Cold work die steel and preparation method thereof

A technology of cold working die steel and molten steel, which is applied in the field of alloy materials, can solve problems such as uneven distribution of carbides, lower mechanical properties of steel, and easy appearance of surface cracks, and achieve the effects of light weight, long service life, and small heat treatment deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

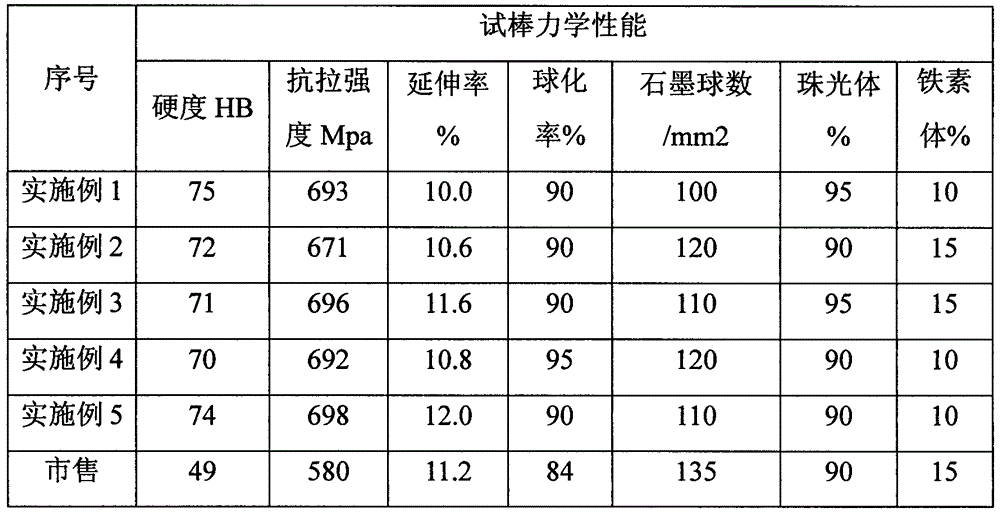

Examples

Embodiment 1

[0021] Cold work die steel, including the following components in weight percentage: C 3.5%, Si 4.2%, Mn 0.44%, Cr 9.8%, Mo 0.78%, W 2.16%, V 2.20%, P 0.10%, S 0.02%, Cu 0.35%, Mg 0.64%, Ti0.36%, Sr 0.77%, Zr 0.77%, B 0.49%, Zn 1.00%, Re 0.17%, Sn 0.26%, Pb 0.62%, Be 0.10%, Sc 0.15%, Li 0.46%, Ni 0.55%, La 0.02%, Al 0.14%, the rest is iron, and the sum of the mass percentages of each component is 100%.

[0022] The present invention also provides the preparation method of above-mentioned cold working die steel, comprises the following steps:

[0023] (1) Smelting each raw material at 1500°C for 5 hours, blowing argon and stirring at 1500°C for 2 hours to obtain primary molten steel;

[0024] (2) Vacuum degas the primary molten steel at 1500°C and 80 Pa for 20 minutes to obtain high-purity molten steel;

[0025] (3) Casting high-purity molten steel at 1400°C, annealing at 800°C for 12 hours, cooling down to 400°C and standing to cool to room temperature to obtain electroslag ...

Embodiment 2

[0030] Cold work die steel, including the following components in weight percentage: C 3.6%, Si 4.3%, Mn 0.46%, Cr 9.5%, Mo 0.76%, W 2.12%, V 2.24%, P 0.11%, S 0.03% , Cu 0.33%, Mg 0.62%, Ti0.34%, Sr 0.75%, Zr 0.80%, B 0.50%, Zn 1.04%, Re 0.16%, Sn 0.25%, Pb 0.63%, Be 0.11%, Sc 0.16%, Li 0.47%, Ni 0.53%, La 0.01%, Al 0.14%, the rest is iron, and the sum of the mass percentages of each component is 100%.

[0031] The present invention also provides the preparation method of above-mentioned cold working die steel, comprises the following steps:

[0032] (1) Smelting each raw material at 1600°C for 3 hours, blowing argon and stirring at 1600°C for 1 hour to obtain primary molten steel;

[0033] (2) Vacuum degas the primary molten steel at 1600°C and 60-80Pa for 10 minutes to obtain high-purity molten steel;

[0034](3) Cast high-purity molten steel at 1500°C, anneal at 900°C for 8 hours, cool down to 500°C and let it stand to cool to room temperature to obtain electroslag rods;...

Embodiment 3

[0039] Cold work die steel, including the following components by weight: C 3.3%, Si 4.1%, Mn 0.42%, Cr10.0%, Mo 0.80%, W2.22%, V 2.18%, P 0.09%, S 0.01% , Cu0.36%, Mg0.66%, Ti0.40%, Sr0.80%, Zr0.74%, B0.48%, Zn0.98%, Re0.18%, Sn0.27%, Pb0.59%, Be0.09%, Sc 0.14%, Li 0.47%, Ni 0.57%, La 0.03%, Al 0.13%, the rest is iron, and the sum of the mass percentages of each component is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com