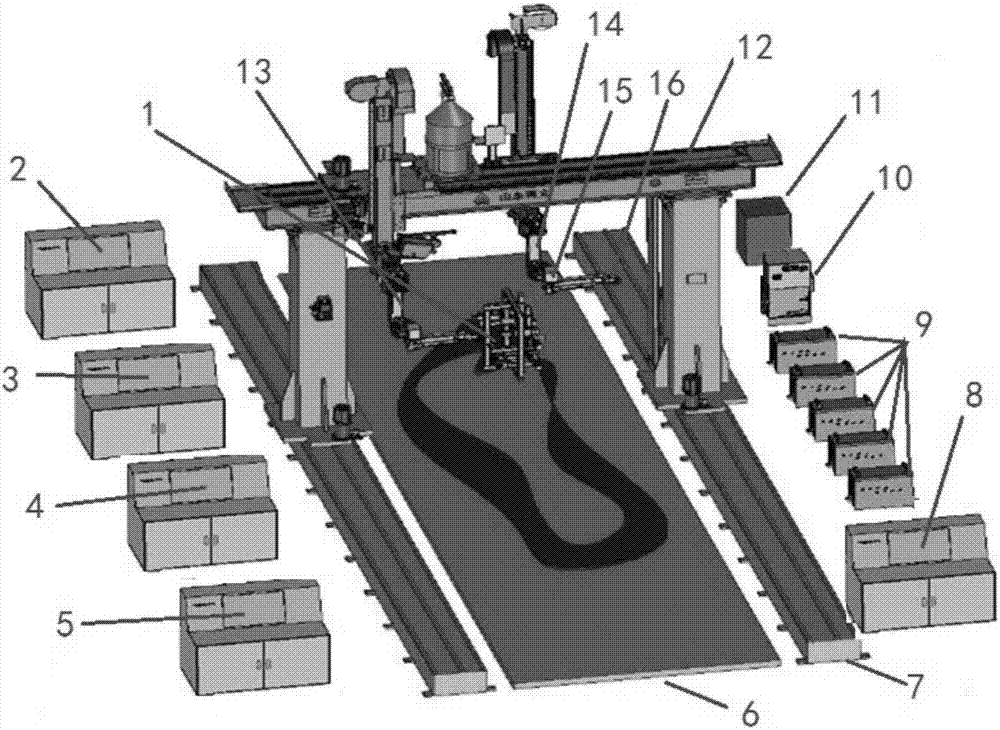

Shape and property integrated metal component additive manufacturing system

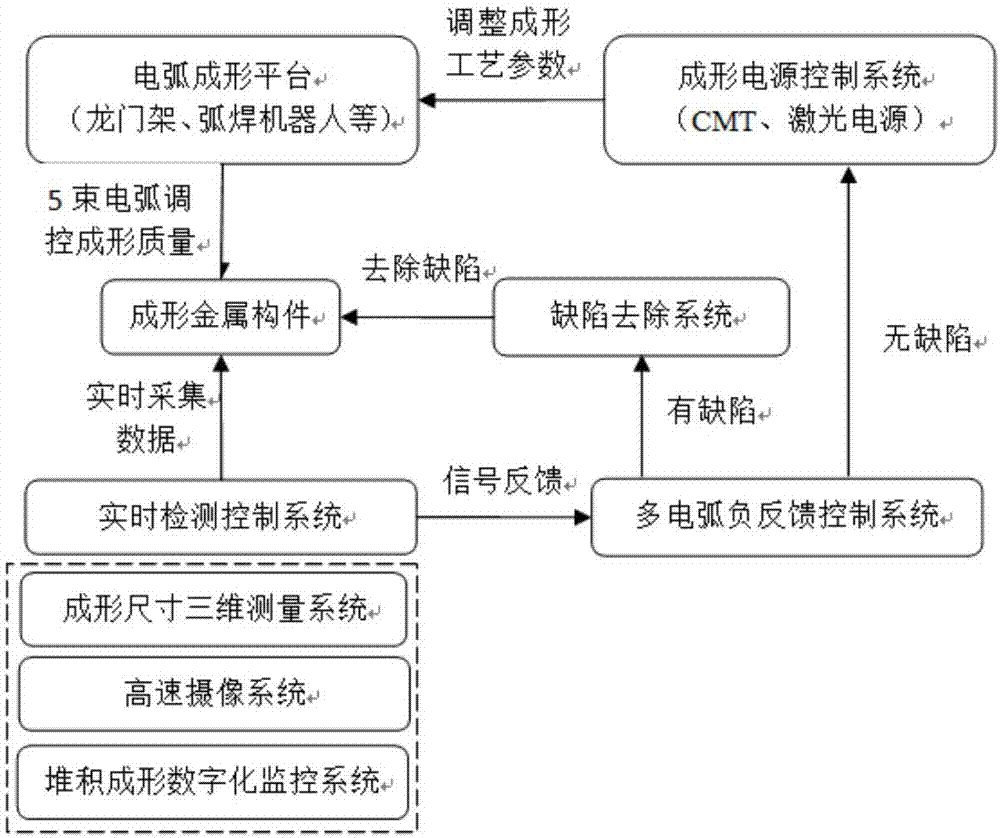

A metal component and additive manufacturing technology, which is applied in the field of additive manufacturing, can solve the problems of thick grains, unstable arcs, and performance deterioration of stacked metal components, so as to avoid excessive growth of grains, high-precision manufacturing and forming, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

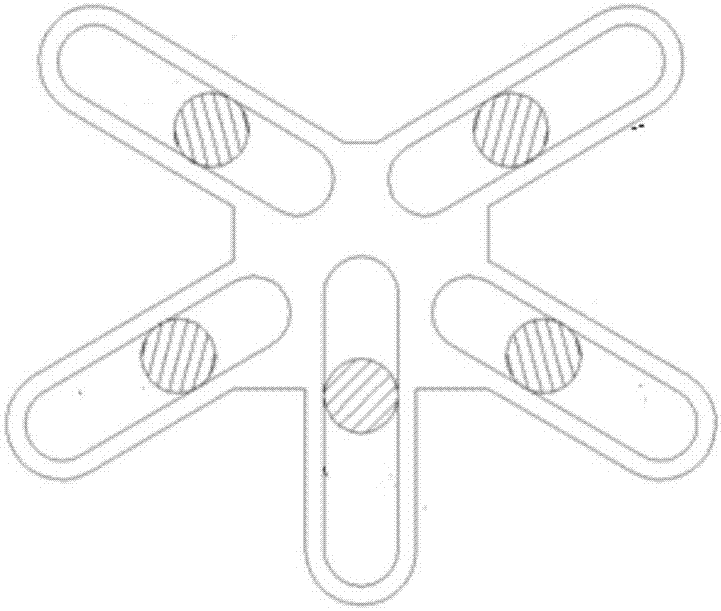

[0062]The key components of a large ship have high requirements for its structural size and performance. The performance requirement is above 1000MPa, and the dimensional accuracy of forming is ±1.5mm. In order to ensure the performance and forming accuracy of arc additive manufacturing metal components, multi-arc synergistic conformity integrated additive manufacturing equipment is used for additive manufacturing. The specific steps are as follows:

[0063] 1. Three-dimensional model establishment: use UG three-dimensional modeling software to draw three-dimensional CAD models of parts, and generate robot numerical control codes and forming path software;

[0064] 2. Select the forming material and set the forming arc parameters: In the process of additive manufacturing, the forming material with high alloy content is selected, and the forming adopts CO 2 Shielding gas, the diameter of the metal wire is 1.2mm, it is shaped into a current of 100A, a voltage of 20V, and the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com