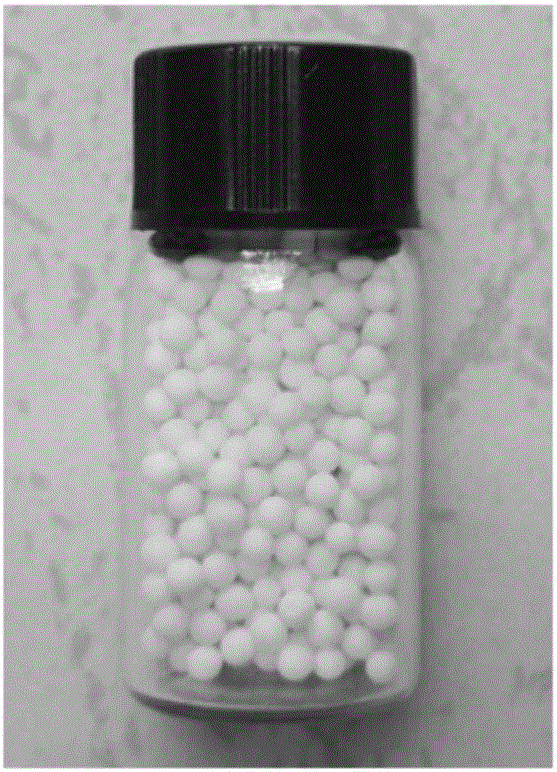

Nanostructured lithium orthosilicate ceramic spheres used for tritium propagation and preparation method thereof

A nanostructure, lithium orthosilicate technology, applied in the field of tritium breeding materials, can solve the problems of material hardening and embrittlement, ceramic breakage or pulverization, tritium release rate reduction, etc., to ease the growth of grain size and reduce sintering temperature, to avoid the effect of significant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

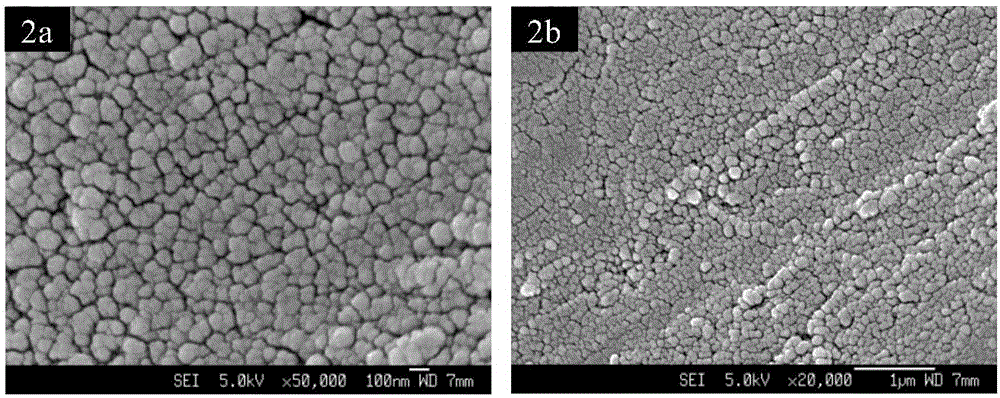

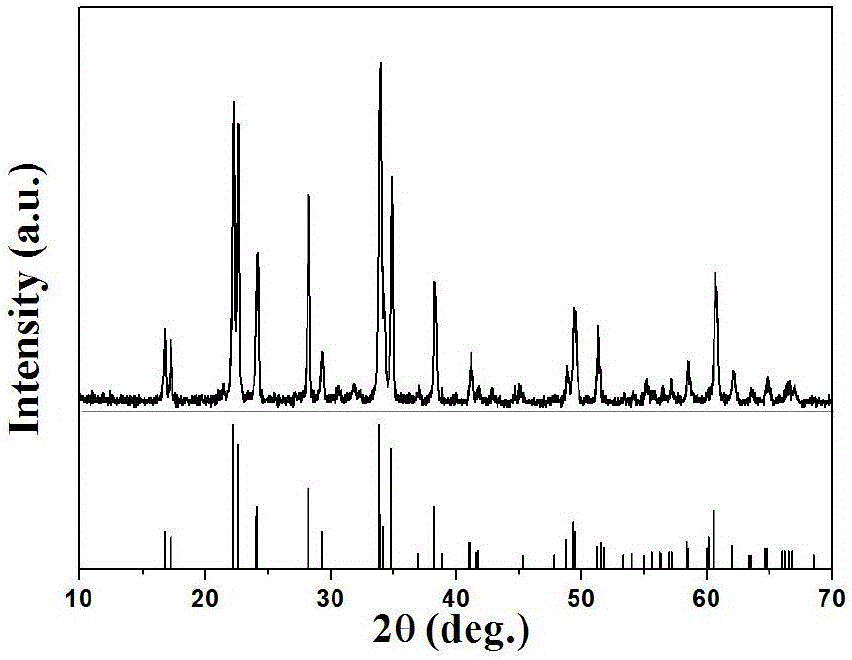

[0034] (1) Preparation of precursor powder

[0035]Weigh 6.712g of lithium hydroxide monohydrate and add it to a composite solvent composed of equal volumes of methanol and ethanol, and stir until the lithium hydroxide is completely dissolved to obtain a solution with a lithium ion concentration of 1mol / L; then weigh 2.4g of gas phase two Silicon oxide was added to the above solution to obtain the first mixed solution, and the obtained first mixed solution was transferred to a reaction kettle and heated to 160° C. for 6 hours of reaction; after the reaction was completed, 0.16 g of nanometer titanium dioxide powder (particles) was added to the reaction solution. 21 nm in diameter), stirred at room temperature for 30 minutes to obtain the second mixed solution, and then put the second mixed solution in a 70°C constant temperature blast drying oven to dry for 12 hours, and then grind the dried material to obtain the precursor powder;

[0036] (2) Preparation of lithium ceramic p...

Embodiment 2

[0043] (1) Preparation of precursor powder

[0044] Weigh 6.712g of lithium hydroxide monohydrate and add it to a composite solvent composed of equal volumes of methanol and ethanol, and stir until the lithium hydroxide is completely dissolved to obtain a solution with a lithium ion concentration of 0.5mol / L; then weigh 2.4g of the gas phase Silicon dioxide was added to the above solution to obtain the first mixed solution, and the first mixed solution was transferred to the reaction kettle and heated to 140° C. for 6 hours; after the reaction was completed, 0.16 g of nano titanium dioxide powder was added to the reaction solution ( particle size 21nm), stirred at room temperature for 30 minutes to obtain the second mixed solution, then put the second mixed solution in a 70°C constant temperature blast drying oven to dry for 12 hours, and then grind the dried material to obtain the precursor powder ;

[0045] (2) Preparation of lithium ceramic pellets

[0046] Weigh the abov...

Embodiment 3

[0051] (1) Preparation of precursor powder

[0052] Weigh 6.712g of lithium hydroxide monohydrate and add it to a composite solvent composed of equal volumes of methanol and ethanol, and stir until the lithium hydroxide is completely dissolved to obtain a solution with a lithium ion concentration of 1.5mol / L; then weigh 2.4g of the gas phase Silicon dioxide was added to the above solution to obtain the first mixed solution, and the first mixed solution was transferred to the reaction kettle and heated to 160° C. for 6 hours; after the reaction was completed, 0.16 g of nano titanium dioxide powder was added to the reaction solution ( particle size 40nm), stirred at room temperature for 30 minutes to obtain the second mixed solution, then put the second mixed solution in a 70°C constant temperature blast drying oven to dry for 12 hours, and then grind the dried material to obtain the precursor powder ;

[0053] (2) Preparation of lithium ceramic pellets

[0054] Weigh the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com