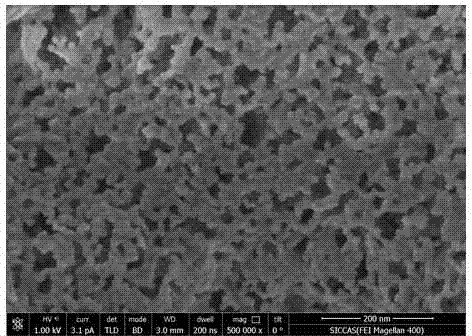

Y2O3-MgO nano-composite ceramic and preparation method thereof

The invention relates to a Y2O3-MgO nano-composite ceramic and a preparation method thereof. The Y2O3-MgO nano-composite ceramic is shown as xY2O3.(1-x)MgO, wherein x is the percentage of the mole number of Y2O3 to the total mole number of Y2O3 and MgO; the value of x is more than or equal to 0.01 and less than or equal to 0.99. The method comprises the following steps: preparing Y2O3-MgO nano-composite powder by adopting a sol-gel method; sintering the sieved composite powder by virtue of discharge plasma sintering or hot isostatic pressing sintering to obtain the infrared transparent Y2O3-MgO nano-composite ceramic.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

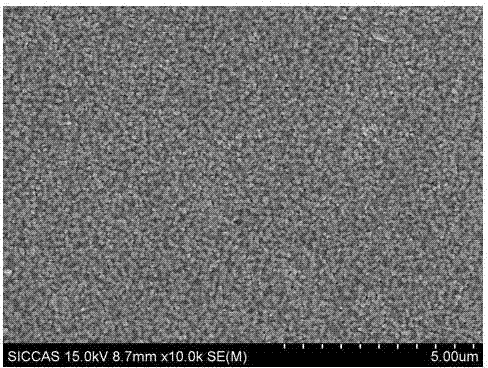

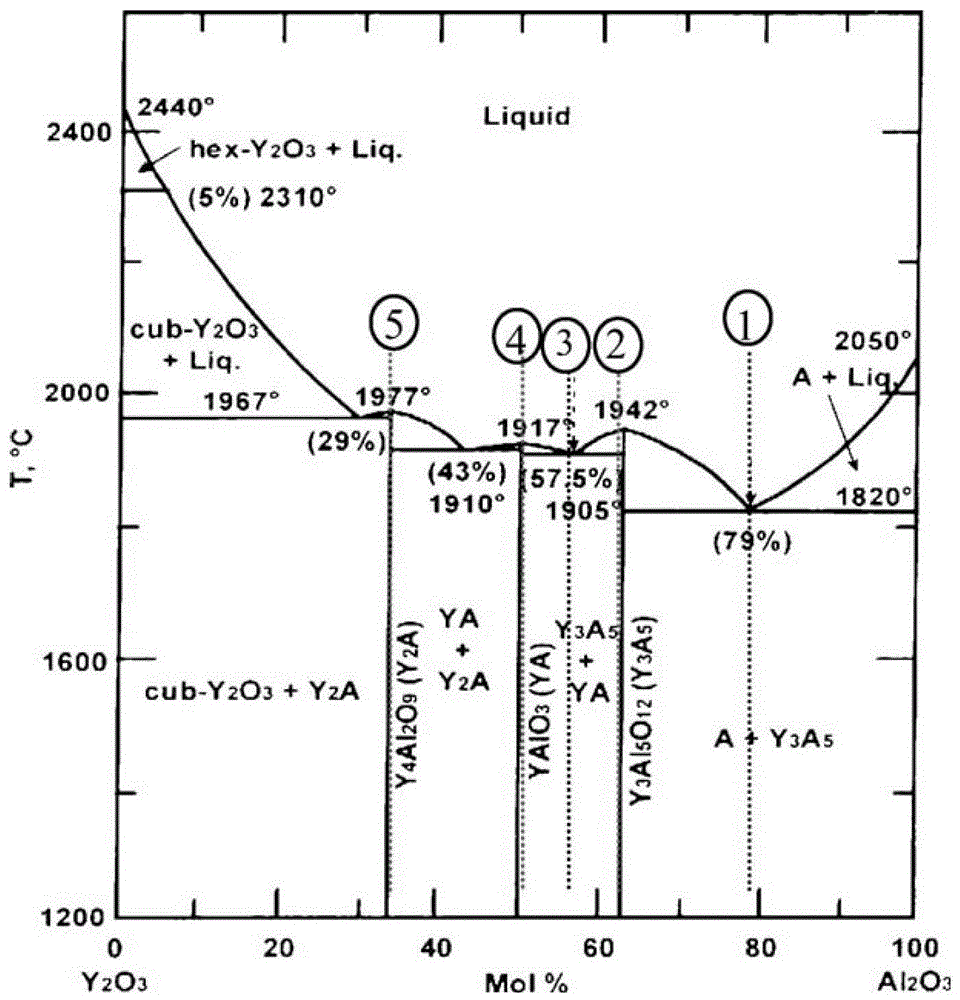

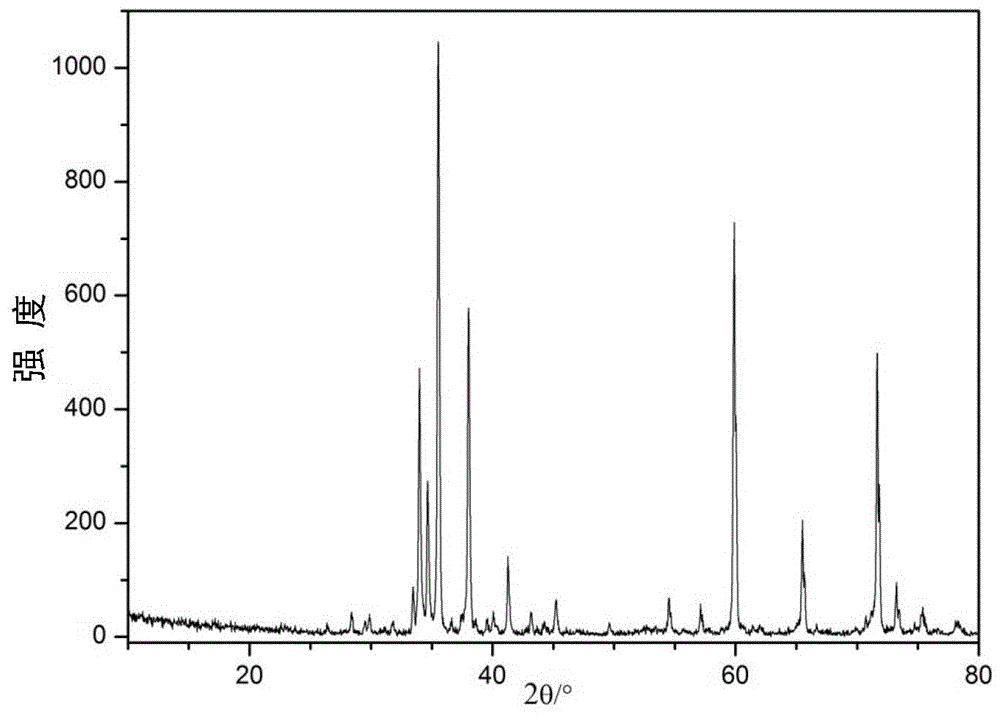

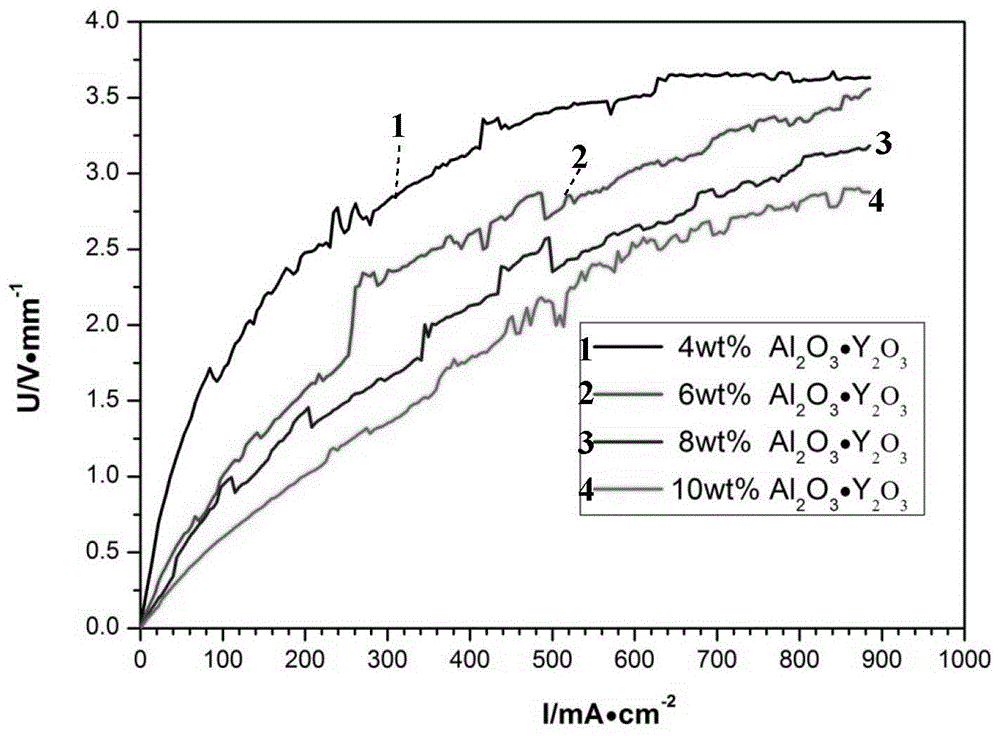

Liquid-phase sintered SiC non-linear resistance ceramic and preparation method thereof

The invention relates to a liquid-phase sintered SiC non-linear resistance ceramic and a preparation method thereof. The preparation method comprises the following steps: by taking SiC powder, Al2O3 powder and Y2O3 powder as raw materials, preparing so as to obtain slurry, wherein the particle size of the Al2O3 powder is smaller than 1[mu] m, and the particle size of the Y2O3 powder is smaller than 1[mu] m; performing spray granulation on the obtained slurry, and molding so as to obtain a blank; and performing vacuum unsticking on the obtained blank, and sintering for 1-2 hours at 1800-2000 DEG C in a normal-pressure insert atmosphere, thereby obtaining the SiC non-linear resistance ceramic. According to the SiC non-linear resistance ceramic prepared by using a liquid-phase sintering method, as eutecticevaporate rare-earth oxide sintering aids (the particle sizes of the Al2O3 powder and the Y2O3 powder are both smaller than 1[mu] m) are introduced, densification of the SiC ceramic sintered at relatively low temperature can be achieved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

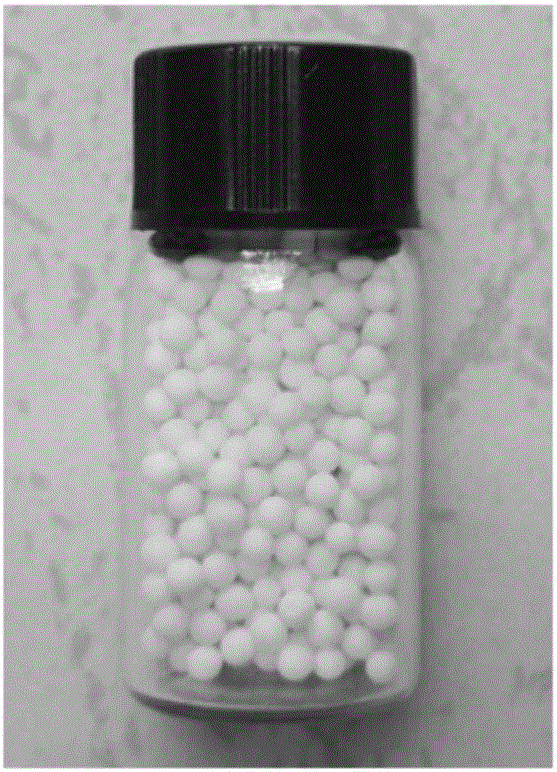

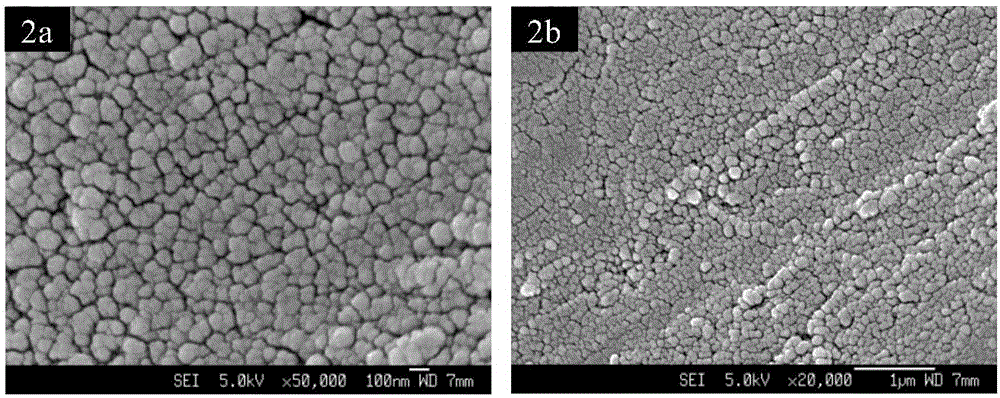

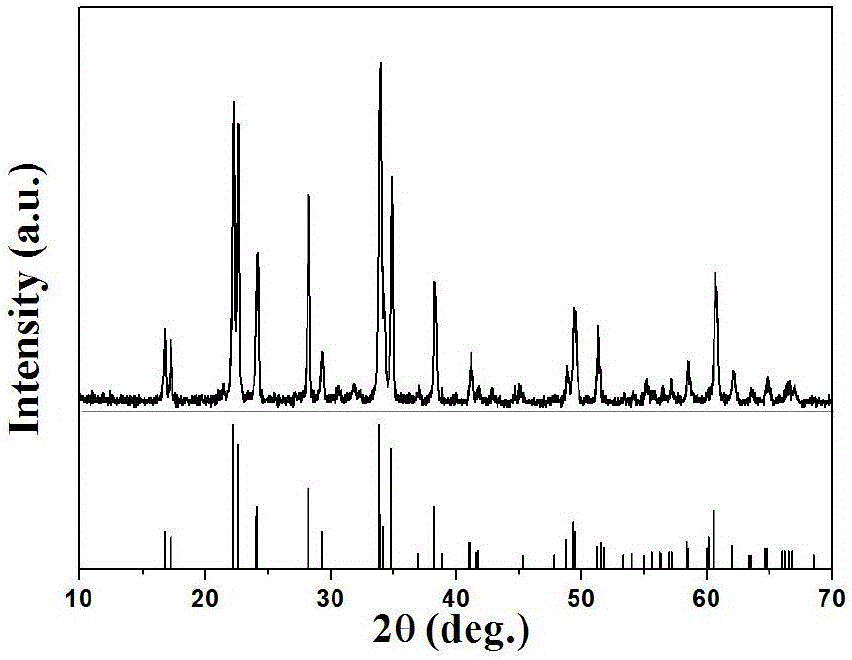

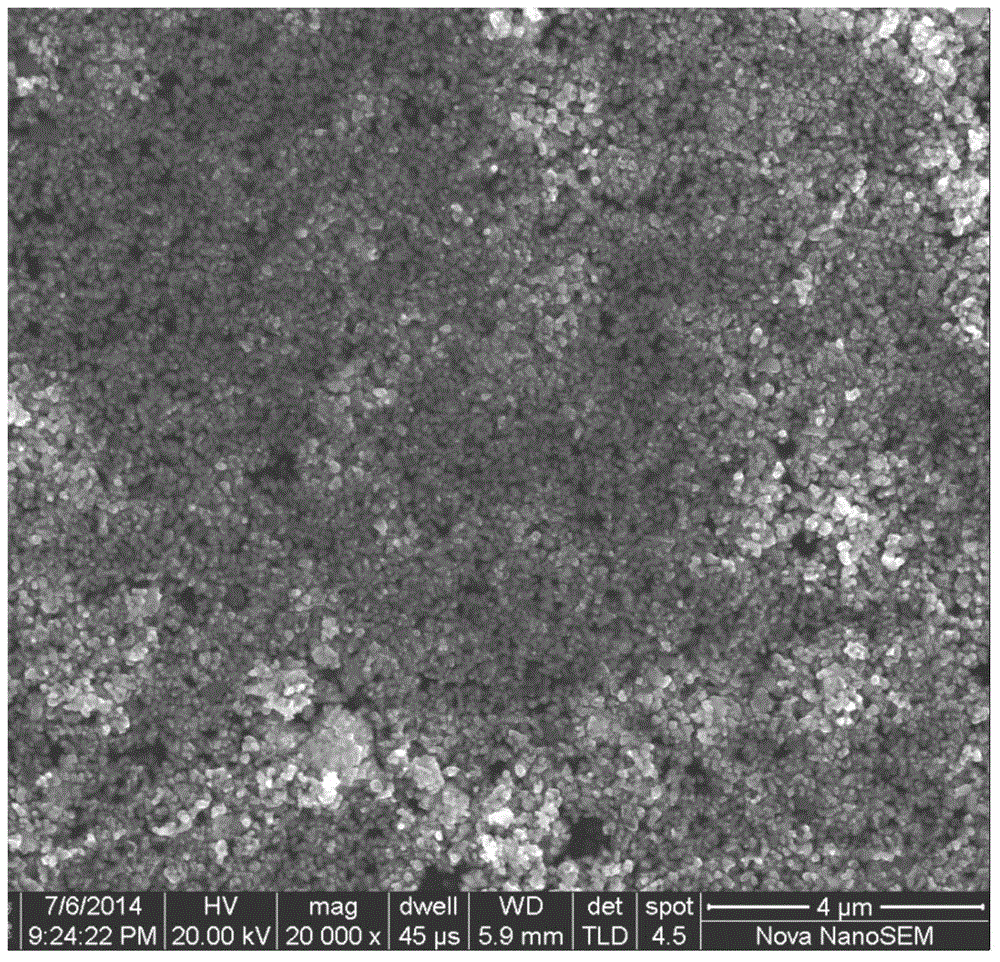

Nanostructured lithium orthosilicate ceramic spheres used for tritium propagation and preparation method thereof

ActiveCN106630985AUniform particle sizeUniform structureNuclear energy generationThermonuclear fusion reactorSolventTwo step

The invention discloses nanostructured lithium orthosilicate ceramic spheres used for tritium propagation and a preparation method thereof. The nanostructured lithium orthosilicate ceramic spheres are made by preparing precursor powder with uniform particle size through a solvothermal method, obtaining a lithium ceramic sphere blank with a uniform microstructure through wet moulding, and carrying out two-step sintering. The prepared lithium orthosilicate ceramics is high in purity, good in sphericility, small in hole size and uniform in hole dispersion, has a crystal grain size in nanometer order and allows the radiation resistance, mechanical properties and tritium release properties of tritium propagation ceramics to be improved at the same time.

Owner:SICHUAN UNIV

Method for preparing high density nanocrystalline hard alloy by step sintering

The invention provides a method for preparing a high density nanocrystalline hard alloy by step sintering, and belongs to the technical field of novel materials and novel powder metallurgy. The method comprises the following steps: firstly determining the dosage of the raw materials according to the requirements on the content of Co in the final hard alloy based on nanoscale purple tungsten oxide, cobaltous oxide, carbon black and mixed powder of vanadium oxide and chromic oxide as raw materials, mixing the raw materials and performing ball milling, then pressing the raw materials to blocks and conveying the pressed raw materials into a vacuum pump to perform a in-situ reaction to prepare nanometer composite powder with uniform distribution and good dispersity; filling the nanometer composite powder into a high density hard alloy mold, performing discharge plasma sintering, and performing segmented heating, heating up and heat preservation processes to obtain a pre-sintered block with controllable length and size of crystalline grain; finally, putting the pre-sintered block in a high-strength graphite mold to perform high temperature instant discharge plasma quick sintering densification to finally obtain a dense nanocrystalline hard alloy block material. The method provided by the invention can be used for effectively improving the density and mechanical properties of the hard alloy block material.

Owner:BEIJING UNIV OF TECH

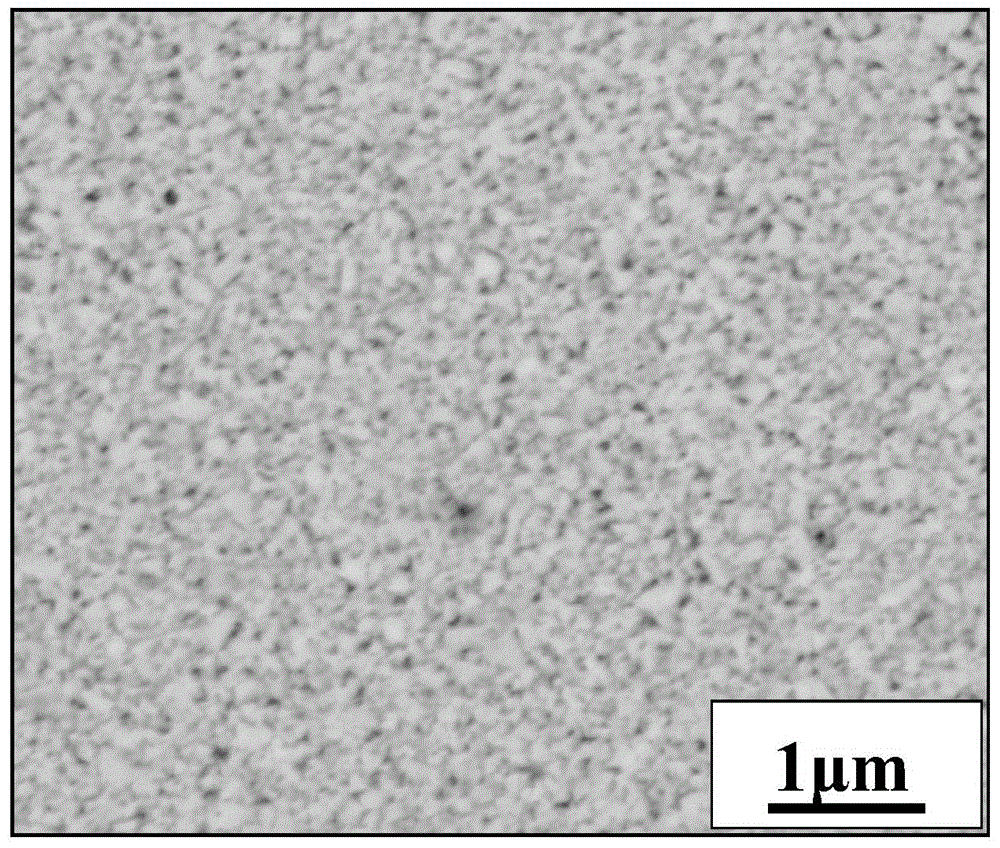

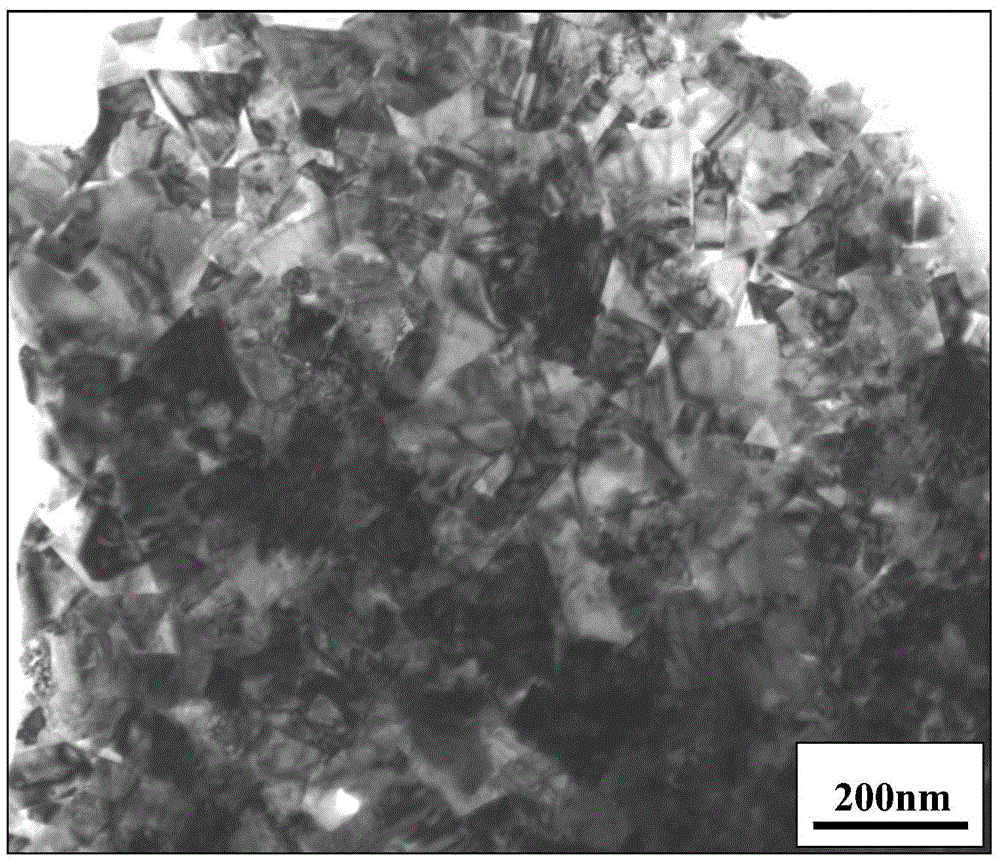

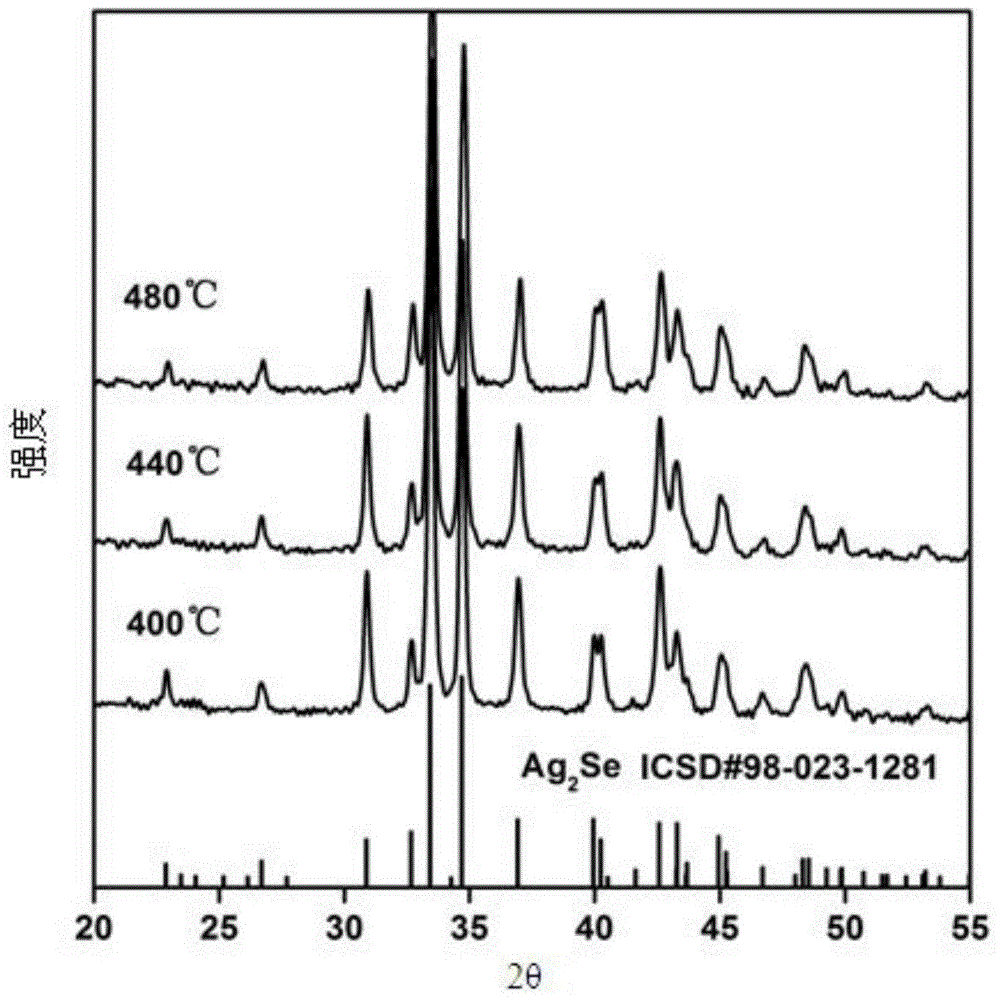

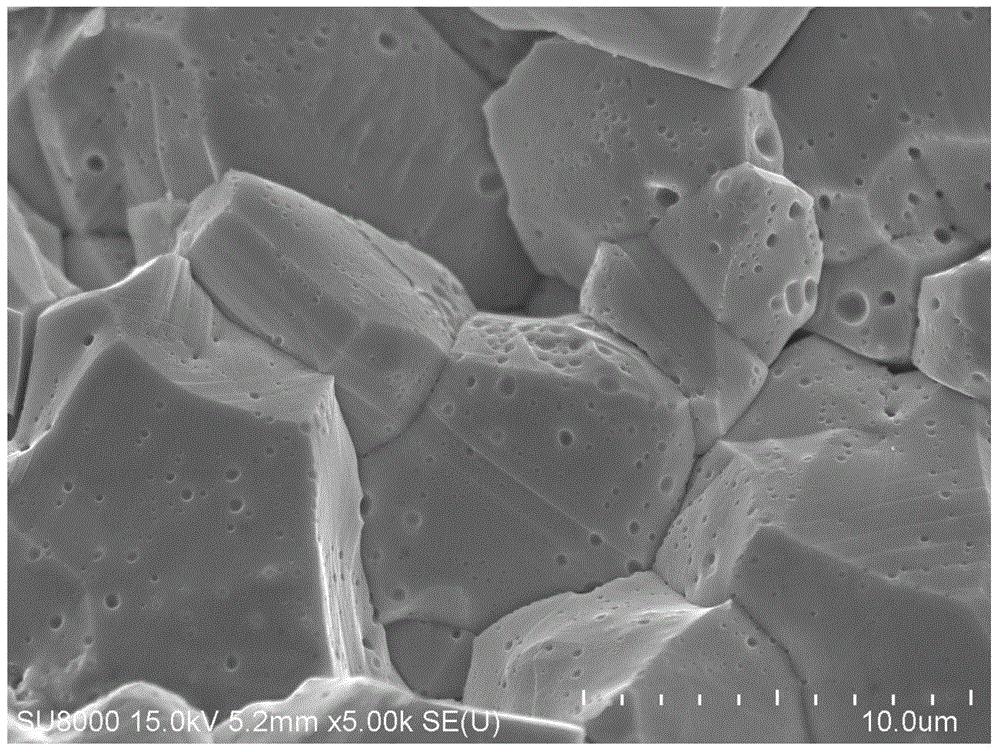

Method for quickly preparing Ag2Se block thermoelectric material through self-homogenization

ActiveCN104878234AAchieve densificationSignificant self-homogenizing effectThermoelectric device manufacture/treatmentThermoelectric materialsRoom temperature

The invention discloses a method for quickly preparing an Ag2Se block thermoelectric material through self-homogenization for the first time. Ag powder and Se powder are used as raw materials; firstly the raw materials are easily mixed, and then the mixed raw materials are directly subjected to plasma activated sintering (PAS), so compact Ag2Se block thermoelectric material can be prepared in several minutes. The process dissolved by the method is super easy, the preparation time is super short, the obtained product is uniform in component distribution, and an obvious effect of self-homogenization is shown. The prepared Ag2Se block thermoelectric material is superior in performance, the room temperature ZT exceeds 0.6, and a good foundation is laid for large-scale preparation and large-scale application of the Ag2Se compound.

Owner:WUHAN UNIV OF TECH

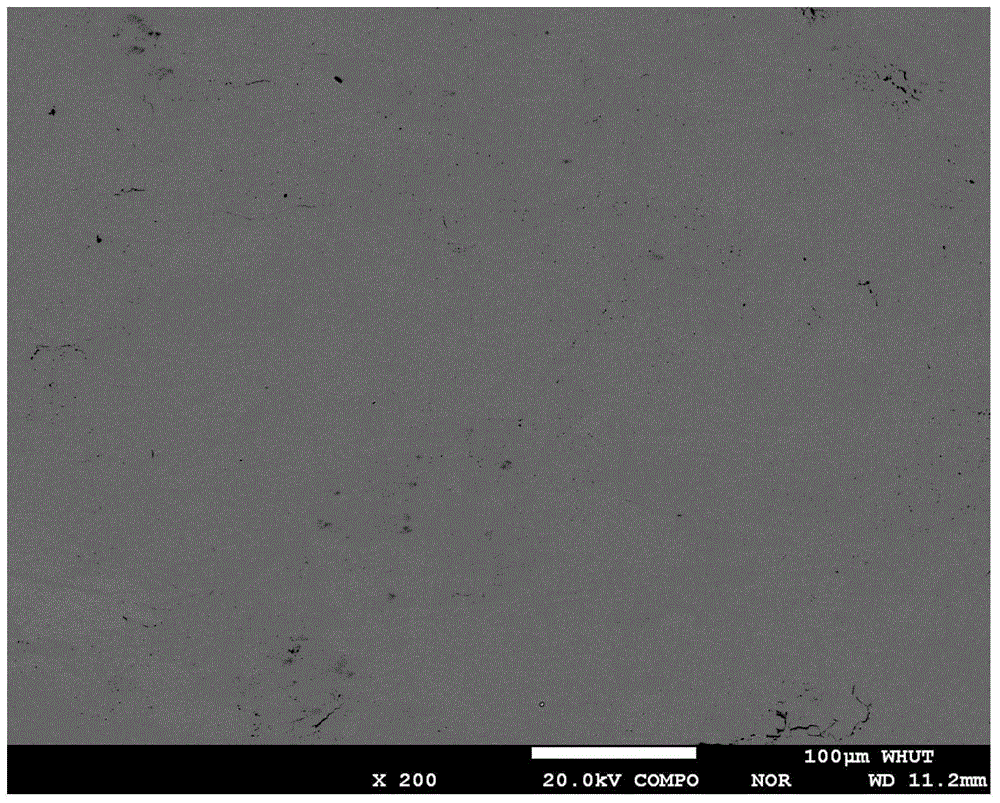

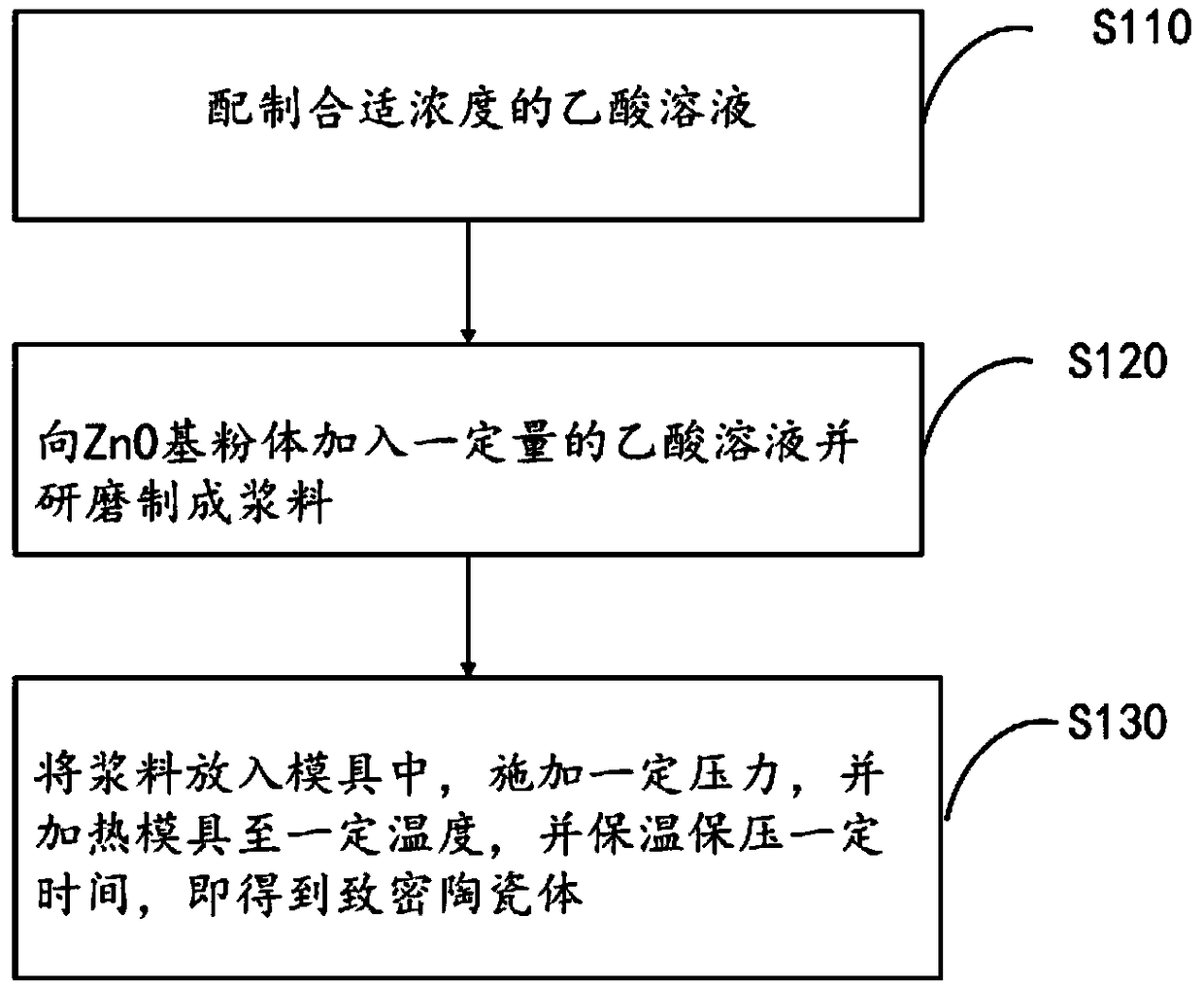

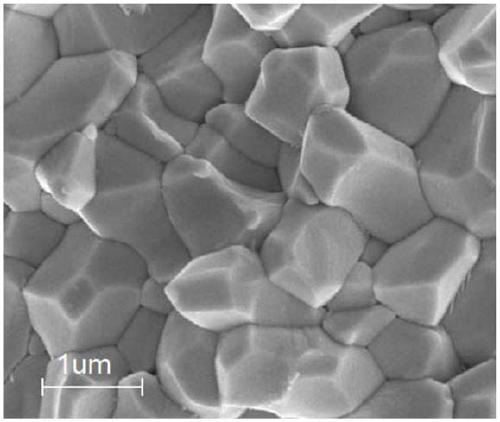

Ultralow-temperature cold sintering method of ZnO-based ceramic

An ultralow-temperature cold sintering method of ZnO-based ceramic comprises the following steps: obtaining slurry of ZnO-based powder from an acetic acid solution with certain concentration and the ZnO-based powder by grinding and dispersing, placing the slurry in a mold, applying proper pressure, heating the mold to a certain temperature, and keeping the temperature and pressure for a period oftime to obtain the dense ZnO-based ceramic. The ZnO-based ceramic with fine and uniform grains and relative density higher than 98% can be prepared at the temperature of 300 DEG C of lower by controlling concentration and adding amount of acetic acid, applied pressure and sintering temperature and time. Compared with the traditional high-temperature sintering technique for ceramics, the method hasthe characteristics that sintering temperature is low, process is simple, energy is saved and nanocrystalline ceramic can be obtained, and can be widely applied to ultralow-temperature cold sinteringof the ZnO-based ceramic.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Heat-conductive lubricating grease, adhesive, elastic composition, and cooling device

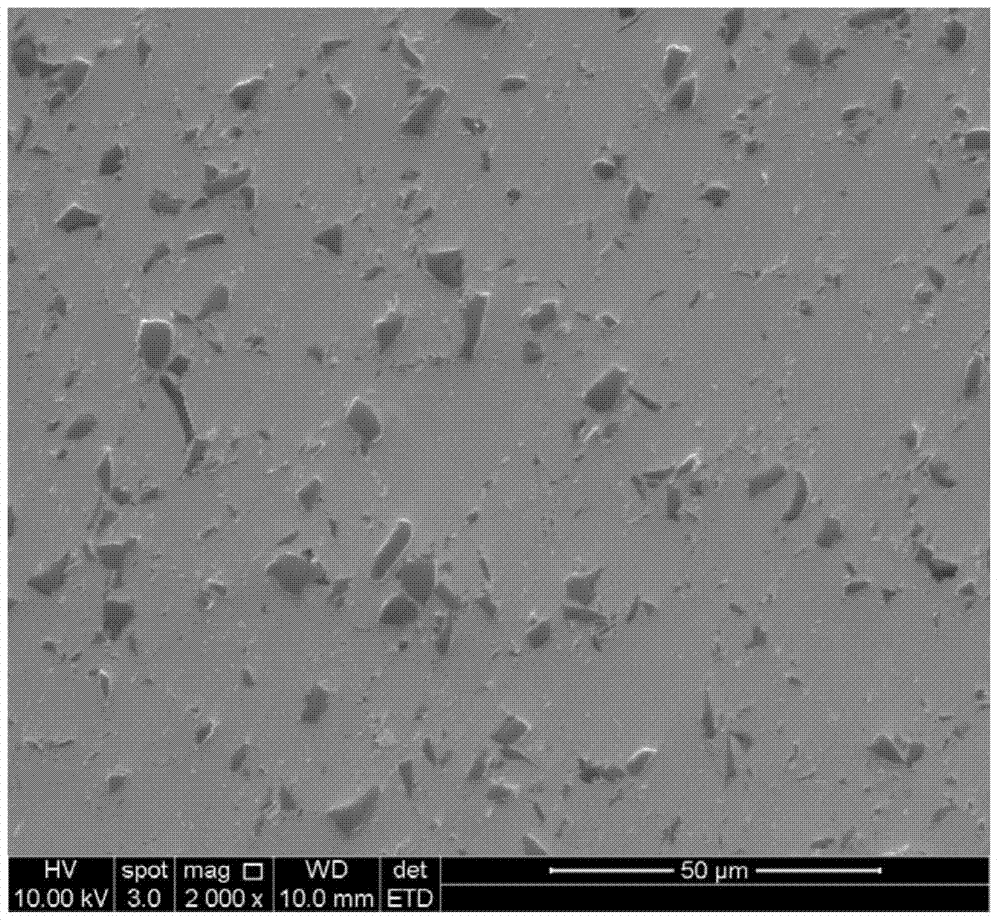

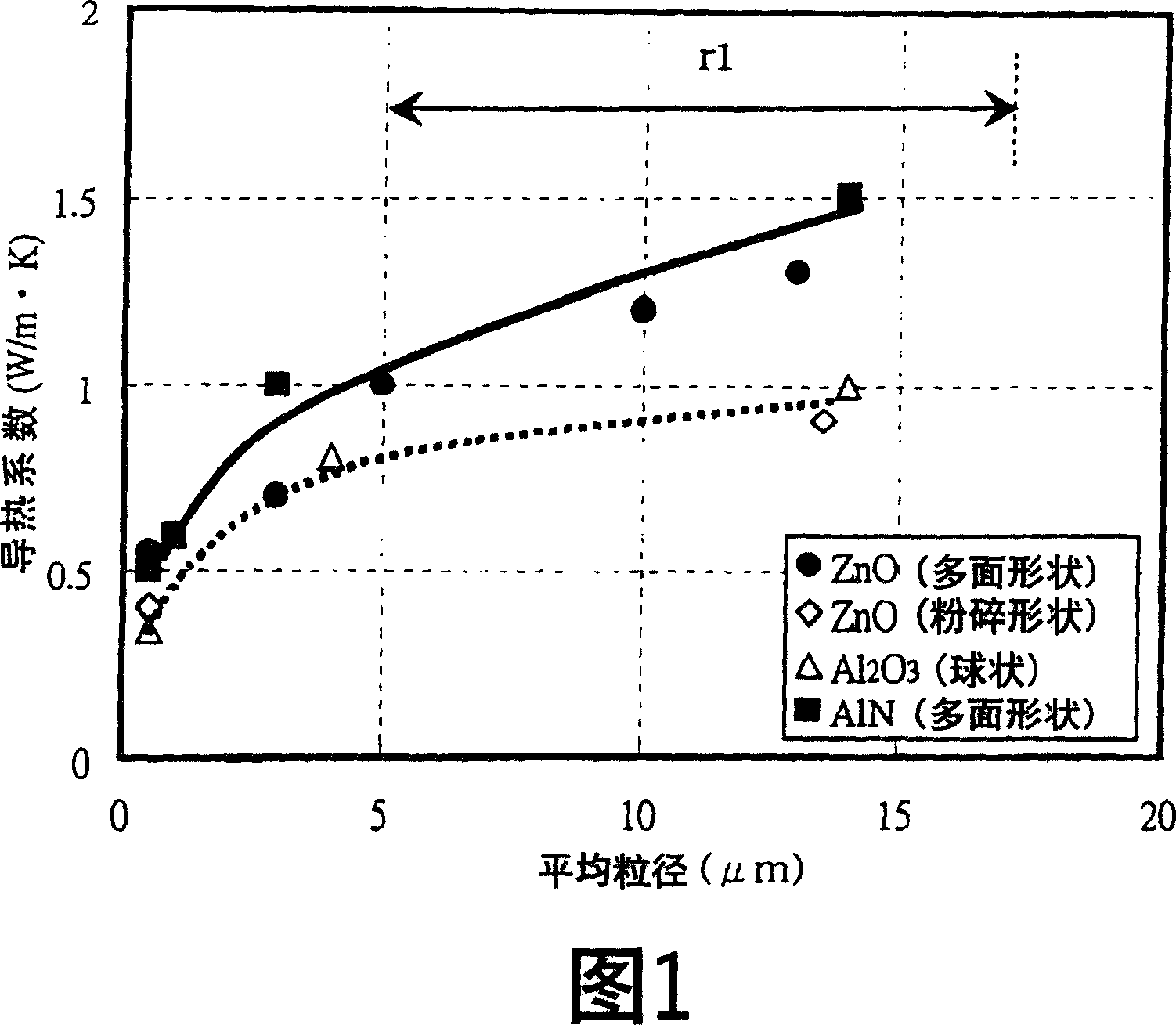

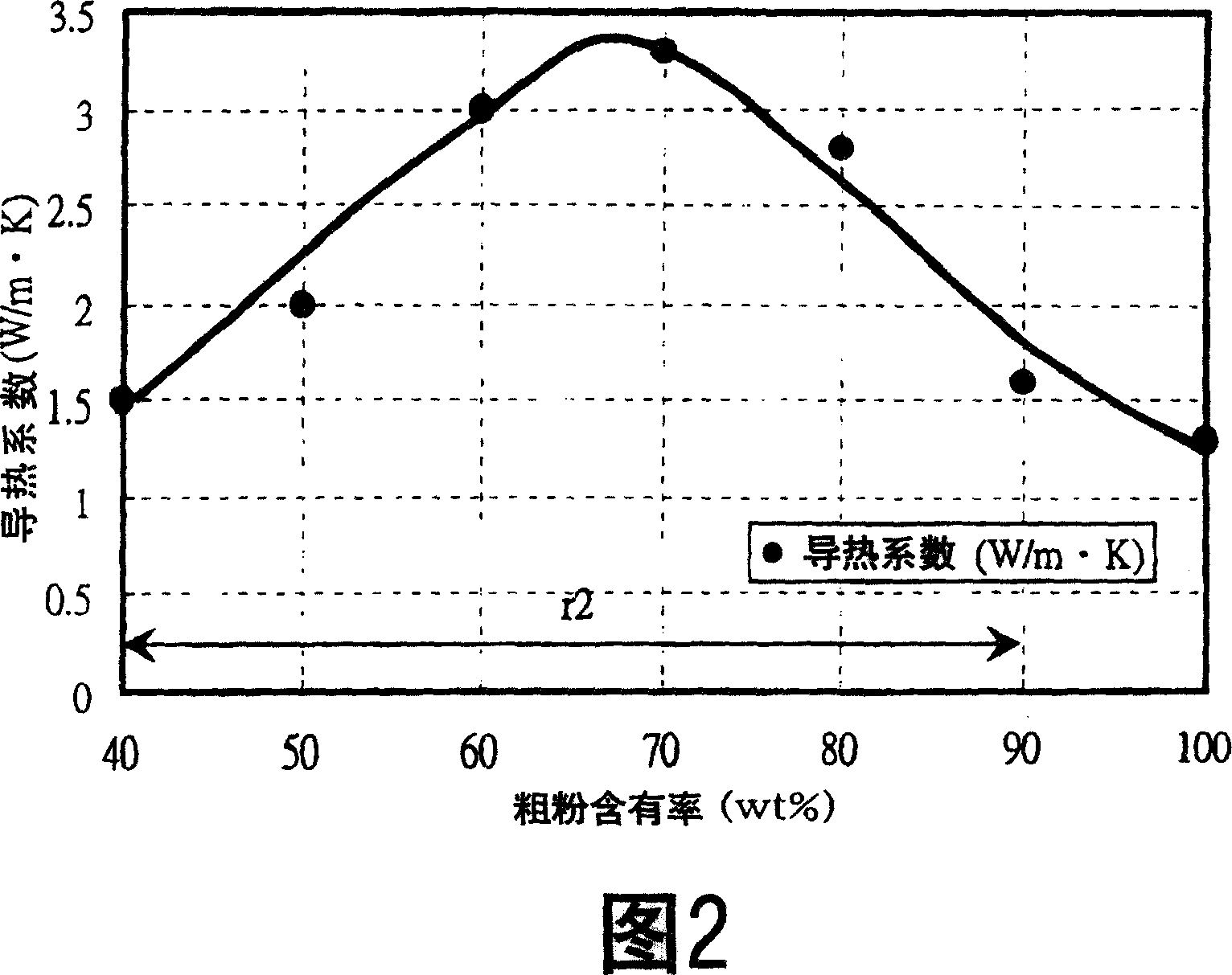

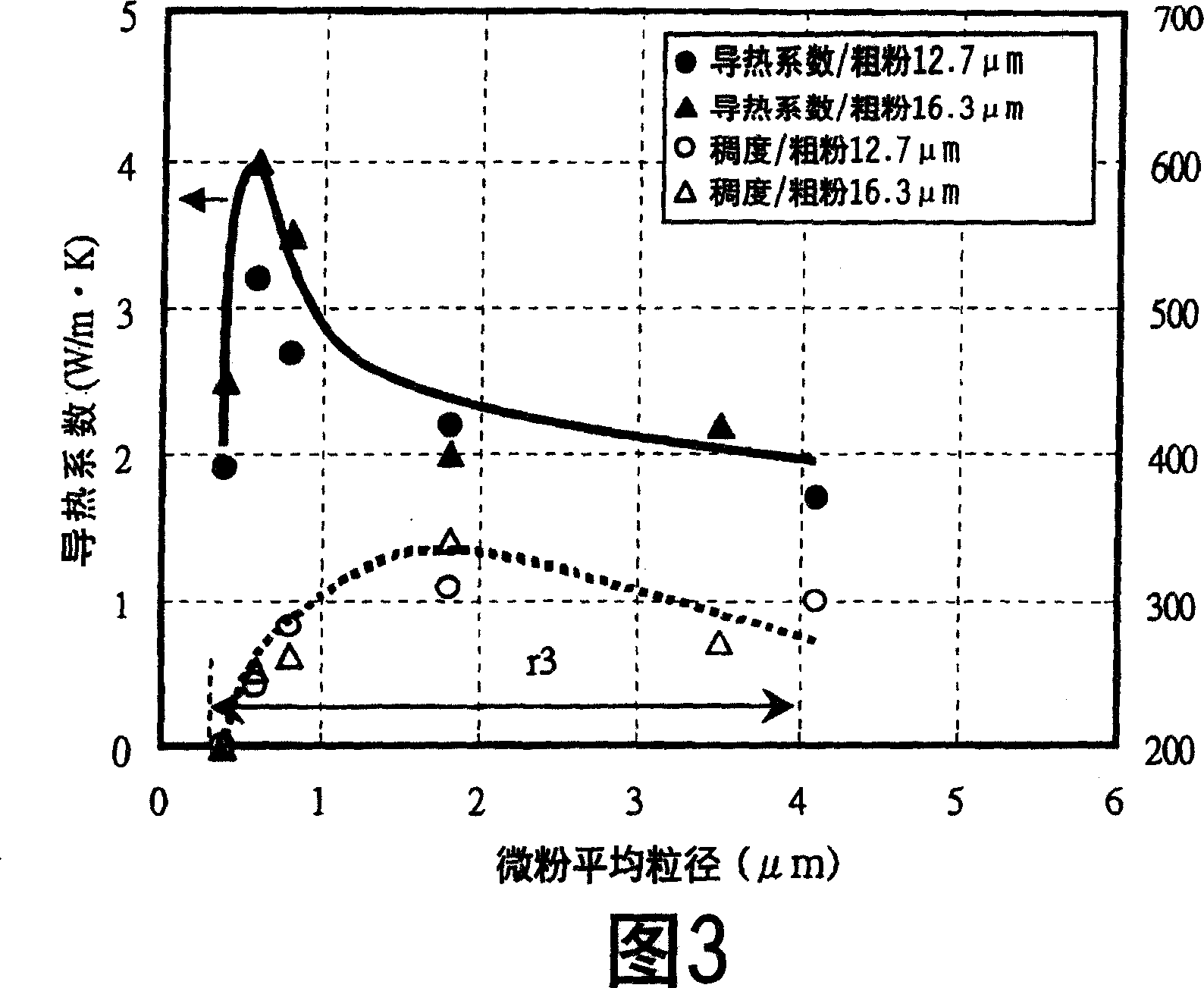

InactiveCN1928039AAchieve densificationImprove cooling effectAdditivesBase-materialsElastomerMicroparticle

In the thermally conductive grease of the present invention, etc., the particles of the inorganic powder have a polyhedral shape, and 0.2 to 2.0 wt% of a nonionic surfactant is added with respect to 40 to 90 volume % of the mixed powder, and 10 to 90 wt % of the nonionic surfactant is mixed. 60% by volume of base oil (resin), the mixed powder is composed of 40-90% coarse particles with an average particle diameter of 5-17 μm and 10-60% with an average particle diameter of 1 / 3-1 / 3 of the coarse particles Composed of 40 particles.

Owner:HITACHI LTD

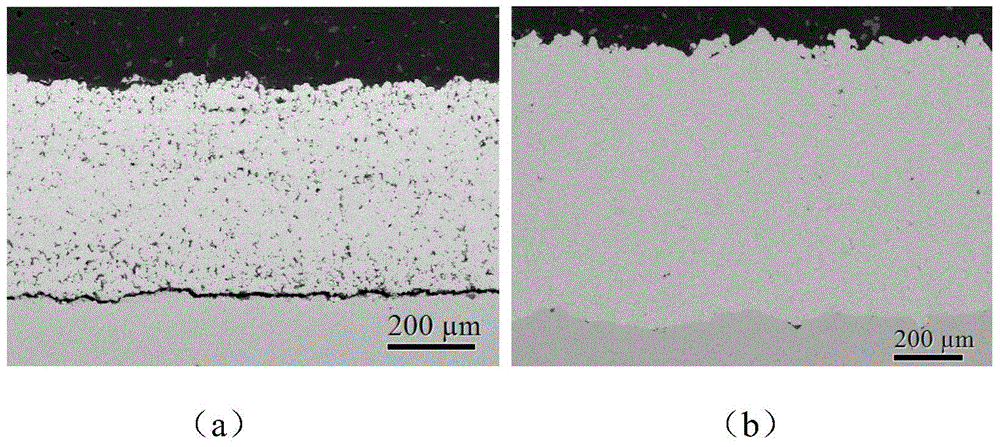

Carbon-ceramic composite material and preparation method for same through precursor impregnation

InactiveCN108129156AAchieve multi-level densificationAchieve densificationCeramic compositeMetallurgy

The invention discloses a carbon-ceramic composite material and a preparation method for the same through precursor impregnation, and belongs to the technical field of preparation of carbon-ceramic composite materials. The preparation method of the present invention comprises the steps of putting a fiber preform with a certain density in a deposition furnace, performing chemical vapor infiltrationby taking nitrogen gas as a carrier gas, and then performing high-temperature treatment in a protective atmosphere of nitrogen; then putting the perform subjected to chemical vapor densification in amixture, performing ultrasonic oscillating, taking out the treated system for standing, and then transferring the system to an atmosphere furnace for sintering, so as to obtain a sintered preform; and finally, performing precursor impregnation-cracking process on the sintered perform for multiple times, so as to obtain the carbon-ceramic composite material. The method is simple to operate and lowin equipment requirement, and can achieve multi-level densification of a porous preform.

Owner:西安天运新材料科技有限公司

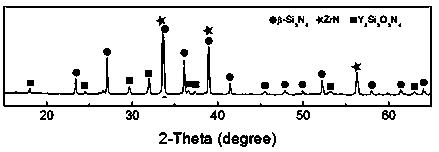

Method for rapidly preparing high heat conduction Si3N4 ceramic with low cost

The invention discloses a method for rapidly preparing high heat conduction Si3N4 ceramic with low cost. The method is characterized in that Si powder is taken as a raw material, ZrO2 powder is taken as a nitridation catalyst, ZrO2-MgO-Re2O3 is taken as a sintering aid, wherein Re2O3 is taken as a rare earth oxide, Si, ZrO2 and MgO-Re2O3 are mixed according to mass fraction and then dried to obtain a Si-ZrO2-MgO-Re2O3 mixing powder; the mixing powder is subjected to a two-step insulation method and a pressureless sintering process to obtain the high heat conduction Si3N4 ceramic; According to the ceramic material, the relative density is higher than 95%, hardness is 8-20 GPa, fracture toughness is 3-8MPa.m<1 / 2>, bending strength is 200-1000Mpa, and the thermal conductivity is 20-100W.m<-1>,K<-1>. By introducing a ZrO2 catalyst, Si powder nitridation IS accelerated, the introduction of ZrO2-MgO-Re2O3 can improve the densification of Si3N4, and the high heat conduction Si3N4 ceramic can be rapidly prepared with low cost.

Owner:GUANGDONG UNIV OF TECH

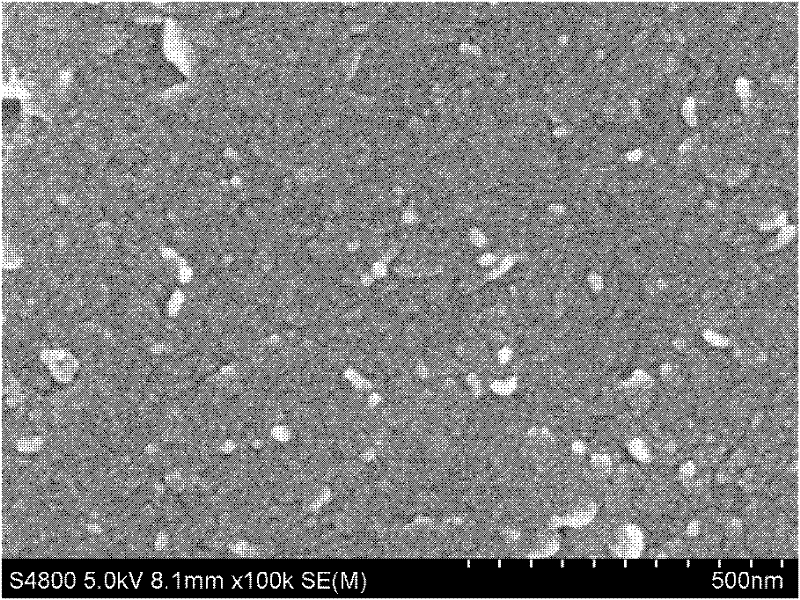

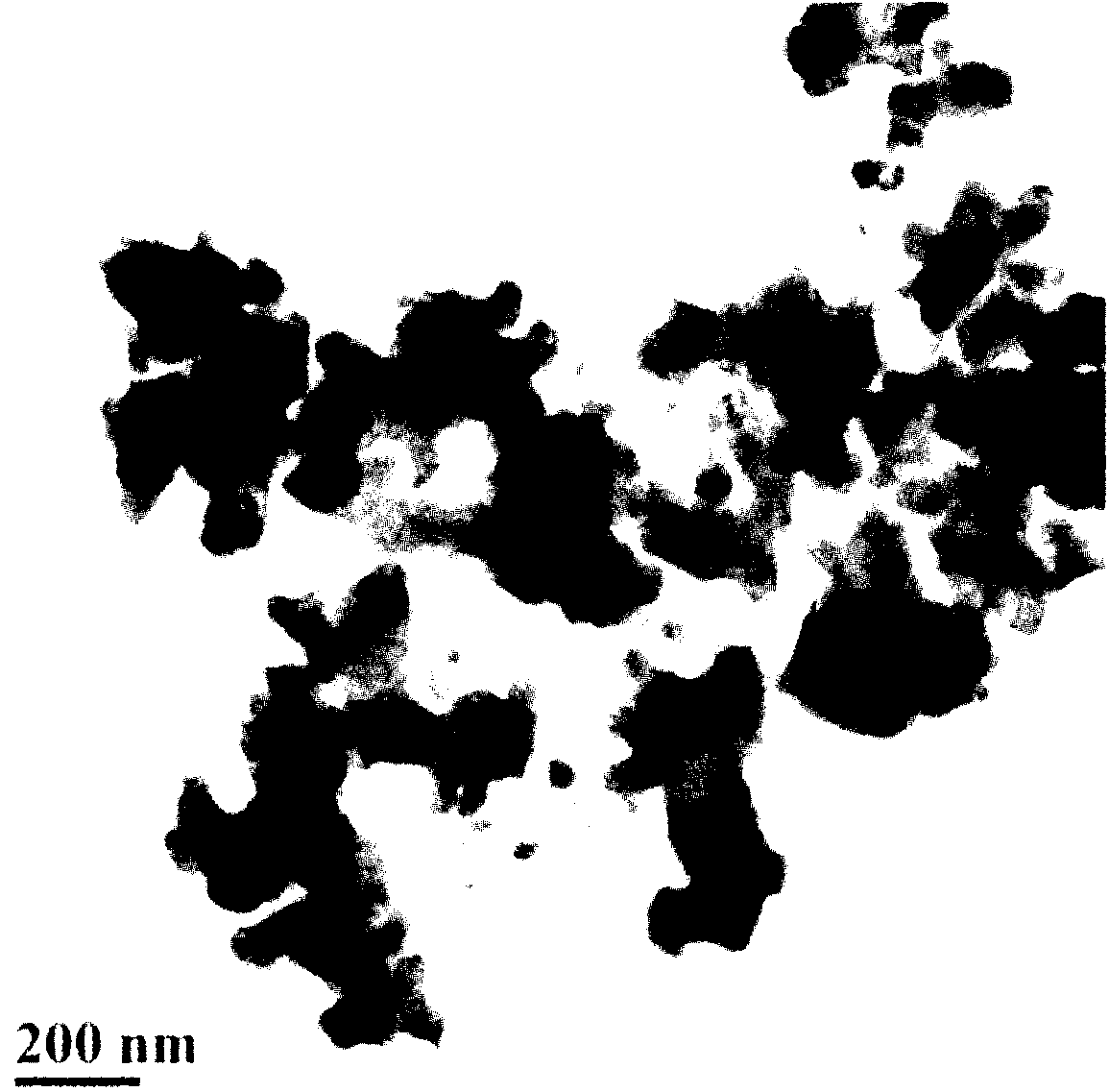

Method for preparing WC-Co (tungsten carbide-cobalt) nano-powder

InactiveCN102078965ASimple preparation processThe preparation process is practicalNanotechnologyCarbonizationMixed gas

The invention discloses a method for preparing WC-Co (tungsten carbide-cobalt) nano-powder, which comprises the following steps of: firstly, preparing tungsten oxide-cobalt oxide powder by adopting a citrate or package method; secondly, introducing ammonia gas into the obtained tungsten oxide-cobalt oxide powder for nitridation to obtain tungsten nitride-cobalt nitride powder; and thirdly, mixing the obtained tungsten nitride-cobalt nitride powder with carbon black, performing ball milling, and performing heat treatment under a vacuum or inert atmosphere with the air pressure of less than 200Pa to obtain the WC-Co nano-powder; or directly charging the obtained tungsten nitride-cobalt nitride powder into a tube furnace, and introducing mixed gas of methane and hydrogen gas into the tube furnace for carbonization to obtain the WC-Co nano-powder. The preparation process disclosed by the invention has the advantages of simplicity and practicality, strong maneuverability, and easiness of large-scale production. Moreover, the prepared powder has the advantages of small particle diameter, uniform particle size distribution and good sintering activity.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

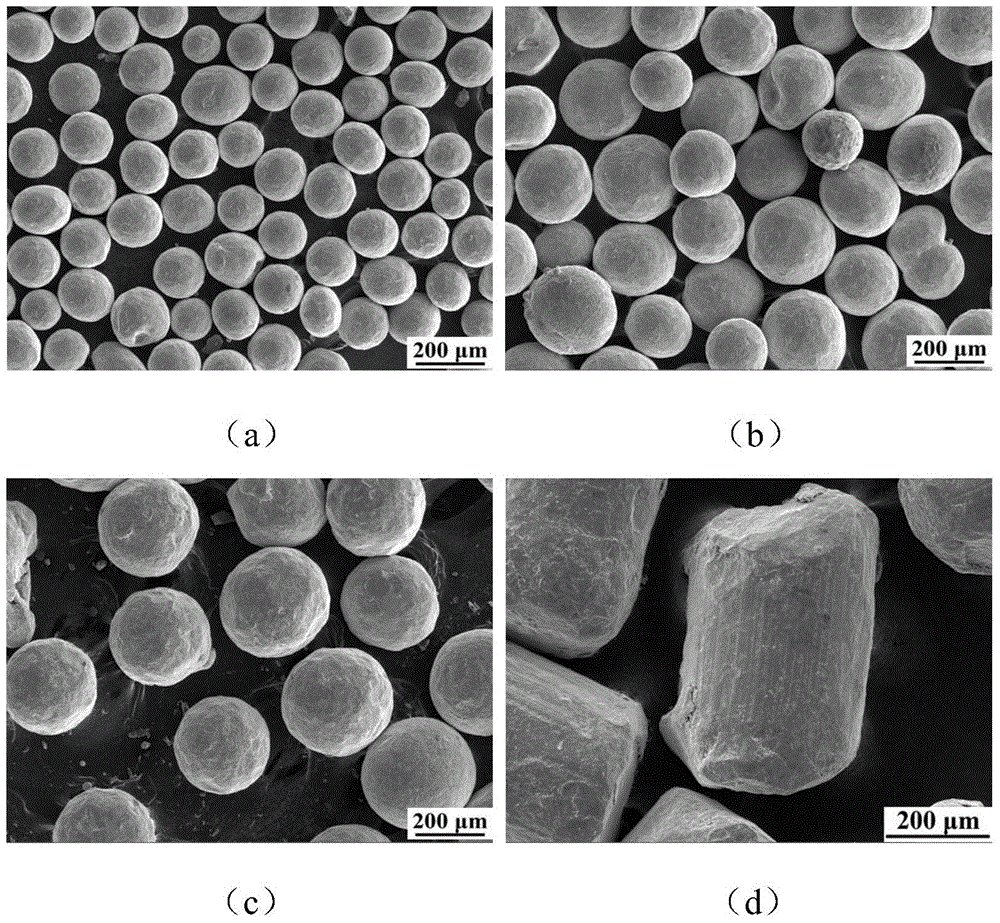

Preparation method of solid spherical metal powder for additive manufacturing

ActiveCN108907210AChange particle size distributionHigh sphericityAdditive manufacturing apparatusTransportation and packagingManufacturing technologySpherical shaped

The invention provides a preparation method of solid spherical metal powder for additive manufacturing, and belongs to the field of additive manufacturing. According to different requirements of different additive manufacturing technologies for powder, atomized powder is subjected to mechanical ball milling and plasma balling, through the compatibility of milling balls with different diameters andthe synergistic effect of ball milling parameters, ball-milling powder within the required particle size range is obtained through ball milling, then, ball-milling powder is subjected to balling treatment through plasma balling, and powder which is uniform in particle size distribution, solid, free of defect, high in degree of sphericity and good in fluidity is obtained and completely meets the additive manufacturing requirements.

Owner:CENT SOUTH UNIV

Method for increasing bismuth layer structure piezoelectricity ferroelectric ceramic material density

InactiveCN101186493AInhibit migrationGrowth inhibitionPiezoelectric/electrostrictive/magnetostrictive devicesVolumetric Mass DensityMaterial density

The invention discloses a density enhancing method of piezoelectric ferroelectric ceramic materials with bismuth layer structure. According to a chemical formula: (Am-1BmO3m+1) <2-> (Bi2O2) <2+>; and molar ratio A: B: Bi = m-1: m : 2, materials are calculated and weighted, wherein, the A is univalent, bivalent, trivalent or quadrivalent metal ion that is suitable for dodecahedral coordination; the B is trivalent, quadrivalent, pentavalent or sexivalent metal ion that is suitable for octahedral coordination; the production processes are that: mixing, pre-synthesizing, grinding, forming and sintering; the sintering process is that: the temperature of the obtained material from the last step is raised to 1100 to 1250 DEG C at a speed of 2 to 5 DEG C per minute, and is lowered to 50 to 150 DEG C within 1 to 5 minutes; under the temperature of 950 to 1150 EDG C, insulation at the low temperature is done for 5 to 20 hours; then the temperature is lowered to 500 DEG C at a speed of 3 to 7 DEG C per minute, and the obtained material is naturally cooled with a furnace. The invention can obtain the piezoelectric ferroelectric ceramic materials with grain-refining and density bismuth structure.

Owner:SOUTH CHINA UNIV OF TECH

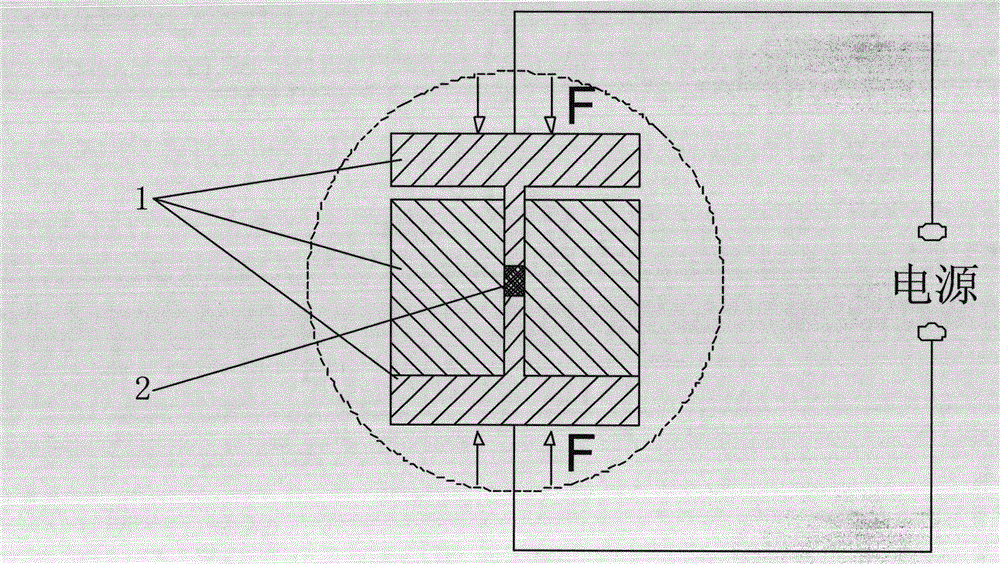

Method for preparing MnZn ferrite magnetic core by multi-physical field coupling

InactiveCN102976730AAccelerated solid phase diffusionHigh densityInorganic material magnetismInductances/transformers/magnets manufactureMultiphysics couplingPhysical field

The invention discloses a method for preparing an MnZn ferrite magnetic core by multi-physical field coupling. The method comprises the following steps of filling MnZn ferrite powder having particle sizes of 0.7 to 2.0 micrometers into a mold, directly powering on the mold with the MnZn ferrite powder to fast heat the mold at a heating rate of 5 to 200 DEG C / s under the pressure of 10<-2> Pa, simultaneously, applying an acting force of 50 to 100MPa to two ends of the mold, heating to a temperature of 600 to 1200 DEG C under the action of a continuous electric field, carrying out heat preservation for 2 to 10min so that the MnZn ferrite powder undergoes a solid-phase reaction in the mold and is molded fast, interrupting power supply, and taking out a sintered body. The method has the advantages that a heating rate is greatly improved so that diffusion between atoms is promoted; and through the pressure on the two ends of the mold, a MnZn ferrite magnetic core solid-phase reaction, compaction molding and compact sintering are carried out simultaneously so that performances of a molded magnetic core are guaranteed.

Owner:SICHUAN UNIV

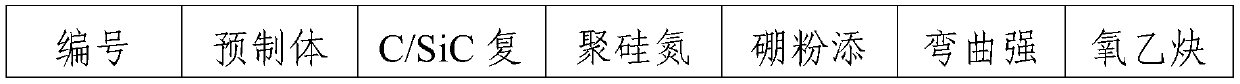

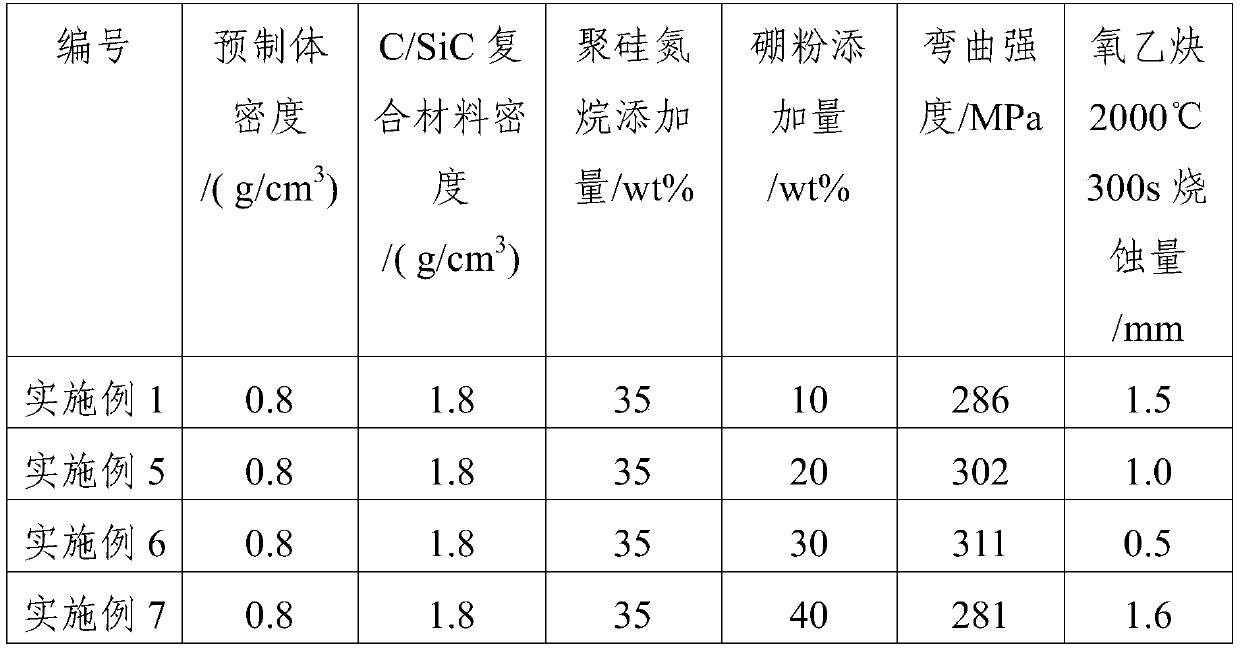

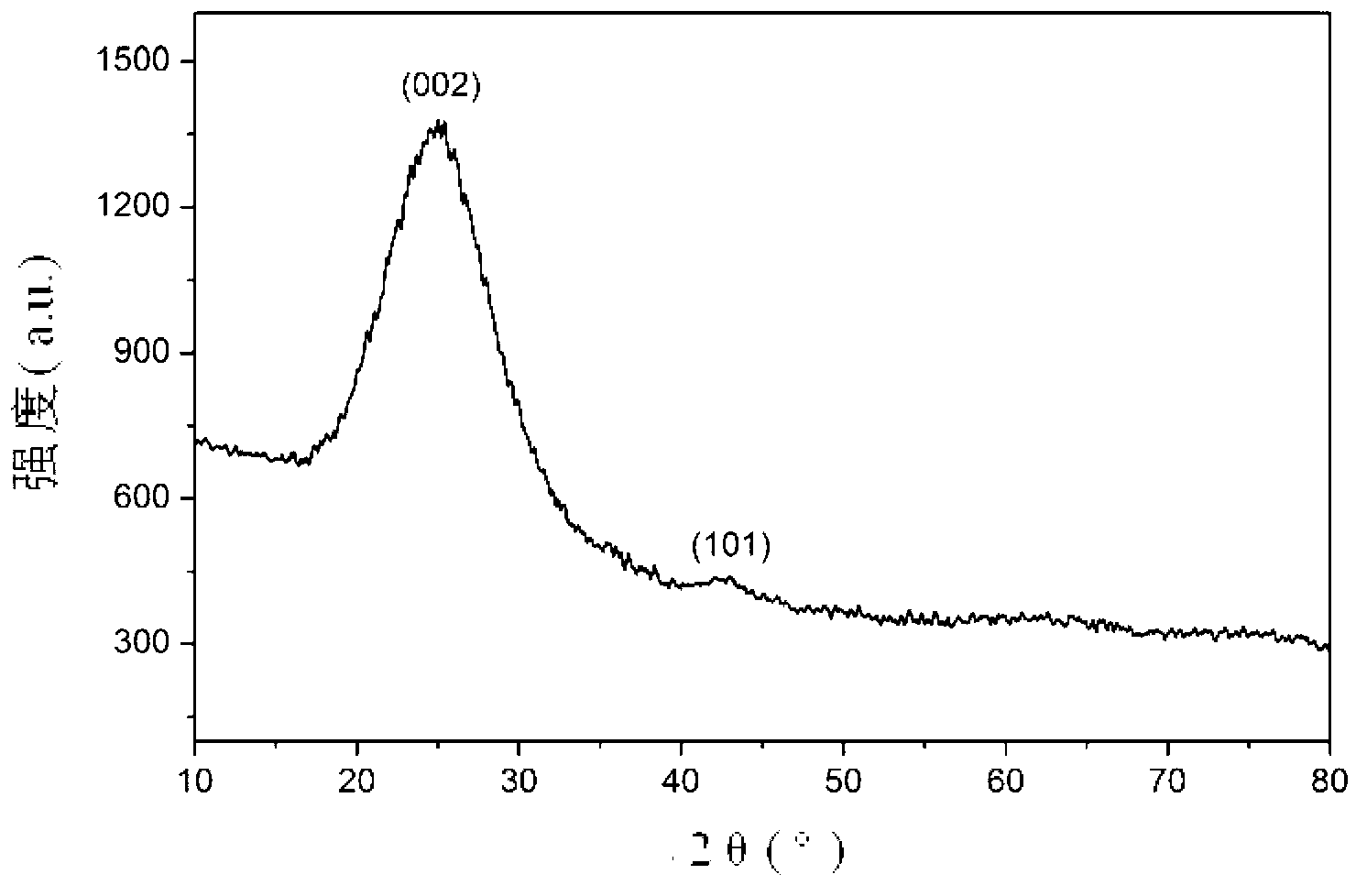

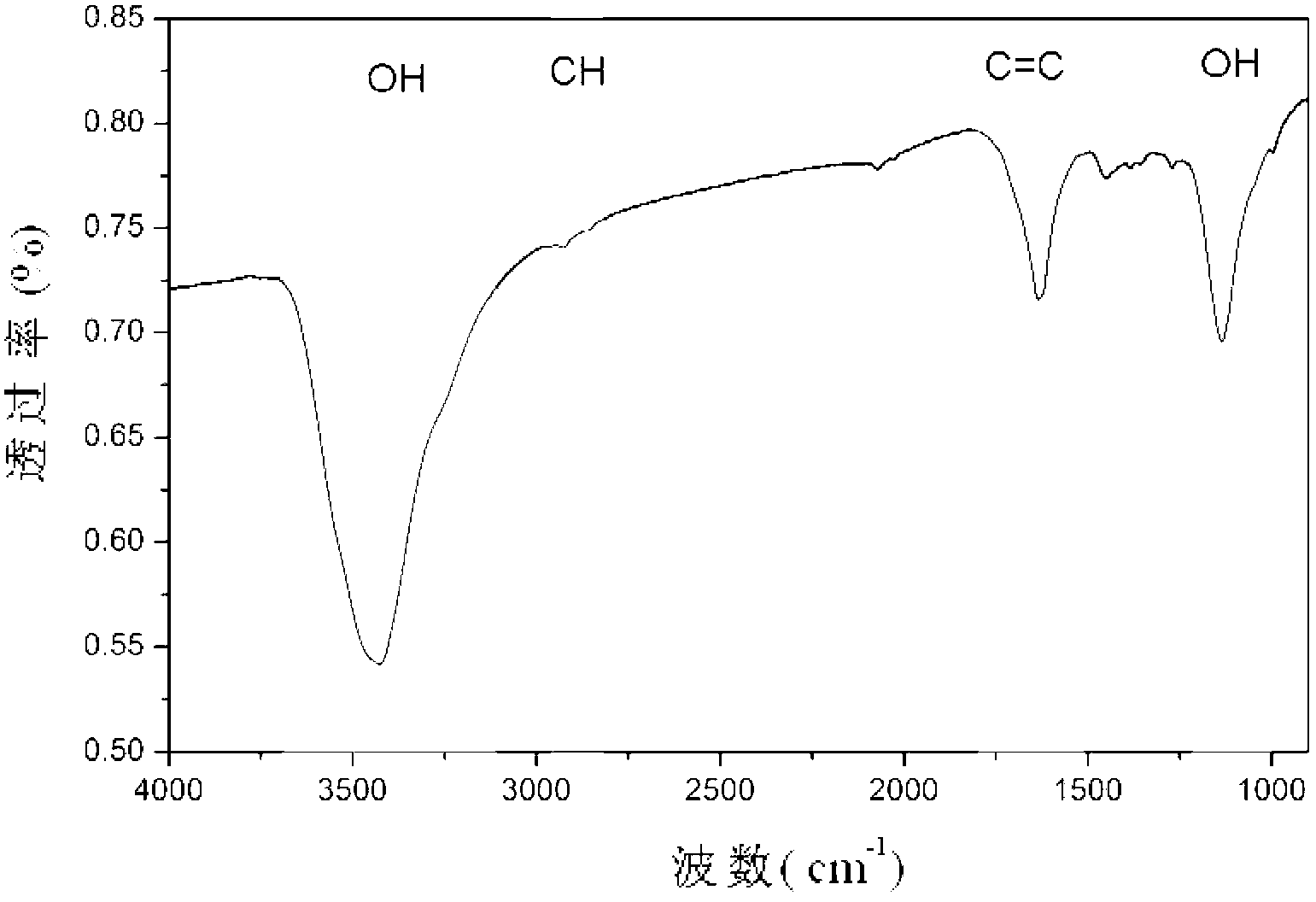

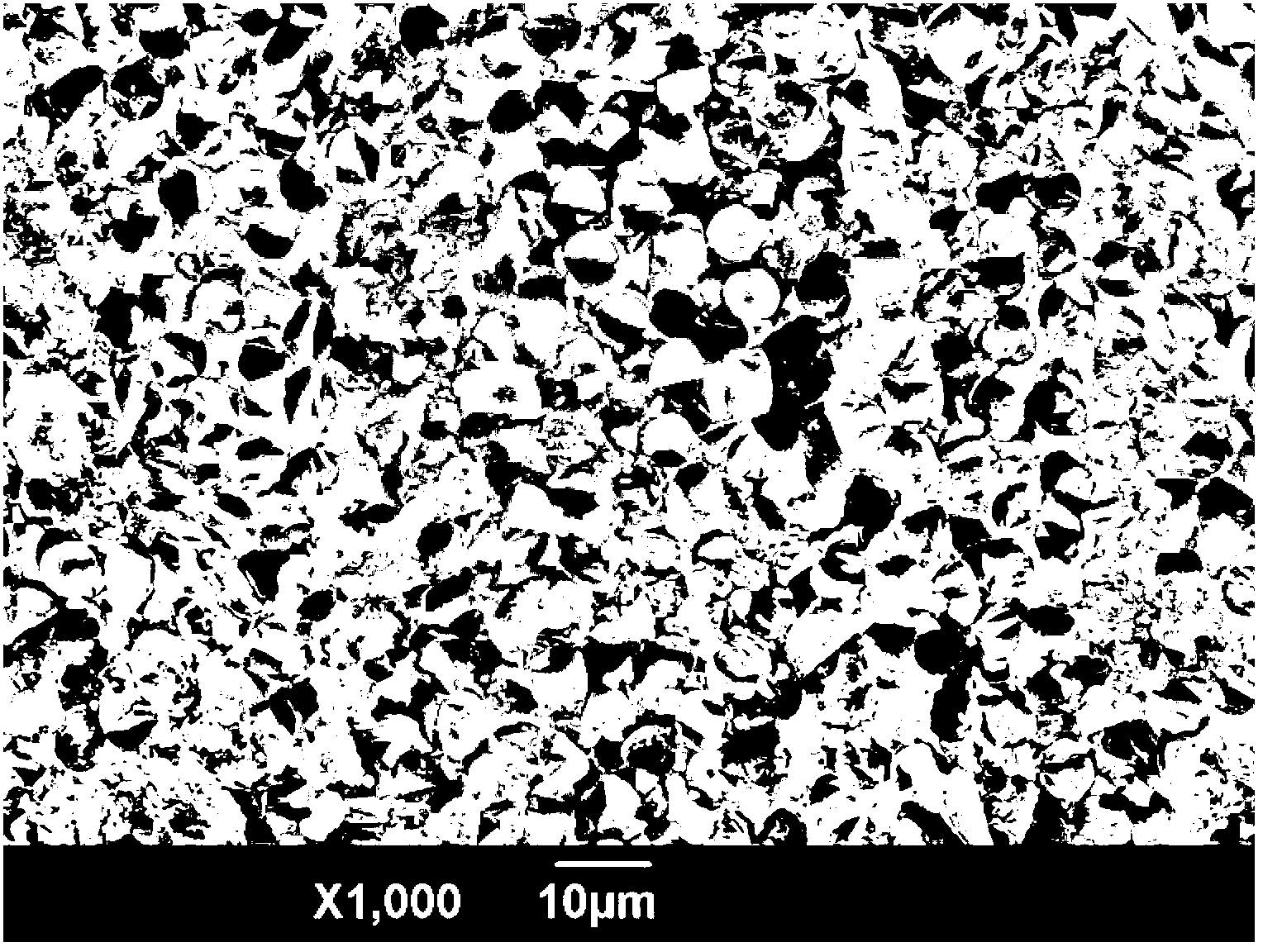

Preparation method of ablation resistant C/SiC ceramic matrix composite material

The invention relates to a preparation method of an ablation resistant C / SiC ceramic matrix composite material. The method includes the steps of: (1) providing a porous C / C composite preform; (2) making the preform into a C / SiC composite material; (3) mixing polysilazane, boron powder and a solvent, with the mass percentage of polysilazane in the mixture being 30-40% and the mass percentage of boron powder in the mixture being 10-30%, and mixing the mixture uniformly to obtain a SiBCN precursor solution; and (4) using the SiBCN precursor solution for impregnation curing and cracking of the composite material, thus obtaining the ablation resistant C / SiC ceramic matrix composite material. The method provided by the invention can acquire the composite material with high density, low ablationrate and excellent comprehensive properties.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for preparing carbon/carbon composite material

The invention discloses a method for preparing a carbon / carbon composite material. The method comprises the steps of: uniformly mixing a biomass capable of being hydrolyzed with water to obtain a biomass dispersing liquid; immersing a carbon fiber prefabricated body in the biomass dispersing liquid to obtain a reaction system Al; then reacting the reaction system A in a hydrothermal kettle under the heating condition, after the reaction is ended and the reaction system is cooled, taking the carbon fiber prefabricated body deposited with the biomass out and washing with water to obtain the carbon / carbon composite material. The method is green and environmental-friendly, efficient and feasible, is low in cost and reaction temperature and is capable of realizing rapid densification of the carbon / carbon composite material. The prepared carbon / carbon composite material is a carbon fiber reinforced composite material using the biomass carbon as a matrix, and is rich in hydroxide groups and carbonyl groups on the surface, thereby being good in biological activity.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

High-power LED (Light-Emitting Diode) heat dissipation ceramic substrate

The invention belongs to the technical field of ceramic substrates, and particularly relates to a high-power LED (Light-Emitting Diode) heat dissipation ceramic substrate. The ceramic substrate comprises the following materials in percentage by mass: 70-80 percent of alumina powder, 3-8 percent of melamine, 3-6 percent of hydroxymethyl cellulose, 6-10 percent of deionized water and 5-10 percent of composite sintering aid, wherein the composite sintering aid comprises the following materials in percentage by mass: 40-60 percent of silicon powder, 5-10 percent of aluminum powder, 20-30 percent of kaolin powder and 10-30 percent of calcium fluoride. The ceramic substrate has the advantages of high heat conductivity coefficient, excellent heat resistance, high bending strength and avoidance of the phenomena of bending, wrapping and the like. Through adoption of an appropriate sintering method and selection of an appropriate sintering aid, denseness of an alumina ceramic sintered body is realized, and the heat conductivity of alumina ceramics is increased greatly.

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com