Ultralow-temperature cold sintering method of ZnO-based ceramic

An ultra-low temperature and ceramic technology, applied in the field of low-temperature ceramic sintering, can solve the problems of coarse grains, energy consumption, and easy deformation, and achieve the effects of small deformation of ceramics, improved production efficiency, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

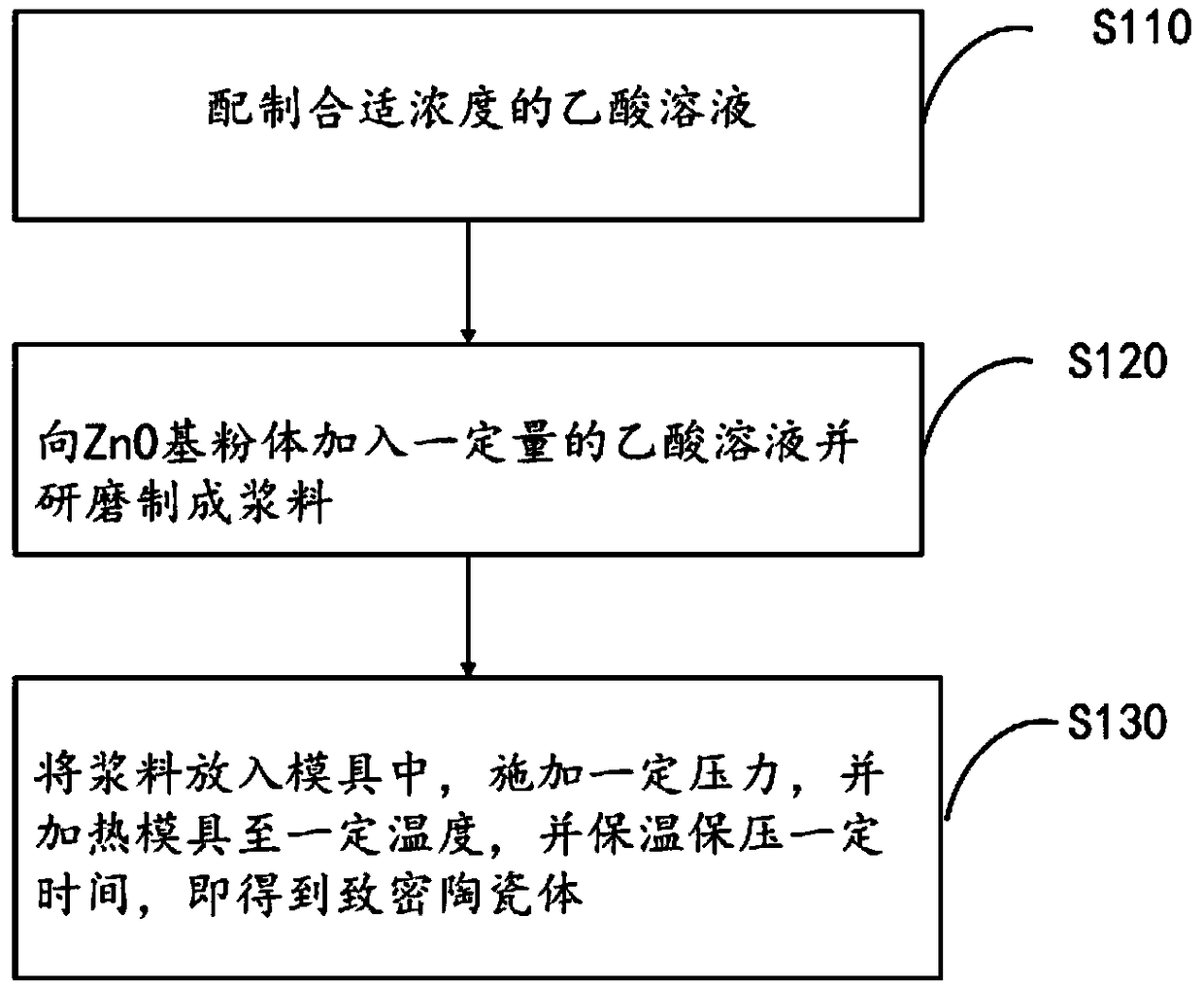

[0051] A method for ultra-low temperature cold sintering of ZnO-based ceramics, the process steps comprising:

[0052] (1) Prepare 1mol / L acetic acid solution.

[0053] (2) Slurry preparation: Weigh 50 g of pure ZnO powder and place it in a mortar, then weigh 20% of the above-mentioned acetic acid solution of the mass of ZnO powder and add it dropwise to the powder and grind it evenly to form a slurry.

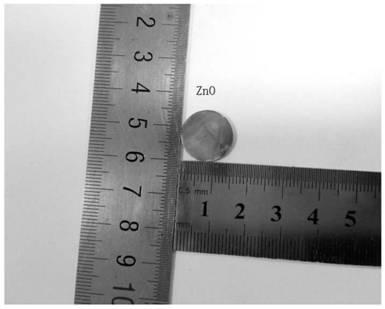

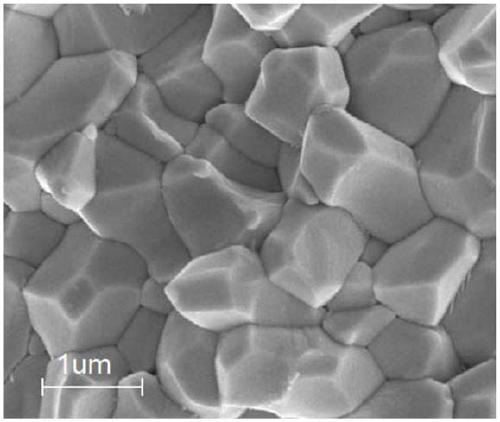

[0054] (3) Cold sintering: choose a steel mold with heating function, the diameter of the inner hole of the mold is 15mm, before using the mold, use degreased cotton dipped in absolute ethanol to wipe the inner wall of the mold, the ejector pin, and the cushion block, and wait for the mold to dry Finally, weigh an appropriate amount of slurry and put it into the mold, apply a pressure of 200MPa with a uniaxial press, and heat the mold to 50°C at a heating rate of 5°C / min, keep it warm for 10min, and then raise the temperature at 10°C / min Heating at a rate of 300° C. for 1 hou...

Embodiment 2

[0057] A method for ultra-low temperature cold sintering of ZnO-based ceramics, the process steps comprising:

[0058] (1) Prepare 0.1mol / L acetic acid solution.

[0059] (2) Slurry preparation: Weigh 10 g of pure ZnO powder and place it in a mortar, then weigh 40% of the above-mentioned acetic acid solution of the mass of ZnO powder and add it dropwise to the powder and grind it evenly to form a slurry.

[0060] (3) Cold sintering: choose a steel mold with heating function, the diameter of the inner hole of the mold is 15mm, before using the mold, use degreased cotton dipped in absolute ethanol to wipe the inner wall of the mold, the ejector pin, and the cushion block, and wait for the mold to dry Finally, weigh an appropriate amount of slurry and put it into the mold, apply a pressure of 80MPa with a uniaxial press, and heat the mold to 50°C at a heating rate of 5°C / min, keep it warm for 10min, and then raise the temperature at 10°C / min Heating at a rate of 300° C. for 4 ho...

Embodiment 3

[0063] A method for ultra-low temperature cold sintering of ZnO-based ceramics, the process steps comprising:

[0064] (1) Prepare 2mol / L acetic acid solution.

[0065] (2) Slurry preparation: Weigh 10 g of pure ZnO powder and place it in a mortar, then weigh 30% of the above-mentioned acetic acid solution of the mass of ZnO powder and add it dropwise to the powder and grind it evenly to form a slurry.

[0066] (3) Cold sintering: choose a steel mold with heating function, the diameter of the inner hole of the mold is 15mm, before using the mold, use degreased cotton dipped in absolute ethanol to wipe the inner wall of the mold, the ejector pin, and the cushion block, and wait for the mold to dry Finally, weigh an appropriate amount of slurry and put it into the mold, use a uniaxial press to apply a pressure of 300MPa, and heat the mold to 50°C at a heating rate of 5°C / min, keep it warm for 25min, and then raise the temperature at 10°C / min Heating at a rate of 100° C. for 4 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com