Patents

Literature

149results about How to "Avoid grain growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

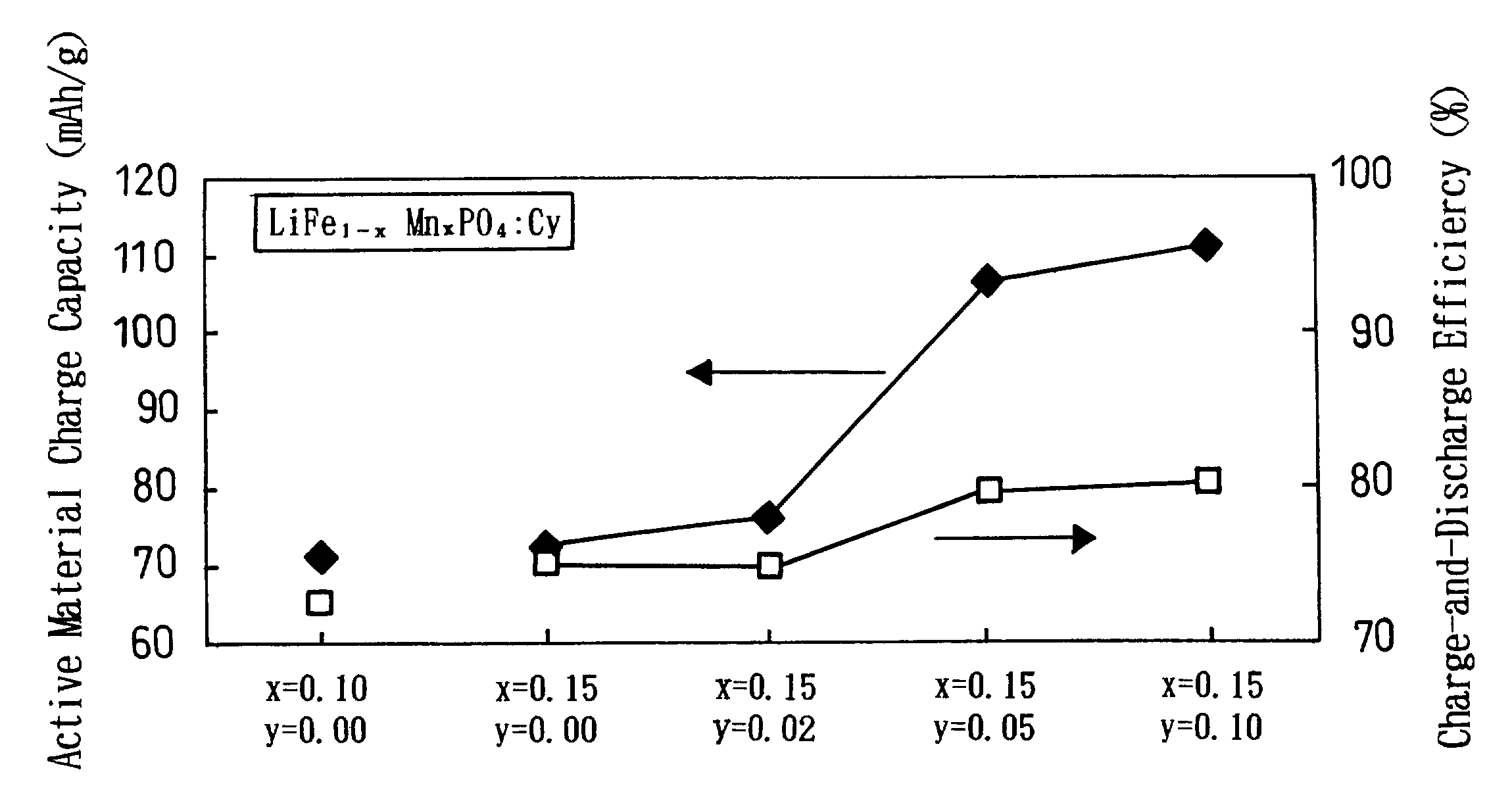

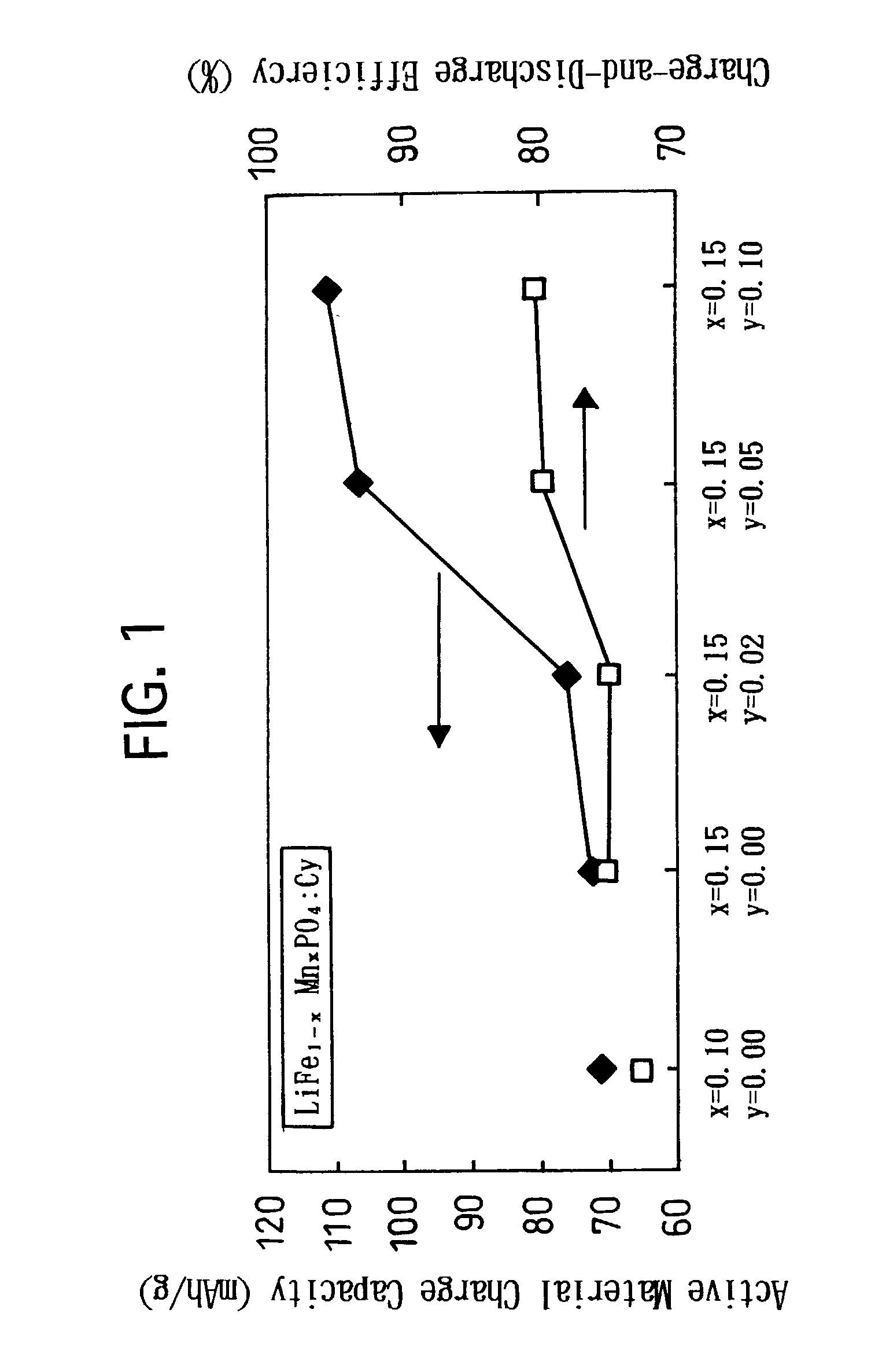

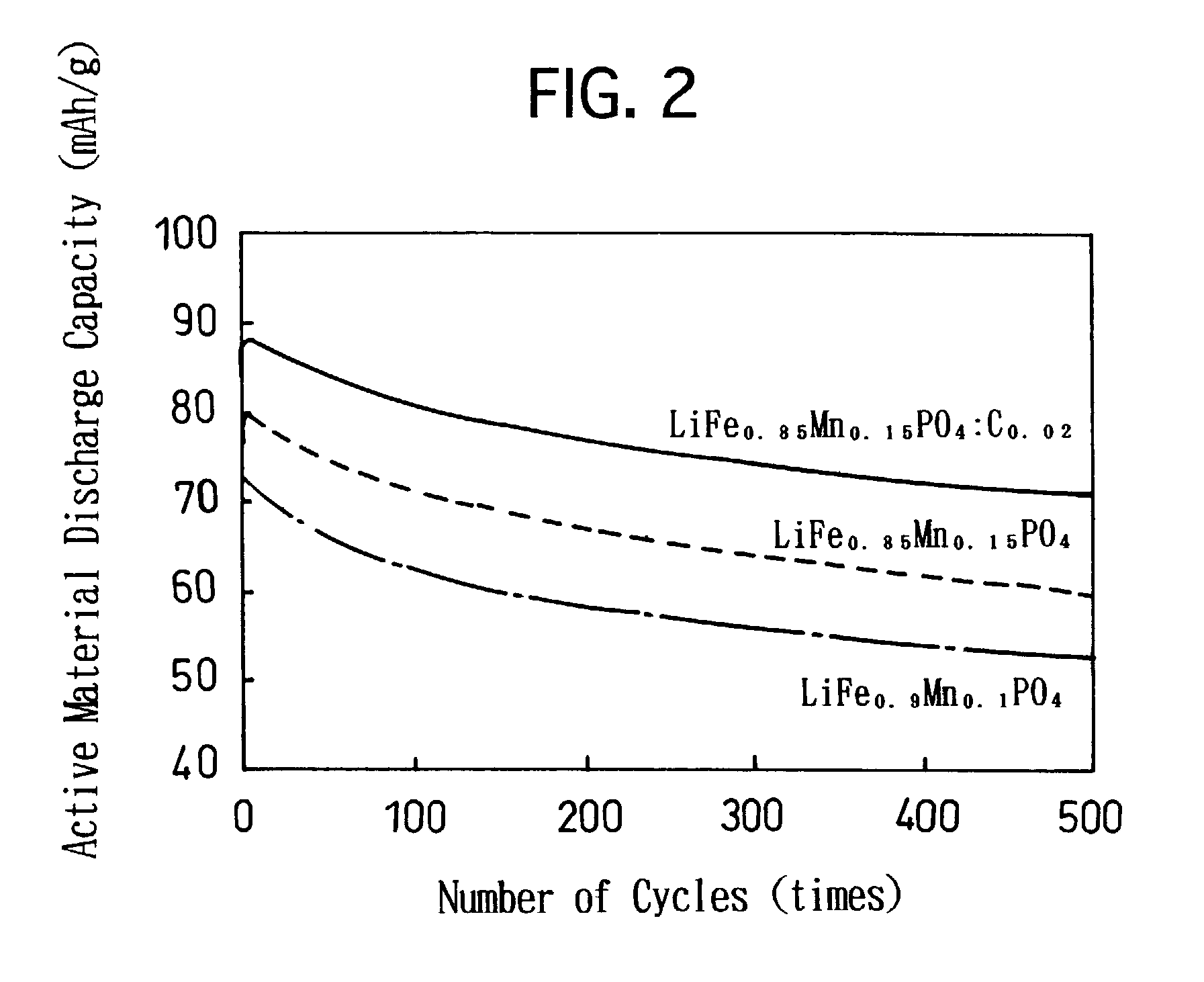

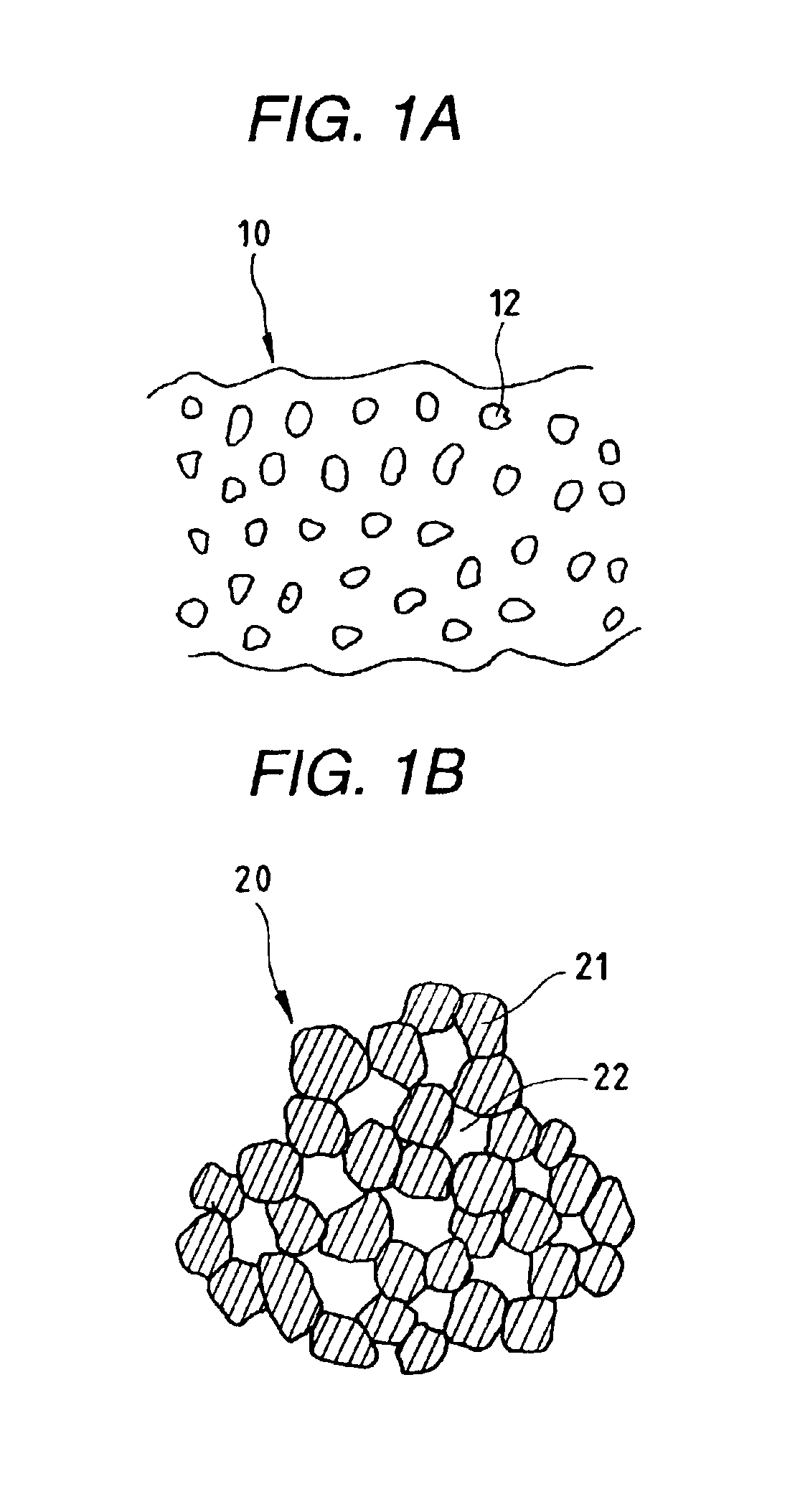

Carbon-containing lithium-iron composite phosphorus oxide for lithium secondary battery positive electrode active material and process for producing the same

InactiveUS7025907B2Shorten the diffusion distanceIncrease capacityPhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMicroparticleOlivine

A carbon-containing lithium-iron composite phosphorus oxide for a lithium secondary battery positive electrode active material, includes particles being composed of a lithium-iron composite phosphorus oxide having an olivine structure whose basic composition is LiFePO4, and being composited with carbonaceous fine particles. A process for producing the same includes the steps of mixing a lithium compound making a lithium source, an iron compound making an iron source, a phosphorus-containing ammonium salt making a phosphorus source and carbonaceous fine particles, thereby preparing a mixture, and calcicing the mixture at a temperature of from 600° C. or more to 750° C. or less.

Owner:TOYOTA CENT RES & DEV LAB INC

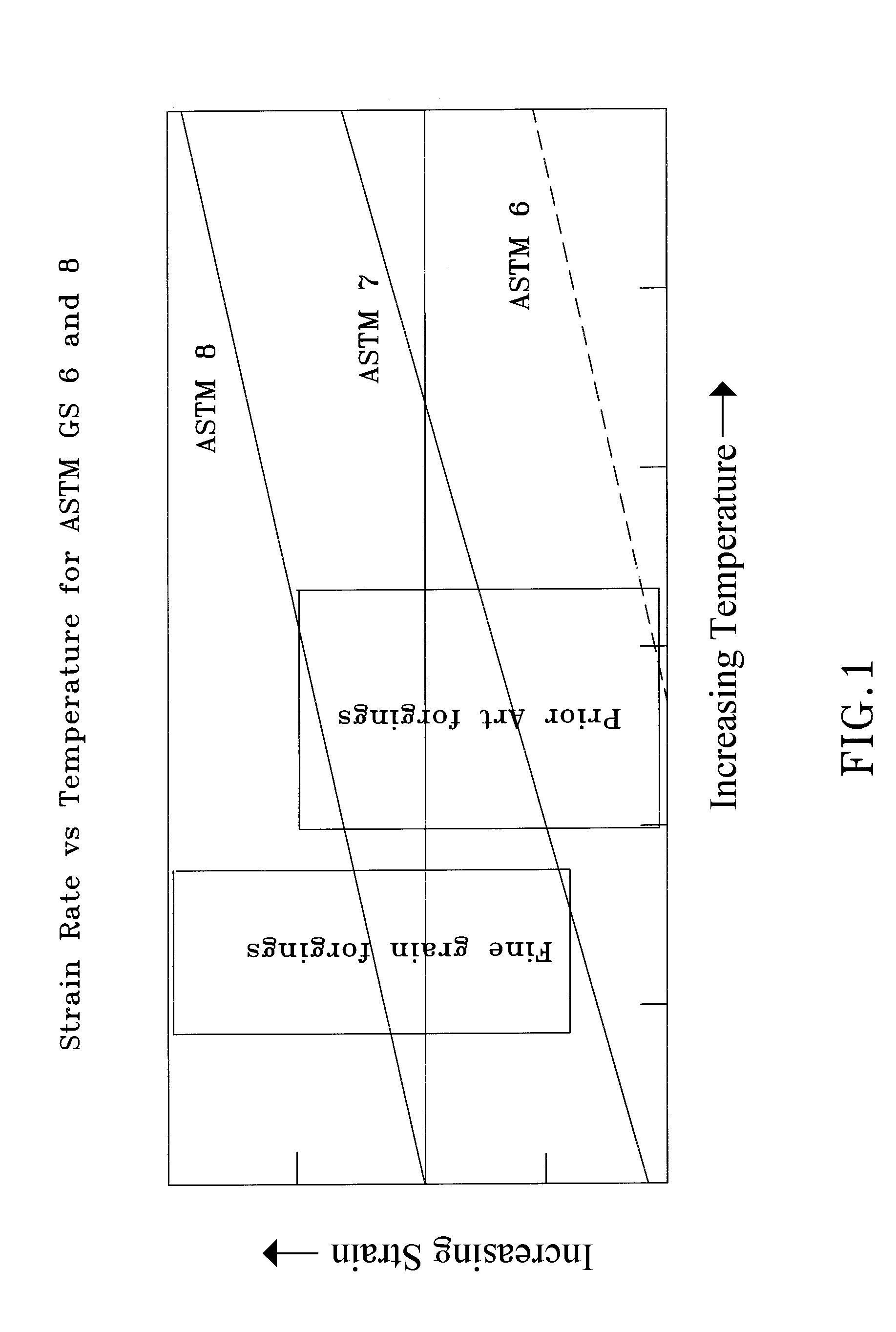

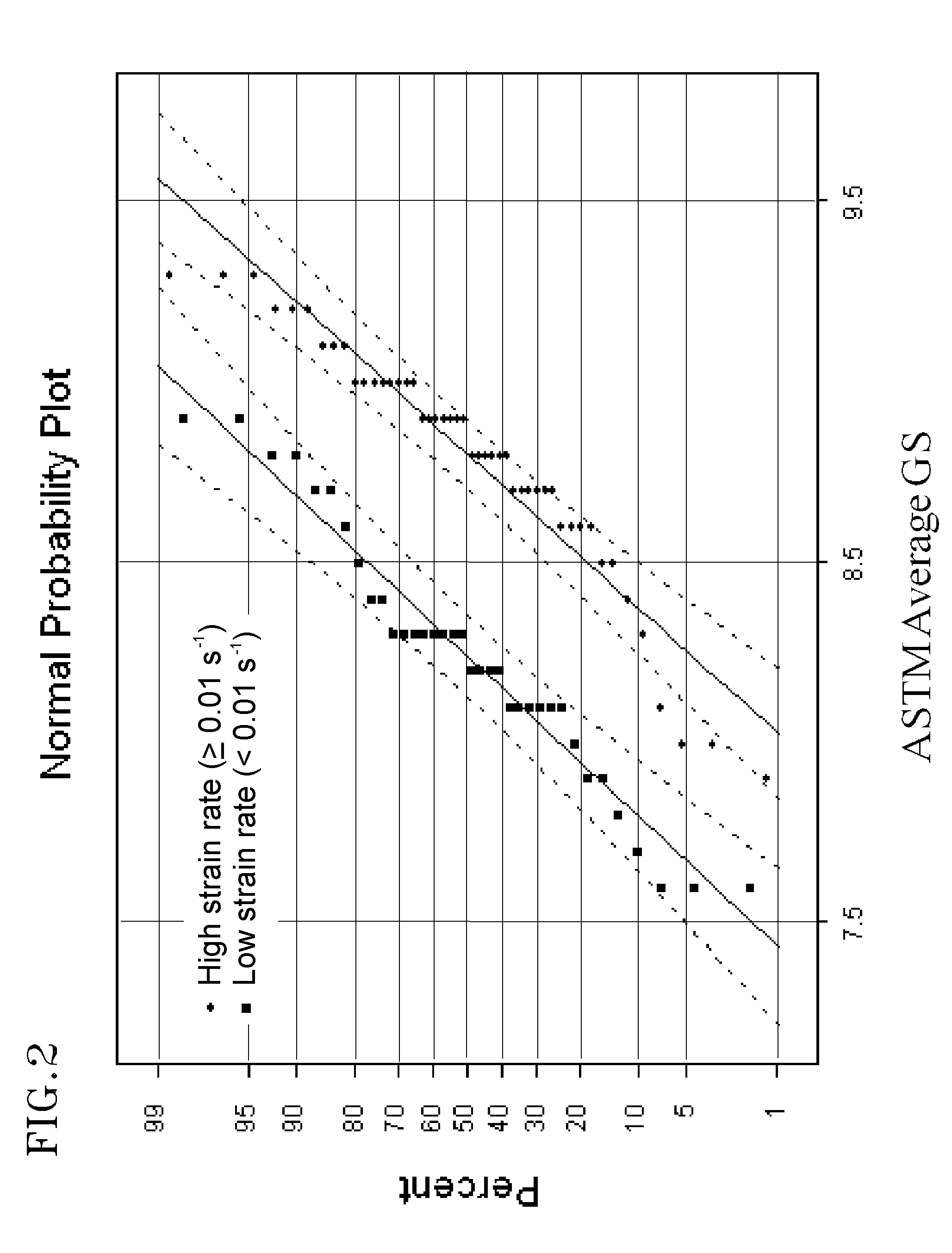

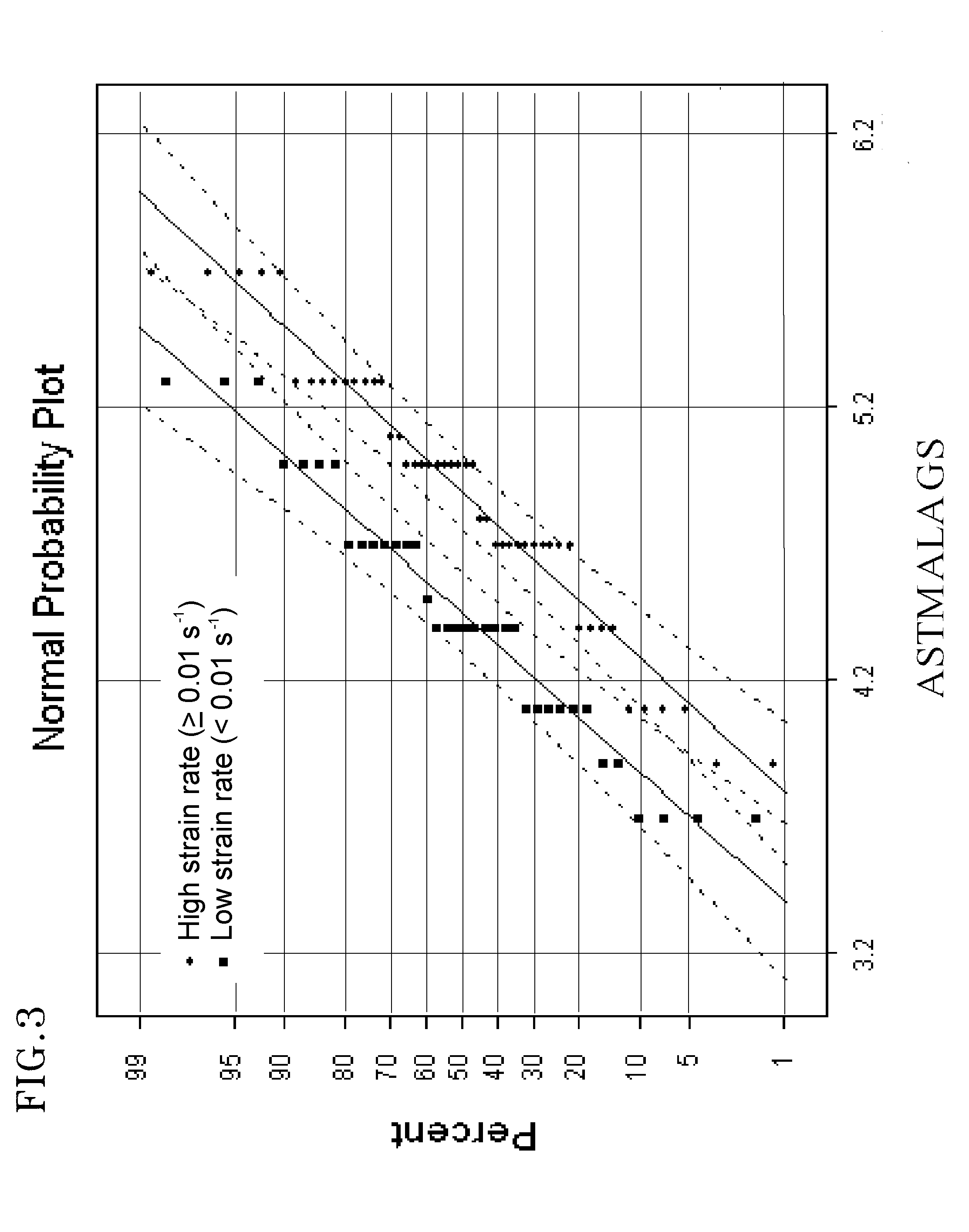

Method of controlling and refining final grain size in supersolvus heat treated nickel-base superalloys

InactiveUS20090000706A1High strain rateAvoiding necessity to forge superplasticallyHigh carbonHeat treated

A method of forming a component from a gamma prime precipitation-strengthened nickel-base superalloy. The method entails formulating the superalloy to have a sufficiently high carbon content and forging the superalloy at sufficiently high local strain rates so that, following a supersolvus heat treatment, the component is characterized by a fine and substantially uniform grain size distribution, preferably finer than ASTM 7 and more preferably in a range of about ASTM 8 to 10.

Owner:GENERAL ELECTRIC CO

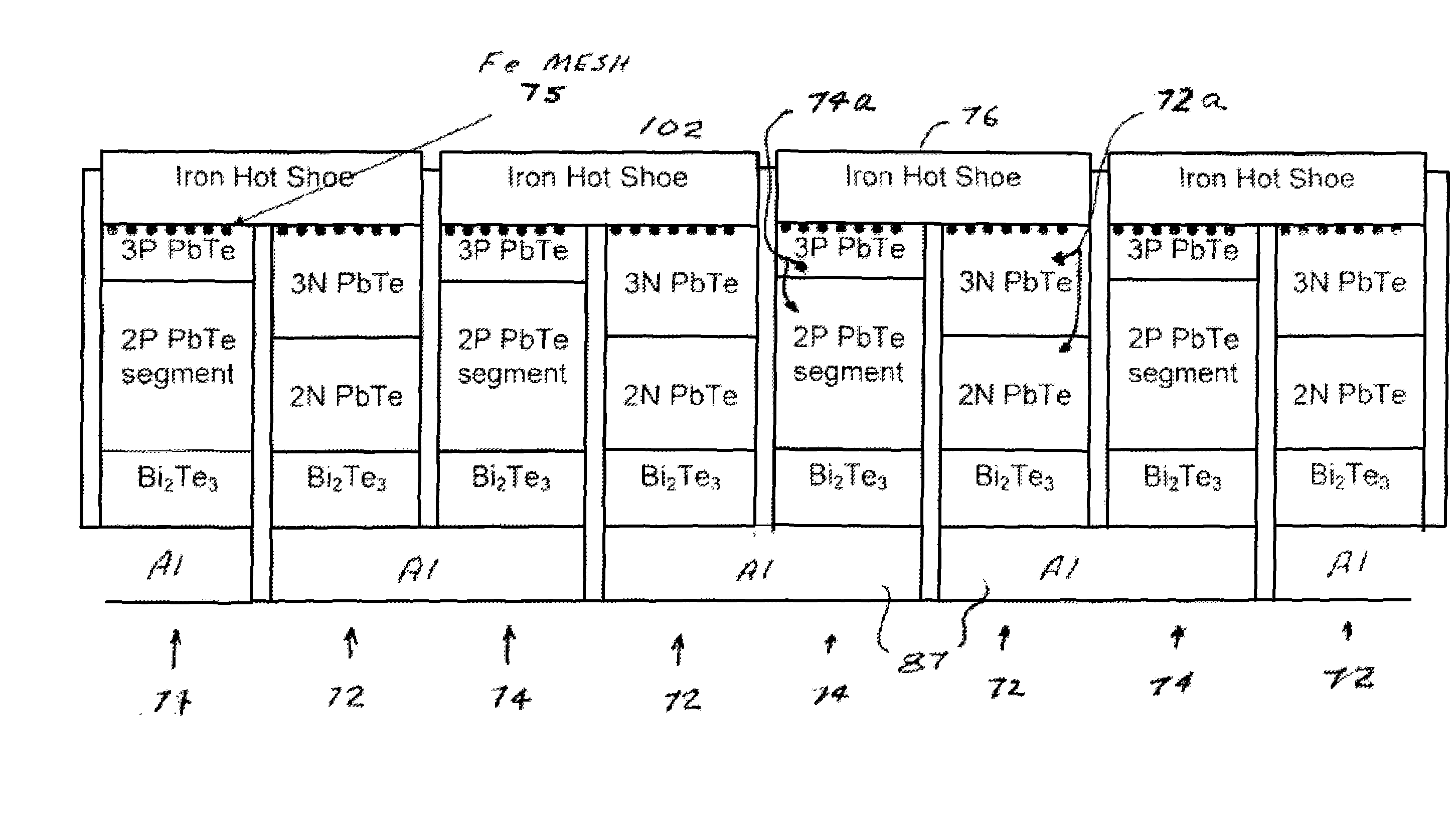

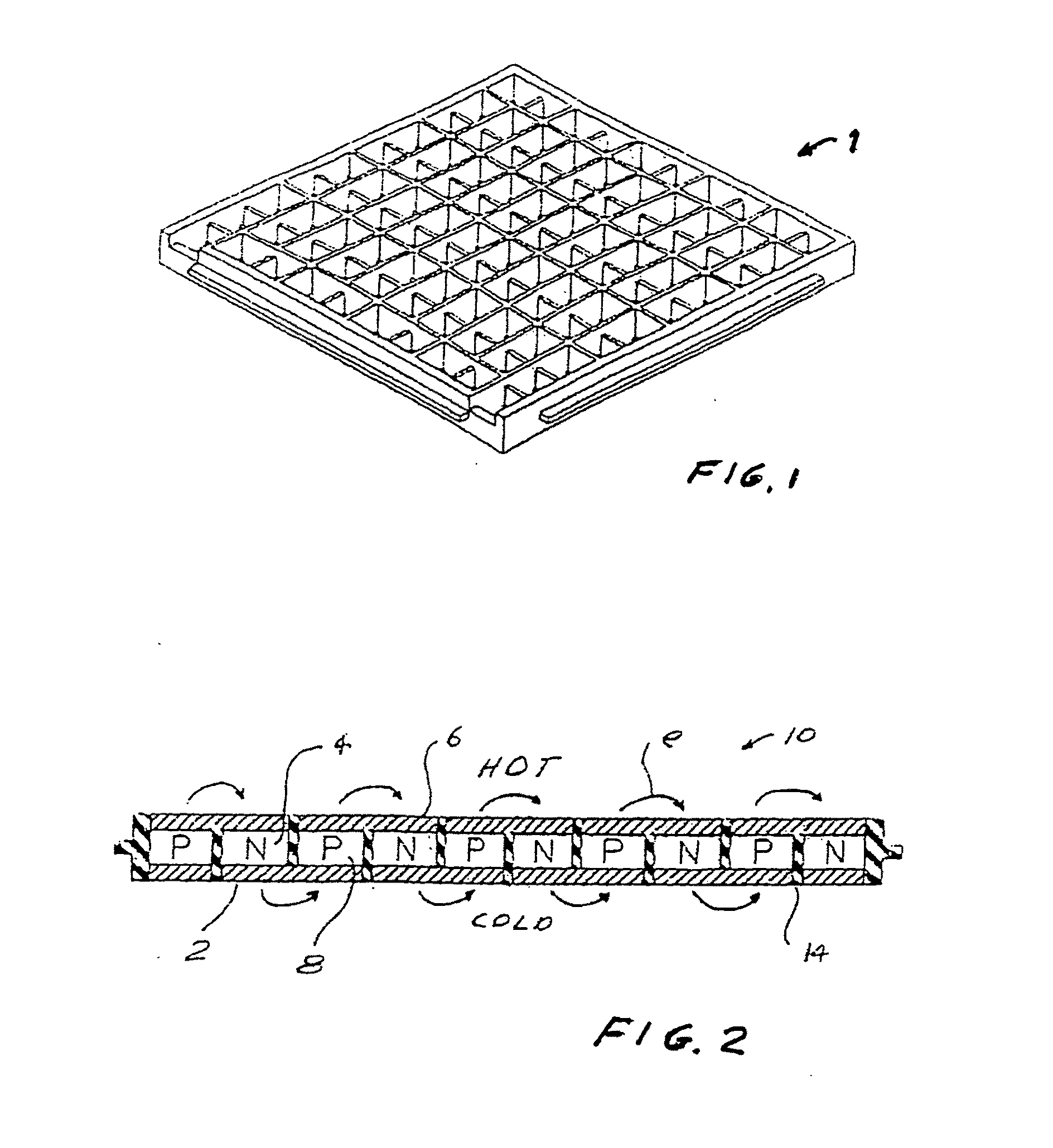

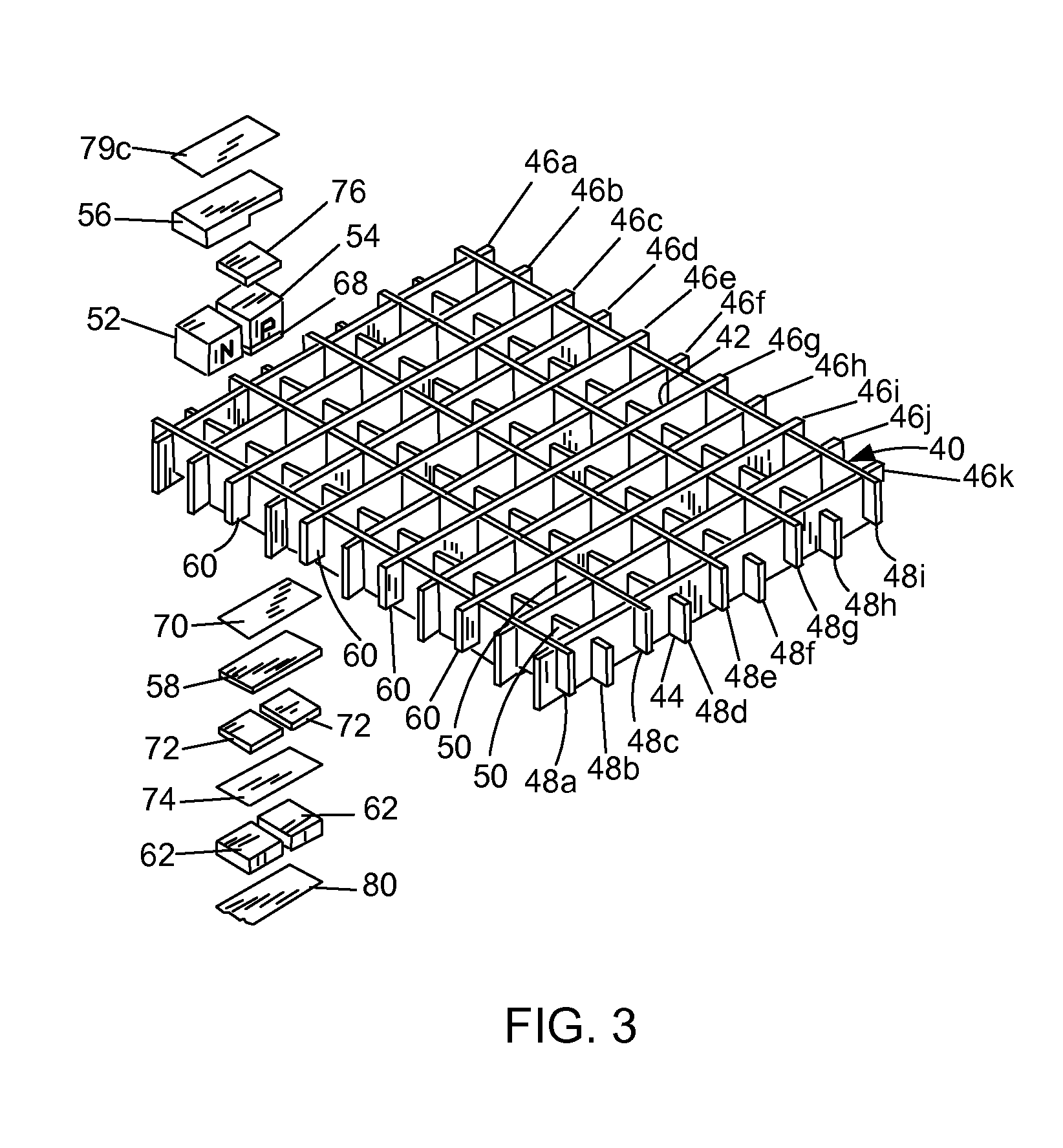

High temperature, high efficiency thermoelectric module

InactiveUS20100229911A1Low thermal conductivityImprove ZTThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsElectrical connection

A long life, low cost, high-temperature, high efficiency thermoelectric module. Preferred embodiments include a two-part (a high temperature part and a cold temperature part) egg-crate and segmented N legs and P legs, with the thermoelectric materials in the three segments chosen for their chemical compatibility or their figure of merit in the various temperature ranges between the hot side and the cold side of the module. The legs include metal meshes partially embedded in thermoelectric segments to help maintain electrical contacts notwithstanding substantial temperature variations. In preferred embodiments a two-part molded egg-crate holds in place and provides insulation and electrical connections for the thermoelectric N legs and P legs. The high temperature part of the egg-crate is comprised of a ceramic material capable of operation at temperatures in excess of 500° C. and the cold temperature part is comprised of a thermoplastic material having very low thermal conductivity.

Owner:HI Z TECH +1

Method for preparing nano molecular sieve

ActiveCN101182004ANarrow particle size distributionMass transfer limitationNanostructure manufactureCrystalline aluminosilicate zeolitesSolubilityMolecular sieve

The invention discloses a preparation method of nanometer molecular sieve. The method is to firstly mix hydrocarbon components and surfactants evenly, then add silica gel and silica-alumina gel, and continue to stir until the raw materials are evenly mixed to obtain a super-solubilizing system of oil-in-melt, and then undergo crystallization, drying and roasting Finally, nano molecular sieves are obtained. The crystallization of the molecular sieve in the present invention is carried out in a supersolubilized micelle system of molten silica gel or silica-alumina gel in oil, and the growth of the molecular sieve crystal is limited in the nano-micelle to avoid excessive growth of the molecular sieve crystal. The surfactant and hydrocarbon components used in the method of the invention are used in small amounts and low in cost. The method has a simple process and can be used for large-scale industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

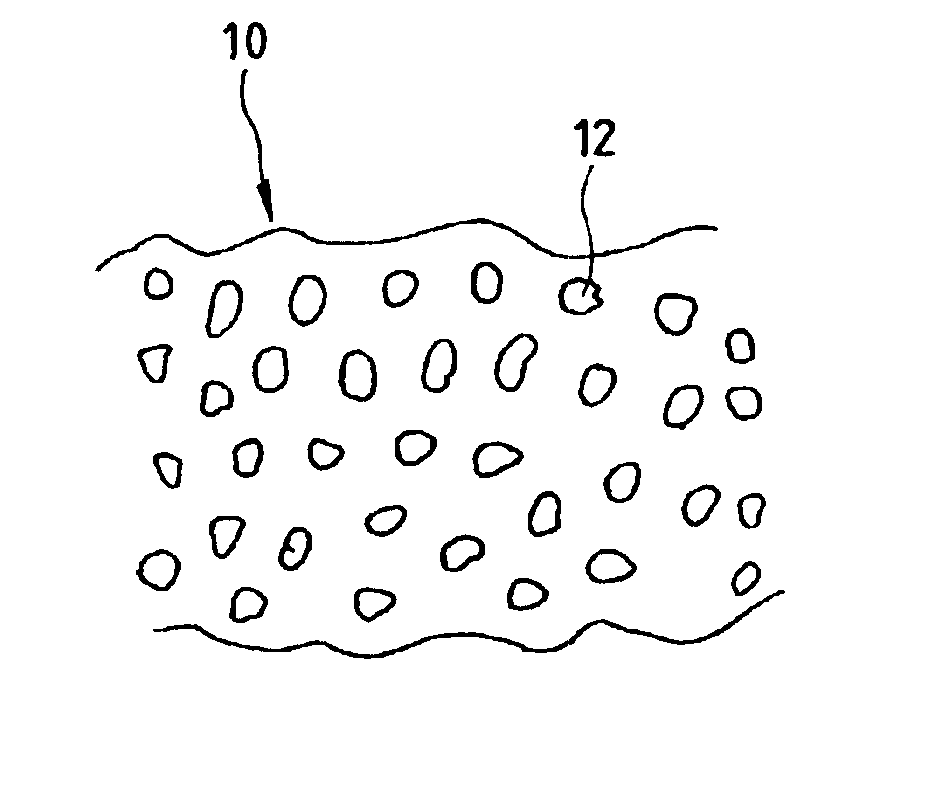

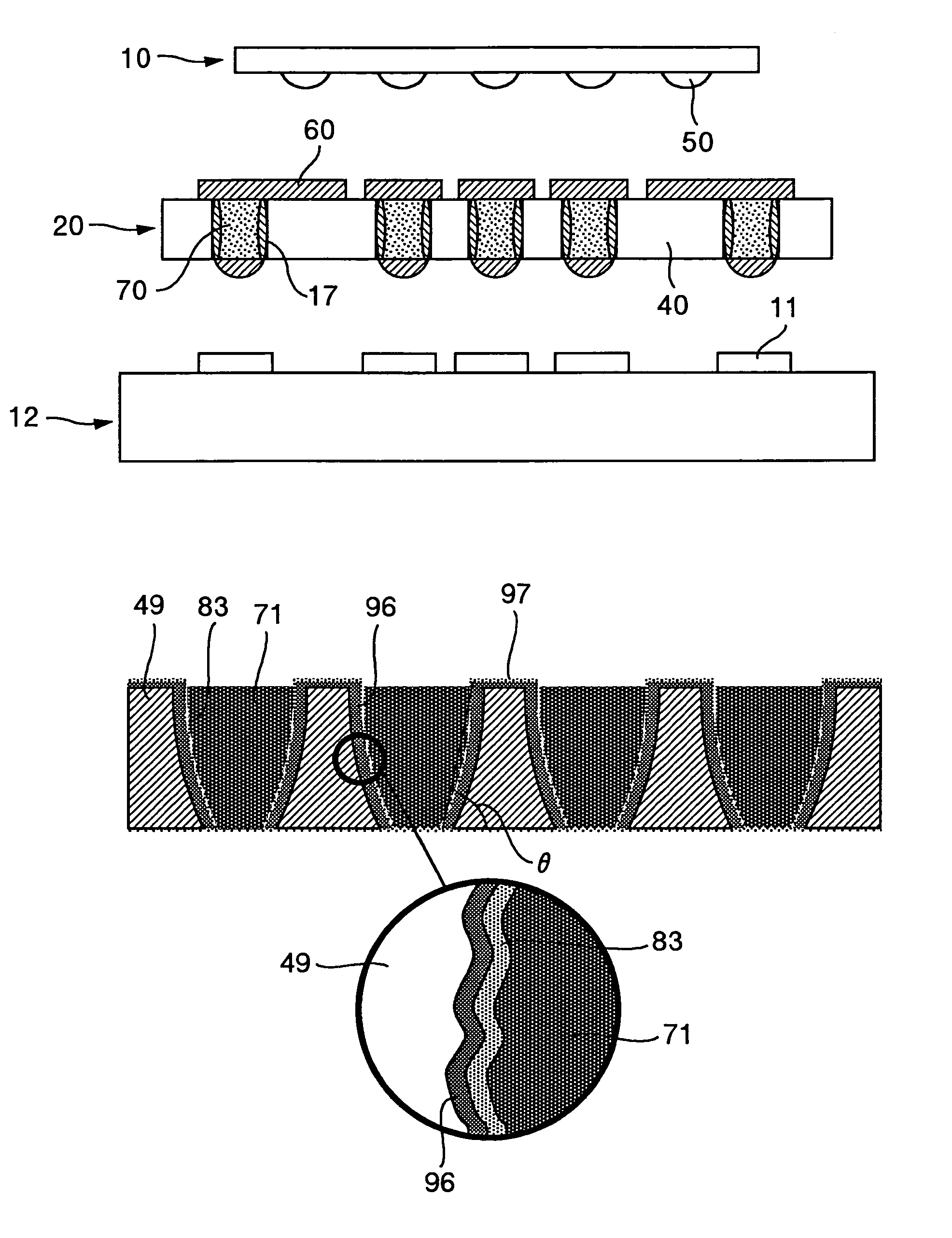

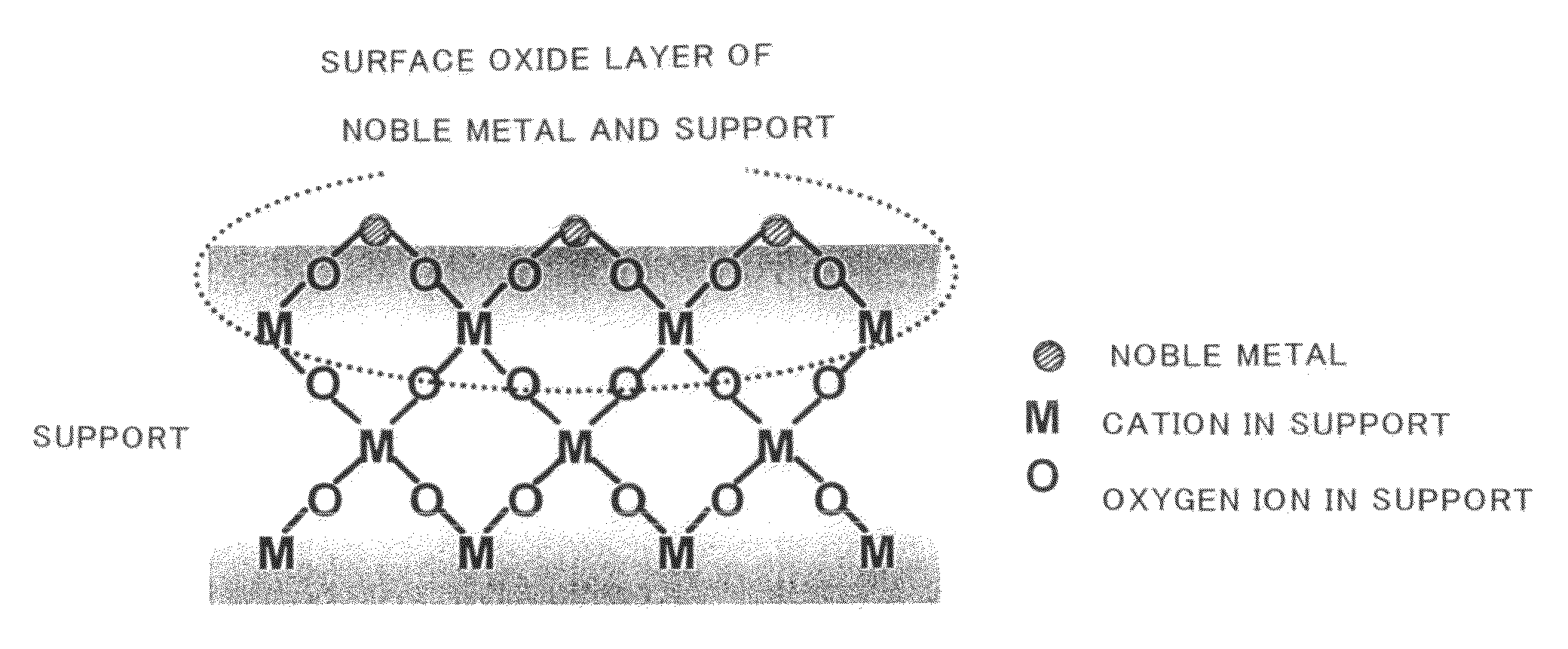

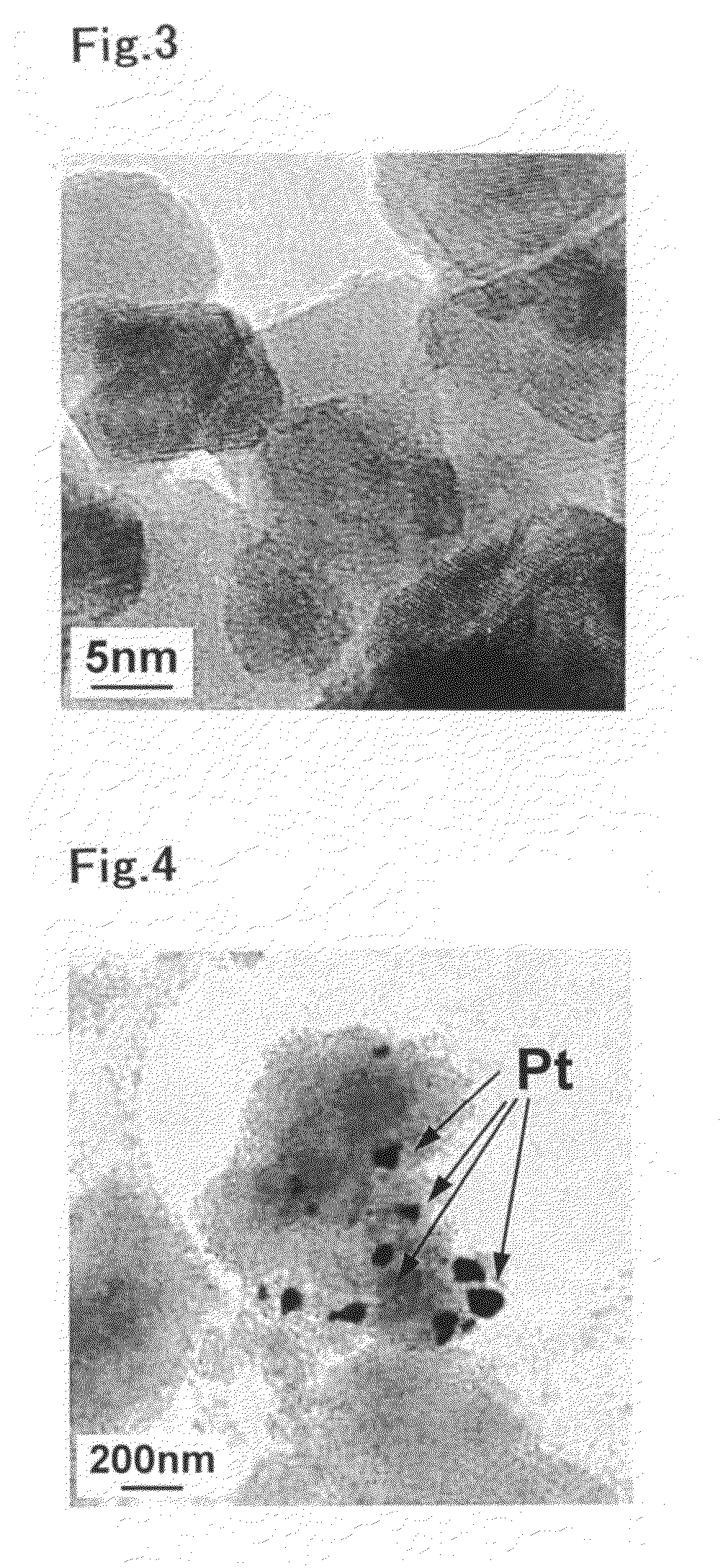

Porous material process of producing the porous material, catalyst for purifying exhaust gas comprising the porous material, method of purifying exhaust gas

InactiveUS6926875B2Excellent characteristicsImprove heat resistanceNitrogen compoundsInternal combustion piston enginesHigh resistanceMeson

Disclosed are a porous material comprising particles without substantial fibrous structure and having pores, the pores having a mean pore diameter in a meson-pore region, sharp pore size distribution, and at least a part of the pores being connected three-dimensionally to form a three-dimensional network structure with random passages, the porous material preferably being of alumina and having a spongy structure or the porous material preferably being an aggregate of particles having an aspect ratio of 3 or less; a process of producing the porous material which includes a step of aging a system capable of becoming an oxide on thermal decomposition; a catalyst for exhaust gas purification having excellent NOx removal performance, high resistance against sulfur poisoning, and satisfactory high-temperature durability which comprises the porous material as a carrier having supported thereon a noble metal and an NOx storage component; and a method of exhaust gas purification using the catalyst.

Owner:TOYOTA CENT RES & DEV LAB INC

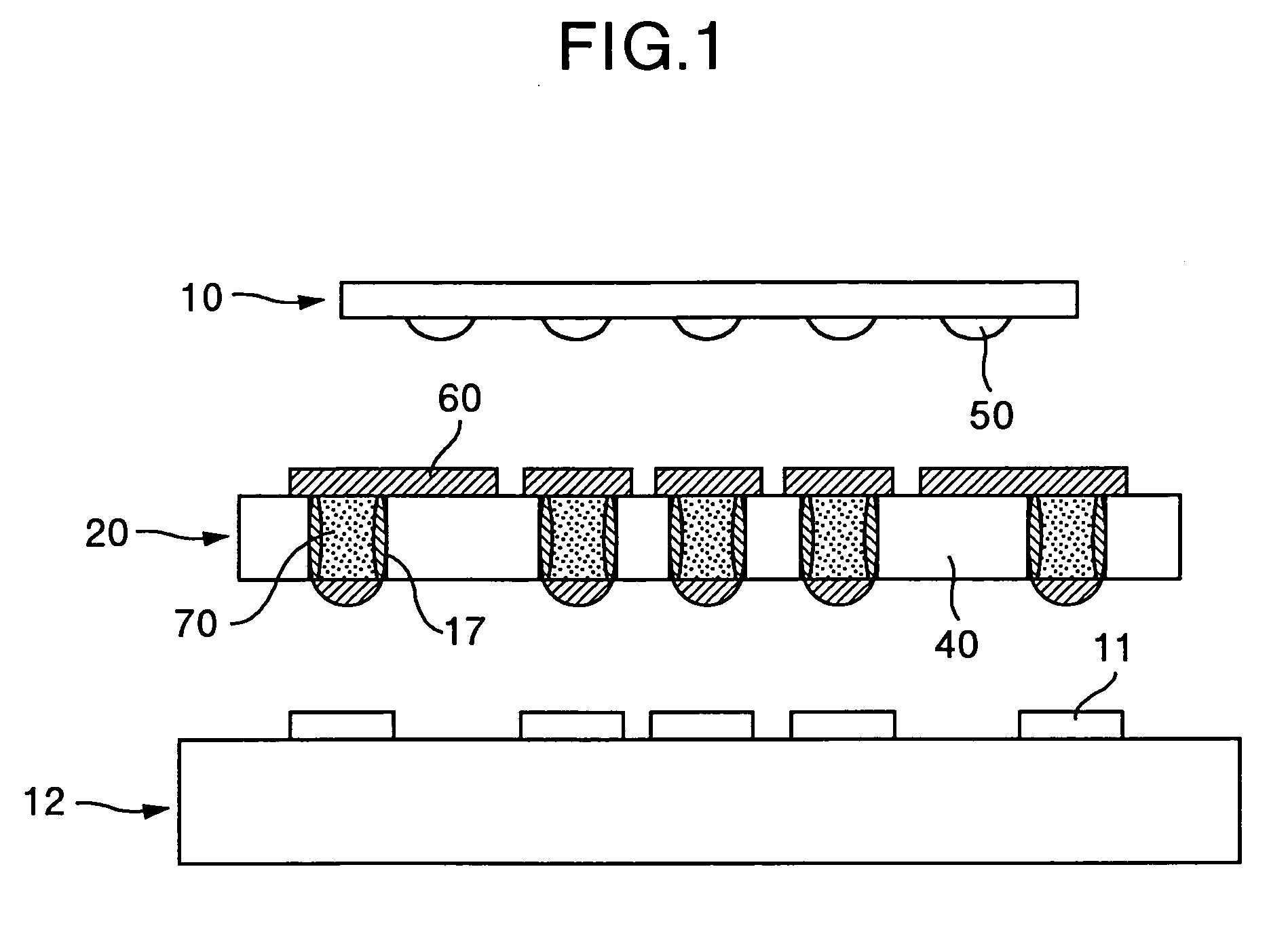

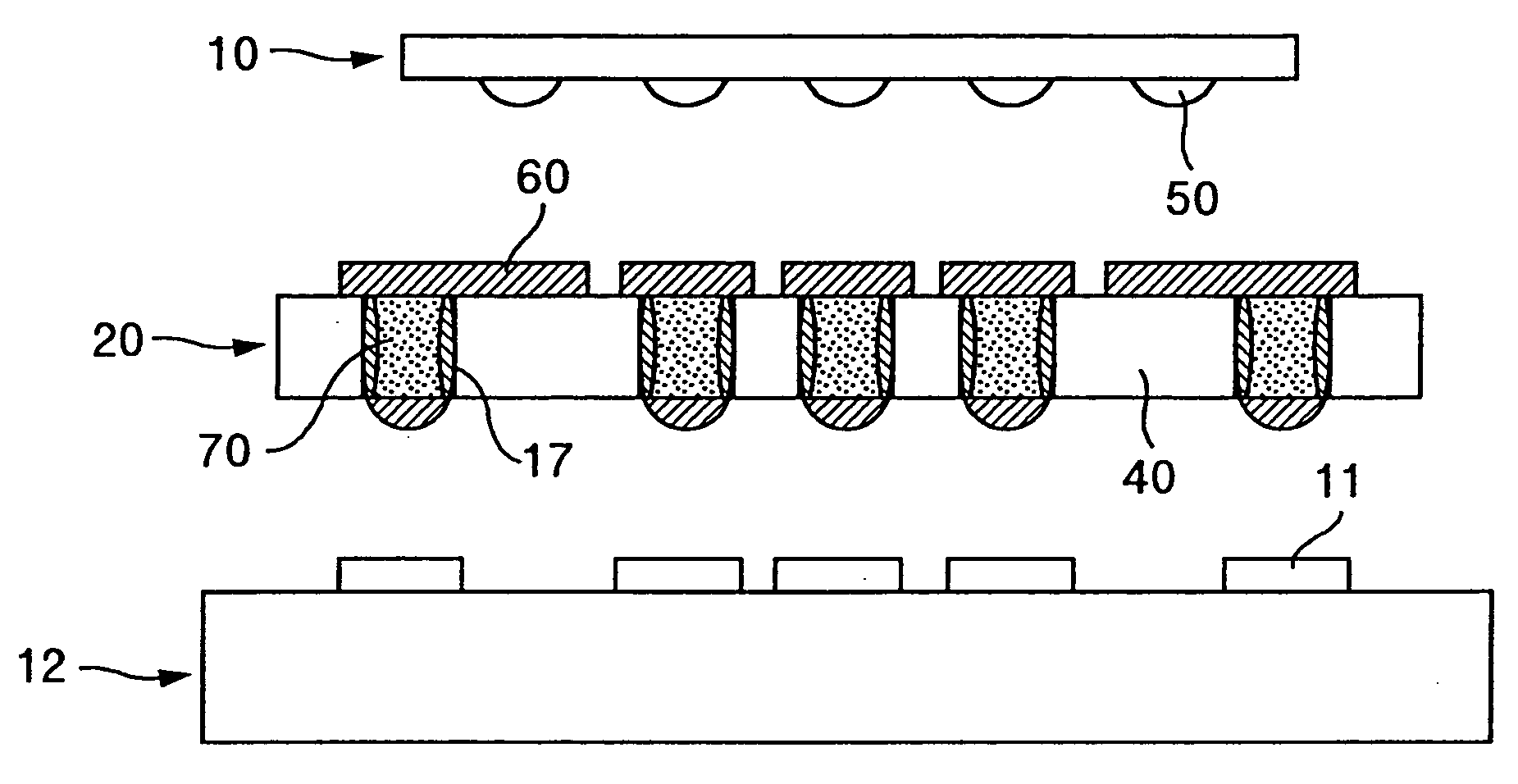

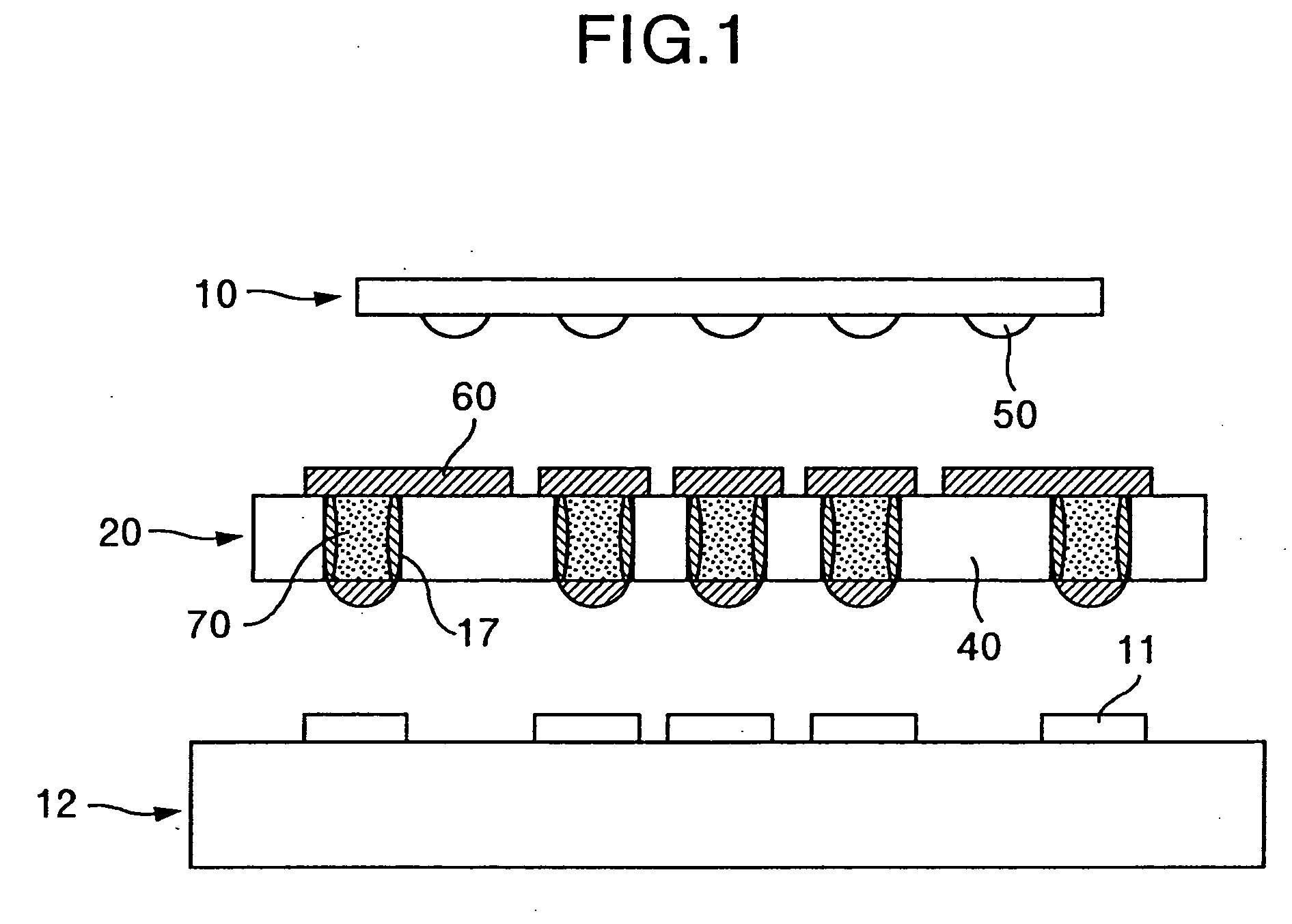

Wiring glass substrate for connecting a semiconductor chip to a printed wiring substrate and a semiconductor module having the wiring glass substrate

InactiveUS7183650B2Lower resistanceComposition ratio is notPorous dielectricsSemiconductor/solid-state device detailsSemiconductor chipConductive materials

Owner:RENESAS TECH CORP

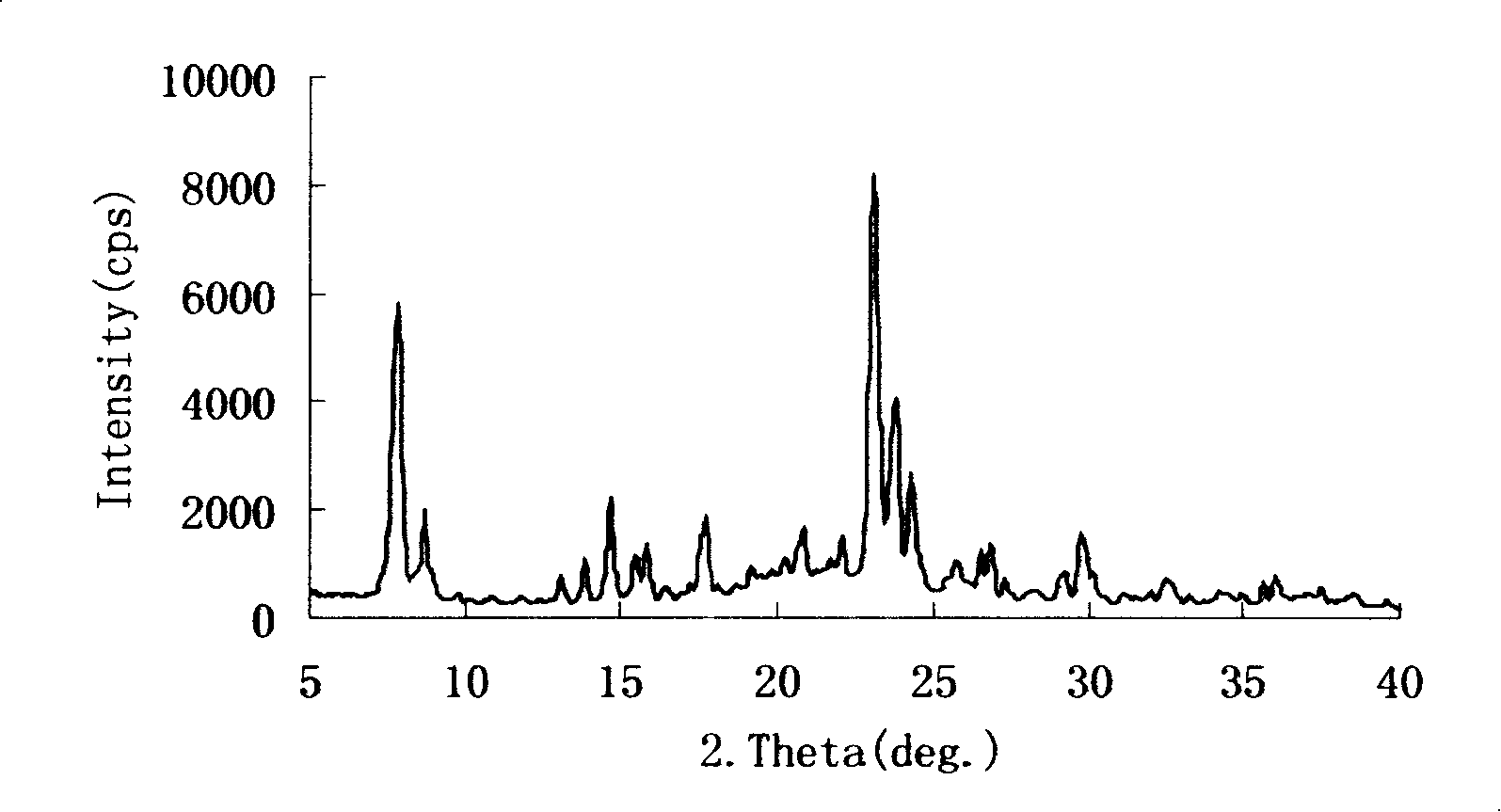

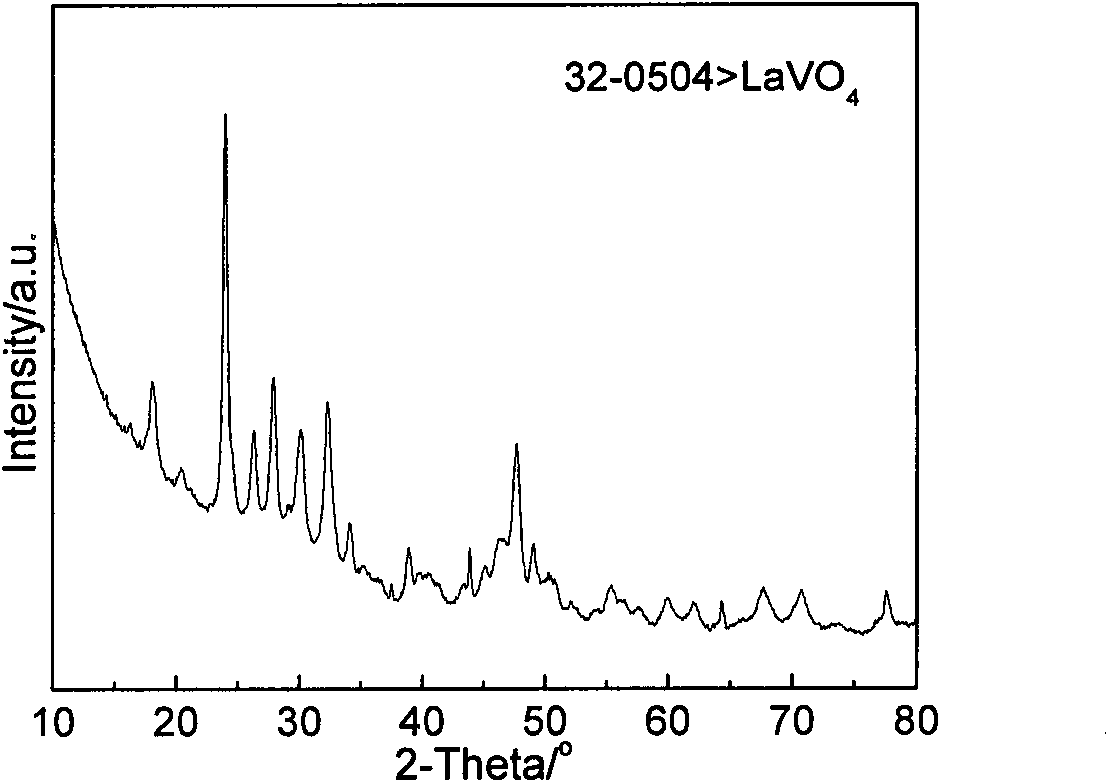

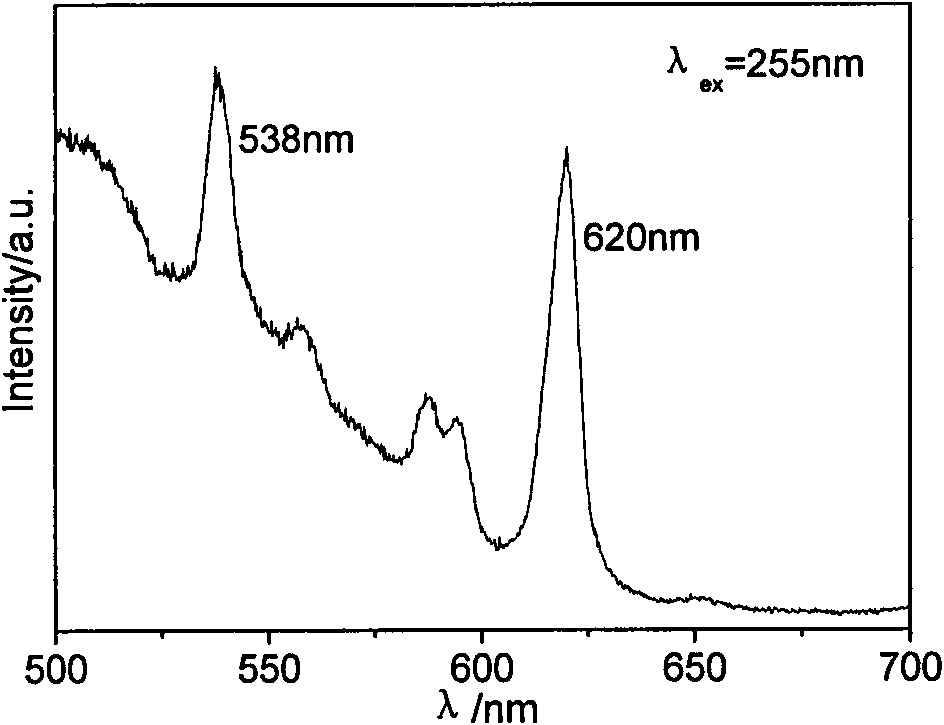

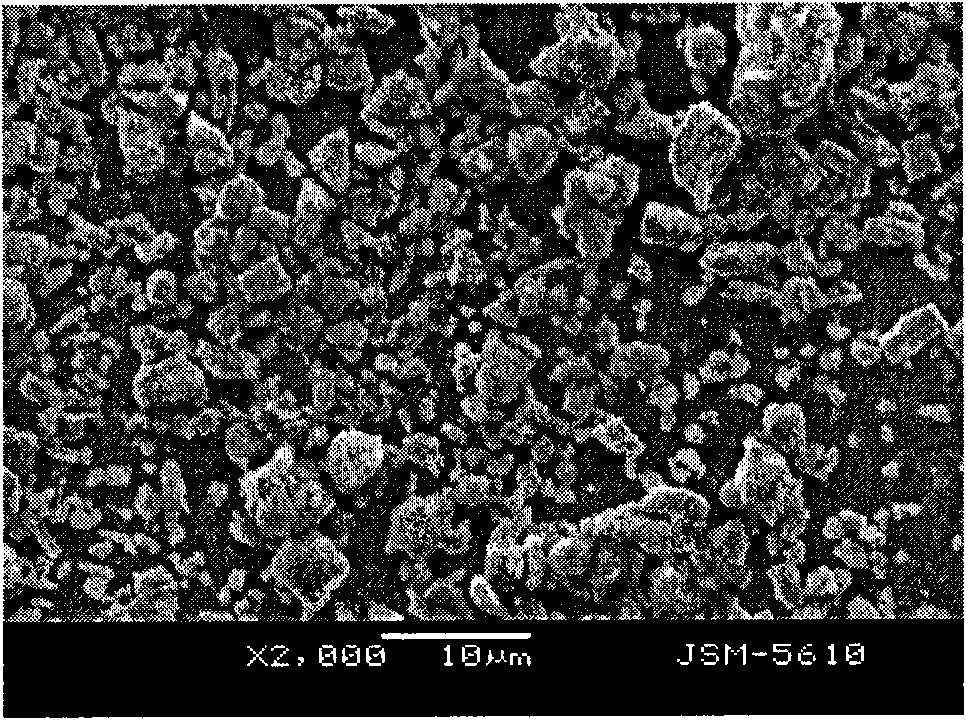

Method for preparing rare-earth vanadate LaVO4:Eu red fluorescent powder

The invention discloses a method for preparing rare-earth vanadate LaVO4:Eu red fluorescent powder, which comprises the following steps: weighing La2O3 and Eu2O3 according to molar ratio; dissolving two oxides with concentrated nitric acid, and diluting the two oxides with deioniezed water; weighing NH4VO3 of which the mole number is two times that of rare-earth oxide to be prepared into dilute solution, and adding the dilute solution into rare-earth solution to obtain yellow clear solution; adding citric acid of which the mole number is 0.75 time that of rare-earth atoms and taken as a complexing agent into the yellow clear solution; adjusting the pH value of the mixed solution to be 5 to 7 with nitric acid and ammonia water; pouring the obtained emulsion into a polytetrafluoroethylene reaction kettle after the mixed solution is stirred, placing the reaction kettle into a microwave oven, and performing microwave irradiation for 8 to 10 minutes; and removing supernatant liquid after performing high speed centrifugation on the obtained suspension liquid, and washing and drying sediment to obtain the red fluorescent powder LaVO4:Eu. The method has the advantages of simple and convenient operation and quick synthesis. The obtained powder has the characteristics of high purity, high crystallinity, uniform particle size, and stable luminescence.

Owner:ZHEJIANG SCI-TECH UNIV

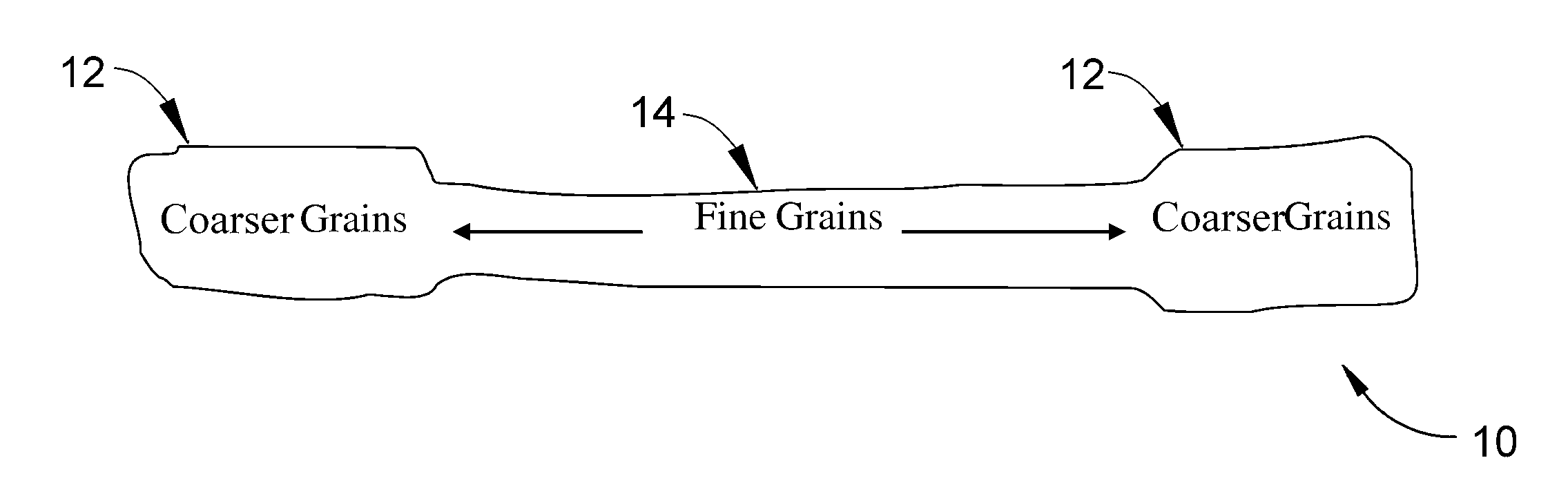

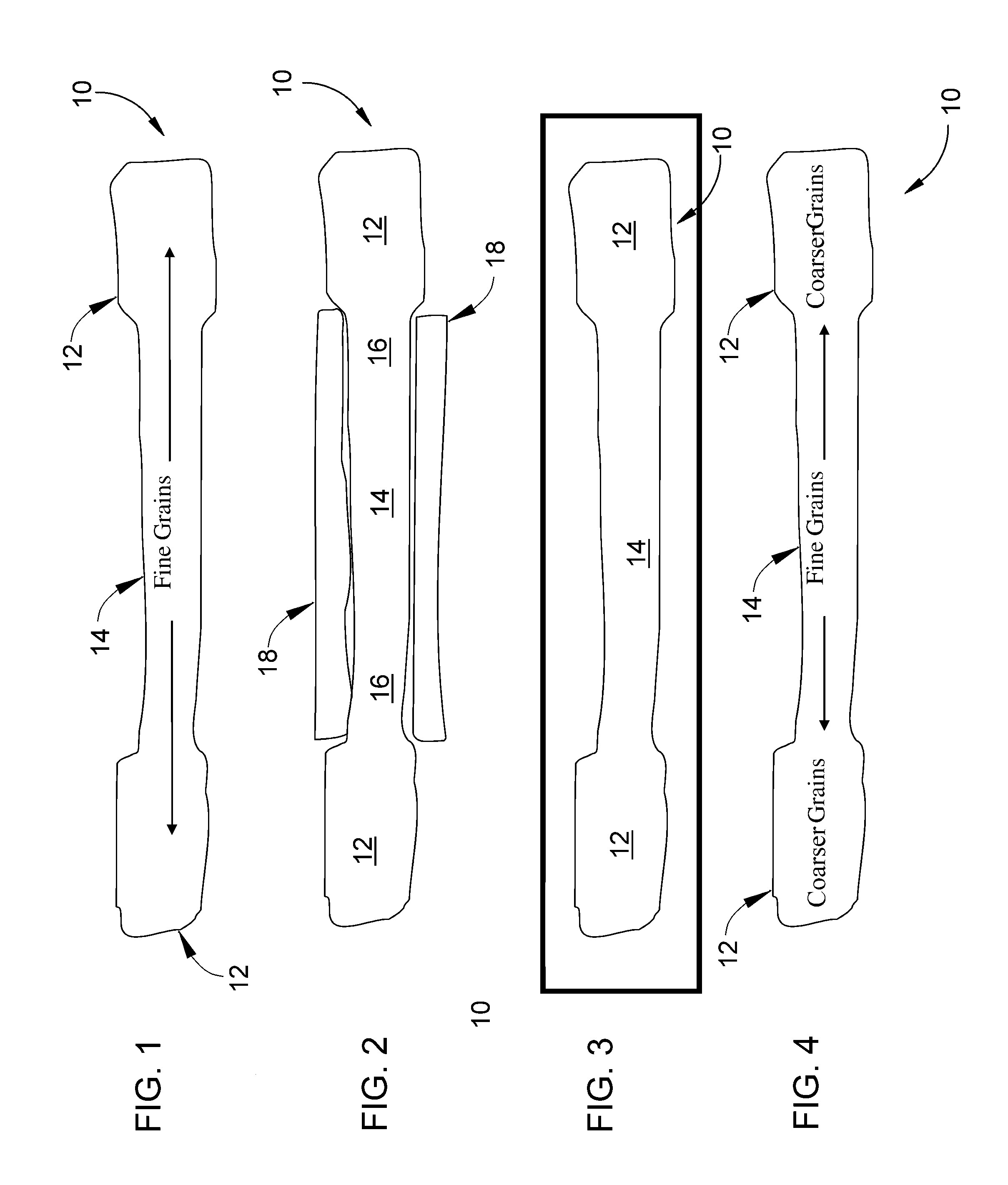

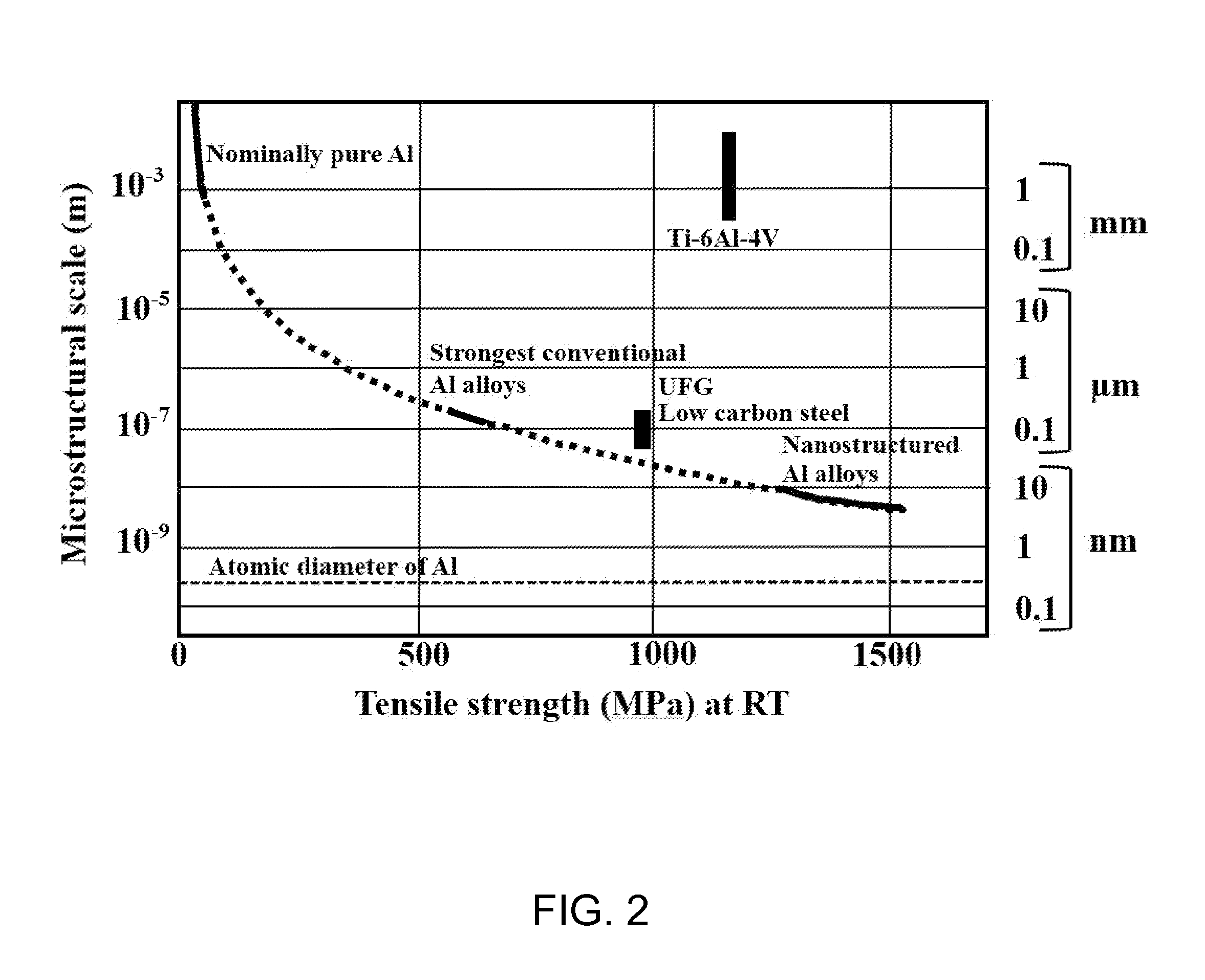

Method of controlling grain size in forged precipitation-strengthened alloys and components formed thereby

ActiveUS8679269B2Significant control of average grain sizeAvoid grain growthBlade accessoriesReaction enginesAlloyPrecipitation

Components and methods of processing such components from precipitation-strengthened alloys so that the components exhibit desirable grain sizes following a supersolvus heat treatment. The method includes consolidating a powder of the alloy to form a billet having an average grain size. The billet is then forged at a temperature below the solvus temperature to form a forging having an average grain size of not coarser than the grain size of the billet. The billet is then forged at a total strain of at least 5%, after which at least a portion of the forging is heat treated at a temperature below the solvus temperature to pin grains within the portion. The entire forging can then be heat treated at a temperature above the solvus temperature of the alloy without coarsening the grains in the portion.

Owner:GENERAL ELECTRIC CO

Conductive ink composition, reflective member, circuit substrate, and electronic apparatus

InactiveUS20050285084A1Improve adhesionImprove surface smoothnessPhotosensitive materialsConductive materialAlloyCarboxylic acid

A conductive ink composition is obtained by dispersing, in an organic solvent, a solid material made from metal fine particles each coated with protective colloids each made of at least two organic compounds, the metal fine particles consisting of an alloy containing at least a noble metal. Each of the protective colloids is made from, e.g., a raw material containing an (A) amine and a (B) carboxylic acid. By applying and baking the conductive ink composition, grain growth is restrained. This allows acquirement of a metal film whose surface smoothness is excellent, and whose adhesiveness to an application target is improved as compared with that of a metal film made from a conventional conductive ink composition.

Owner:SHARP KK +1

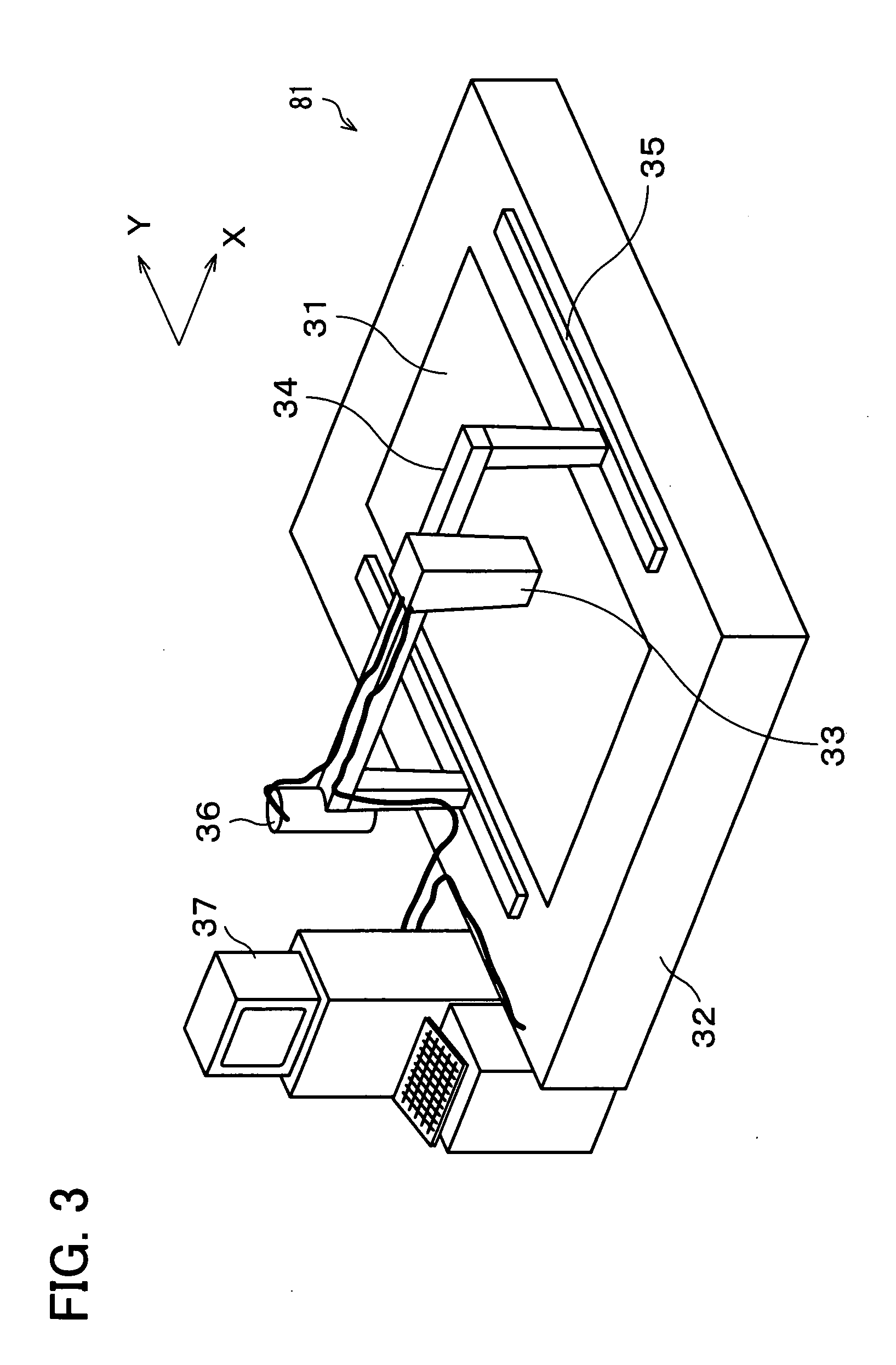

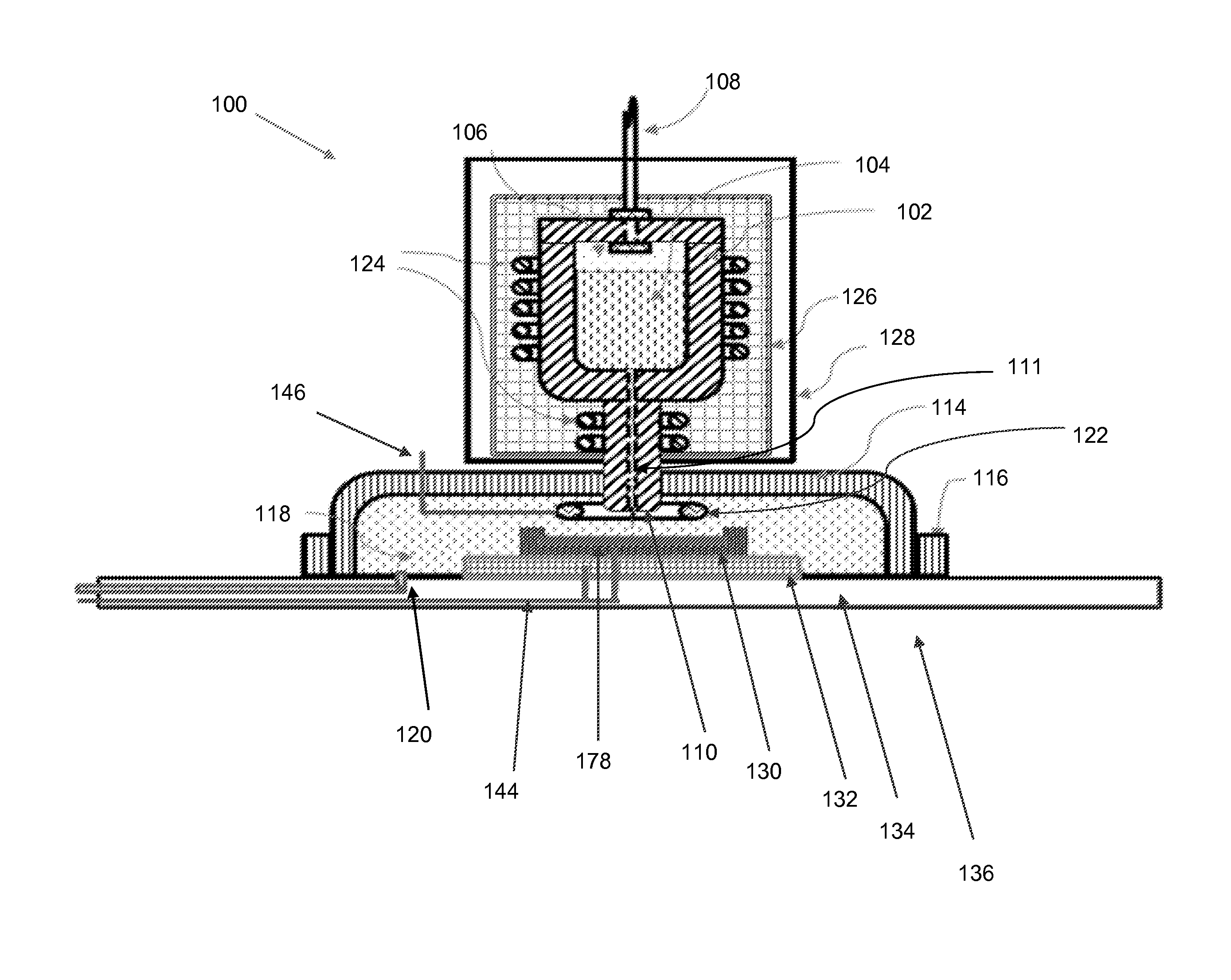

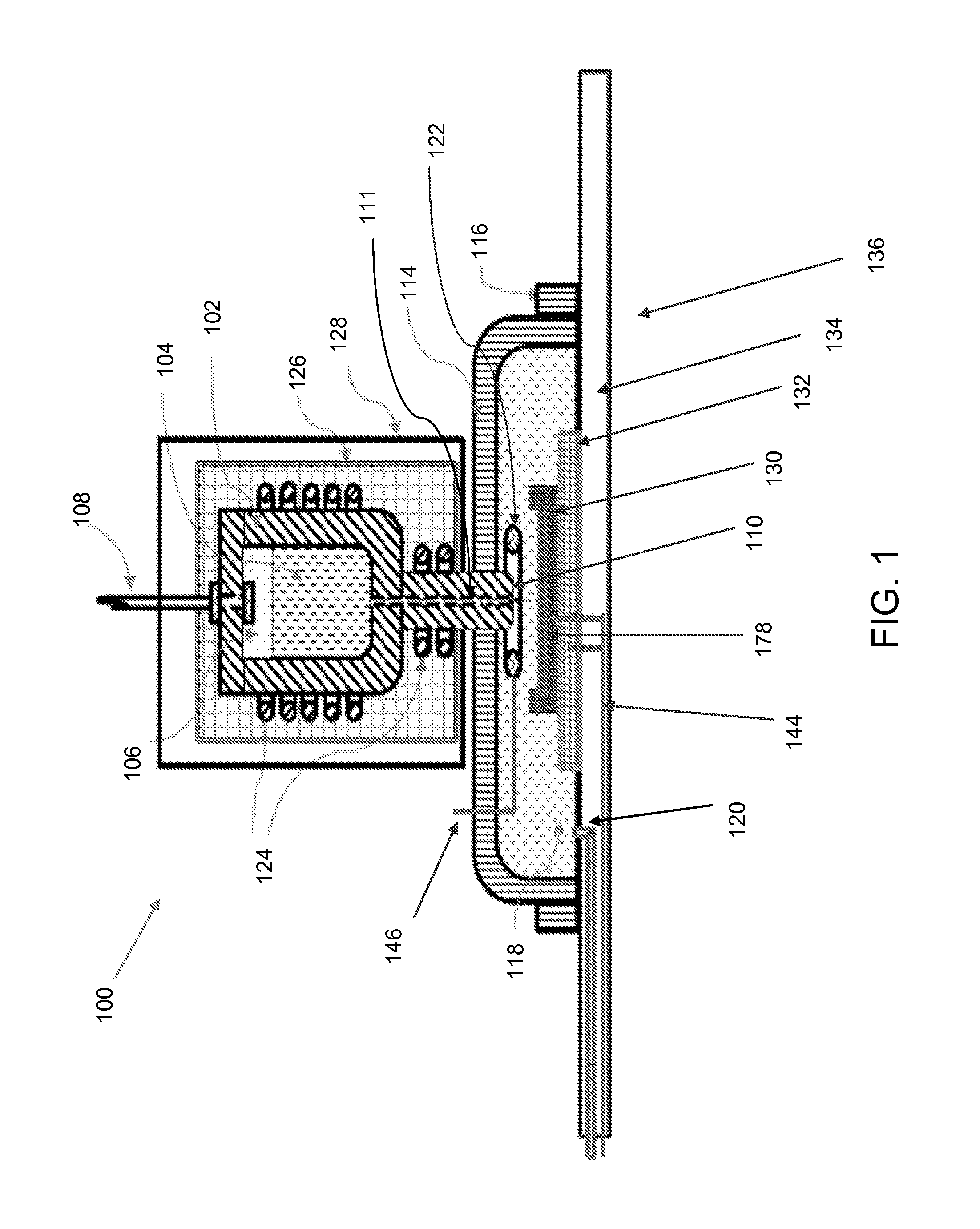

Electrospray pinning of nanograined depositions

ActiveUS20150251213A1Inhibition of recrystallizationEnhanced nucleationLiquid surface applicatorsAdditive manufacturing apparatusGrain growthElectric field

A method and apparatus for fabrication of objects retaining nano-scale characteristics. A composition is provided comprising grain growth inhibitor particles in solution with a binding agent in a molten phase. An electric field and a magnetic field are generated with a combined extraction electrode. The composition is electrosprayed from a nozzle with the electric field to form a stream of droplets. The electric field drives the droplets toward a moving stage holding an object comprising successive deposition layers. The magnetic field limits dispersion of the stream of droplets. The stage is moved laterally as the stream of droplets impacts the object to form a current deposition layer of the object. The stage is moved vertically as necessary to maintain a target stand-off distance between the nozzle and a previous deposition layer of the object, based on profile data of the previous deposition layer.

Owner:Q21 CORPORATION +1

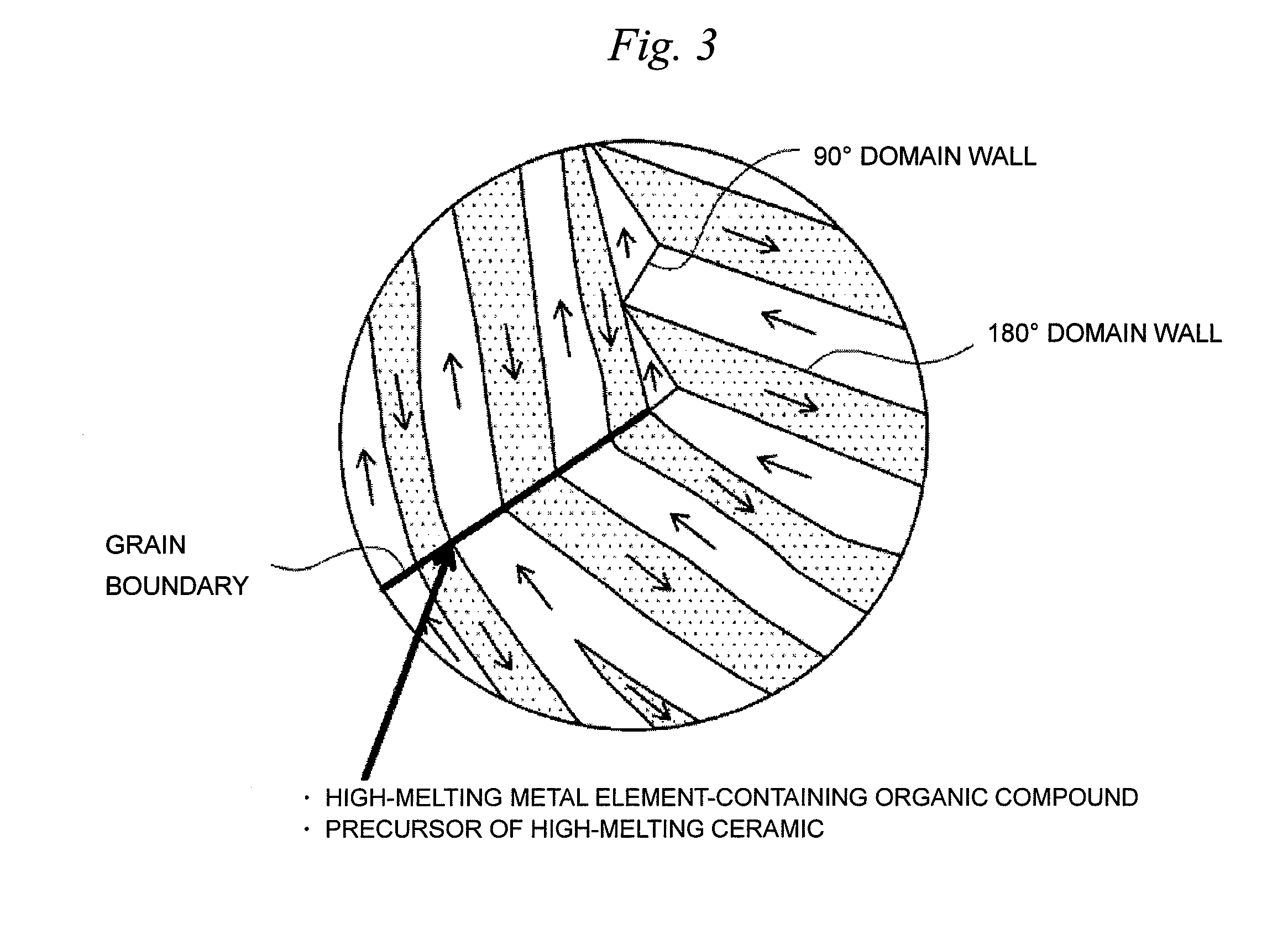

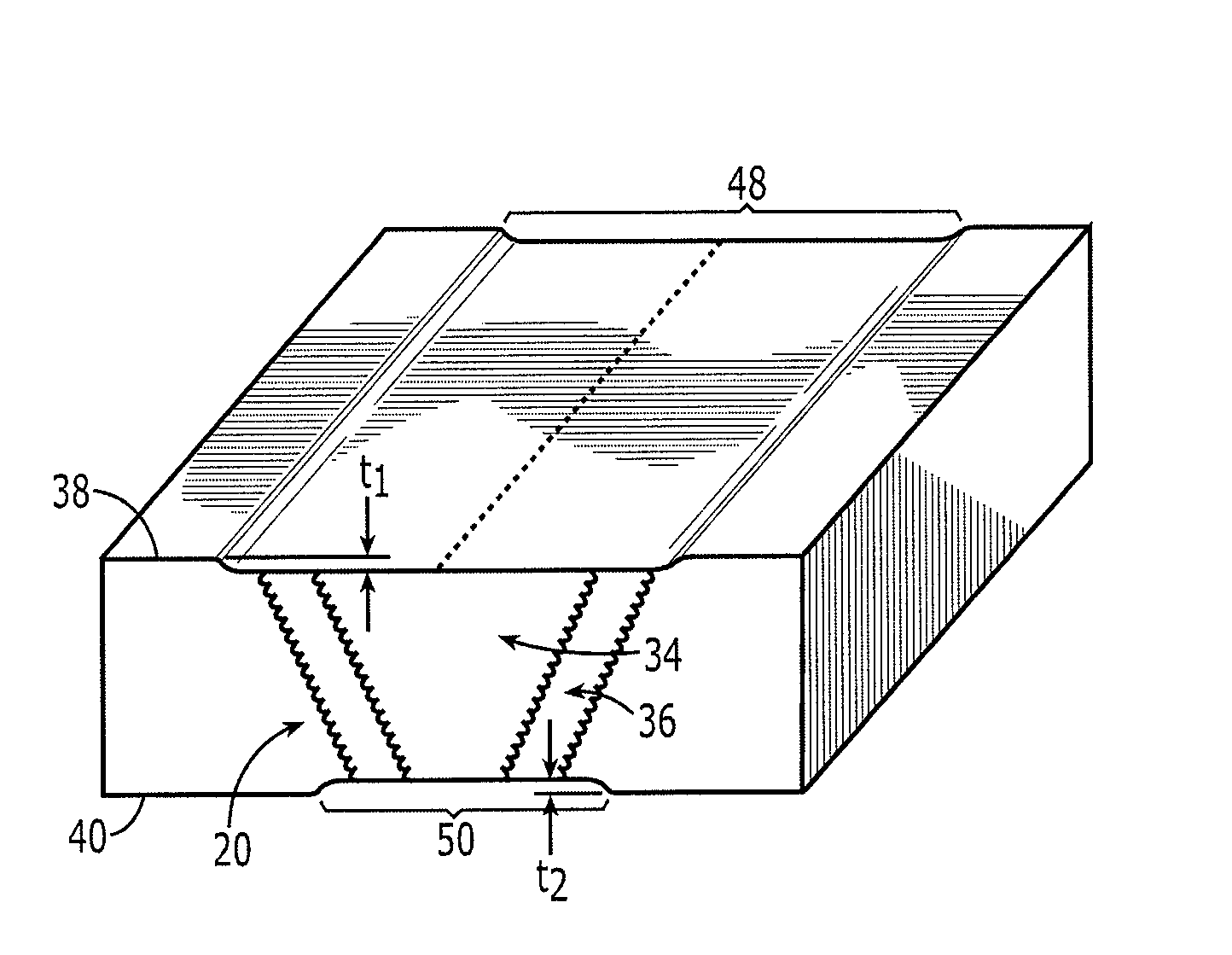

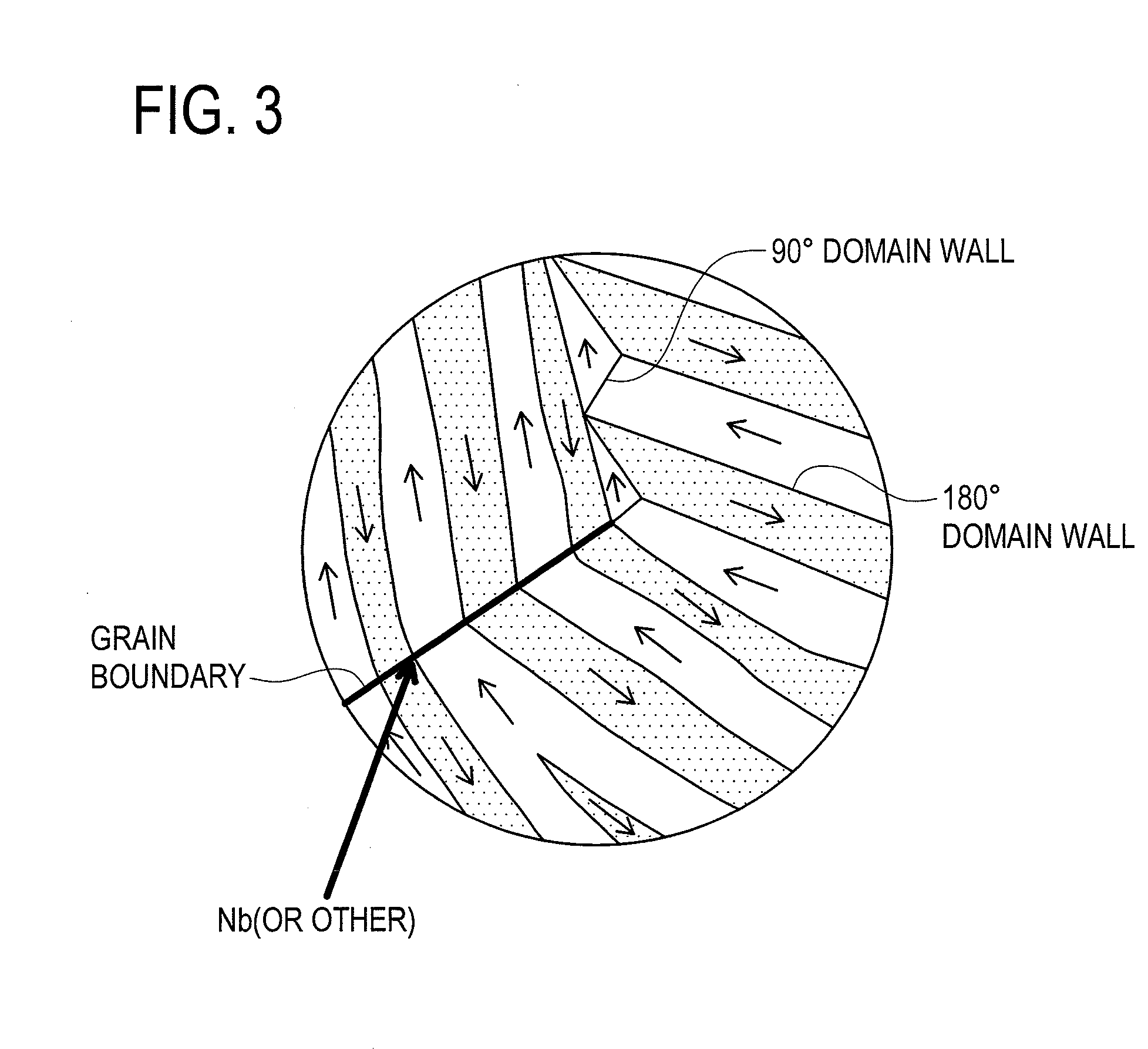

Permanent magnet and process for producing permanent magnet

InactiveUS20110267160A1Improve featuresImprove magnetismTransportation and packagingMetal-working apparatusCompression moldingSlurry

The present invention relates to a permanent magnet manufactured by steps of: pulverizing a magnet raw material into fine particles having a grain size of 3 μm or less; mixing the pulverized magnet raw material with a rust preventive oil in which a high-melting metal element-containing organic compound or a precursor of a high-melting ceramic is dissolved, thereby preparing a slurry; compression molding the slurry to form a molded body; and sintering the molded body.

Owner:NITTO DENKO CORP

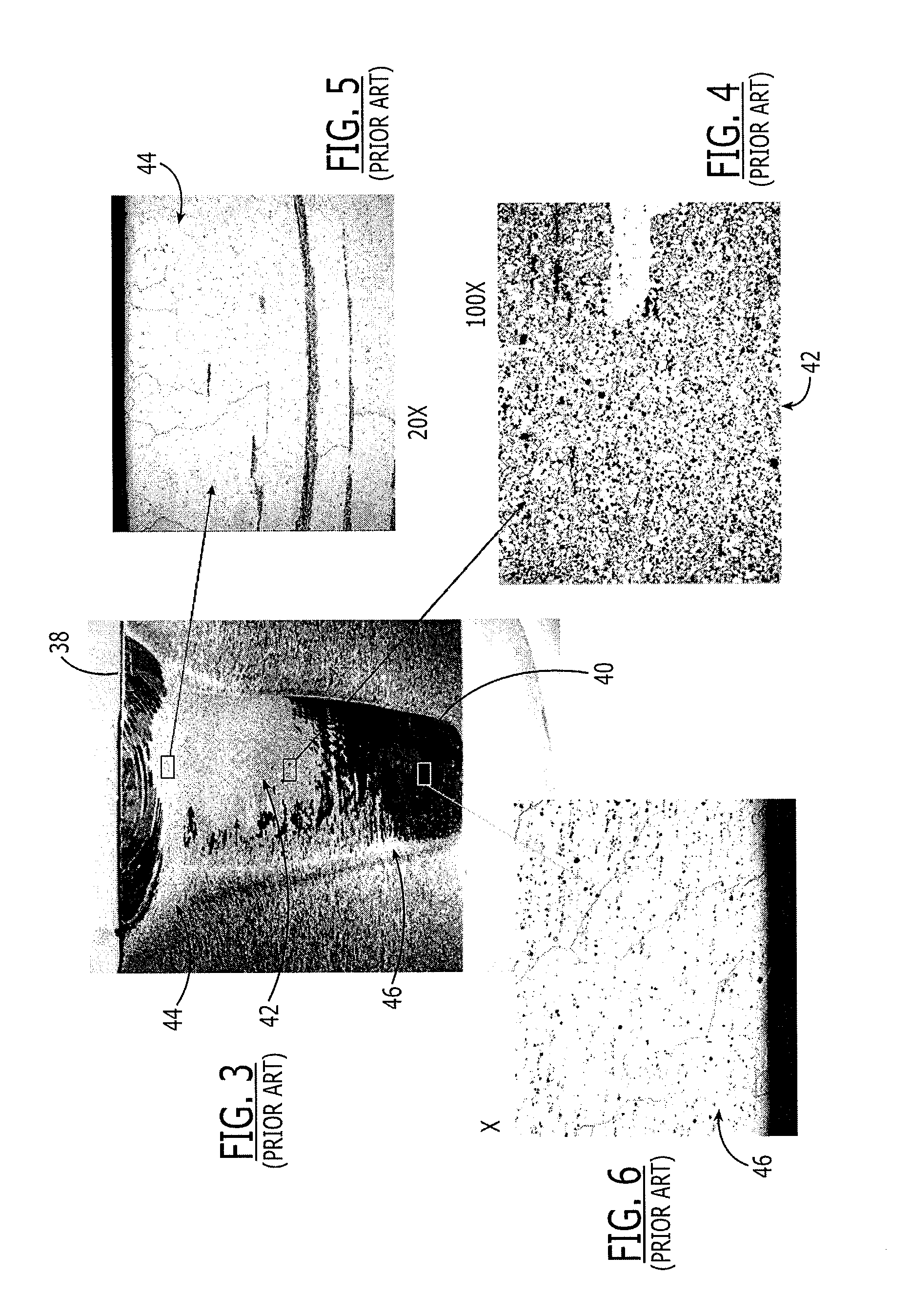

Method for Manufacturing a Workpiece by Friction Welding to Reduce the Occurrence of Abnormal Grain Growth

InactiveUS20080230584A1Avoid grain growthNon-electric welding apparatusCrystalliteStructural element

A method of manufacturing a workpiece is provided. The method generally includes friction stir welding at least one structural member, selectively removing material from the surfaces of the workpiece at the location of a friction stir weld joint, and thereafter subjecting the workpiece to a solution treat, quench, and age treatment. By selectively removing regions from the surfaces of the workpiece that are defined by nonuniform material properties adapted to nucleate nonuniform grain growth during the solution treat, quench, and age treatment, a subsequent grain growth during the thermal treatment can be at least partially prevented.

Owner:THE BOEING CO

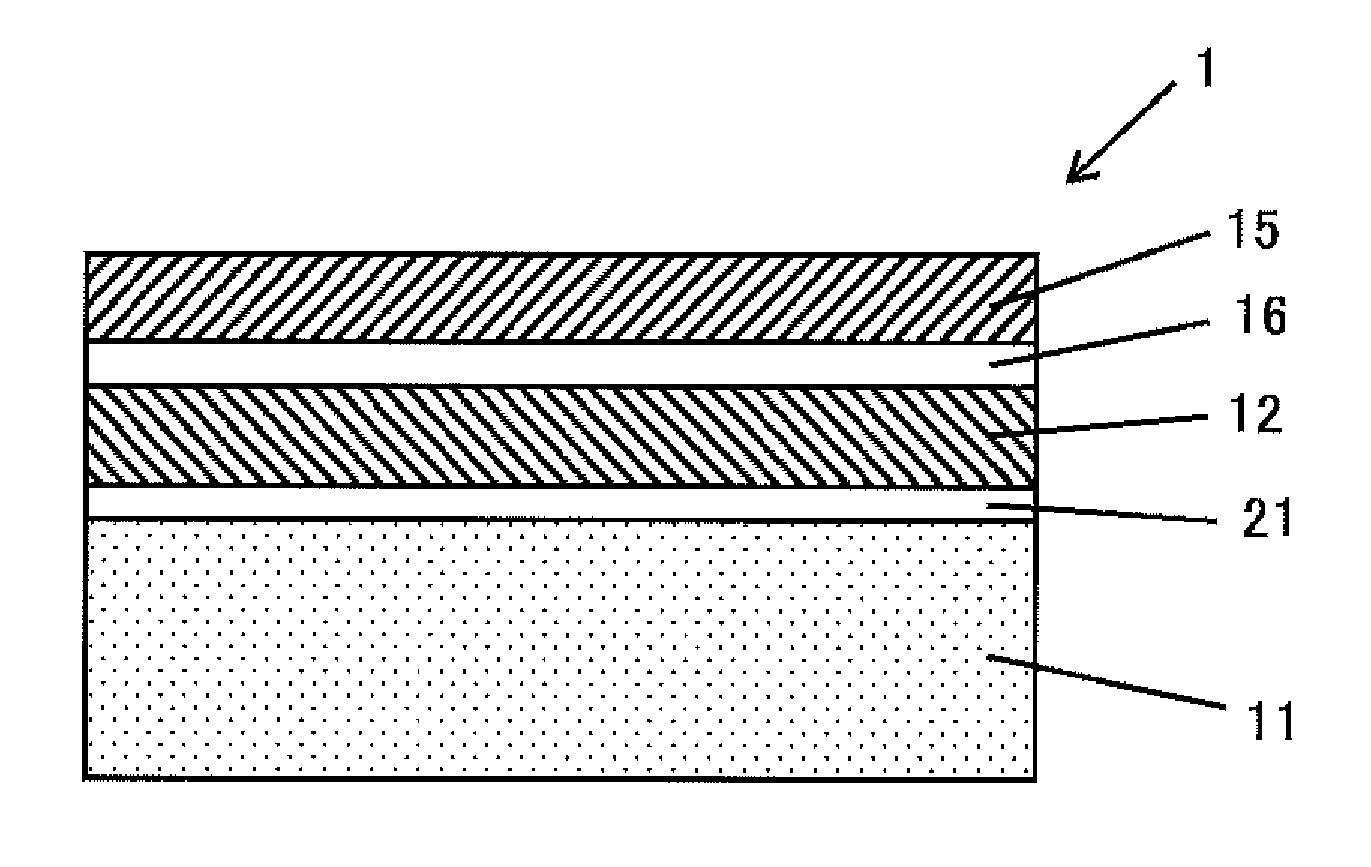

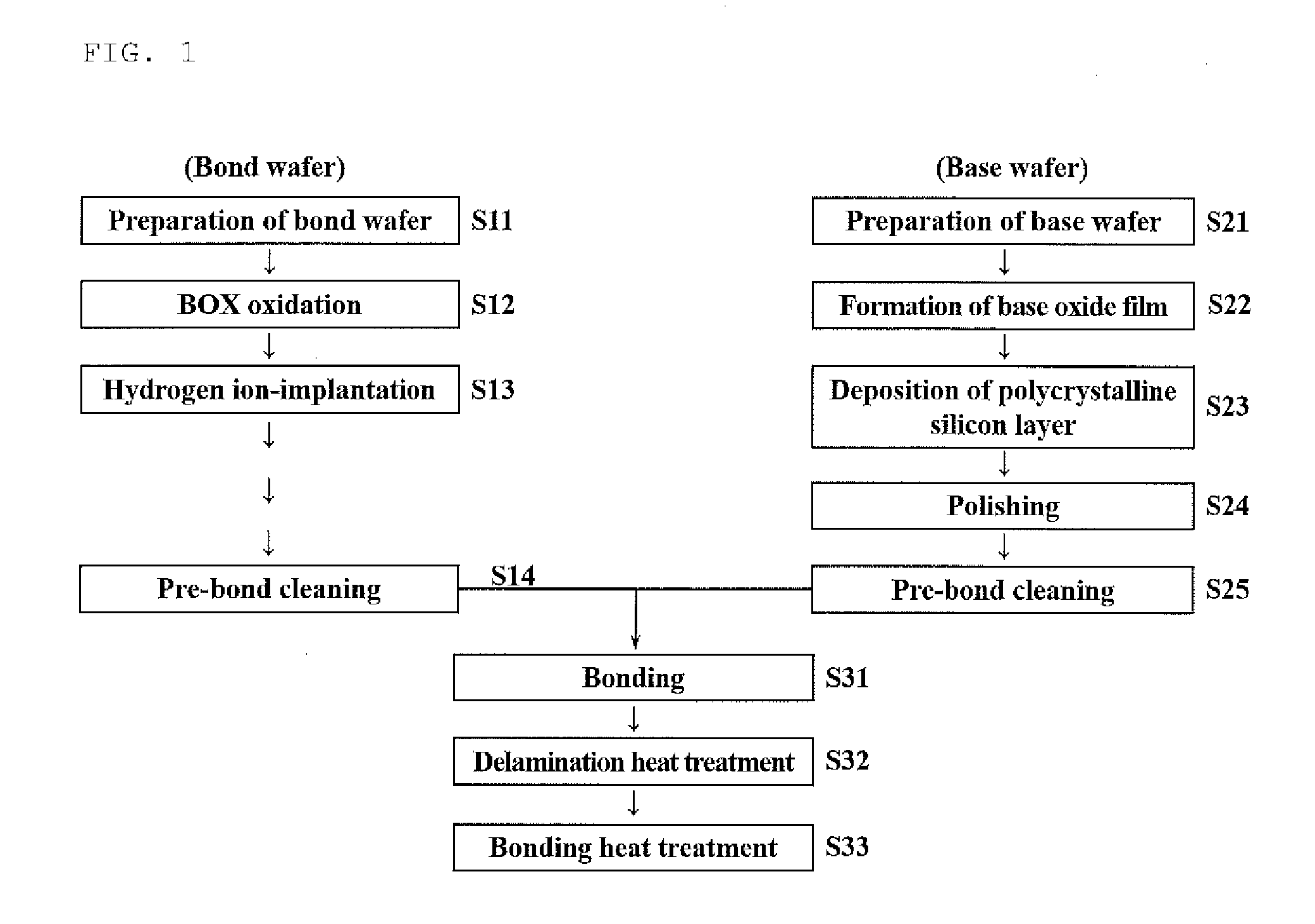

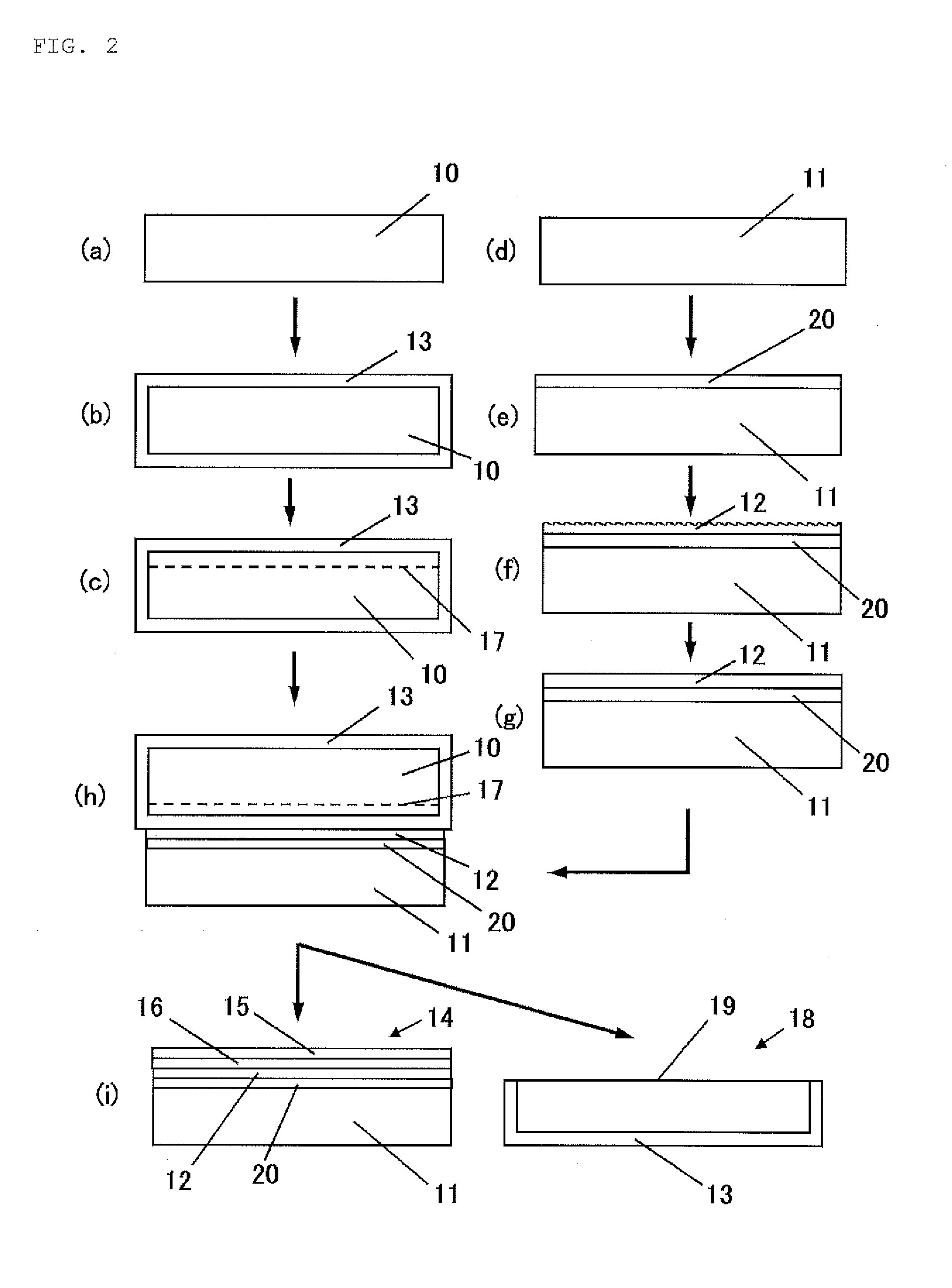

Method for manufacturing a bonded soi wafer and bonded soi wafer

ActiveUS20170033002A1Sustained effectAvoid grain growthLayered productsSolid-state devicesPolycrystalline siliconSingle crystal

A bonded SOI wafer is manufactured by bonding a bond and a base wafer, each composed of a silicon single crystal, via an insulator film, depositing a polycrystalline silicon layer on the bonding surface side of the base wafer, polishing a surface of the polycrystalline silicon layer, forming the insulator film on the bonding surface of the bond wafer, bonding the polished surface of the polycrystalline silicon layer and the bond wafer via the insulator film, and thinning the bonded bond wafer to form an SOI layer; wherein, the base wafer is a silicon single crystal wafer having a resistivity of 100 Ω·cm or more, depositing the polycrystalline silicon layer further includes a stage for previously forming an oxide film on the surface of the base wafer on which the polycrystalline silicon layer is deposited, and the polycrystalline silicon layer is deposited at a temperature of 900° C. or more.

Owner:SHIN-ETSU HANDOTAI CO LTD

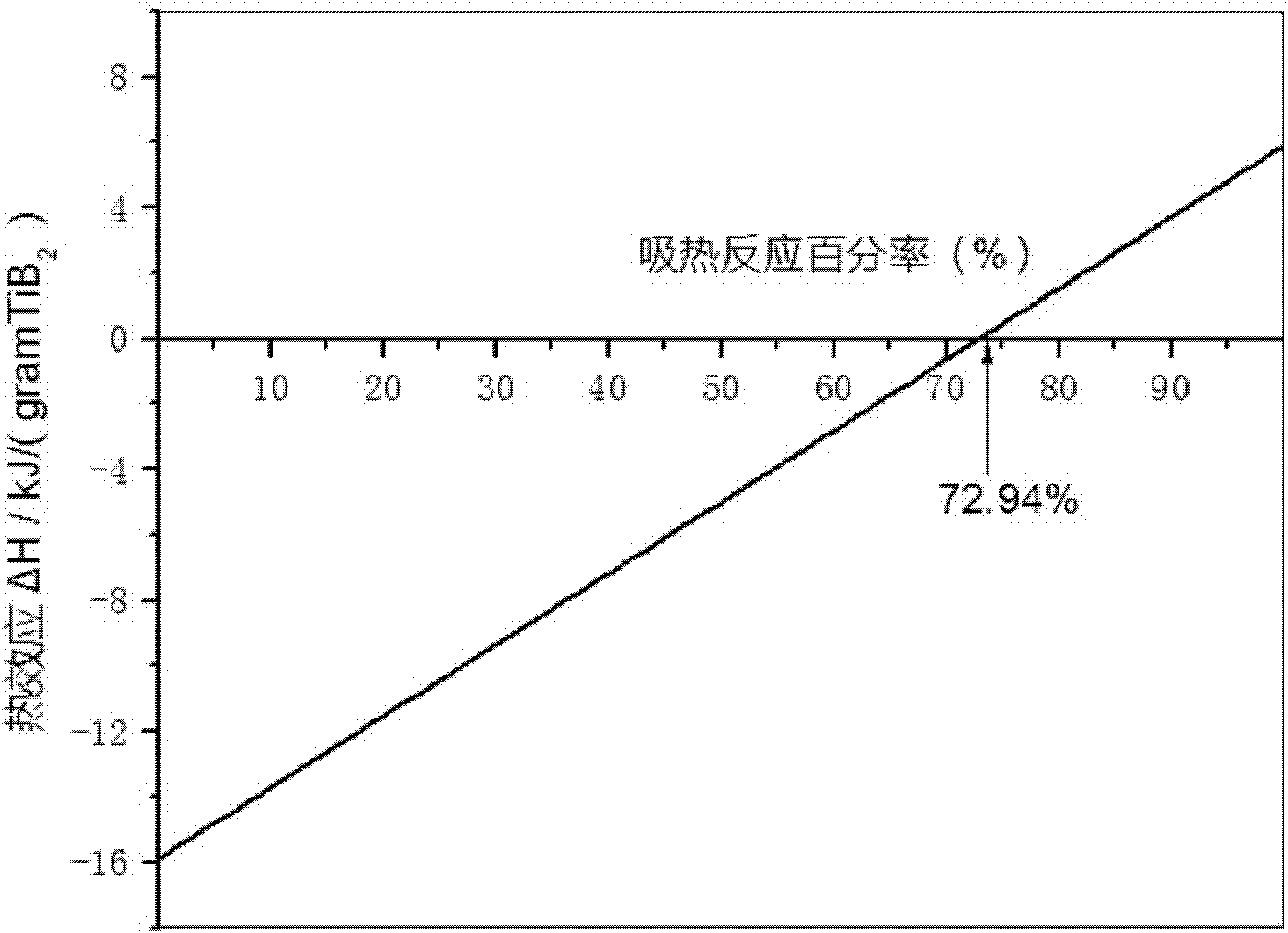

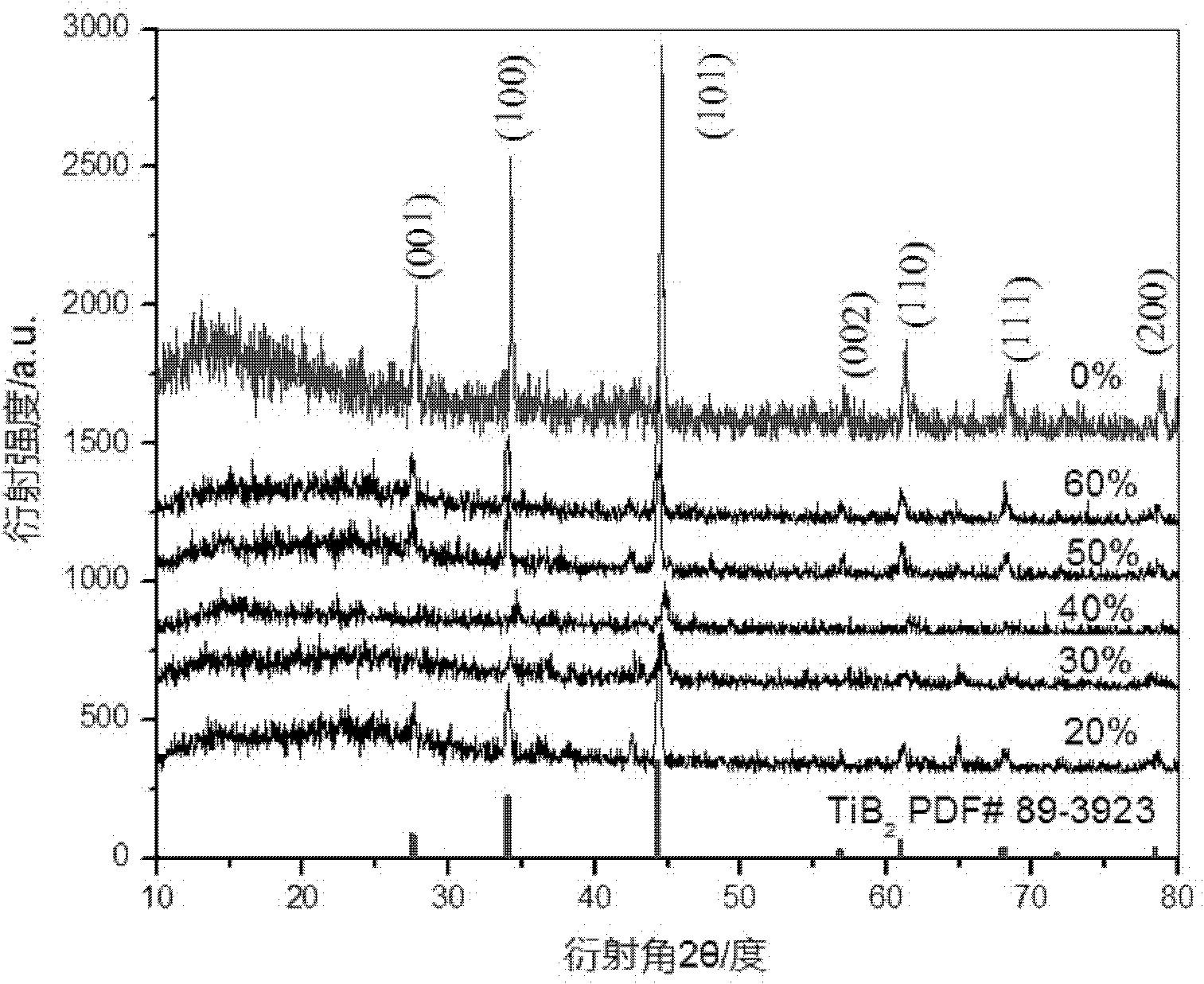

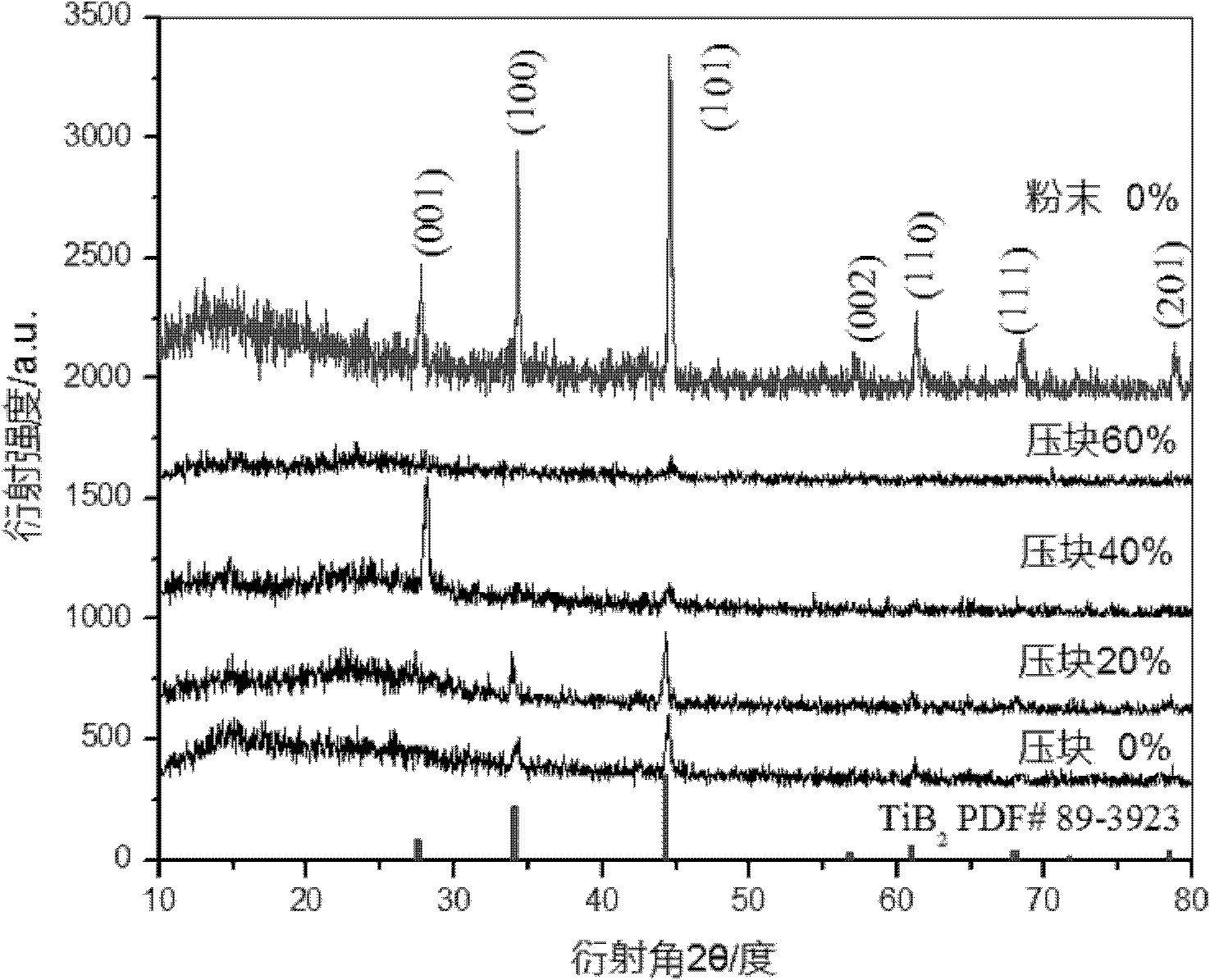

Method for preparing nano titanium diboride polycrystalline powder

InactiveCN101891215AReduce manufacturing costAvoid grain growthNanostructure manufactureMetal boridesReaction temperatureSide reaction

The invention relates to a method for preparing nano titanium diboride polycrystalline powder, which comprises the following steps of: mixing raw materials B2O3, TiO2, Mg and KBH4 uniformly, directly performing self-propagating reaction or performing self-propagating reaction after briquetting on the obtained mixed raw materials, and separating and purifying the self-propagating reaction product to obtain the nano titanium diboride polycrystalline powder. The method has the advantages that: (1) the method controls the heat effect of the reaction system, can save energy, reduce the self-propagating reaction temperature and inhibit side reaction and byproduct impurities, and greatly improves the purity of the product; (2) a large amount of gas formed in the reaction process inhibits product grain growth and sintering agglomeration and realizes grain size control of the nano TiB2; and (3) the method has simple reaction process and technique, is easy to control and suitable for industrial production, reduces the preparation cost for preparing the nano titanium diboride polycrystalline powder, and has great utility value.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

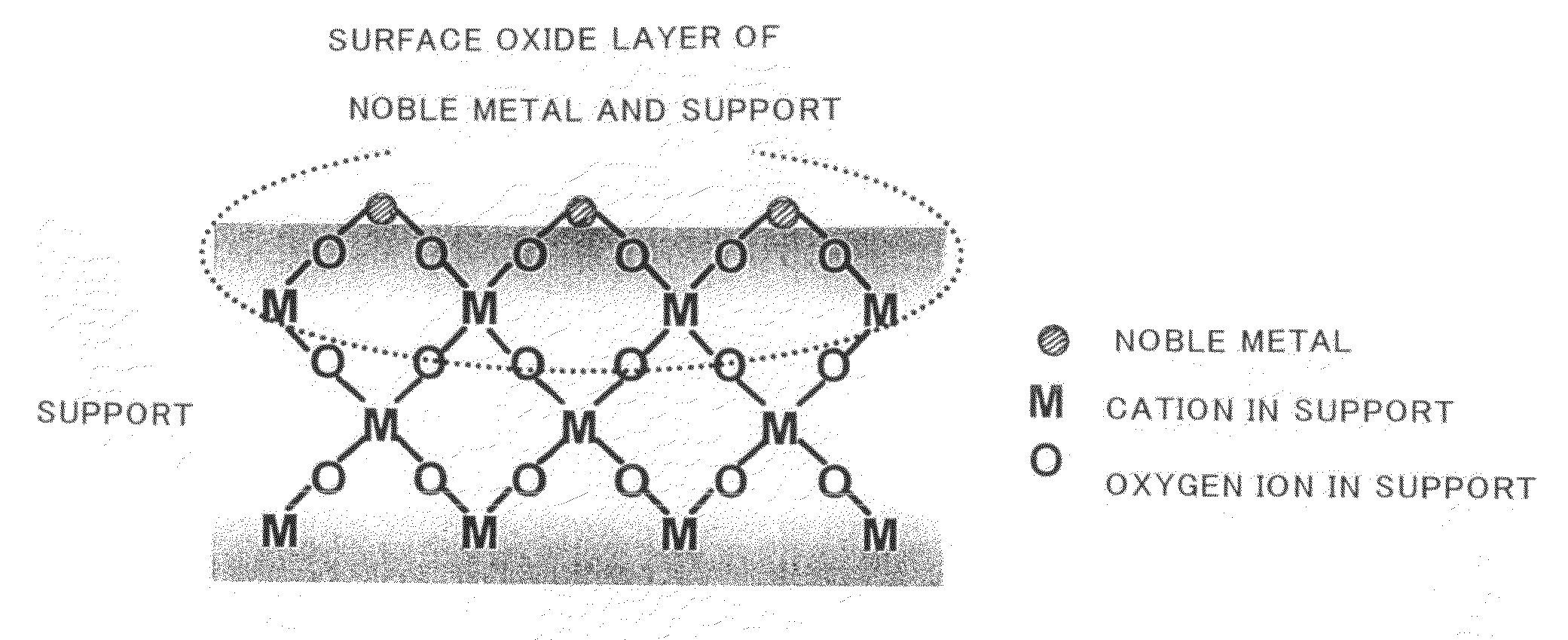

Catalyst for Purification of Exhaust Gas, Regeneration Method for the Catalyst, and Apparatus and Method for Purification of Exhaust Gas Using the Catalyst

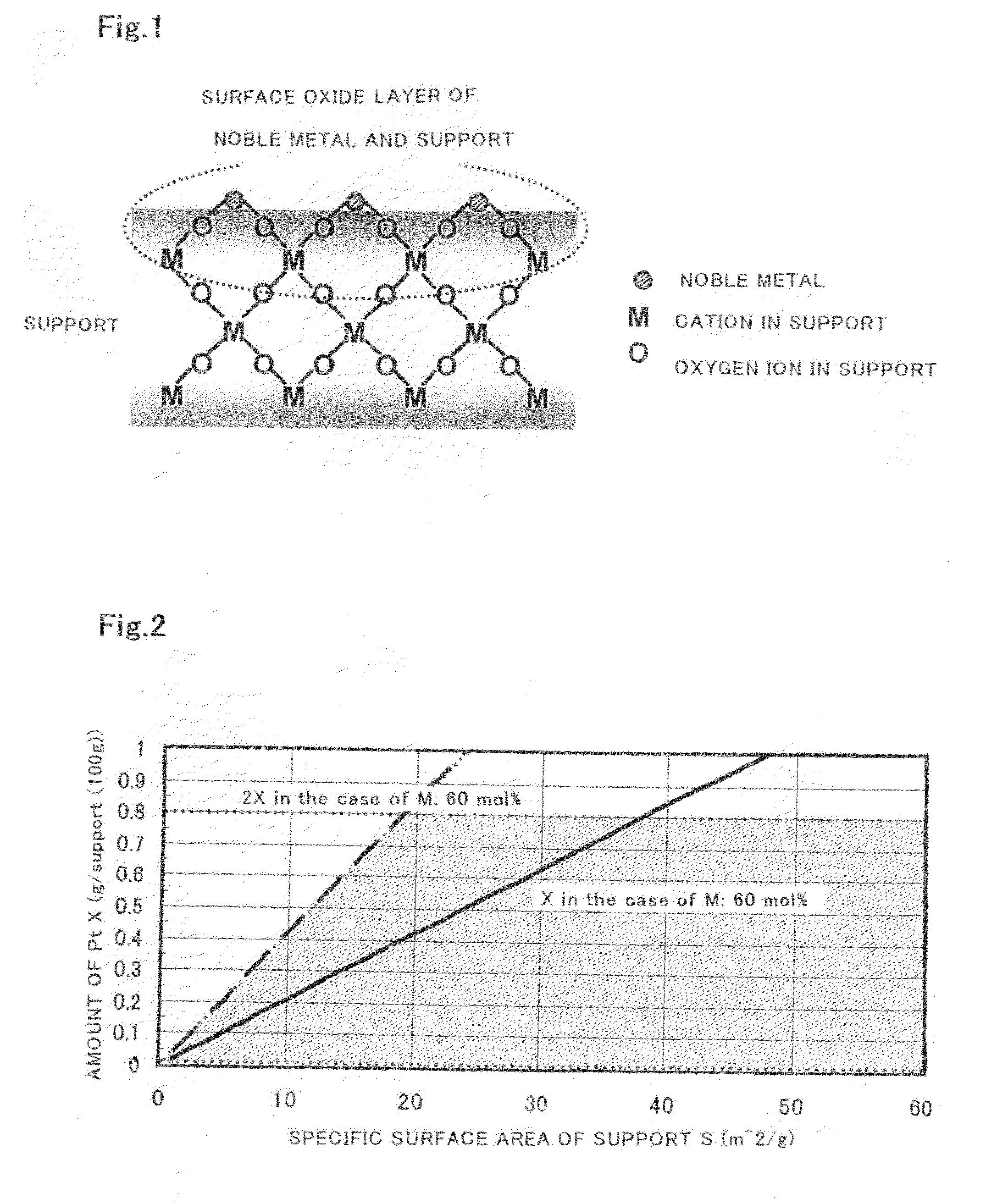

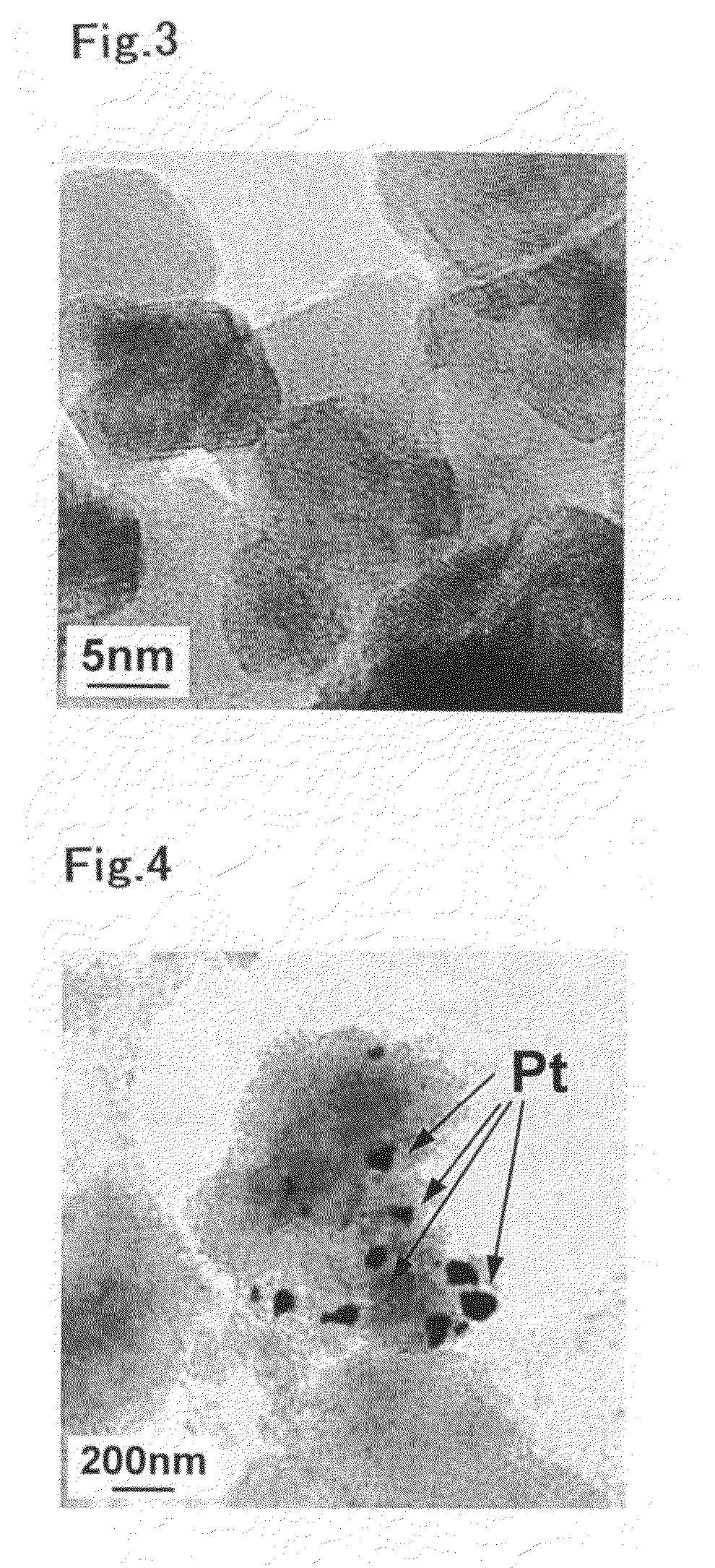

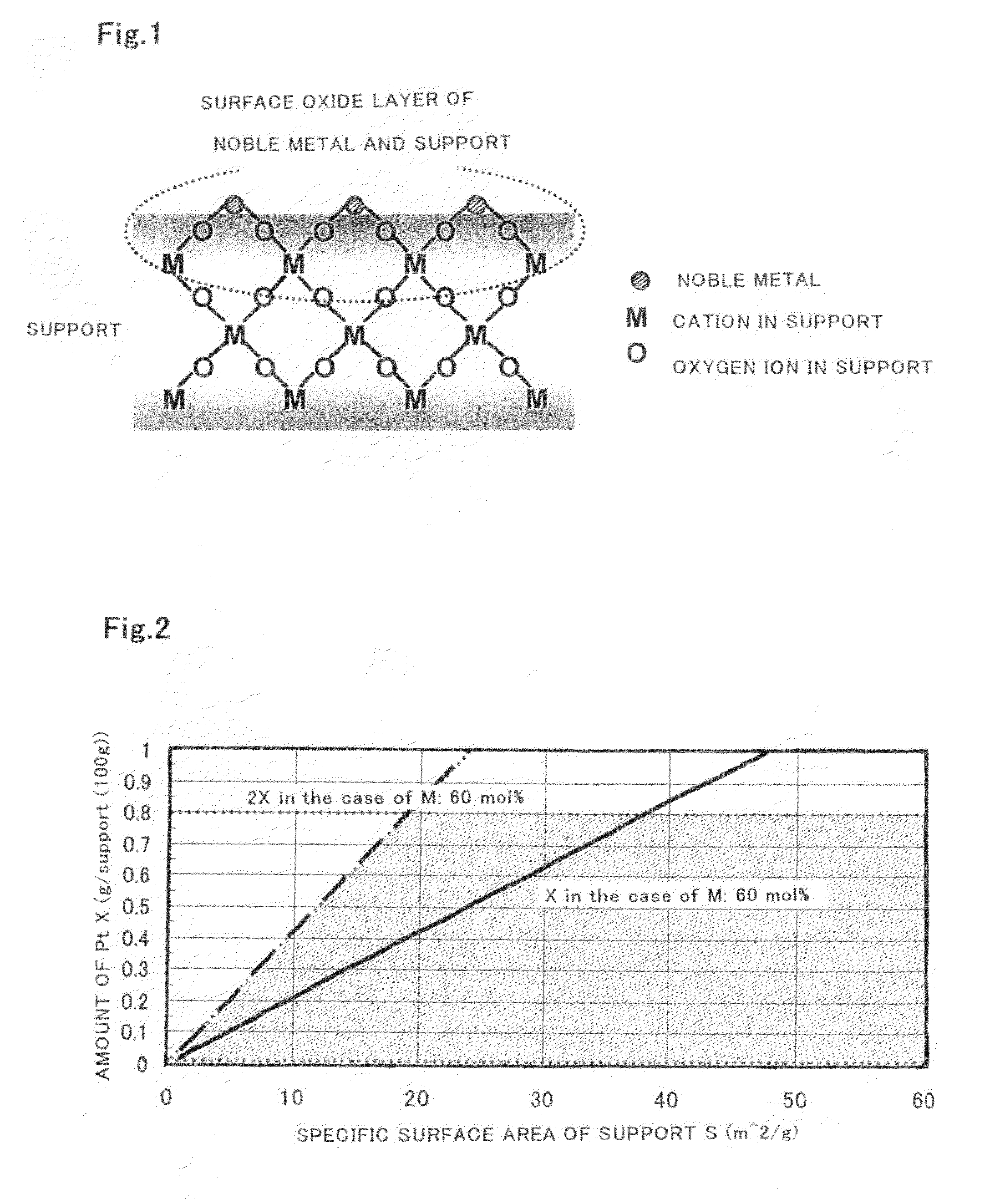

InactiveUS20090170689A1Inhibit lowering of catalytic activityEasily regenerateNitrogen compoundsInternal combustion piston enginesExhaust gasOxygen atom

A catalyst for purification of exhaust gas in which a noble metal is supported on a metal-oxide support wherein, in a oxidation atmosphere, the noble metal exists on the surface of the support in high oxidation state, and the noble metal binds with a cation of the support via an oxygen atom on the surface of the support to form a surface oxide layer and, in a reduction atmosphere, the noble metal exists on the surface of the support in a metal state, and an amount of noble metal exposed at the surface of the support, measured by CO chemisorption, is 10% or more in atomic ratio to a whole amount of the noble metal supported on the support.

Owner:TOYOTA CENT RES & DEV LAB INC +1

Catalyst for purification of exhaust gas, regeneration method for the catalyst, and apparatus and method for purification of exhaust gas using the catalyst

InactiveUS8105561B2Inhibiting lowering of catalytic activityPromote regenerationNitrogen compoundsInternal combustion piston enginesOxidation stateChemisorption

A catalyst for purification of exhaust gas in which a noble metal is supported on a metal-oxide support wherein, in a oxidation atmosphere, the noble metal exists on the surface of the support in high oxidation state, and the noble metal binds with a cation of the support via an oxygen atom on the surface of the support to form a surface oxide layer and, in a reduction atmosphere, the noble metal exists on the surface of the support in a metal state, and an amount of noble metal exposed at the surface of the support, measured by CO chemisorption, is 10% or more in atomic ratio to a whole amount of the noble metal supported on the support.

Owner:TOYOTA CENT RES & DEV LAB INC +1

Cemented Carbides

InactiveUS20080276544A1Avoid grain growthHigh hardnessPigmenting treatmentOther chemical processesIron groupAlloy

The present invention provides a cemented carbide with superior strength and toughness by refining the WC in the alloy uniformly and by restricting the growth of coarse WC efficiently. In this cemented carbide, WC with a mean particle diameter of no more than 0.3 microns serves as a hard phase and at least one type of iron group metal element at 5.5-15 percent by mass serves as a binder phase. In addition to this hard phase and binder phase, this cemented carbide contains 0.005-0.06 percent by mass of Ti, Cr at a weight ratio relative to the binder phase of at least 0.04 and no more than 0.2, with the remaining portion being formed from inevitable impurities. In particular, this cemented carbide does not contain Ta.

Owner:SUMITOMO ELECTRIC IND LTD +1

Wiring glass substrate for connecting a semiconductor chip to a printed wiring substrate and a semiconductor module having the wiring glass substrate

InactiveUS20070114653A1Lower resistanceComposition ratio is notPorous dielectricsSemiconductor/solid-state device detailsSemiconductor chipEngineering

Owner:RENESAS ELECTRONICS CORP

Cold work die steel and preparation method thereof

The invention provides cold work die steel. The cold work die steel comprises C, Si, Mn, Cr, Mo, W, V, P, S, Cu, Mg, Ti, Sr, Zr, B, Zn, Re, Sn, Pb, Be, Sc, Li, Ni, La, Al and the balance iron, wherein the sum of the mass percentages of the components is 100%. The nodular cast iron comprises multiple kinds of nonmetal, metal and transition metal elements. Because the elements are added and cooperate with one another, the oxidation resistance, the corrosion resistance, the abrasion resistance, the compression resistance and the shock resistance of a compressor cylinder block of an air conditioner are improved, and the service life of the compressor cylinder block of the air conditioner under severe working conditions is prolonged.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Method for welding ferritic stainless steel with trailing intense cooling

ActiveCN102941401AAdvancedAvoid grain growthArc welding apparatusHeat-affected zoneSS - Stainless steel

The invention relates to a method for welding ferritic stainless steel with trailing intense cooling and aims at the problem that a crystal grain grows and is brittle in the welding process of the ferritic stainless steel. A argon tungsten-arc welding machine is adopted, liquid nitrogen is used in the welding process to conduct welding with trailing intense cooling, and argon is used for protection, so that the problem that the crystal grain grows and is brittle in the welding heat affected zone is effectively prevented, the data are full and accurate, the quality of a welding joint is good, a welding line is good in fusion property and is not easily cracked, the strength of extension of the welding line is up to 481.5MPa, and therefore, the method is a quite ideal method for welding ferritic stainless steel.

Owner:太原理工技术转移有限公司

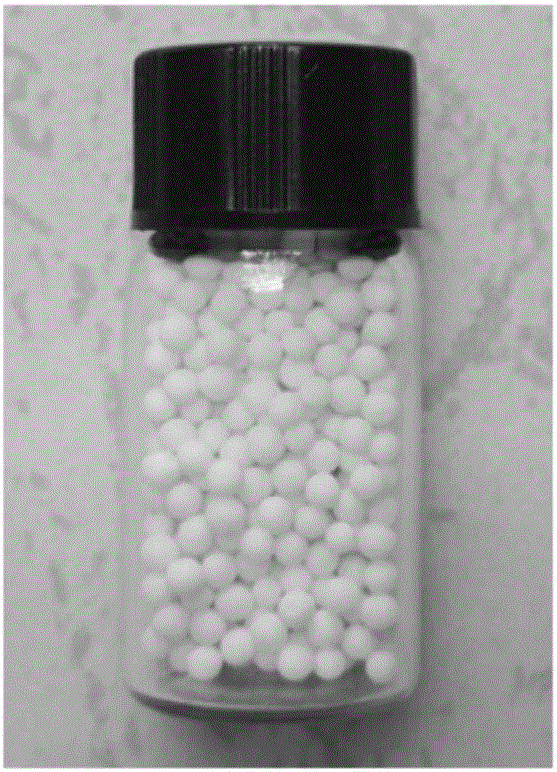

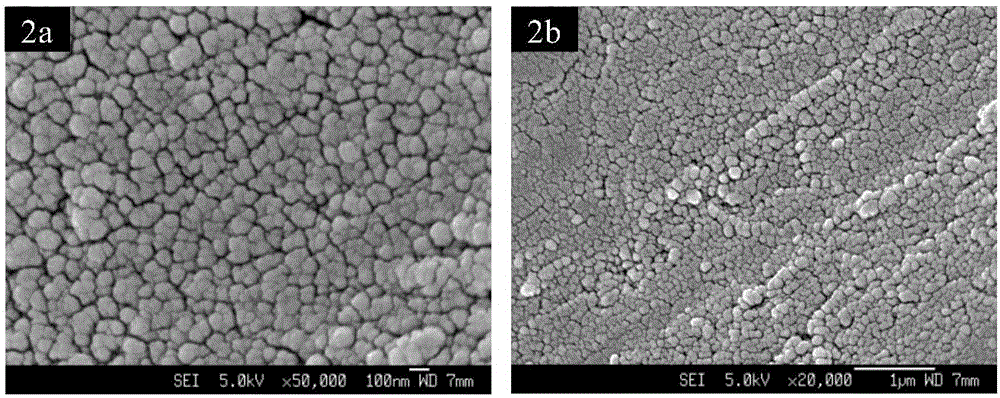

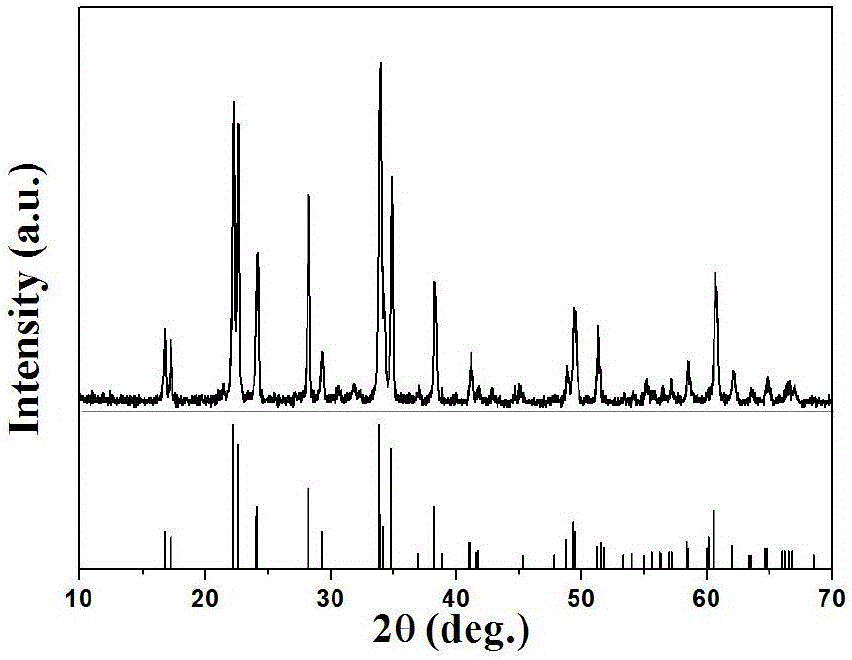

Nanostructured lithium orthosilicate ceramic spheres used for tritium propagation and preparation method thereof

ActiveCN106630985AUniform particle sizeUniform structureNuclear energy generationThermonuclear fusion reactorSolventTwo step

The invention discloses nanostructured lithium orthosilicate ceramic spheres used for tritium propagation and a preparation method thereof. The nanostructured lithium orthosilicate ceramic spheres are made by preparing precursor powder with uniform particle size through a solvothermal method, obtaining a lithium ceramic sphere blank with a uniform microstructure through wet moulding, and carrying out two-step sintering. The prepared lithium orthosilicate ceramics is high in purity, good in sphericility, small in hole size and uniform in hole dispersion, has a crystal grain size in nanometer order and allows the radiation resistance, mechanical properties and tritium release properties of tritium propagation ceramics to be improved at the same time.

Owner:SICHUAN UNIV

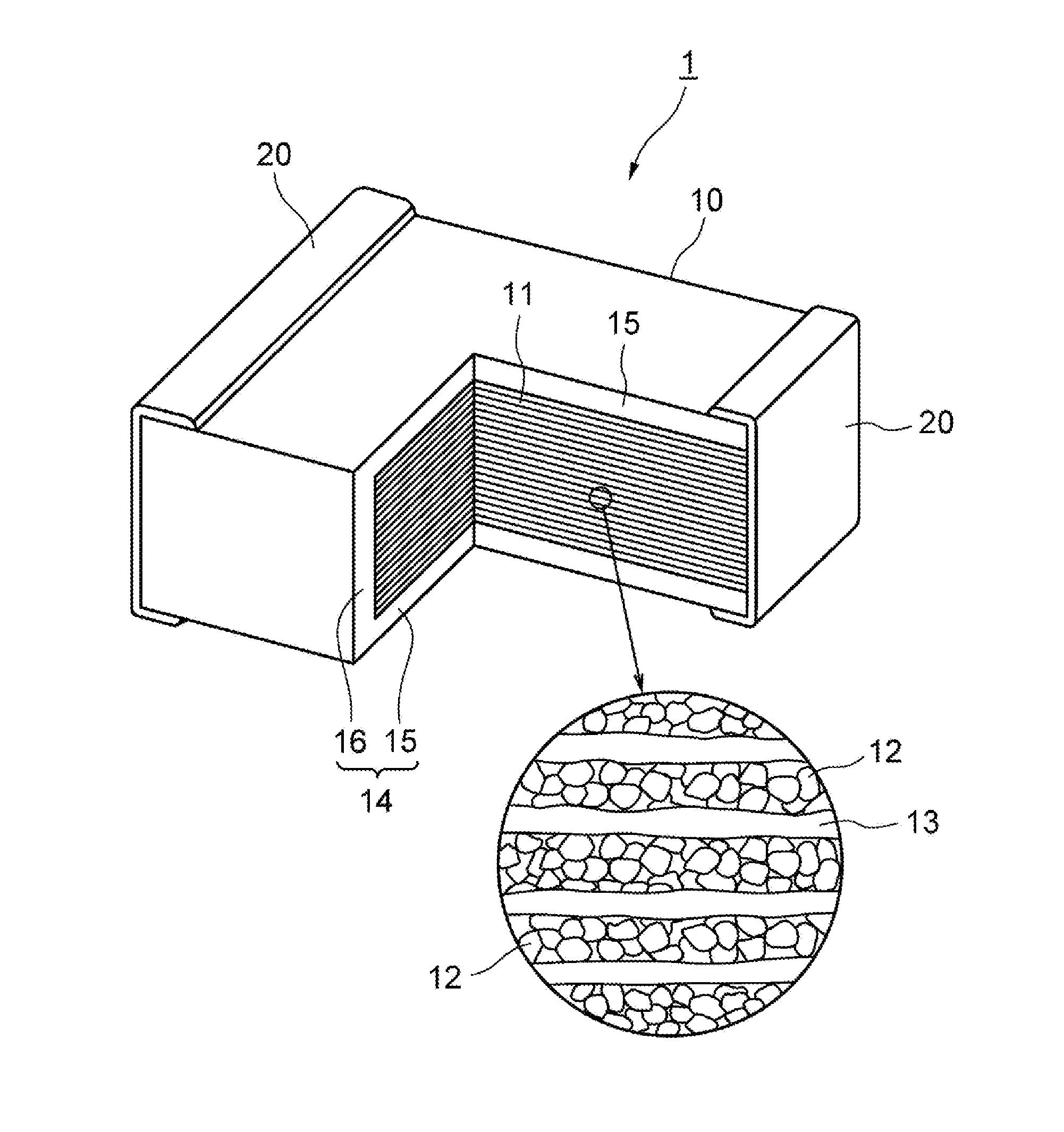

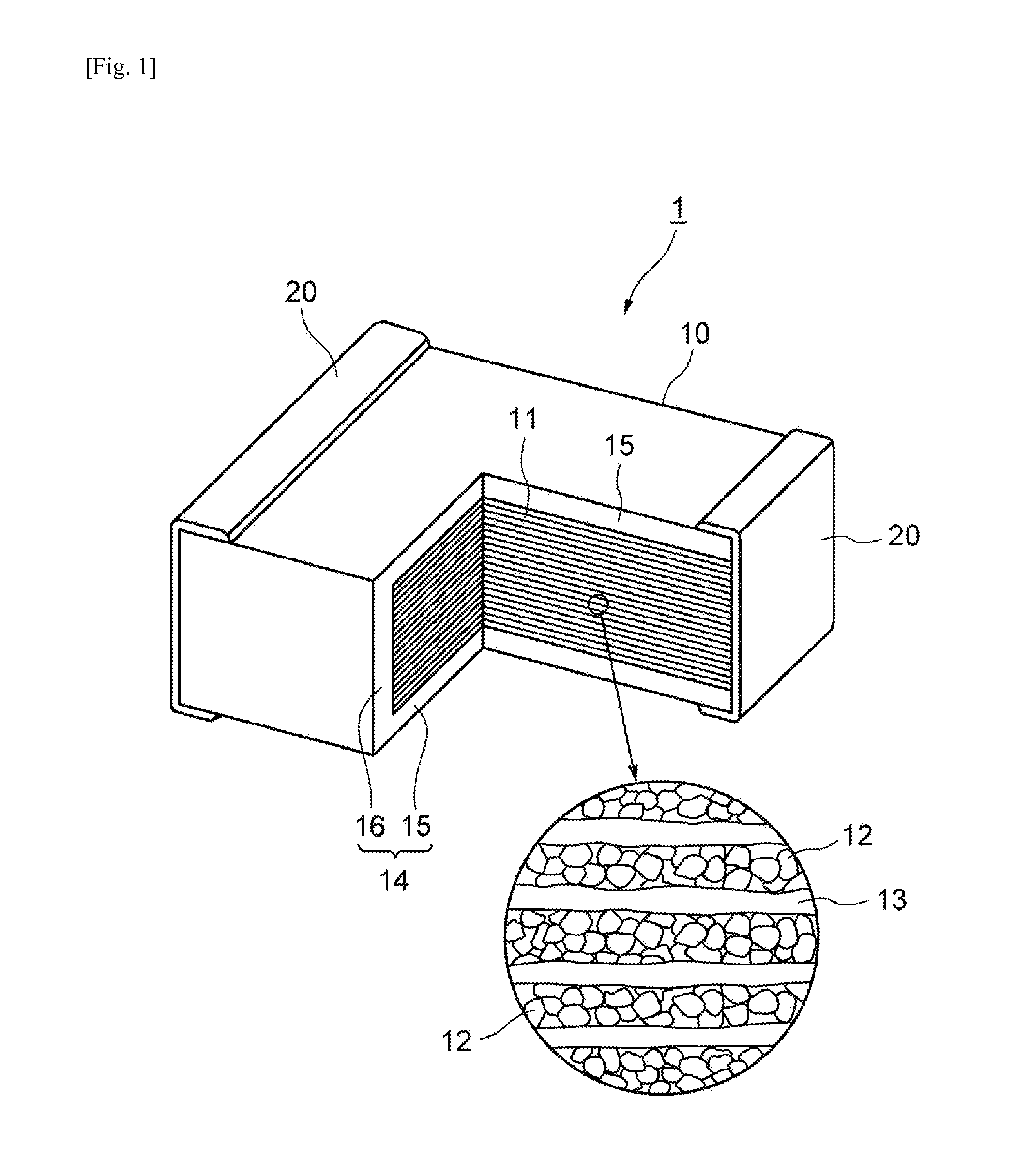

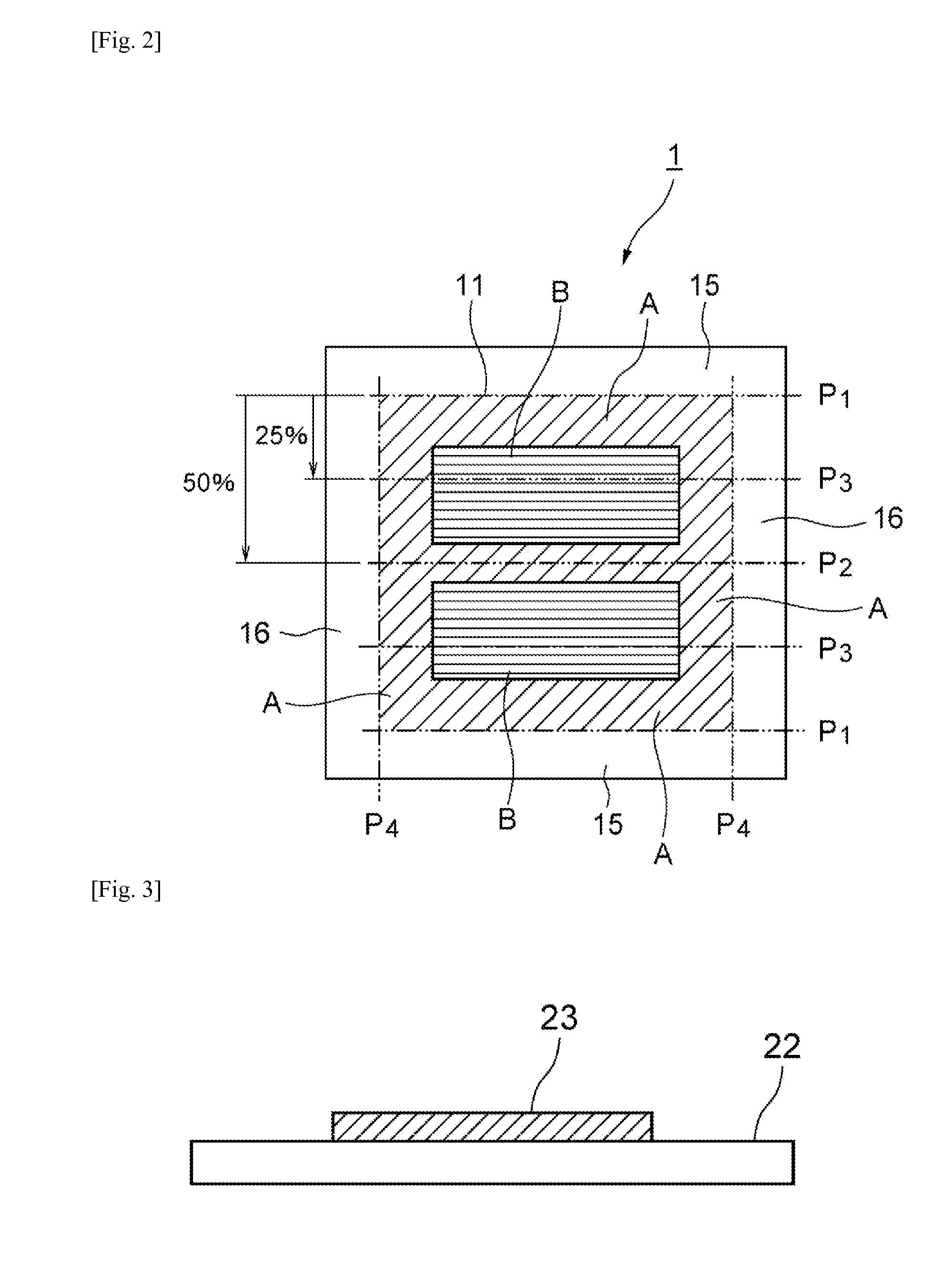

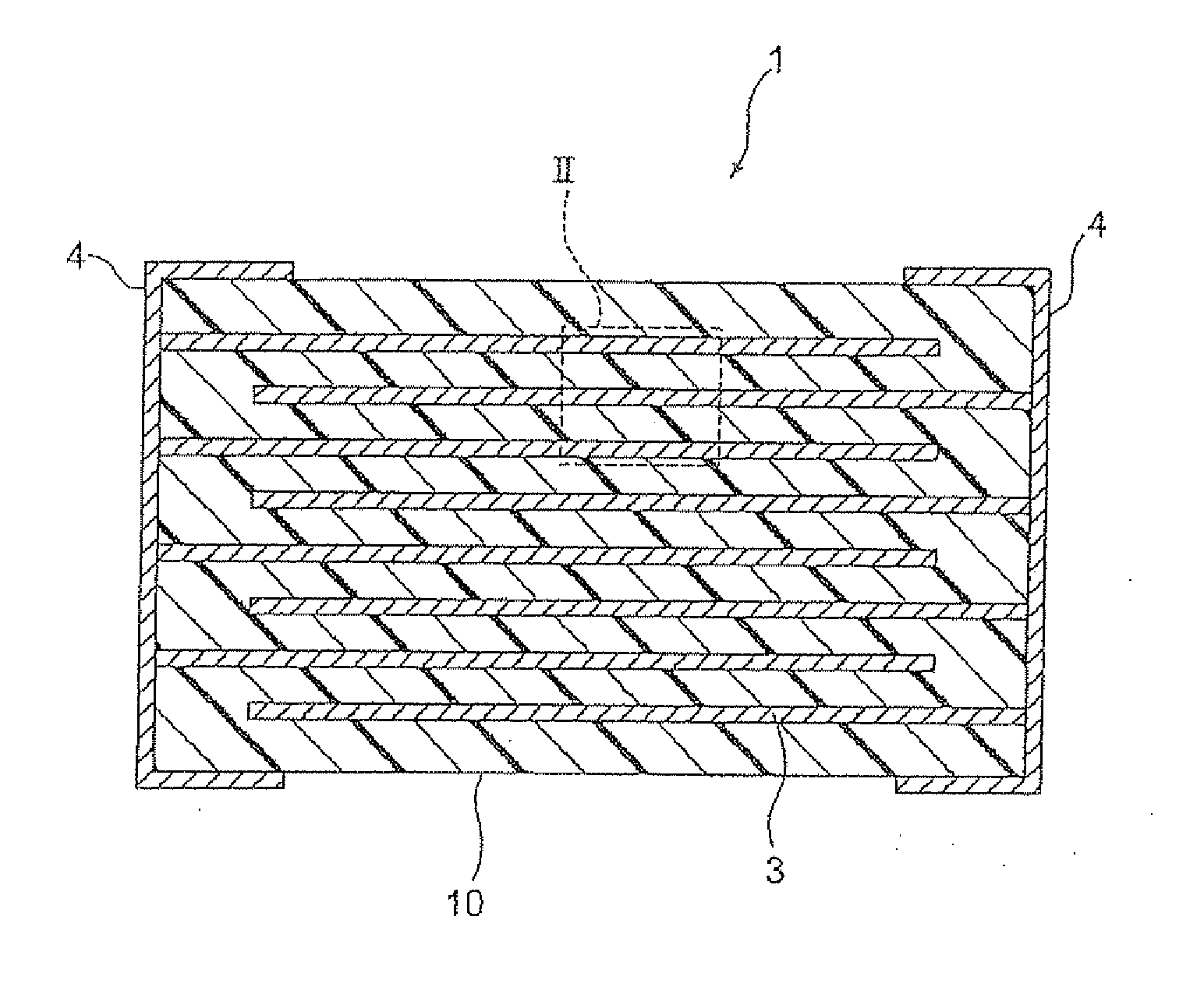

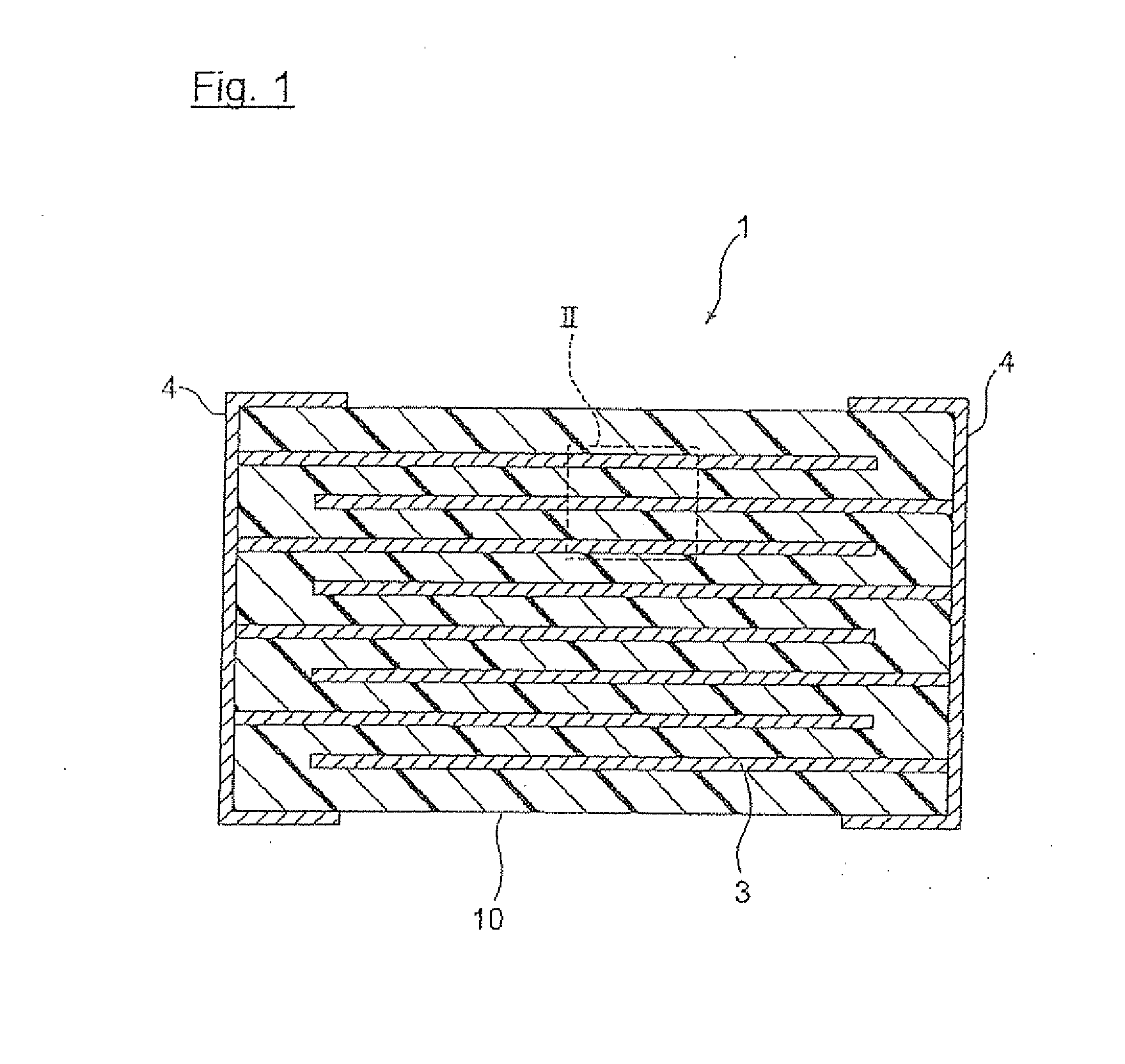

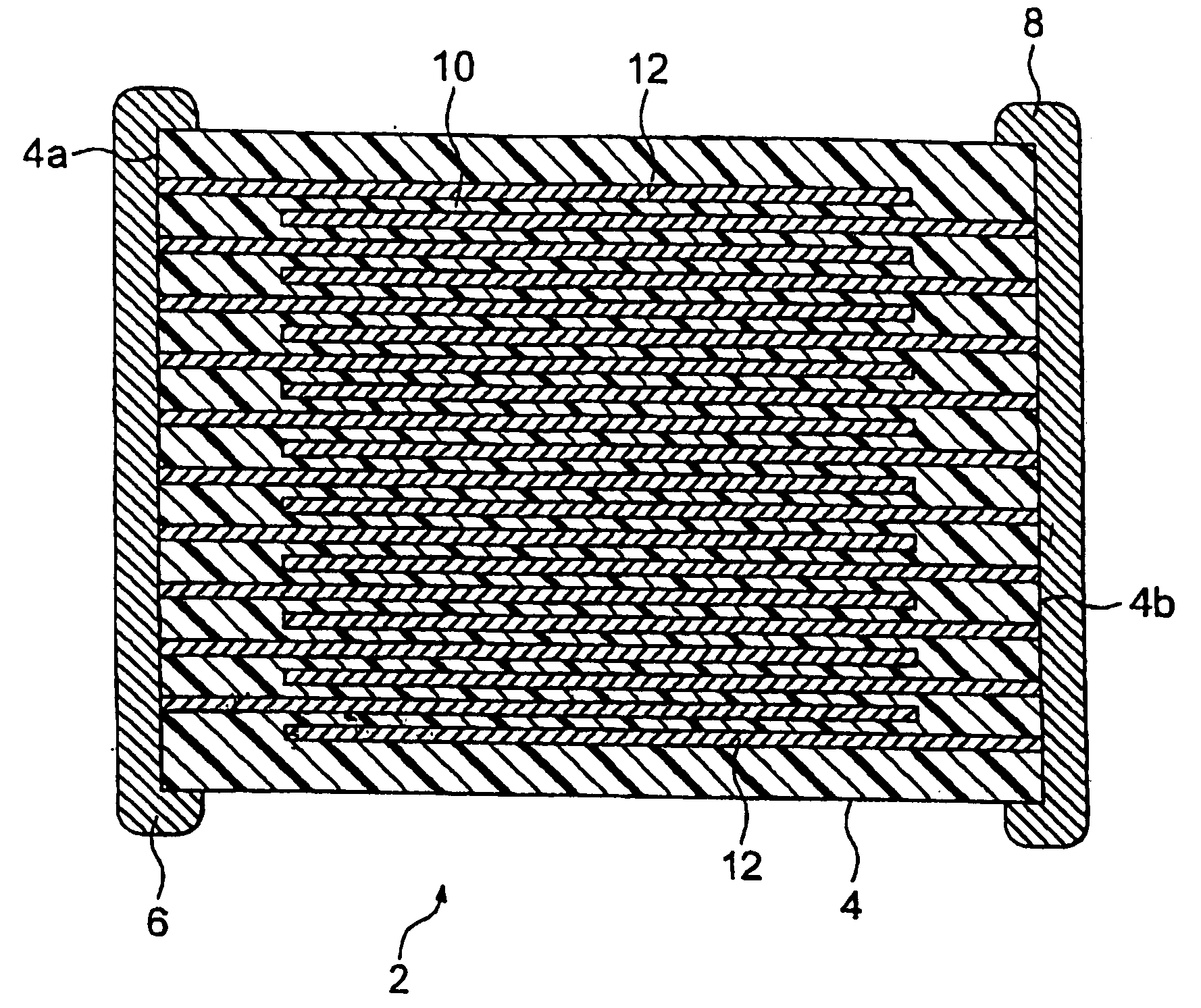

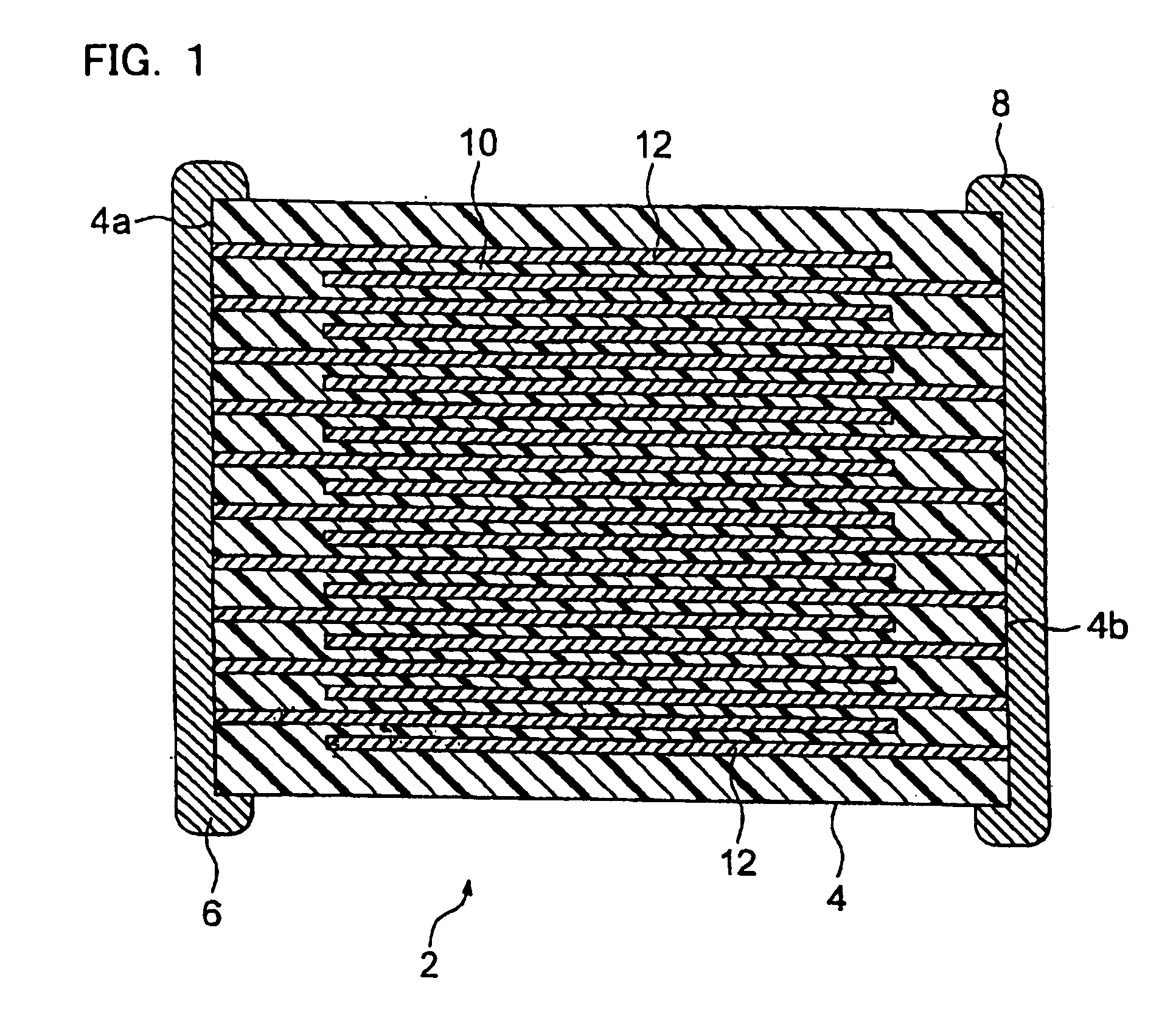

Multilayer ceramic capacitor

ActiveUS20140211367A1Sufficient CR productSmall sizeFixed capacitor dielectricStacked capacitorsCeramic capacitorCrystallite

With a multilayer ceramic capacitor whose average grain size of the dielectric grains present at the outermost layer position P1 in the laminate is given by D1, average grain size of the dielectric grains present at the center position P2 in the laminate is given by D2, and average grain size of the dielectric grains present at the 25%-penetrated position P3 which is a position penetrated into the laminate by 25% is given by D3, growth of the dielectric grains occurring as a result of sintering is partially suppressed in such a way that the relationships of average grain sizes D1, D2, and D3 satisfy the conditions of 1.5×D1<D3 and 1.2×D2<D3. This way, a sufficient CR product can be obtained even with a dielectric thickness of 1 μm or less.

Owner:TAIYO YUDEN KK

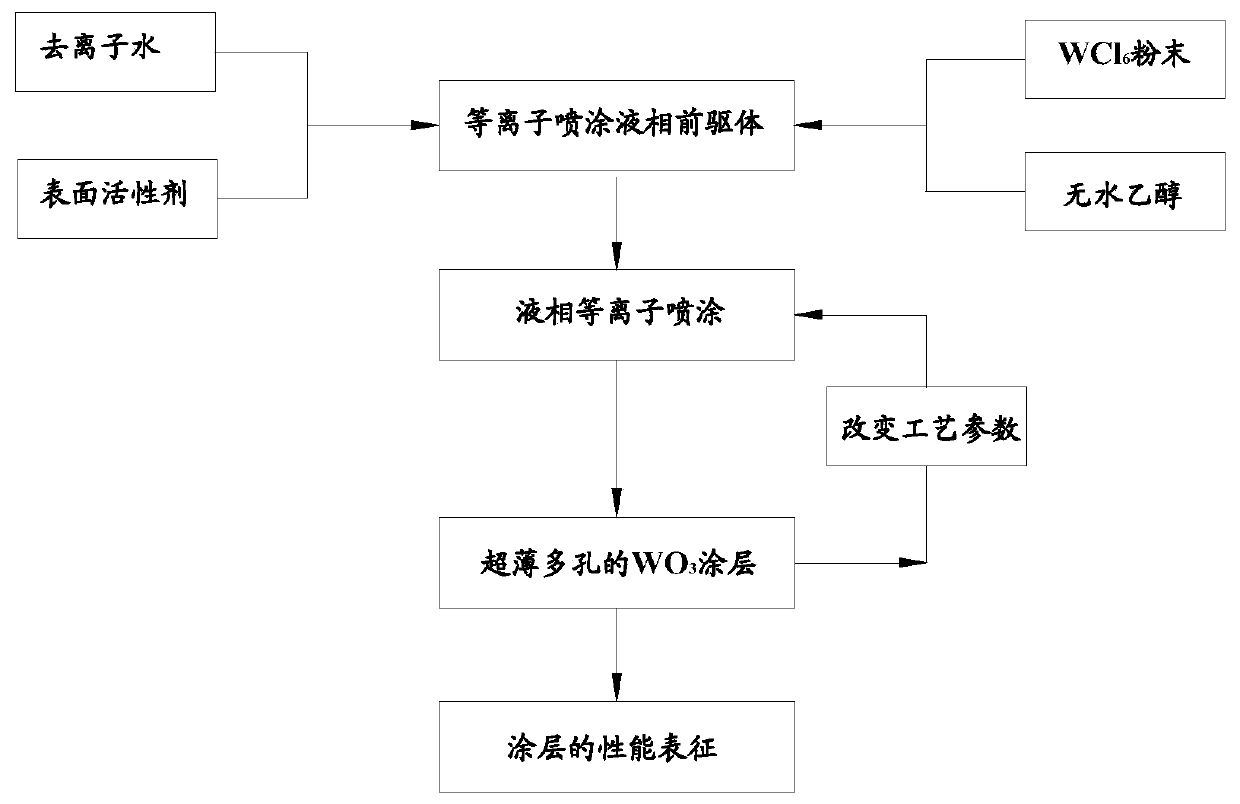

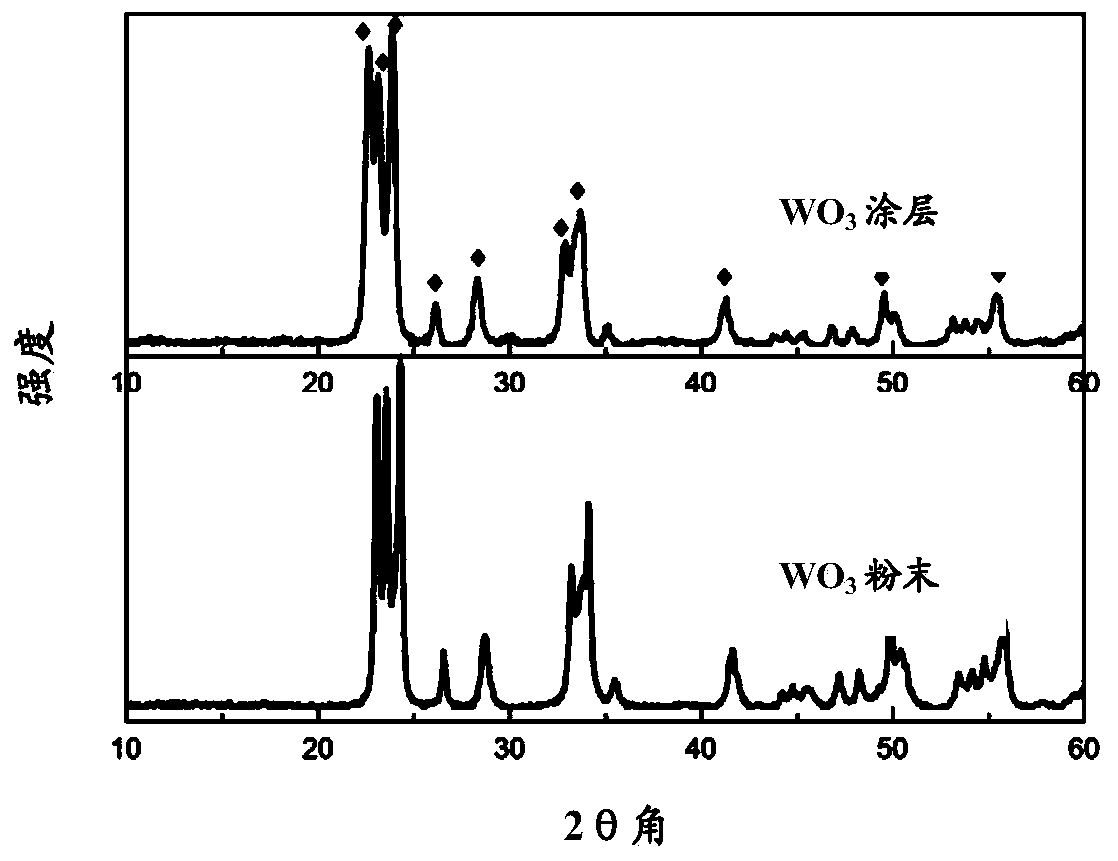

Method and product for preparing ultra-thin porous WO3 gas-sensitive coating by using thermal spraying technology

ActiveCN103741089AOvercome the disadvantage of not being easy to spray directlyAvoid grain growthMolten spray coatingThermal sprayingLiquid phase

The invention discloses a method and a product for preparing an ultra-thin porous WO3 gas-sensitive coating by using a thermal spraying technology. The preparation method comprises the following steps: (1) preparing a WC16 liquid-phase precursor; (2) cleaning a substrate, degreasing, derusting and carrying out surface roughening treatment; (3) feeding the WC16 liquid-phase precursor prepared in the step (1) to thermal spraying equipment, and carrying out high-temperature reaction, drying, burning, coagulation and sedimentation on the surface of the substrate so as to obtain the ultra-thin porous WO3 gas-sensitive coating. The preparation method disclosed by the invention has the advantages of simple operation, fewer technological processes, low cost, applicability to industrial production and the like, and the prepared WO3 gas-sensitive coating has an ultra-thin porous submicrometer structure, and has excellent gas sensitivity, and the thickness is 500nm to 1mu m.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Hot extrusion technological process for three-way from X80 grade steel plate

The invention discloses a technical process of an X80 steel plate hot extrusion tee. The technical process comprises the following steps: (1) designing chemical compositions of raw materials, selecting agreeable X80 steel plates, controlling the grain size of the X80 steel plates at 11 grade or above; (2) blanking; (3) reel pipe spot welding, selecting agreeable welding rods the chemical compositions and mechanical properties of which are equivalent to or slightly higher than those of a parent material, controlling the interlayer temperature within 200 DEG C, the current between 160A and 190A and the voltage at 30V; (4) flattening; (5) hot press moulding, controlling the heating temperature within 930 DEG C and the temperature of workblank in a furnace lower than 600 DEG C; (6) opening holes for drawing, trimming and shaping and detection; (7) hot treatment, putting welding seams at the same heated layer when a plurality of parts are simultaneously treated in a furnace; and (8) surface cleaning, end part processing and finished product detection. The technical process selects the raw materials with agreeable chemical compositions, reduces the current and the voltage, improves the welding speed and reduces the heat quantity during processing procedures, thus preventing the augmentation of grains and meeting the requirements of the X80 steel plate hot extrusion tee.

Owner:河北恒通管件集团有限公司

Permanent magnet and manufacturing method thereof

InactiveUS20120182109A1Residual magnetic flux density decreaseImprove magnetic propertiesTransportation and packagingMetal-working apparatusNeodymium magnetStructural formula

There are provided a permanent magnet and a manufacturing method thereof capable of inhibiting grain growth of magnet grains having single domain particle size during sintering so as to improve magnetic properties. To fine powder of milled neodymium magnet is added an organometallic compound solution containing an organometallic compound expressed with a structural formula of M-(OR)x (M represents V, Mo, Zr, Ta, Ti, W or Nb, R represents a substituent group consisting of a straight-chain or branched-chain hydrocarbon, x represents an arbitrary integer) so as to uniformly adhere the organometallic compound to particle surfaces of the neodymium magnet powder. Thereafter, the desiccated magnet powder is calcined by utilizing plasma heating and the powdery calcined body is sintered so as to form a permanent magnet 1.

Owner:NITTO DENKO CORP

Extruding, forging and rolling integrated technology of AQ80M magnesium alloy annular part

InactiveCN106944799AImprove yieldImprove mechanical propertiesMetal rollingMagnetic anisotropyFuel efficiency

The invention discloses an extruding, forging and rolling integrated technology of an AQ80M magnesium alloy annular part. The technology comprises the steps of semi-continuous casting, homogenizing annealing, heat extrusion, multi-direction forging, mechanical hole punching and annular part rolling. The extruding, forging and rolling integrated technology can be used for producing and preparing the AQ80M magnesium alloy annular part which is free of cracks on the surface, uniform in structure, good in comprehensive mechanics property, small in mechanical anisotropy and large in size, the annular part can be used for replacing annular parts made of other materials, the effects of reducing weight, improving the fuel efficiency and achieving electromagnetic shielding are achieved, and the technology has the important application value in aerospace and national defense fields.

Owner:CENT SOUTH UNIV

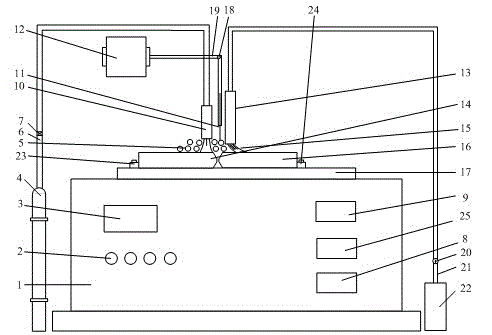

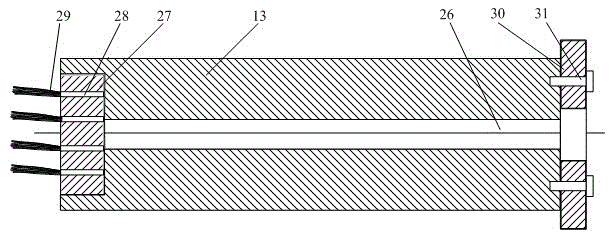

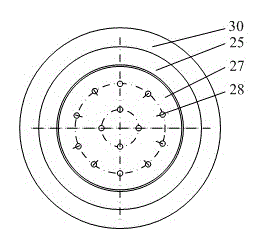

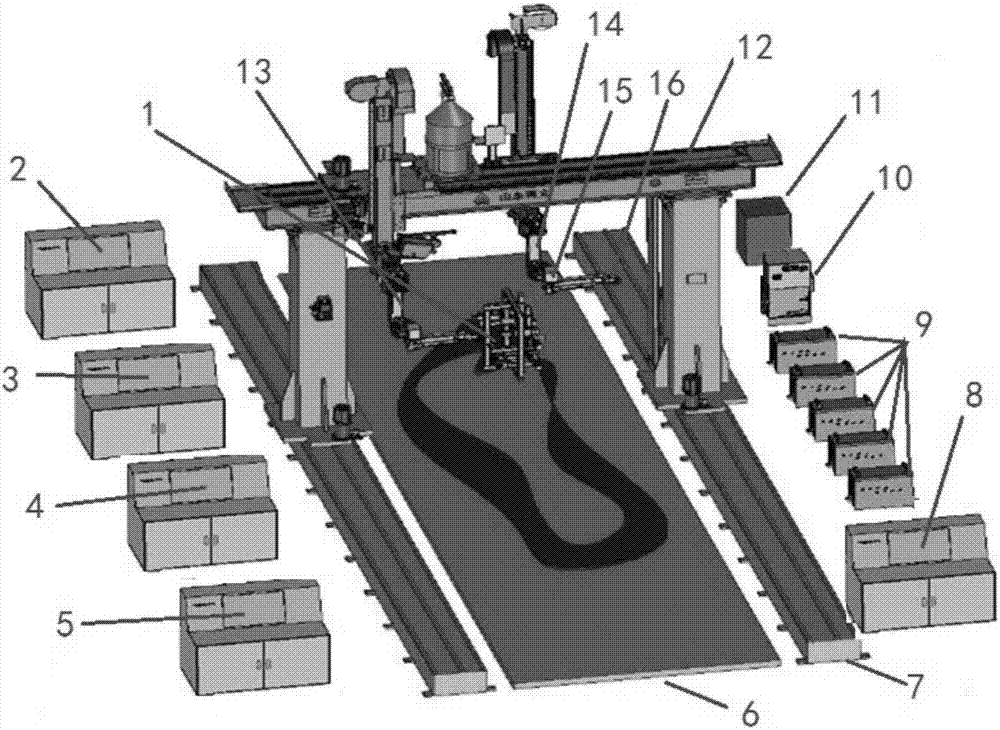

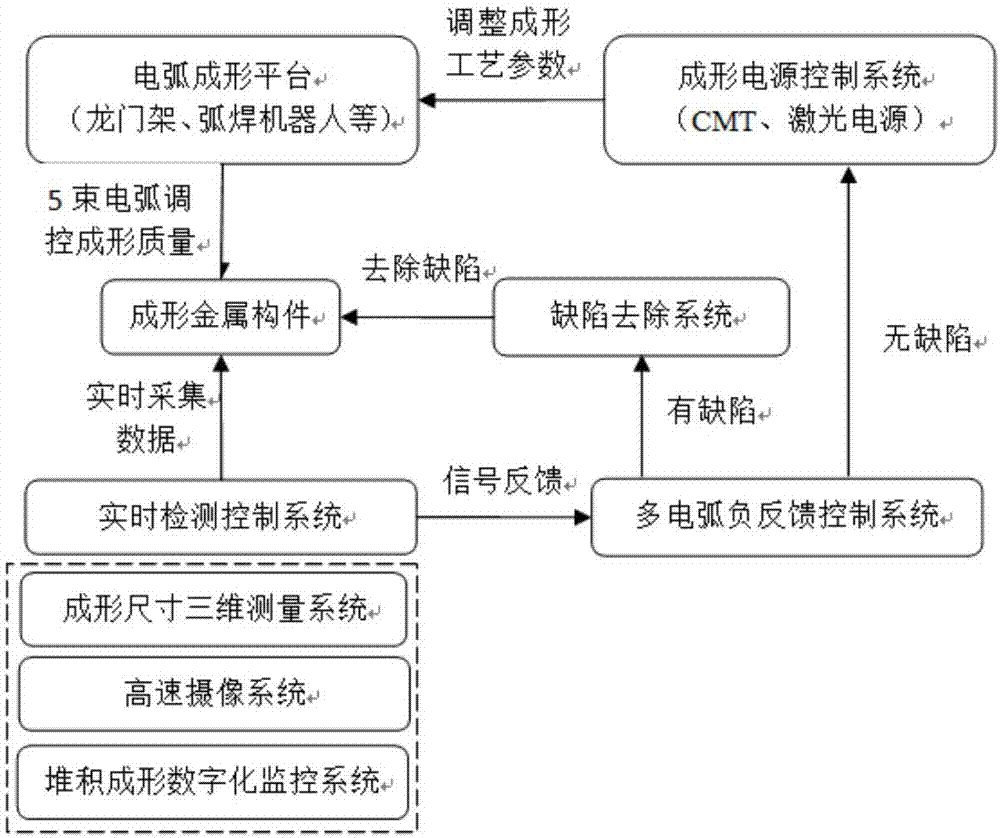

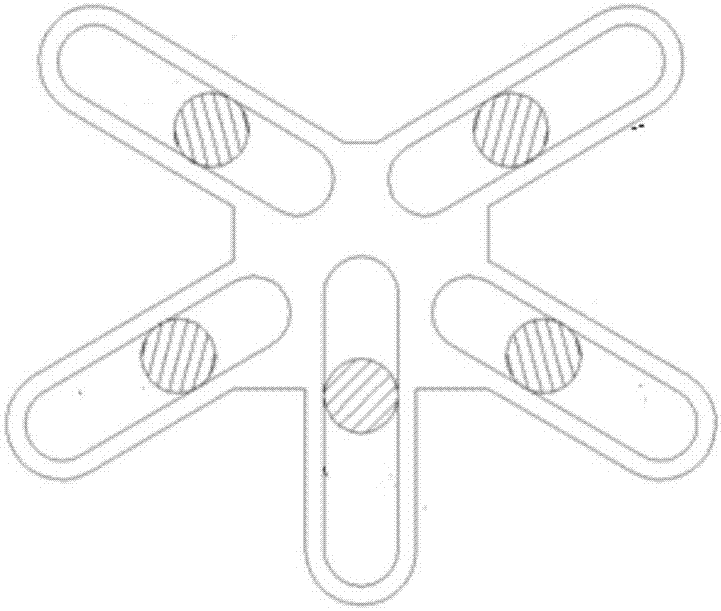

Shape and property integrated metal component additive manufacturing system

ActiveCN107262878ASatisfy multi-arc synergyFulfil requirementsWelding accessoriesNegative feedbackComputer module

The invention belongs to the technical field related to additive manufacturing, and more particularly, relates to a shape and property integrated metal component additive manufacturing system. The shape and property integrated metal component additive manufacturing system comprises an object carrying platform, a multi-electric arc collaborative operation module, an electric arc camera shooting detection unit, a forming size three-dimensional measurement unit, a depositing forming digital monitoring module and the like, and uniform control is executed through a negative feedback monitoring module. The multi-electric arc collaborative operation module is equipped with a plurality of mutually independent electric arc guns, and relative positions and operating postures of the electric arc guns freely change. Through the shape and property integrated metal component additive manufacturing system, electric arc additive manufacturing overall processes of various large metal components can be executed based on a compact structure, convenience in control, high automaticity and high manufacturing accuracy, and the requirements of shape and property integrated collaborative additive manufacturing are met better.

Owner:HUAZHONG UNIV OF SCI & TECH

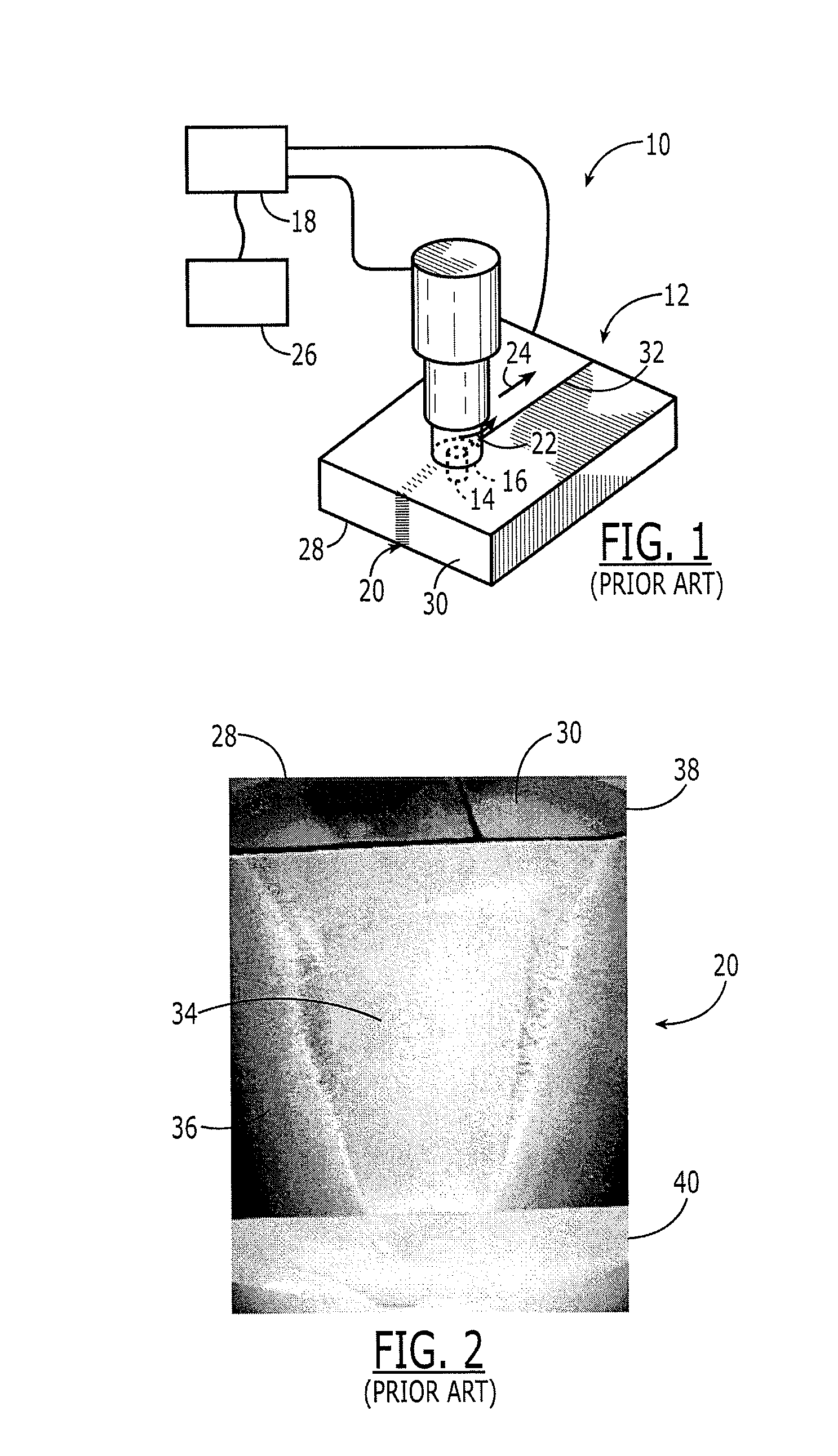

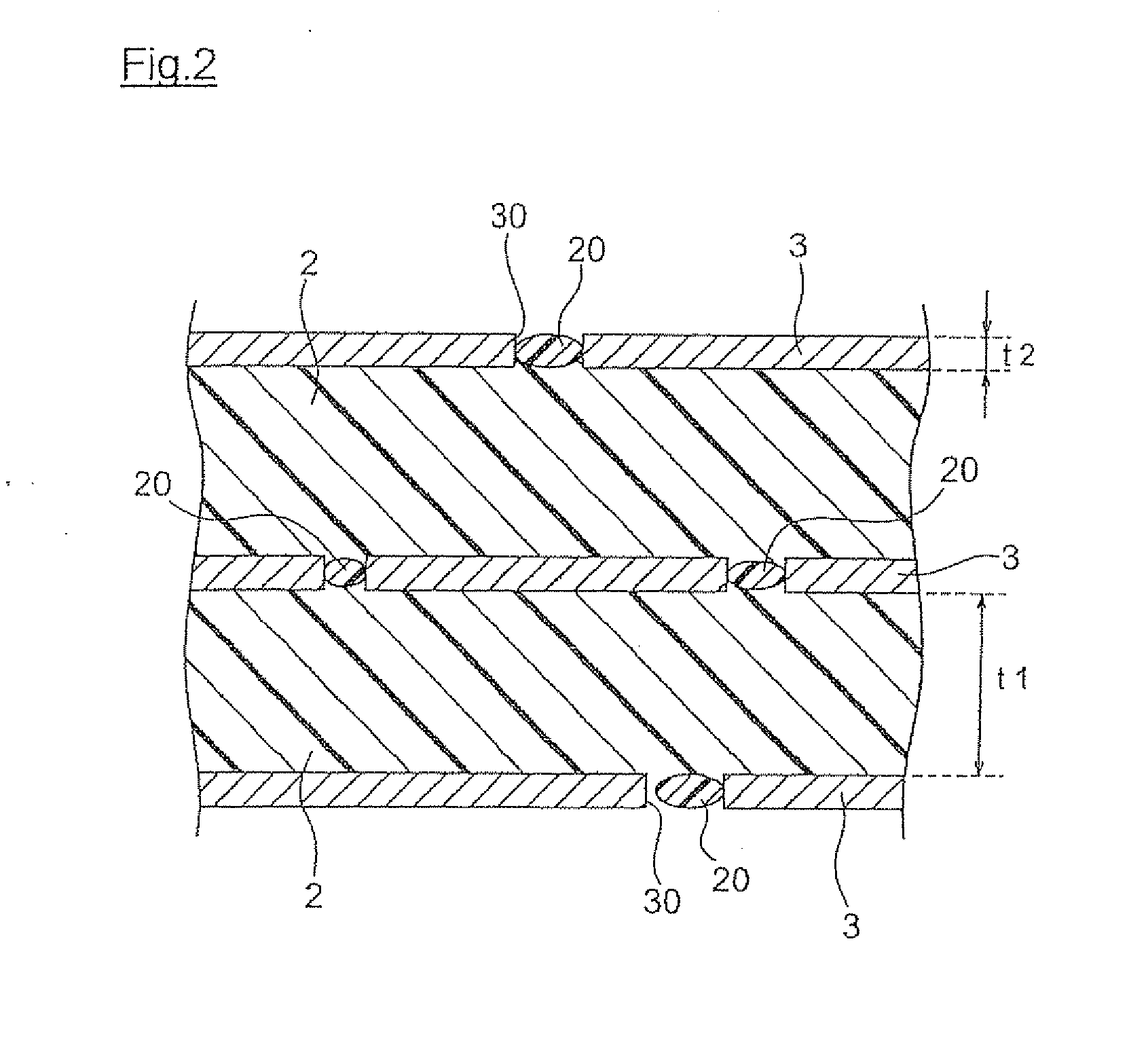

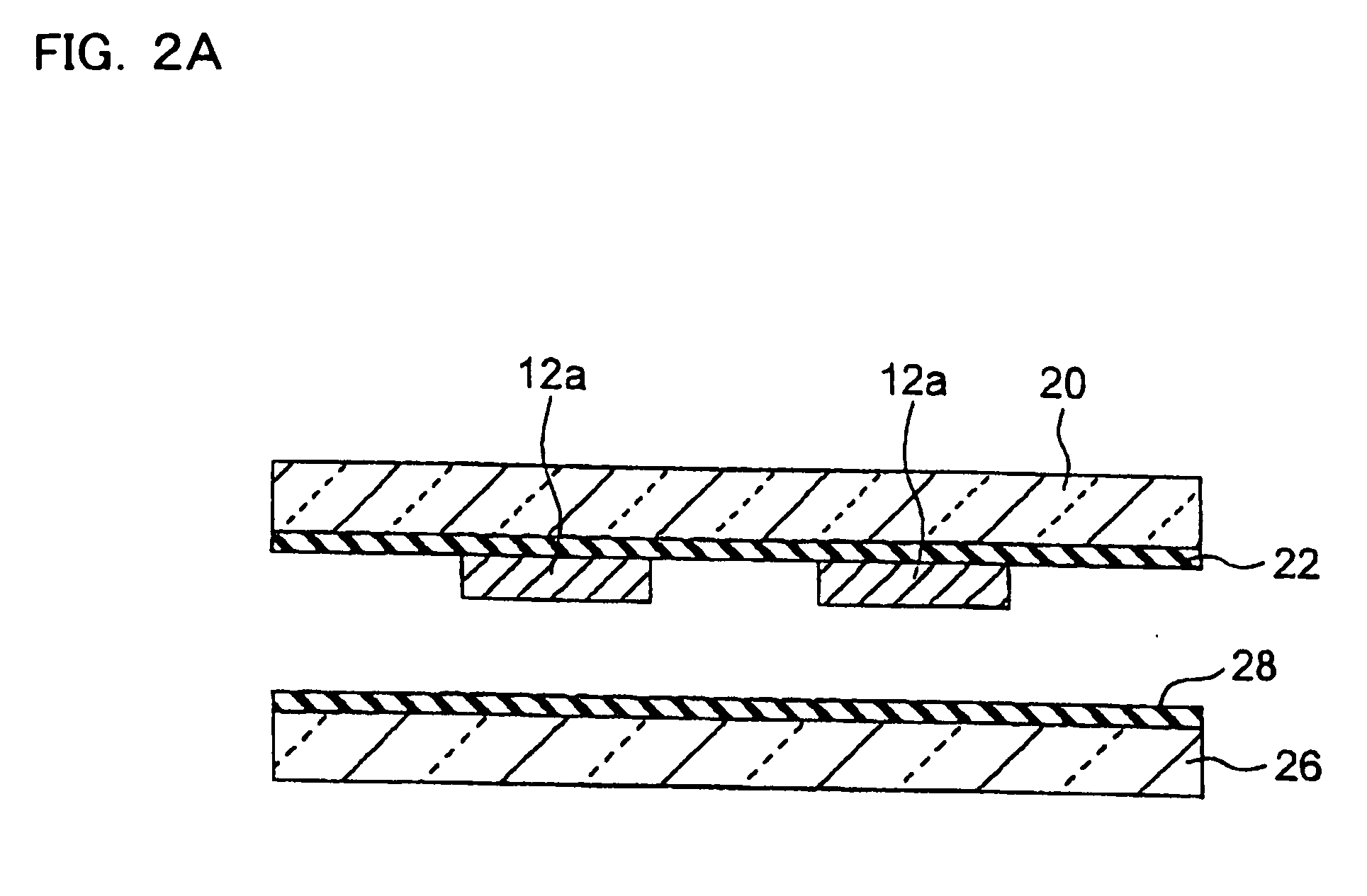

Multilayer ceramic electronic component

ActiveUS20120026642A1Low dielectric lossExcellent high-temperature accelerated lifetimeFixed capacitor electrodesFixed capacitor dielectricOptoelectronicsElectronic component

Disclosed is a multilayer ceramic electronic component, comprising an element body obtained by stacking dielectric layers (thickness t1) and electrode layers (thickness t2). The dielectric layer (2) includes a compound expressed by ABO3 (A includes Ba, and may include Ca or Sr; and B includes Ti, and may include Zr or Hf), and includes 0.75 to 2.0 moles of MgO, 0.4 to 1.0 mole of an oxide of Y, Dy, Ho and the like in terms of the oxide, and 0.4 to 0.8 mole of SiO2 per 100 moles of the compound. A segregation phase (20) containing Mg is formed in at least a part of an electrode missing portion (30), where the electrode layer is supposed to be formed but no electrode layer is formed. Line coverage of the electrode layer (3) is 60 to 90% and relations of 0.3≦̸t1≦̸2.0 and 0.3≦̸t2<1.0 are fulfilled.

Owner:TDK CORPARATION

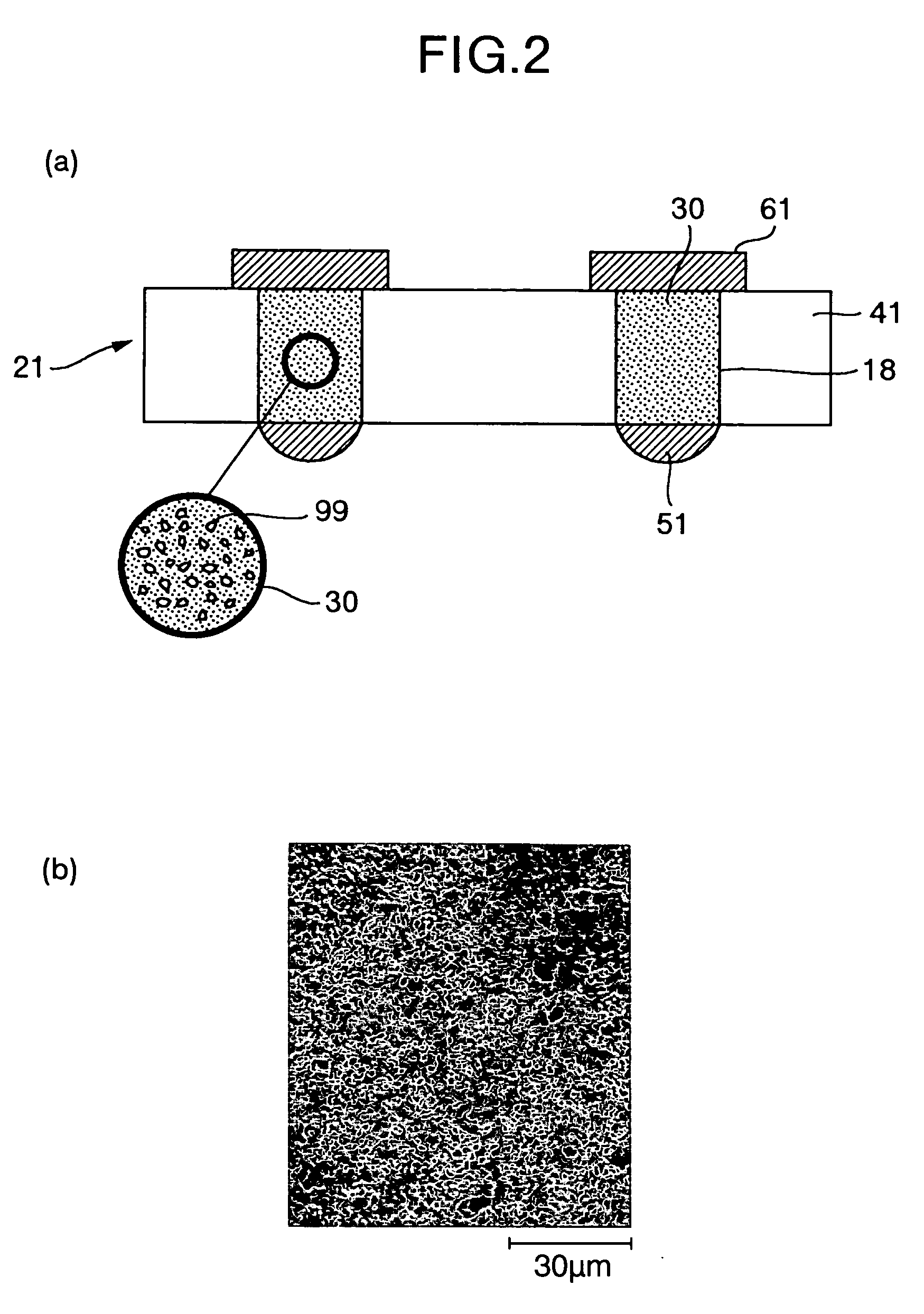

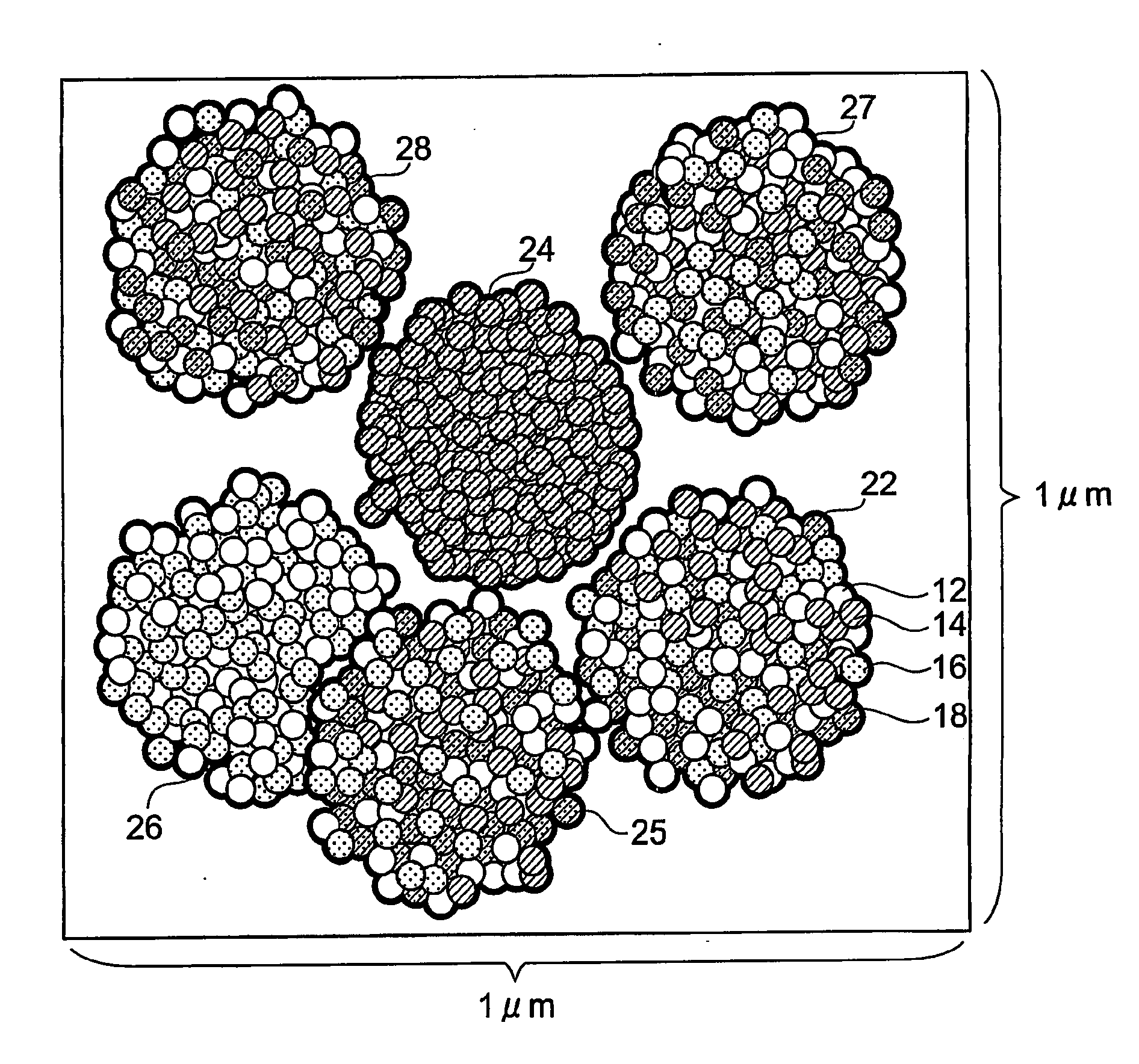

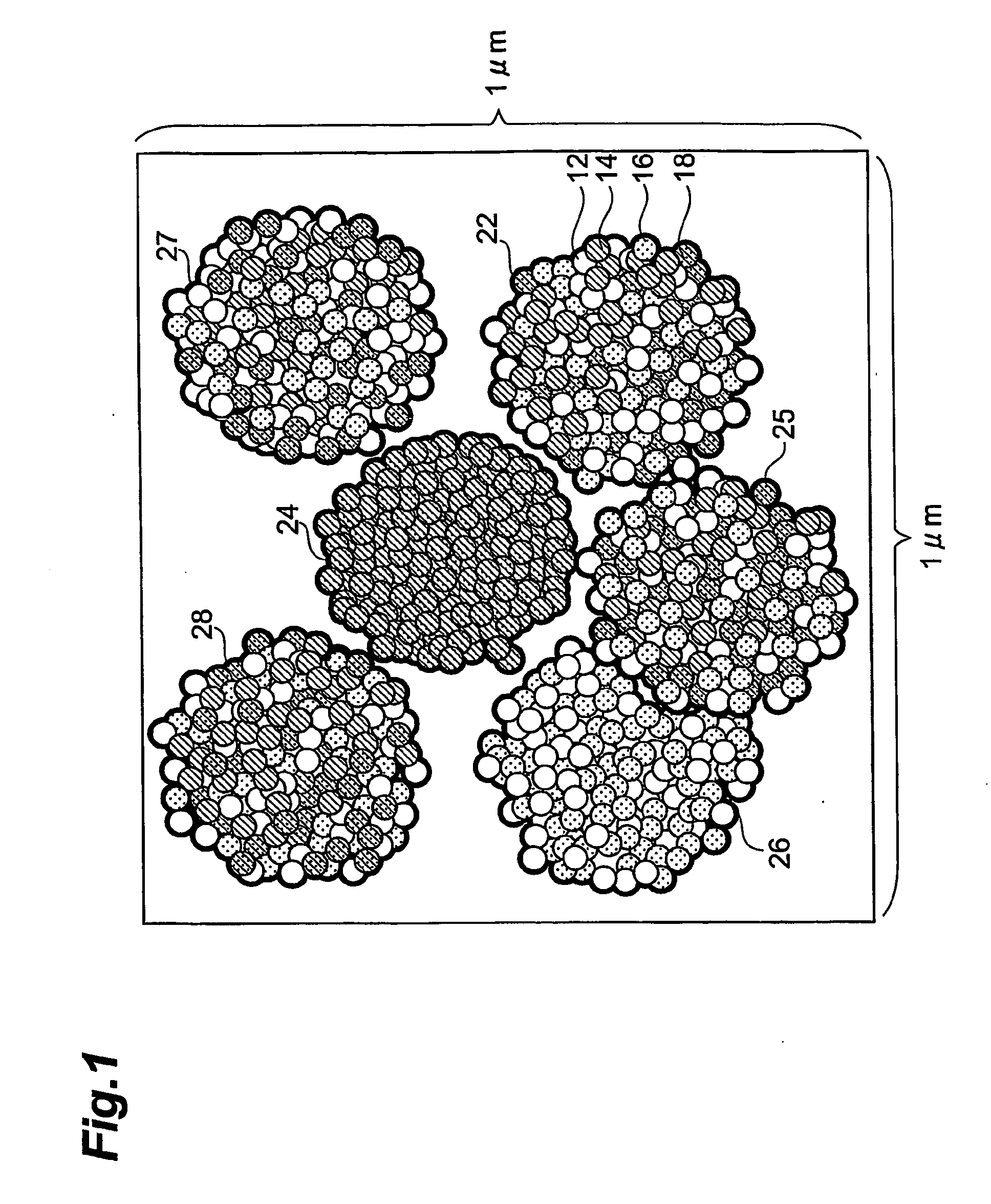

Inorganic oxide, exhaust gas purifying catalyst carrier, and exhaust gas purifying catalyst

ActiveUS20070104950A1Suppress grain growthAvoid grain growthMaterial nanotechnologyAluminium compoundsExhaust gasRare-earth element

A particulate inorganic oxide containing aluminum oxide, a metal oxide forming no composite oxide with aluminum oxide, and an additional element including at least one of a rare-earth element and an alkali earth element, the inorganic oxide containing a secondary particle formed by aggregating primary particles; wherein at least a part of the secondary particle includes a plurality of first primary particles, each having a particle size of 100 nm or less, containing aluminum oxide and the additional element, and a plurality of second primary particles, each having a particle size of 100 nm or less, containing the metal oxide and the additional element; wherein at least a part of the first and second primary particles has a surface concentrated region where the additional element has a locally increased content in a surface layer part thereof.

Owner:TOYOTA JIDOSHA KK +1

Electronic device and manufacturing method thereof

InactiveUS20080212258A1Inhibit deteriorationAvoid crackingFixed capacitor electrodesStacked capacitorsCapacitorElectronic equipment

The electronic device according to the present invention comprises capacitor element body 4 wherein internal electrode layer 12 and ceramic layer 10 is included. Internal electrode layer 12 includes Ni and at least one element from Re, Ru, and Ir. The ceramic layer 10 substantially doesn't include Re, Ru, Os, and Ir.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com