Patents

Literature

48 results about "Ledeburite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

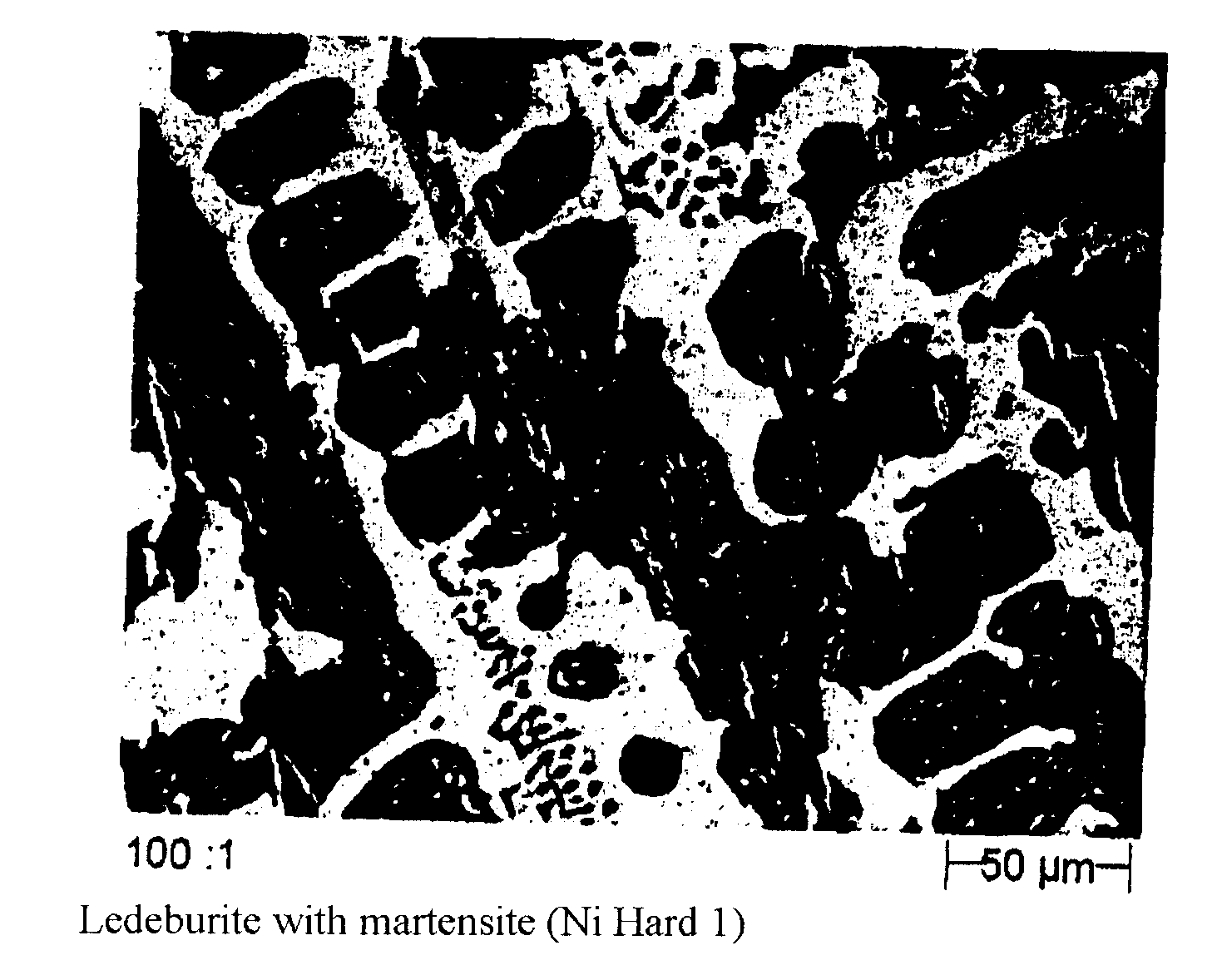

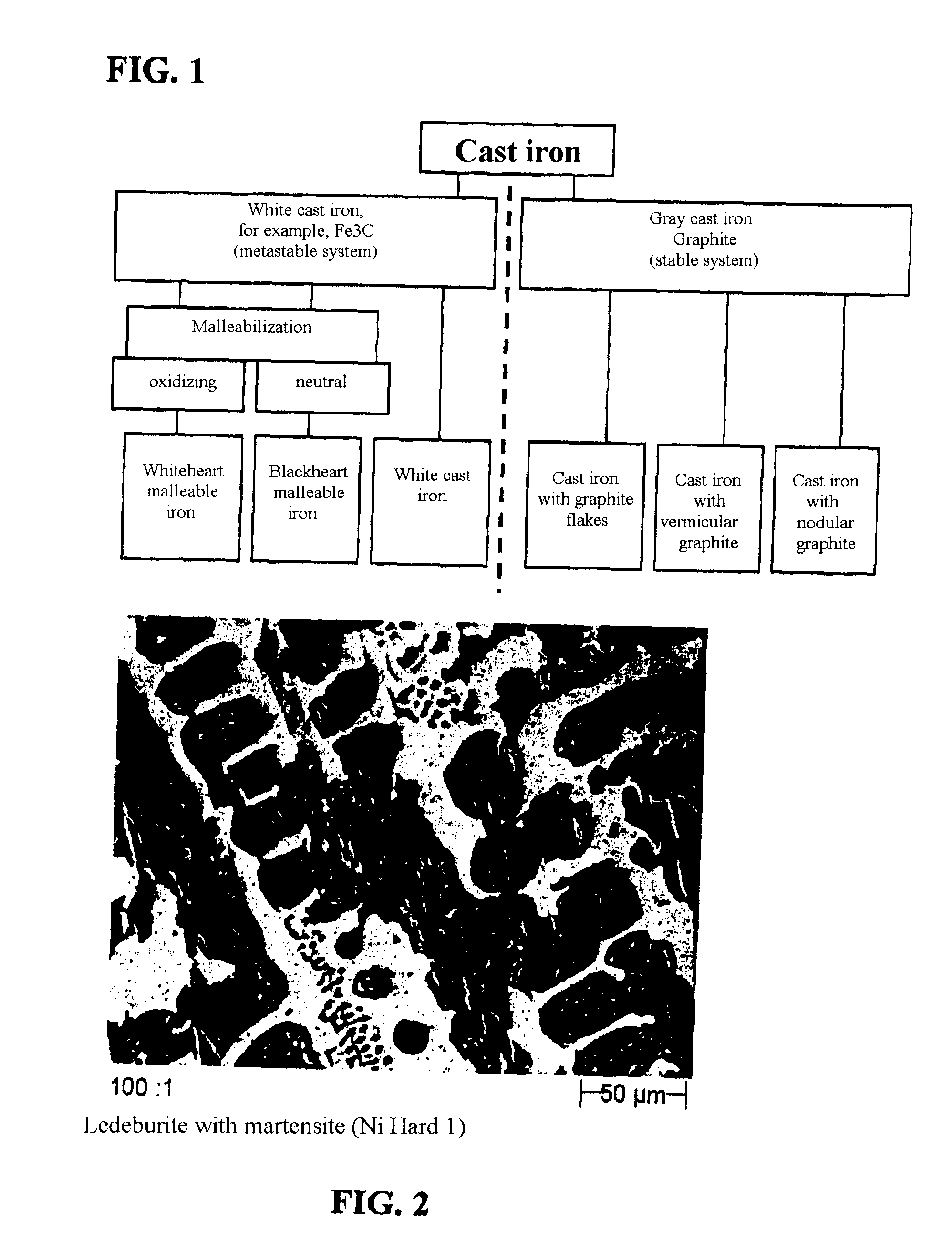

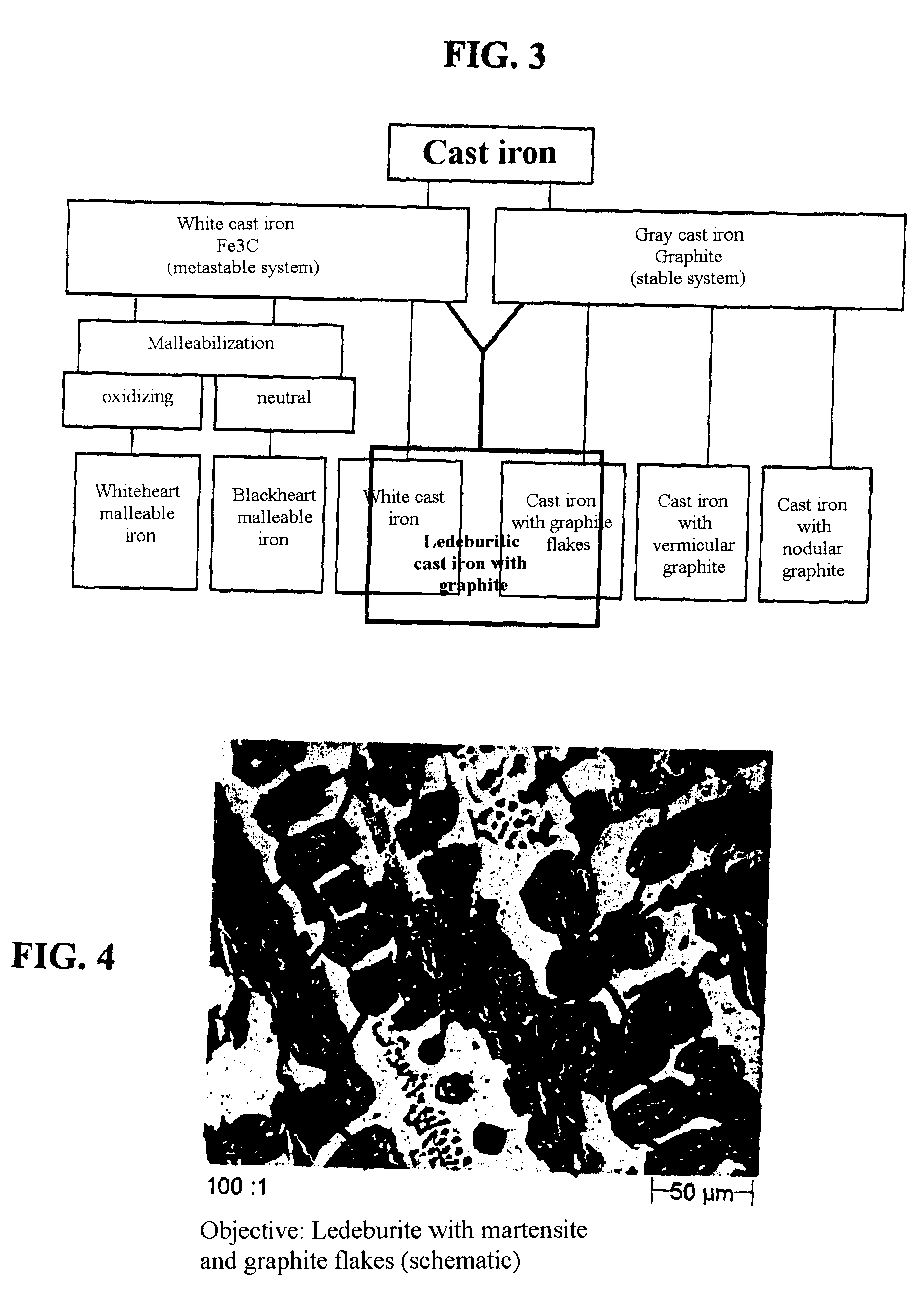

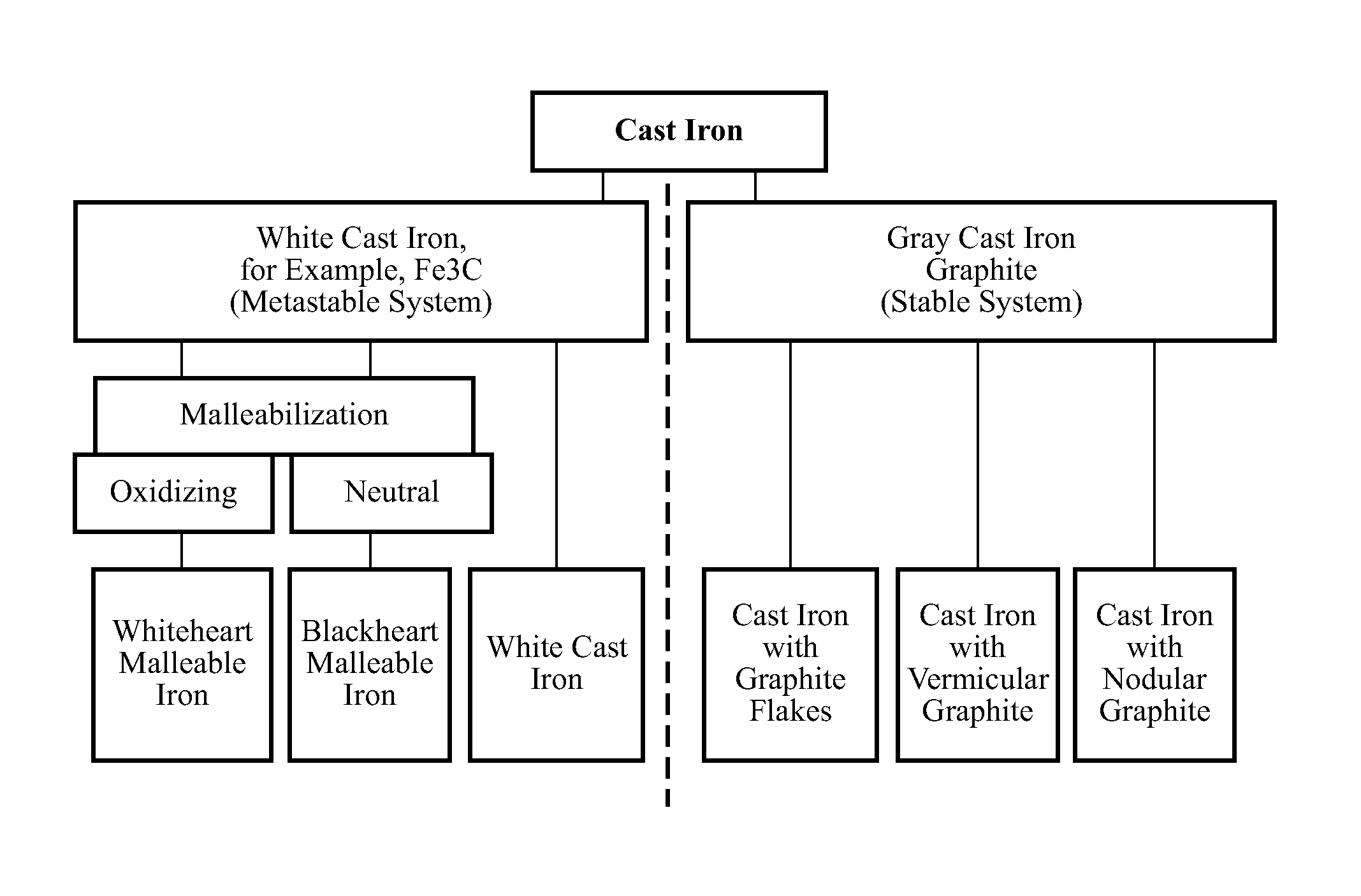

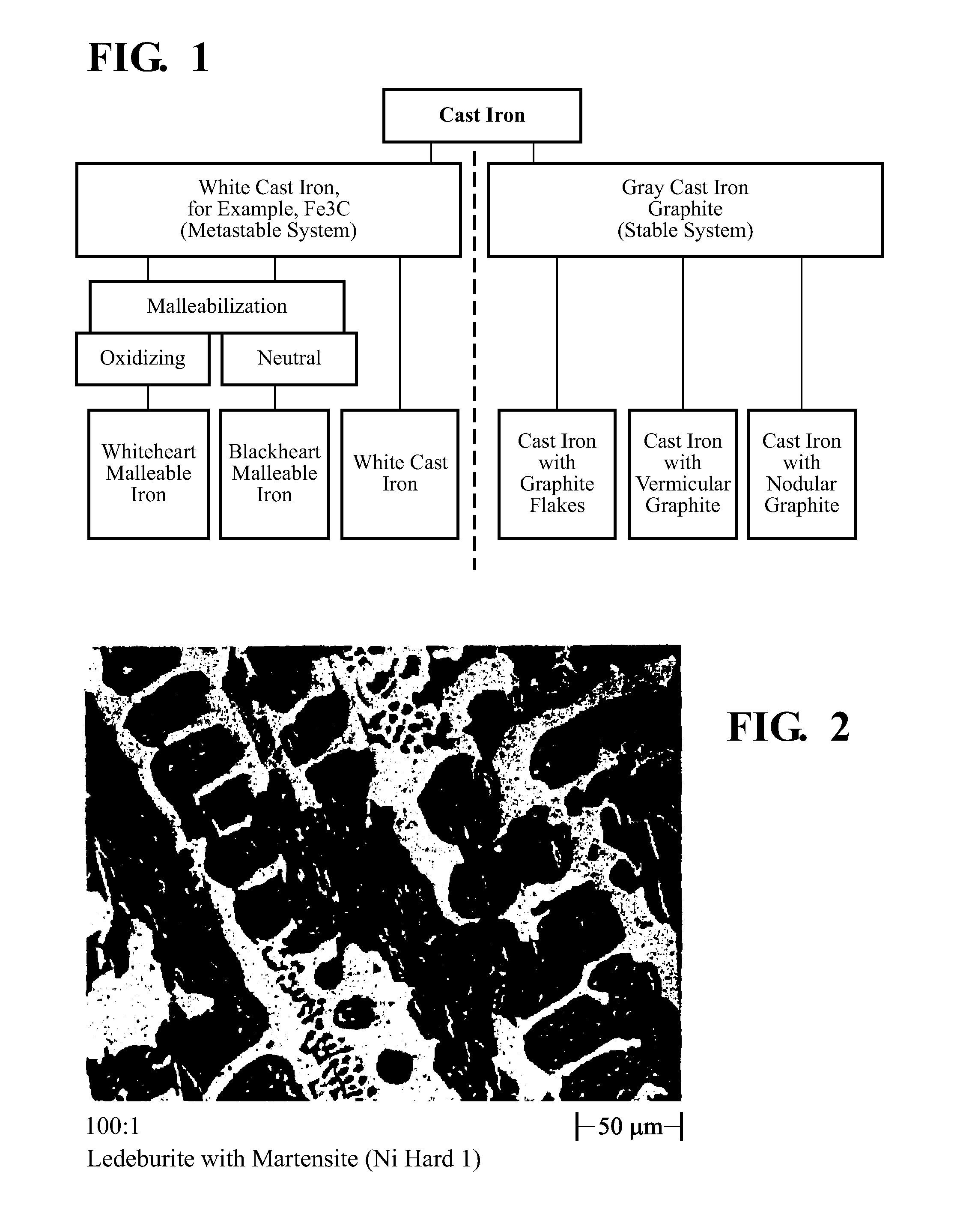

In iron and steel metallurgy, ledeburite is a mixture of 4.3% carbon in iron and is a eutectic mixture of austenite and cementite. Ledeburite is not a type of steel as the carbon level is too high although it may occur as a separate constituent in some high carbon steels. It is mostly found with cementite or pearlite in a range of cast irons.

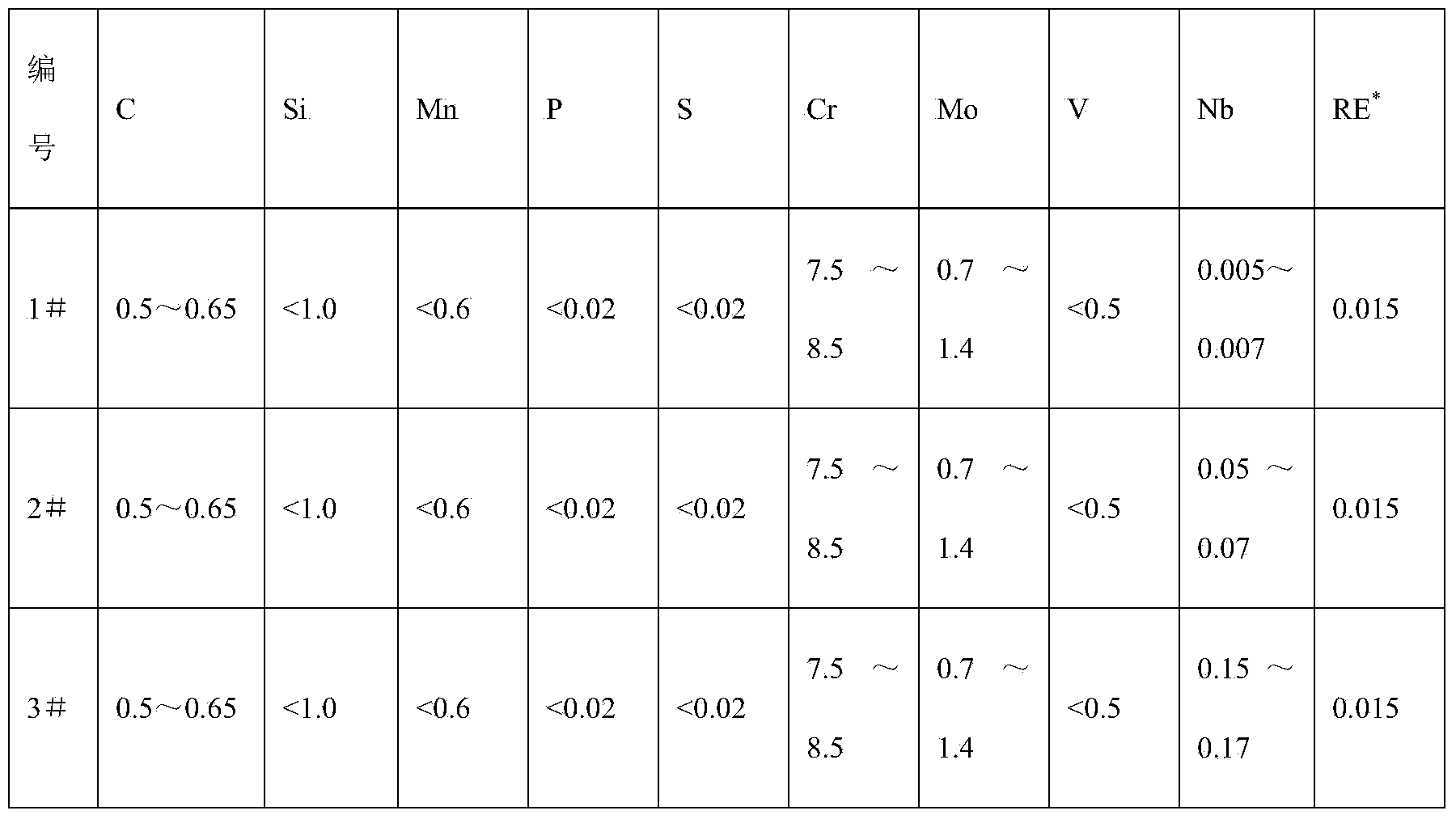

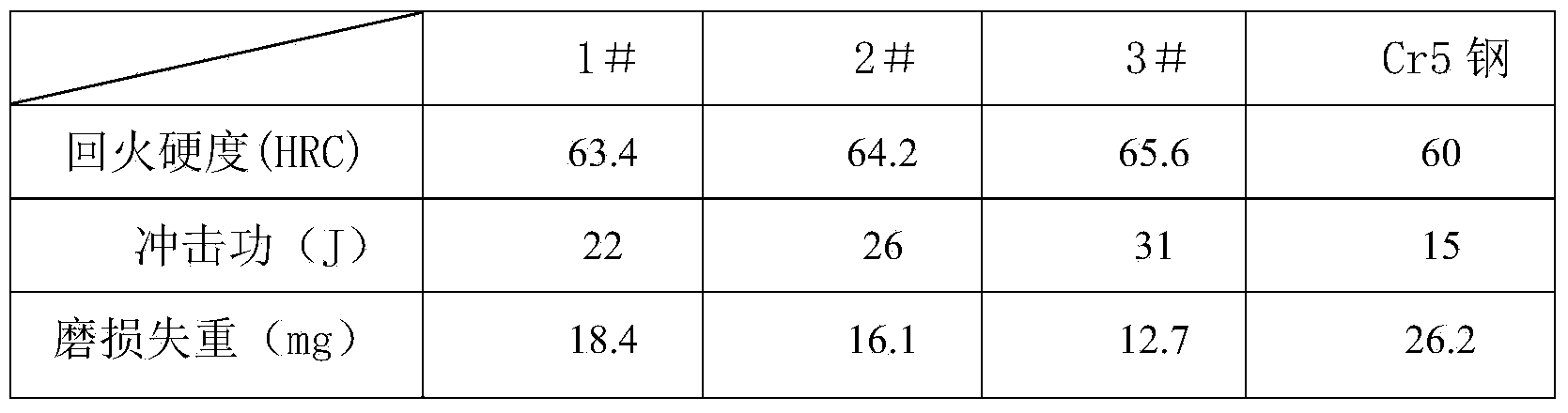

Improved Cr8 steel roll and preparation method thereof

The invention discloses an improved Cr8 steel roll and a preparation method thereof. Based on the Cr5 steel, the Cr8 steel roll also comprises microalloying Nb and RE, wherein Nb is mainly used for refining the crystalline grain, and RE is mainly used for purifying molten steel. The Cr8 steel roll comprises the following components: 0.50-0.65% of C, less than or equal to 1.0% of Si, less than or equal to 0.60% of Mn, less than or equal to 0.020% of S, less than or equal to 0.020% of P, 7.5-8.5% of Cr, 0.70-1.40% of Mo, less than or equal to 0.50% of V, 0.005-0.20% of Nb, 0.003-0.02% of RE, and the balance of Fe and impurities. By combining solidification refining, deformation recrystalization refining and thermal treatment refining, the method refines the tissue of a high chrome ledeburite die steel and obtains fine plate martensite with the length less than 30micron and width less than 0.5micron. Due to rare earth modification, carbide segregation is reduced, and the morphology of the included foreign substances and eutectic carbide is improved. Due to the adoption of proper thermal treatment technology, compared with Cr5 steel, the Cr8 steel roll not only has higher toughness, but also improves the abrasion performance, and greatly prolongs the service life.

Owner:UNIV OF SCI & TECH BEIJING

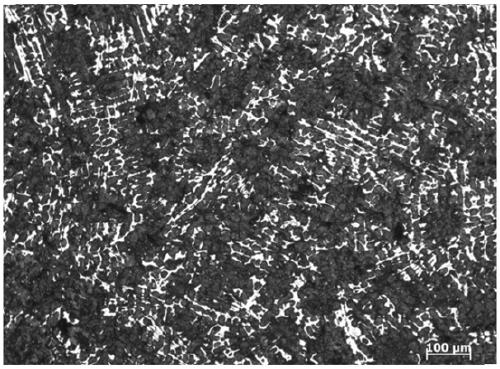

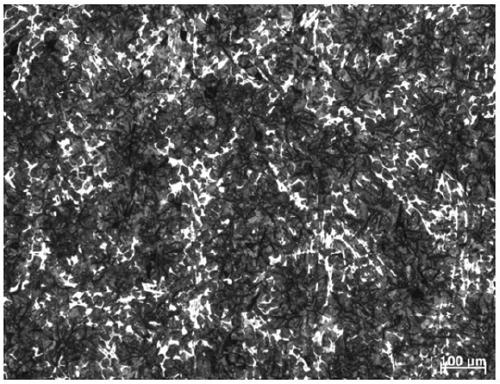

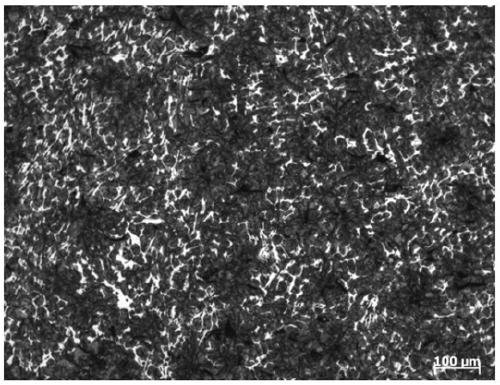

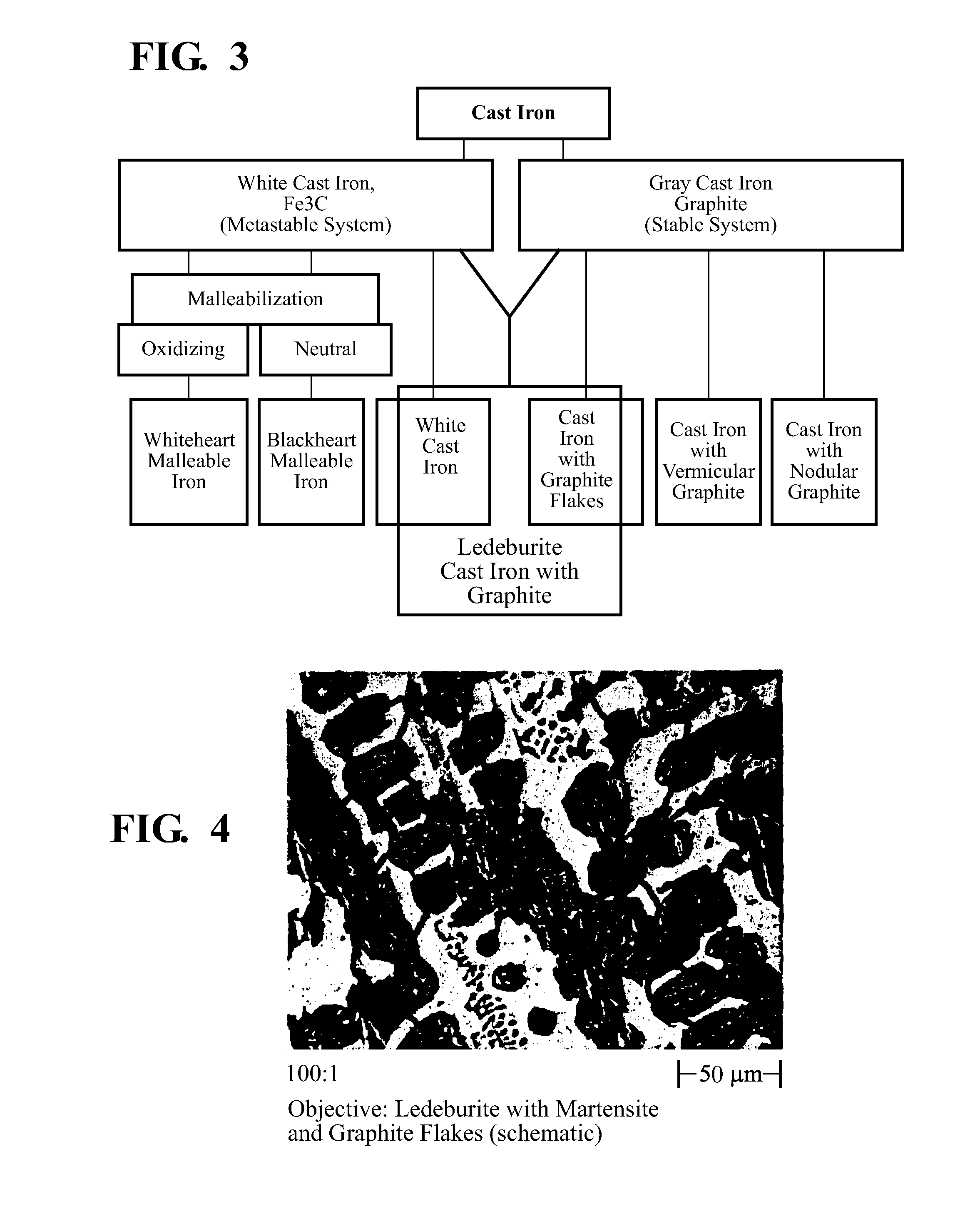

Ledeburite cast iron with a high carbide content and an evenly distributed graphite embodiment

Disclosed is a cast iron material, especially a ledeburite cast iron material which has a high carbide content of at least 15.0 percent by weight and is provided with a characteristic, free, evenly distributed graphite embodiment that can comprise flake graphite and / or vermicular graphite and / or nodular graphite. The basic matrix can be embodied in a pearlitic and / or bainitic and / or martensitic manner according to the application thereof (diameter (D) of the seal of the running gear, peripheral velocity). The thermal conductivity of the inventive material is three to four times greater than that of white cast materials as a result of the high graphite content, thus advantageously preventing seals of running gears from fretting in case of great peripheral velocities (>5 m / s) and large diameters (D>600 mm) of the seals. Additionally, the high carbide content of at least 15 percent by weight provides for good resistance to wear while additional alloying elements such as chromium, vanadium, molybdenum, and nickel provide the material with adequate resistance to corrosion. The disclosed ledeburite cast iron material featuring an evenly distributed graphite embodiment can be used for producing axial face seals and cylinder hushes, for example.

Owner:FEDERAL MOGUL FRIEDBERG

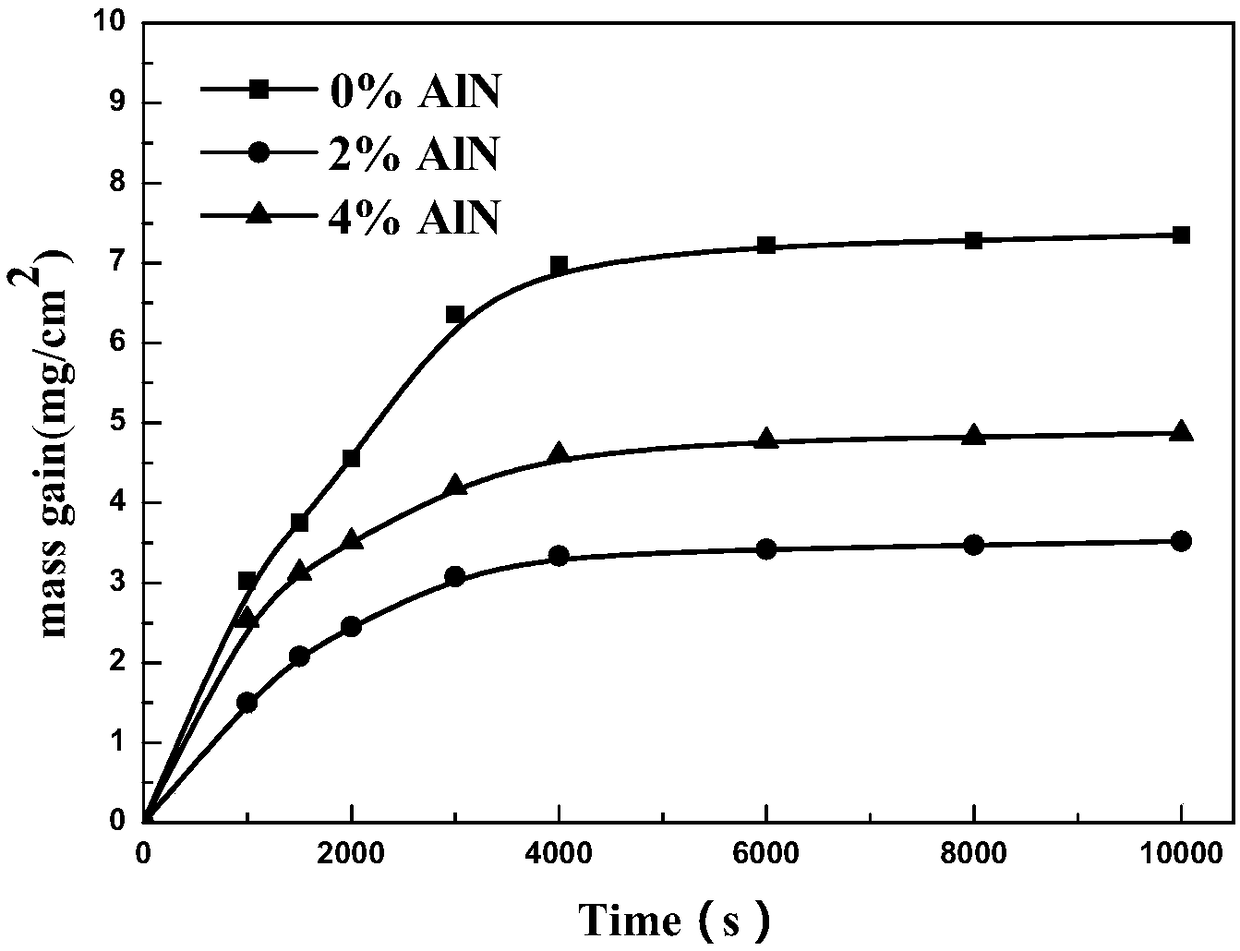

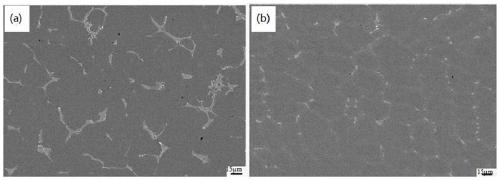

Novel aluminum nitride dispersion strengthening powder metallurgical aluminum high-speed steel and preparation method thereof

ActiveCN108642402AHeat treatment window widthReduced tendency to overheat during heat treatmentMicro structureOxidation resistant

The invention discloses novel aluminum nitride dispersion strengthening powder metallurgical aluminum high-speed steel and a preparation method thereof. Aluminum high-speed steel prepared by the preparation method adopts a novel powder metallurgical high-speed steel direct preparation process to lead in (0.05-5.0) AlN micro powder, and a material mixture is subjected to processes such as wet-milling, pelletizing, isostatic cool pressing and forming, hydrogen gas deoxidizing, hot-pressing composite sintering and vacuum thermal treatment, so that micro-level dispersion distribution of aluminum nitride particles is realized, and therefore, the defects that a conventional casting process easily generates a ledeburite structure, an aluminum nitride strengthening phase is difficulty led in by agas-atomizing-hot isostatic pressing method, and the like are overcome. The novel aluminum nitride dispersion strengthening powder metallurgical aluminum high-speed steel is short in process flow, islow in production cost, is low in impurity content, is high in compactness, and is remarkably improved in wear resistance, oxidization resistance and a micro structure after aluminum nitride is led in, and is novel mould material among conventional high-speed steel, a hard alloy and a ceramic material.

Owner:XIANGTAN UNIV

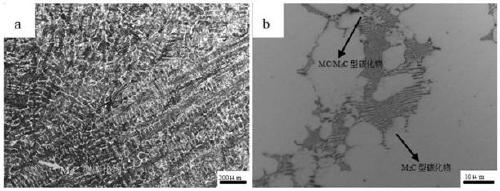

High chromium ledeburite cold work die steel with high tenacity and high abrasive resistance and preparation method thereof

The invention particularly discloses high chromium ledeburite cold work die steel with high tenacity and high abrasive resistance, and a preparation method thereof. The problems that the existing D2 cold work die steel easily generates serious carbide segregation so as to result in low tenacity, small gaps and raptures are solved. The high chromium ledeburite cold work die steel with high tenacity and high abrasive resistance is prepared from the following raw materials by mass percent: 1.40-1.65% of C, no more than 0.60% of Si, no more than 0.60% of Mn, no more than 0.020% of S, no more than 0.020% of P, 8-13.00% of Cr, 0.70-1.20% of Mo, 0.20-1.00% of V, 0.005-0.20% of Nb, 0.003-0.02% of RE, no more than 0.25% of Ni, no more than 0.30% of Cu, and the balance of Fe and impurities. The high chromium ledeburite cold work die steel is excellent in overall performance, and can replace cold work die steel such as Cr12MoV, D2 steel and the like, the tenacity and the abrasive resistance of the die are improved, and the service life is greatly prolonged. Thus, the use cost is reduced, the usable range is expanded, and the problems of poor tenacity, tipping or rapture, low wear resistance and the like in special service environments such as large impact load, high work speed, high accuracy, long service life and the like can be effectively solved.

Owner:SHANXI BUYEASY MACHINERY MFG

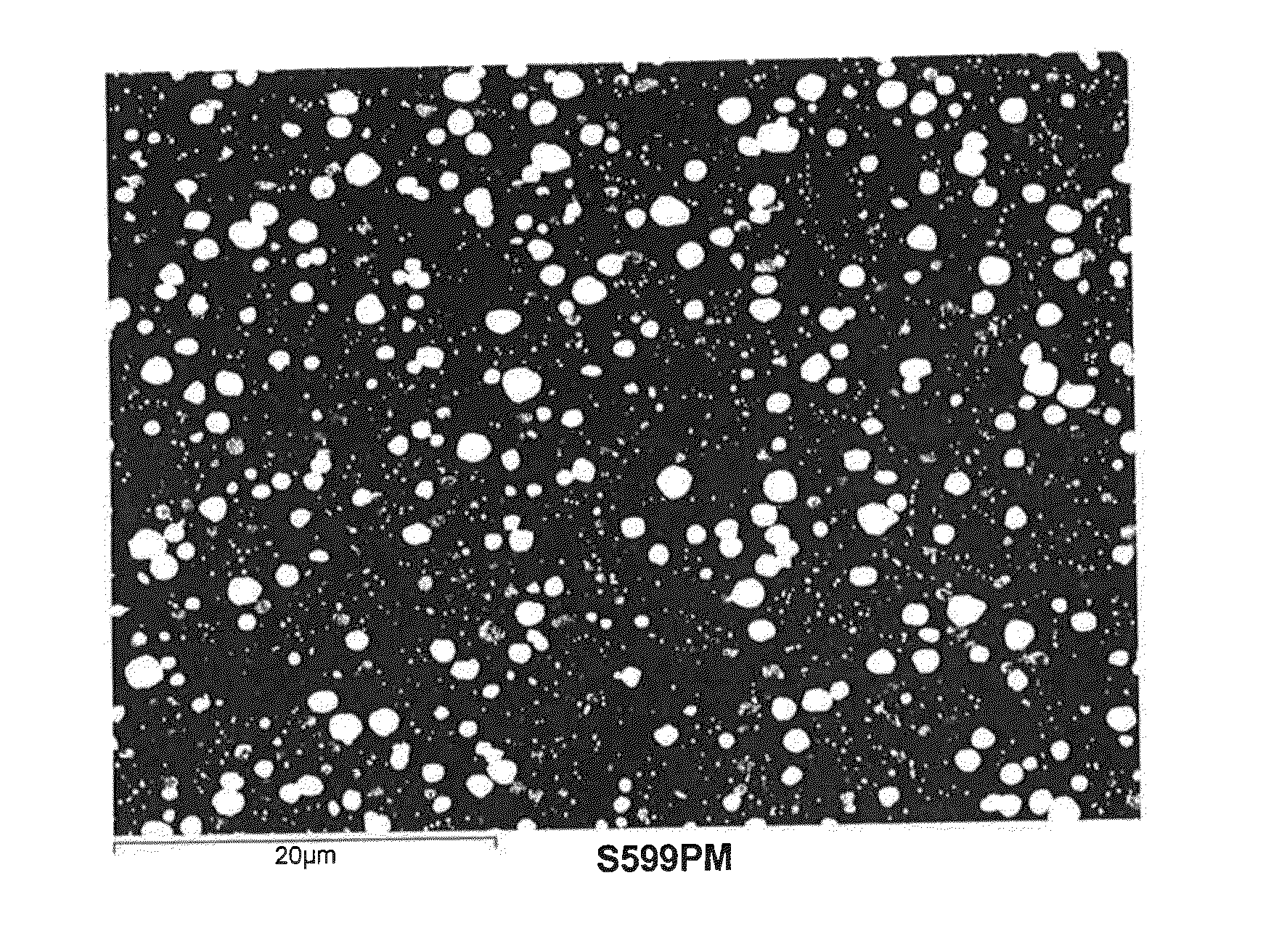

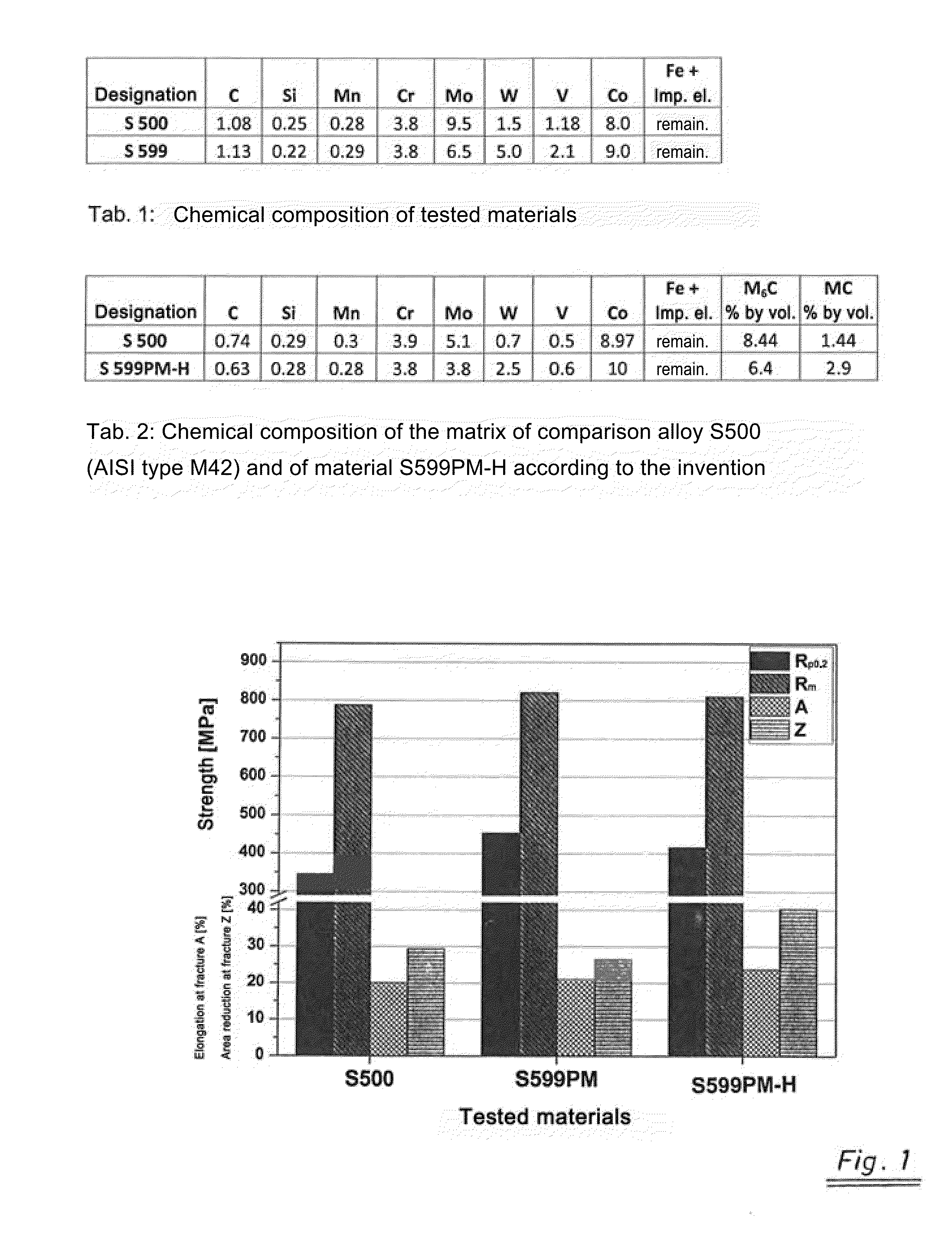

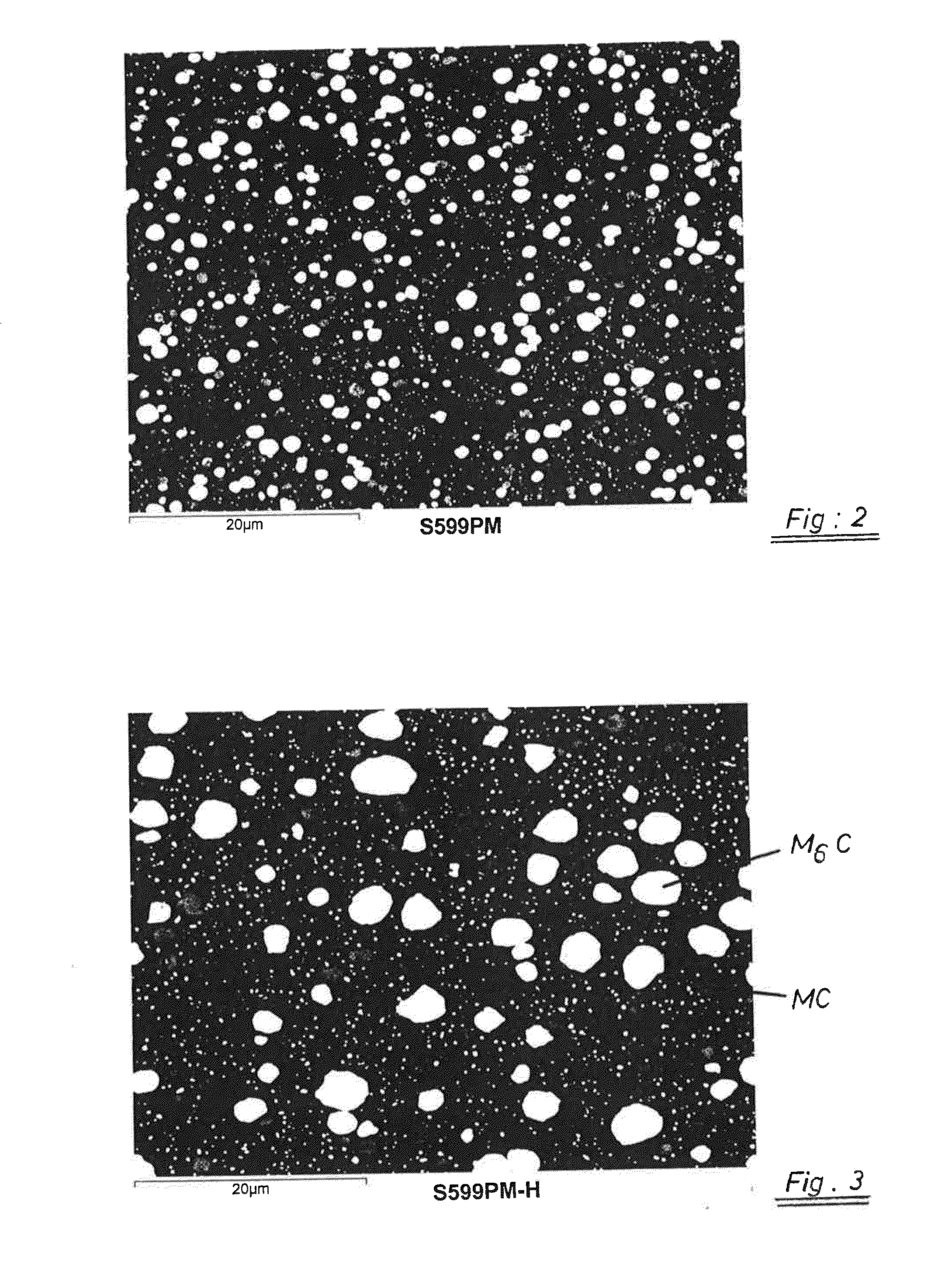

Material with high wear resistance

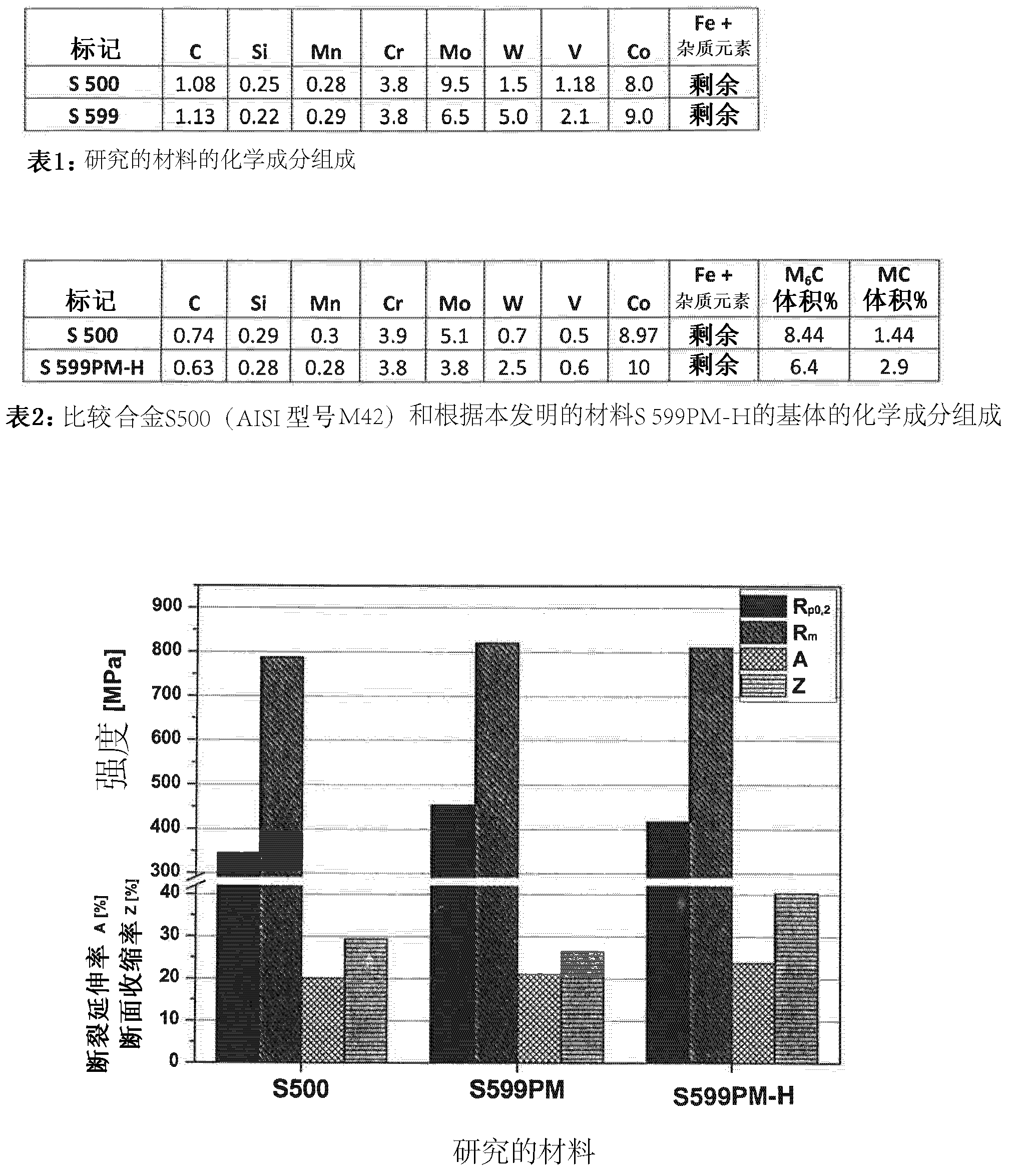

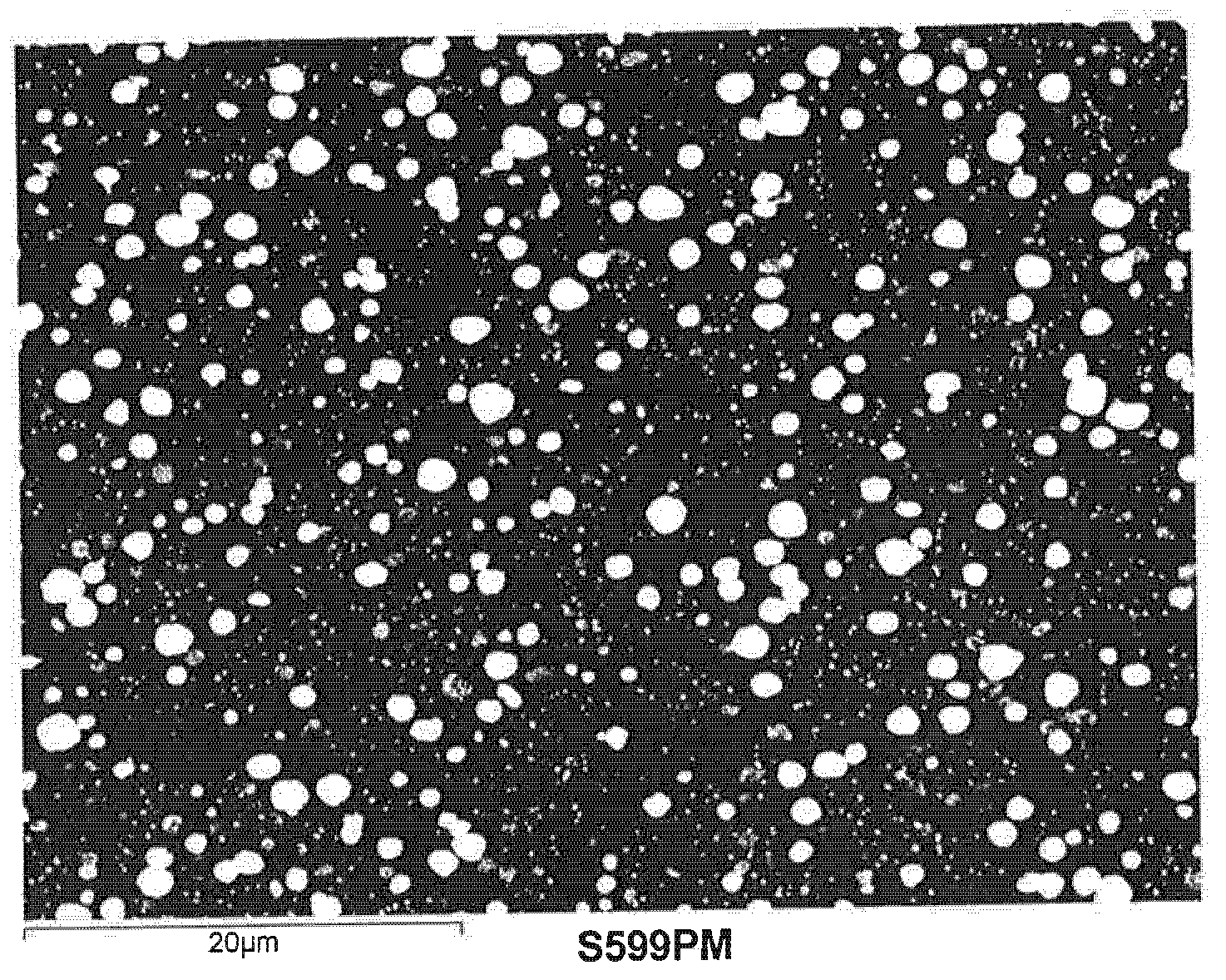

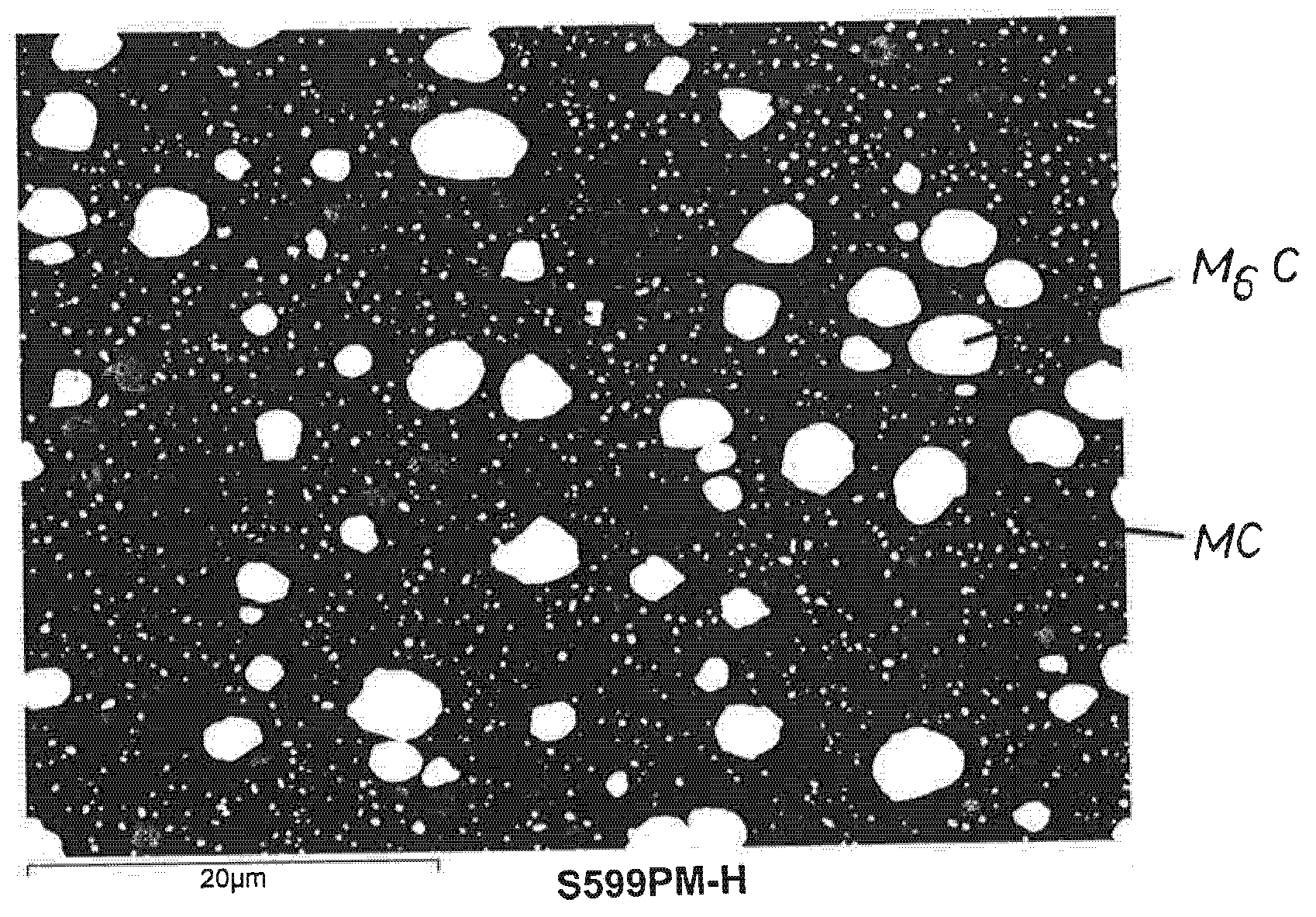

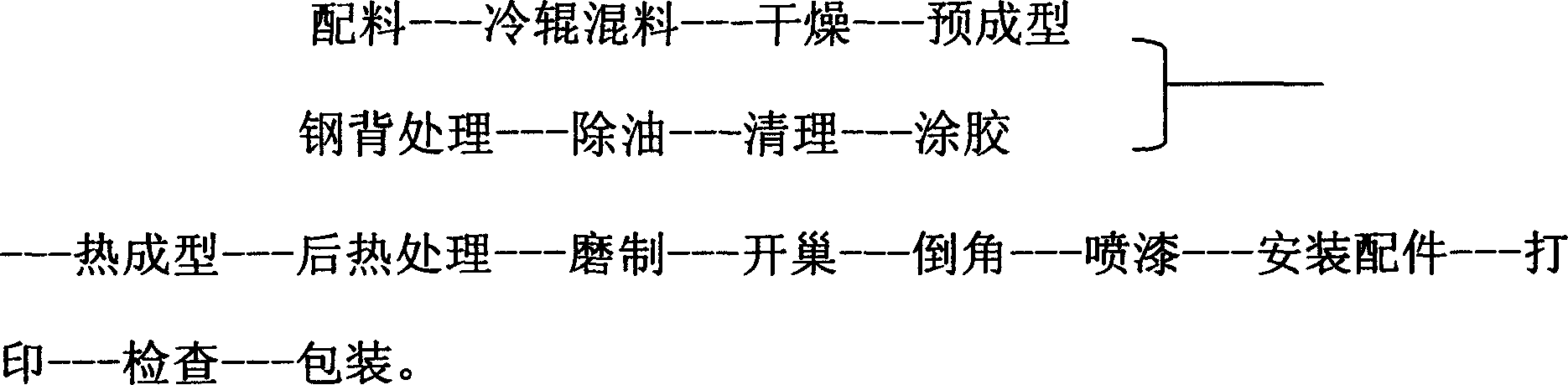

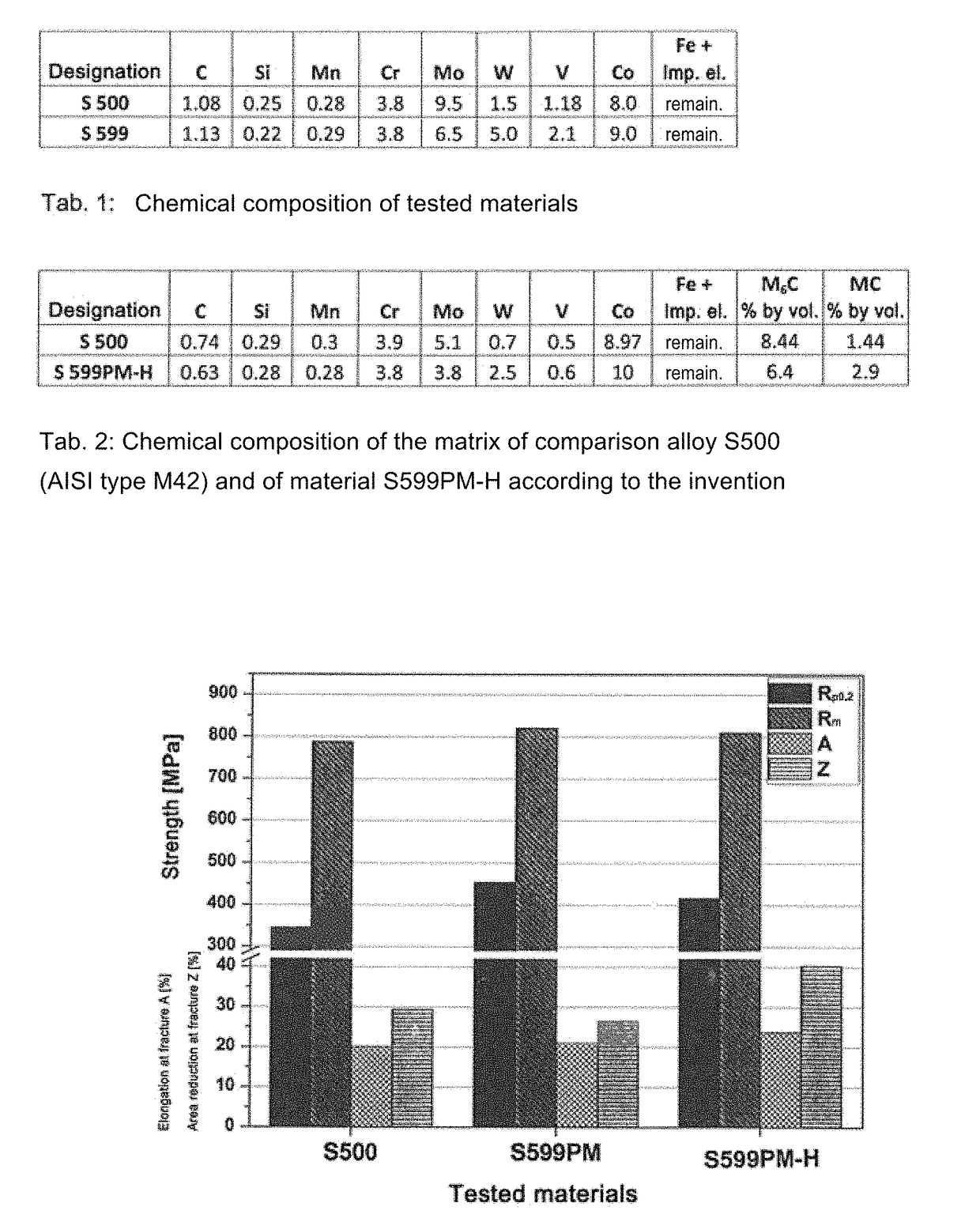

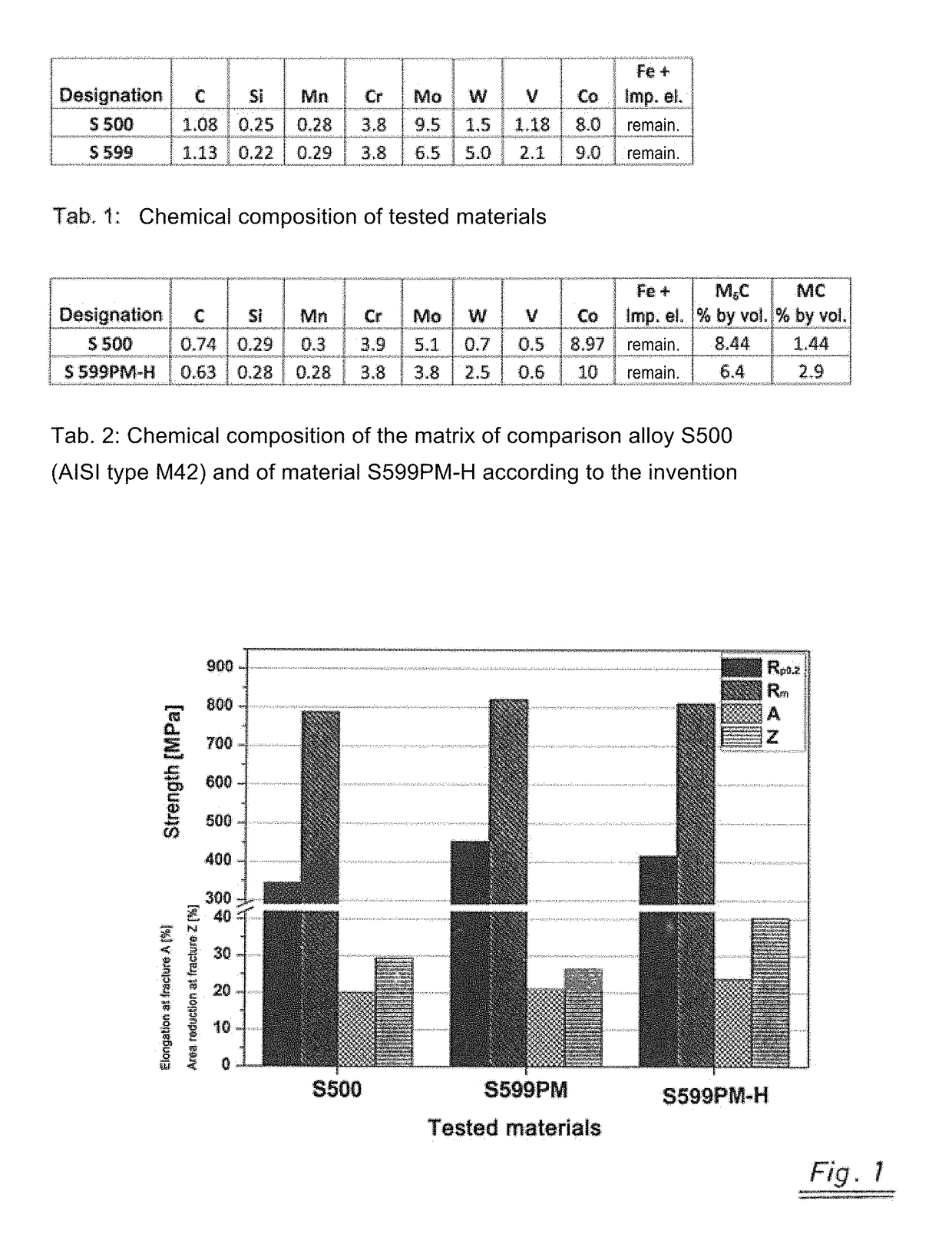

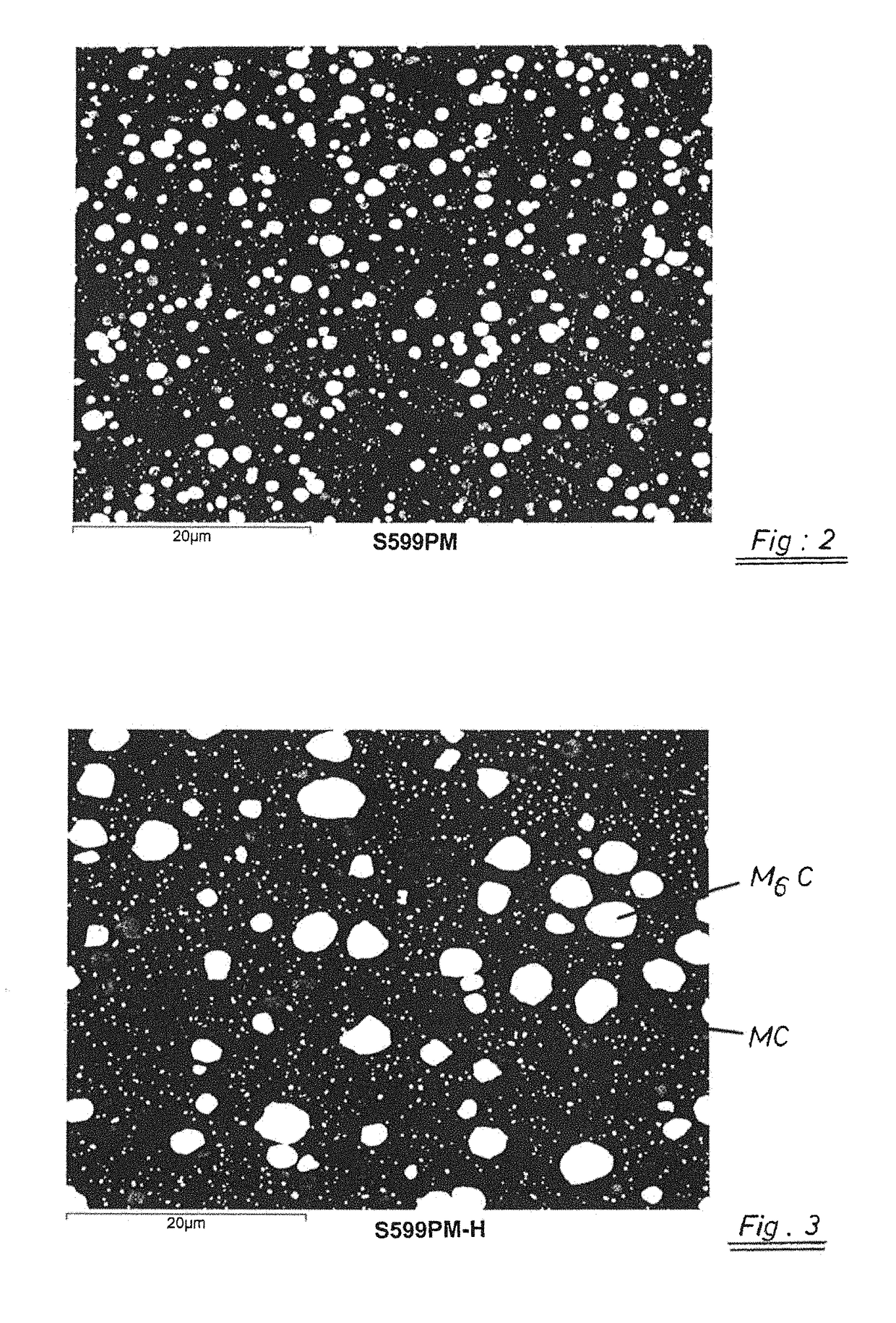

Preparing a material with isotropic, mechanical properties and improved wear resistance and high hardness potential, comprises preparing hot isostatic pressing (HIP) blank or HIP block from a ledeburitic tool steel alloy in a press molding process by spraying a liquid metal alloy with nitrogen to a powder and hot isostatic pressing, heating the HIP block and / or a semi-manufactured product from a coarse-grain, subjecting the HIP block to 10[deg] C below a melting temperature of the lowest melting structural phase, and further processing the blank to thermally treated tools. Preparing a material with isotropic, mechanical properties and improved wear resistance and high hardness potential, comprises preparing hot isostatic pressing (HIP) blank or HIP block from a ledeburitic tool steel alloy in a press molding process by spraying a liquid metal alloy with nitrogen to a powder and hot isostatic pressing, heating the HIP block and / or a semi-manufactured product from a coarse-grain at a temperature of 1100[deg] C, subjecting the HIP block to 10[deg] C below a melting temperature of the lowest melting structural phase with a time period of about 12 hours for increasing average carbide phase size of the material to at least 65%, and further processing the blank to thermally treated tools with high resistance to wear and abrasion. The material has surface in a round shape, and a matrix of the material is homogenized. An independent claim is included for material with isotropic, mechanical properties and improved wear resistance having thermally treated condition at a carbide phase ratio of in M 6C and Mc of 7 vol.%, where the matrix has an average carbide-phase size of 2.8 mm and a carbon concentration of 0.45-0.75 wt.%.

Owner:BAILE SPECIAL STEEL GMBH & CO KG

Hight-performance semi-metal brake sheet material without asbestos

InactiveCN1818003AImprove temperature resistanceIncrease coefficient of frictionOther chemical processesFriction liningFiberBoron nitride

A high-performance semi-metal brake sheet material without asbestos consists of 5-30% ledeburite-phase fortified iron-base alloy powder, 5-20% pure copper powder or bronze powder, 5-25% nanometer budicyan rubber powder, 5-25% modified phenolic resin, 0.5-2% dithiuram sulfide, 0.5-2% tetramethyl trisulfide thiuram improver, 5-20% glass fiber or / and 5-20% steel fiber or / and 1-10% natural bast fiber, 1-10% carbon fiber composite additive, 1-10% nanometer aluminum oxide and other bulking filler, 1-10% flake-shaped graphite, 1-12% zirconium sulfate, 0.3-3% sulfide and 0.5-3% boron nitride. It can endure 350-400 DEG C temperature, its friction coefficient is between 0.35-0.45 and has excellent thermal attenuation performance and long life.

Owner:JIANGYIN POLYTECHNIC COLLEGE

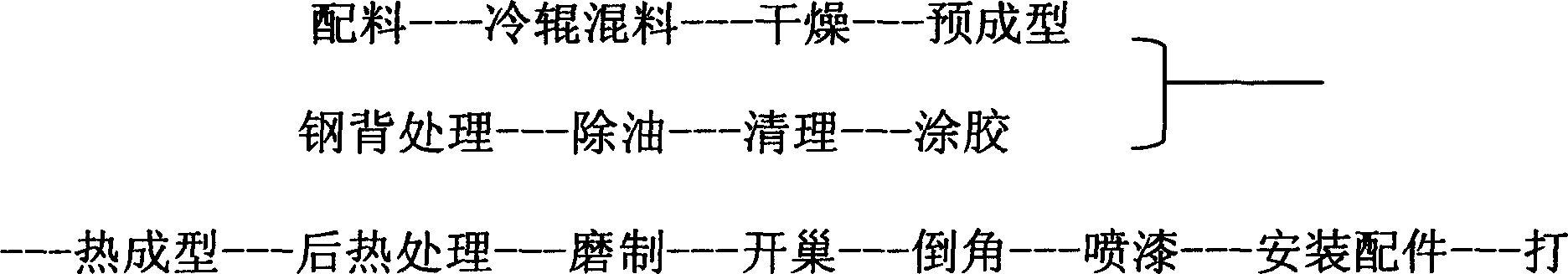

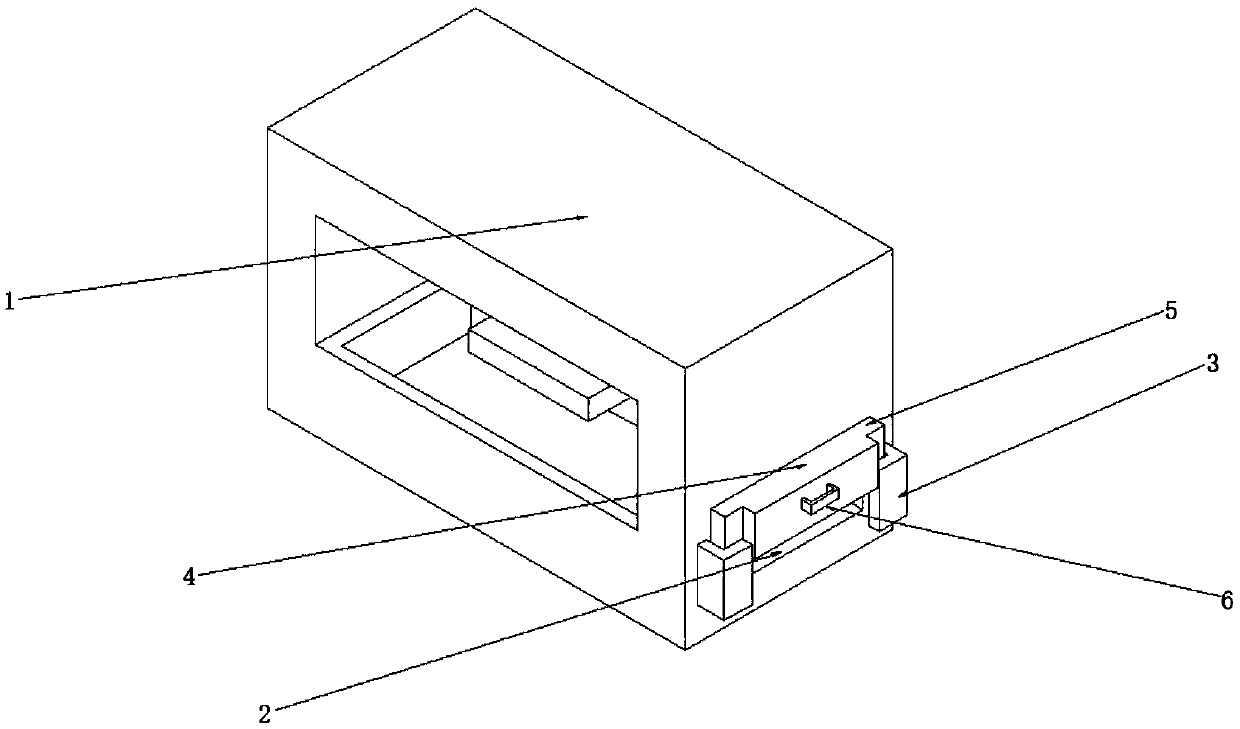

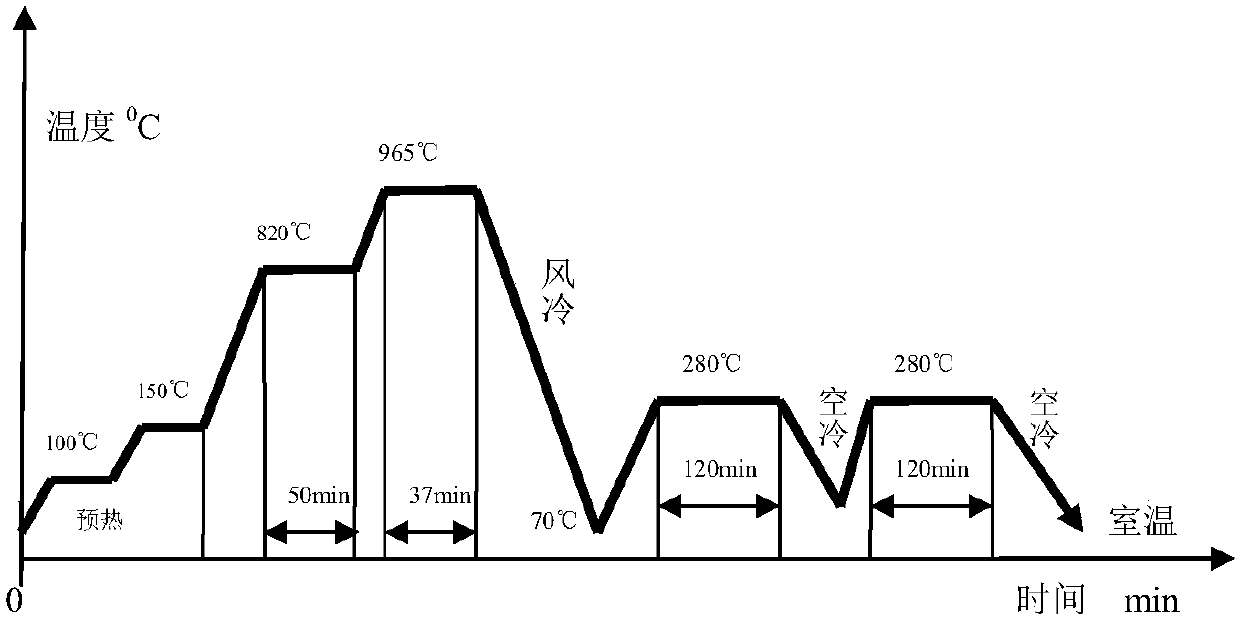

Accurate heat treatment quenching technology of high-carbon high-chromium tool steel precise part

InactiveCN108774675AExtended service lifeImprove mechanical propertiesFurnace typesHeat treatment furnacesHigh carbonLedeburite

The invention provides an accurate heat treatment quenching technology of a high-carbon high-chromium tool steel precise part and belongs to the field of heat treatment of tool steel materials. The accurate heat treatment quenching technology is provided for a two-tool-edge stamping part in a precise stamping die, wherein the material of the part is high-carbon high-chromium ledeburite cold work die steel ASSAB XW-5 imported from Sweden, the main alloy ingredients of the high-carbon high-chromium ledeburite cold work die steel ASSAB XW-5 comprise 2.05% of C, 12.5% of Cr, 1.3% of W, 0.8% of Moand 0.3% of Si. According to the accurate heat treatment quenching technology, based on different workpiece hardness requirements, different tempering temperatures are adopted, so that a small designed hardness difference needed by two tool edges of the precise stamping die can be achieved, different temperature keeping times are adopted for different workpiece thicknesses, so that the hardenability of the material is reliably guaranteed, the crystal structure in the material can be accurately controlled to be refined, uniform and stable, and the part can be good in wear resistance, long in service life, high in reliability and stable in dimension and meets the use demands for a precise part. The accurate heat treatment quenching technology is mainly implemented through the following stepsand technical scheme that (1) workpieces with the thickness difference smaller than 5 mm are placed in a quenching furnace and are preheated to 150 DEG C in two steps; (2) the workpieces are heated to the quenching temperature and keep the temperature for the time of t in two steps in the quenching furnace; (3) the workpieces are discharged from the furnace and air cooled to 50-70 DEG C; (4) theworkpieces are fed into a tempering furnace to be heated to T DEG C for tempering and keep the temperature for the time of t twice, and then the workpieces are discharged from the tempering furnace and air cooled (please refer to the figure 1).

Owner:黄石高校智源技术咨询服务有限公司

Boron cast iron air cylinder sleeve carbon scraping ring coating and preparation and spraying method thereof

InactiveCN106978581AIncrease the amount addedReduce spalling or even failureMaterial nanotechnologyMolten spray coatingCarbon depositCast iron

The invention discloses a boron cast iron air cylinder sleeve carbon scraping ring coating and a preparation and spraying method thereof and belongs to the technical field of improvement of air cylinder sleeves. The boron cast iron air cylinder sleeve carbon scraping ring coating is arranged on the neck of an air cylinder sleeve. The carbon scraping ring coating is a nicr-Cr3C2 composite coating. Nicr alloy has excellent heat resistance, corrosion resistance, high-temperature oxidation resistance and other properties and also achieves a binding phase function. Cr3C2 has good high temperature hardness and high-temperature oxidation resistance and achieves a hard phase function. The component of the air cylinder sleeve is boron cast iron. According to the boron cast iron, boron is added into gray cast iron, and different-amount cast iron containing boron cementite or ledeburite structures can be obtained in a metallographic structure. With increase of the boron content, microhardness is improved, but adding of too much boron can also cause lowering of toughness. Through the boron cast iron air cylinder sleeve carbon scraping ring coating and the preparation and spraying method thereof, the problems that a large number of carbon deposits are very liable to be accumulated on the surface of a piston, and the structure of a carbon scraping ring part is low in hardness and is liable to damage can be solved.

Owner:安徽威龙再制造科技股份有限公司

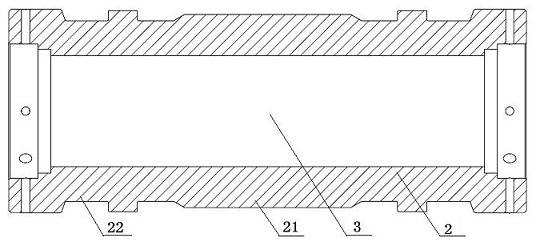

Differential quenching method for large-diameter whole ledeburitic steel cold roll

ActiveCN102041374AOvercomes proneness to crackingLower hardness gradientFurnace typesHeat treatment furnacesWhole bodyLedeburite

The invention relates to a heat treatment method for a ledeburitic steel cold roll, in particular to a differential quenching method for a large-diameter whole ledeburitic steel cold roll, solving the problem that the existing large-diameter whole ledeburitic steel cold roll is easily ruptured after being quenched. The method comprises the following steps: selecting a pre-heat temperature to perform isothermal preheating; quickly heating to a quenching temperature, and preserving the temperature; selecting a cooling temperature to perform isothermal cooling; and cooling in the air, wherein the range of the preheat temperature is more than the critical transition point of complete austenitizing temperature or / and less than the actual quenching temperature 30 DEG C, and the range of the cooling temperature is more than the martensite point and less than the martensite point plus 100 DEG C. In the method, the problem that the existing large-diameter whole ledeburitic steel cold roll is easily cracked after being quenched can be solved through a reasonable design, the whole body is completely quenched and hardened, the hardness of a working layer reaches 60 to 67 HRC, and the hardnessgradient between the cold roll center and the surface layer is less than 10HRC.

Owner:SHANXI BUYEASY MACHINERY MFG

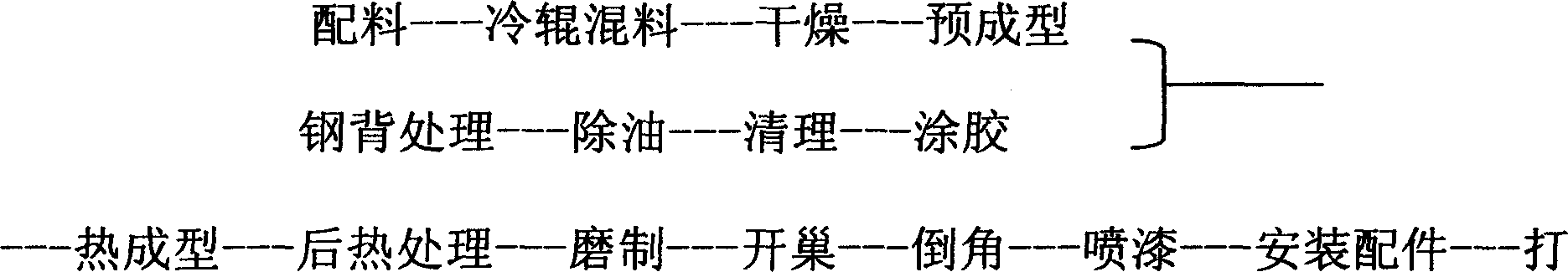

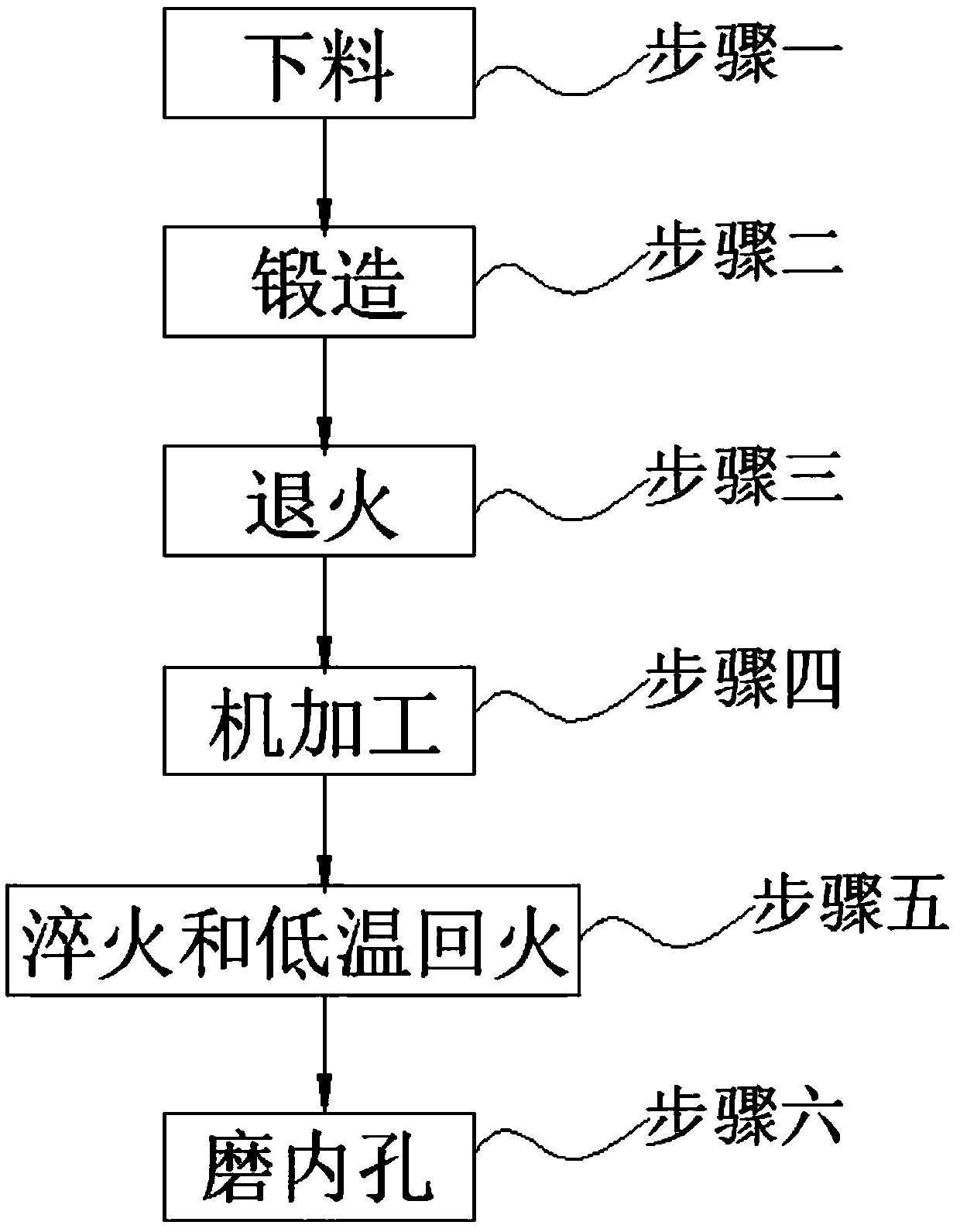

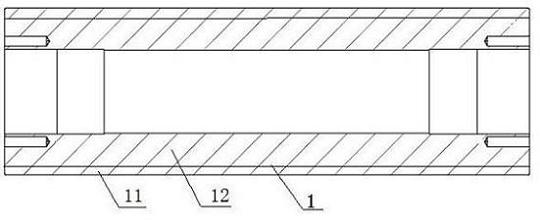

Manufacturing method of high-wear-resistance compression roller shell made of ledeburite steel

ActiveCN111347220AImprove wear resistanceExtended service lifeFurnace typesHeat treatment furnacesTemperingLedeburite

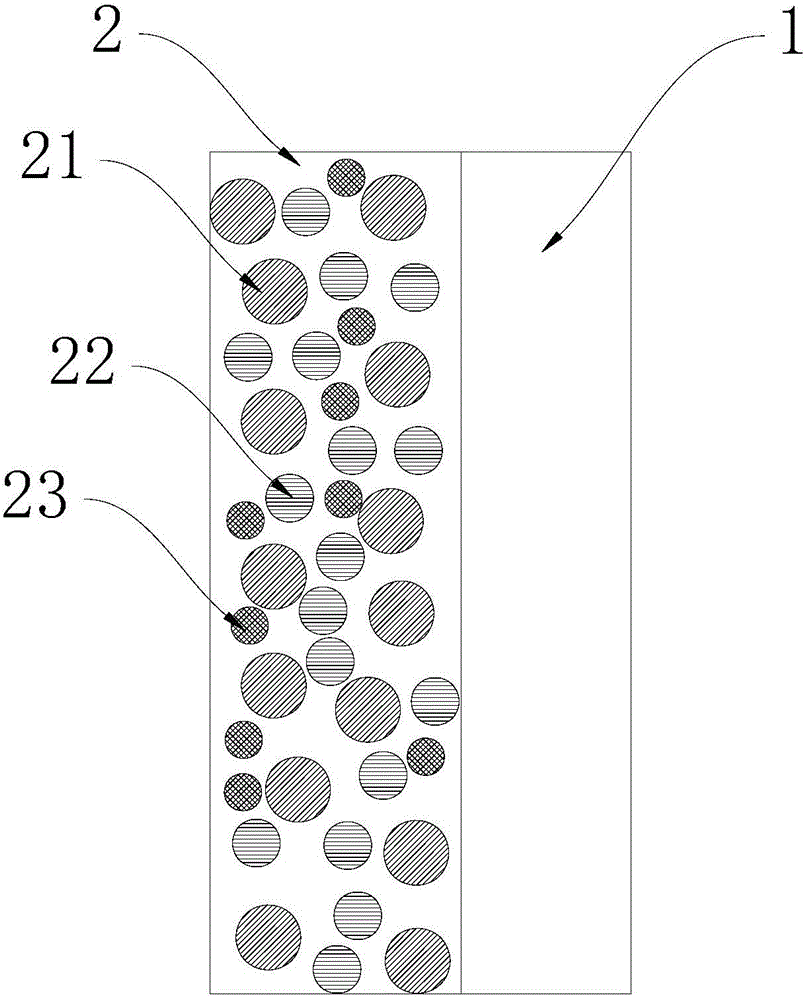

The invention discloses a manufacturing method of a high-wear-resistance compression roller shell made of ledeburite steel. The manufacturing method comprises the following steps of 1, feeding; 2, forging; 3, annealing; 4, machining; 5, quenching and low-temperature tempering; and 6, grinding an inner hole; in the first step, a compression roller shell blank is integrally forged by using the ledeburite steel, and feeding is carried out by using a sawing machine according to the weight required by the process; in the second step, raw materials are heated in a natural gas furnace, sectional heating is adopted, two forging equipment are used for forging, drawing-out and upsetting in three directions are adopted, and the total forging ratio is larger than 8. The method comprises the steps thatthe compression roller shell blank is integrally forged by using the ledeburite steel, quenching and low-temperature tempering heat treatment are carried out after machining; the metallographic structure of a final finished product is tempered martensite, carbide and retained austenite, the carbide comprises eutectic carbide and eutectoid carbide, the wear resistance of a compression roller shellis improved by utilizing the high wear resistance of the eutectic carbide, and the service life of the compression roller shell is prolonged.

Owner:LIYANG JINKUN FORGING & MACHINING

Material with high resistance to wear

Material and method for the production of material with isotropic, mechanical properties and improved wear resistance and high hardness potential. Method includes producing in a powder metallurgical (PM) method a slug or ingot from a material of ledeburite tool steel alloy, and subjecting one of the slug or ingot or a semi-finished product produced from the slug or ingot to full annealing at a temperature of over 1100° C., but at least 10° C. below the fusing temperature of the lowest melting structure phase with a duration of over 12 hrs. In this manner, an average carbide phase size of the material is increased by at least 65%, a surface shape of the material is rounded and a matrix is homogenized. Method further includes subsequently processing the material into thermally tempered tools with high wear resistance occurs or into parts to which abrasive stress is applied.

Owner:BOHLER EDELSTAHL GMBH & CO KG

Powder metallurgical tool steel for automobile separation shifting fork

InactiveCN105886931AHigh strengthHigh surface hardnessTransportation and packagingMetal-working apparatusAlloyCopper sulfide

The invention discloses powder metallurgical tool steel for an automobile separation shifting fork. The tool steel is prepared from the following raw materials weighed in parts by weight: 75 to 78 parts of iron powder, 20 to 25 parts of 316L austenitic stainless steel powder, 1 to 2 parts of diboron trioxide, 0.2 to 0.4 part of chromium powder, 0.005 to 0.01 part of cerium oxide, 0.2 to 0.6 part of copper sulfide, 0.2 to 0.4 part of molybdenum powder, 0.2 to 0.4 part of nickel powder, 0.2 to 0.4 part of zircon powder, 0.002 to 0.003 part of strontium powder, 0.001 to 0.002 part of germanium disulfide and 0.45 to 0.5 part of a polymerizing agent. According to the powder metallurgical tool steel disclosed by the invention, cementite and high-temperature ledeburite are formed inside a material during the processing; meanwhile, some crystal lattices inside the material are distorted, so the strength of alloy is greatly enhanced; moreover, nitrogen atoms penetrate into the surface of the material, so the surface hardness and the wear resistance are improved; meanwhile, the fatigue strength, the corrosion resistance and the impact resistance are also improved; the automobile separation shifting fork manufactured from the material are resistant to corrosion and impact for a long time, and the service life is greatly prolonged.

Owner:CHANGLI FORGING

Novel anti-attrition and wear resistant cast iron and preparation method thereof

InactiveCN109182889AWear resistanceEasy to prepareProcess efficiency improvementWear resistantLedeburite

The invention relates to the technical field of cast alloy iron, in particular to novel anti-attrition and wear resistant cast iron and a preparation method thereof. The novel anti-attrition and wearresistant cast iron is prepared from the following components in percent by mass: 2.8-3.8% of C, 1.8-3.0% of Si, 0.5-2.0% of Mn, 0.3-0.8% of P, 1.2-3.0% of Cr, 0.4-2.0% of Ni, 0.1-1.0% of Mo, 0.2-2.0%of V, 0.5-3.0% of Cu, 0.1-0.5% of Ti, less than or equal to 0.08% of S and the balance Fe. Based on common cast iron components, various alloy elements are added, so that the tissues of the cast ironcontain fine ledeburite eutectic alloys. By adding phosphorus, binary and ternary phosphorus eutectic tissues exist. The eutectic tissues form grid frameworks in the cast iron and the frames are distributed in a pearlite matrix to play an anti-attribution role. Fine flake graphite in the grids can form oil storage holes, thereby playing the anti-wear role.

Owner:TIANJIN LILIN BIT

Ledeburite cast iron with a high carbide content and an evenly distributed graphite embodiment

Owner:FEDERAL MOGUL FRIEDBERG

Heat treatment and quenching process for high-carbon high-chromium tool steel

InactiveCN107739783AExtended service lifeImprove mechanical propertiesHigh carbonMechanical property

The invention discloses a heat treatment and quenching process for high-carbon high-chromium tool steel. The material is high-carbon high-chromium ledeburite cold-worked tool steel with the steel number of ASSAB XW-5 imported from Sweden, and the tool steel mainly comprises, by weight percentage, 2.05% of carbon, 12.5% of chromium, 1.3% of wolfram, 0.8% of molybdenum and 0.3% of silicon. The heattreatment and quenching process comprises the following steps that (1), workpieces are put into a quenching furnace to be preheated to 150 DEG C; (2), the workpieces are put into the quenching furnacefor two-stage heating until the quenching temperature is 965 DEG C, and then heat preservation is carried out; (3), the workpieces are taken out from the quenching furnace for air-blast quenching until the temperature is 70 DEG C; and (4) the workpieces are placed into a tempering furnace, the workpieces are heated to 280 DEG C, heat preservation and tempering are carried out on the workpieces, the workpieces are taken out from the tempering furnace for air cooling, and then the above procedures in the step (4) is repeated. According to the heat treatment and quenching process, staged heatingand twice tempering are adopted, and therefore the heating is more uniform, the hardenability of the workpieces is improved, the crystal grains can be refined, uniform, stable and reliable, the service life and the mechanical property of the parts are obviously improved, the toughness and the impact resistance of the workpieces are improved, and the use requirements of the precise parts are met.

Owner:HUBEI ENG INST

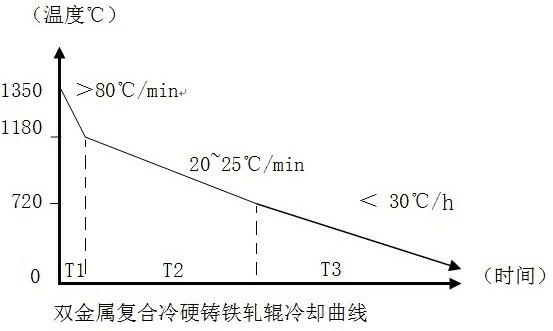

Manufacturing method of double-metal composite chilled cast-iron roll

The invention discloses a manufacturing method of a double-metal composite chilled cast-iron roll. The manufacturing method comprises the following procedures of: smelting an outer-layer chilled cast-iron wear-resistant material and an inner-layer support ash-iron material, centrifugally casting a mold for preparation, centrifugally casting, cooling and demolding for taking a product; a matrix organization structure of the outer-layer chilled cast-iron wear-resistant material is as follows: the content of carbide is 40-50%, the content of pearlite is 40-50%, and the content of ledeburite is 0-20%; and the cooling speed in centrifugal casting is as follows: the cooling speed at an interval with the temperature drop from 1350 DEG C to 1180 DEG C is controlled to be higher than 80 DEG C / min,the cooling speed at an interval with the temperature drop from 1180 DEG C to 720 DEG C is 20-25 DEG C / min, and the cooling speed at an interval with the temperature drop from 720 DEG C to normal temperature is controlled to be lower than 30 DEG C / min. The manufacturing method disclosed by the invention has the advantages that for the outer-layer material of the roll manufactured by utilizing themethod, the crystalline grain is thinner and uniform, the hardness change of a roll body is smaller along the radial direction and the axial direction; and the tensile strength is strong, the wear resistance is good and the service life is long.

Owner:WUXI BUHLER MASCH MFG CO LTD

Forging process for ledeburite steel shaft

The invention belongs to the technical filed of ledeburite steel shaft machining and relates to a forging process for a ledeburite steel shaft. The process includes the following steps that firstly, a blank is selected and rough-machined, and a shaft blank is obtained; secondly, the shaft blank is put into a heating furnace to be preheated and subjected to heat preservation; thirdly, the preheated shaft is put into the furnace to be subjected to primary heating, then subjected to primary heat preservation and then subjected to upsetting; fourthly, the upset shaft is subjected to secondary heating and then the subjected to secondary heat preservation, then the shaft is drawn out, and the drawing-out ratio ranges from 5 to 7; and fifthly, the drawn-out shaft is subjected to tertiary heating and then subjected to tertiary heat preservation, the shaft is air-cooled to the room temperature after being discharged from the furnace, and normalizing treatment is conducted. The ledeburite steel shaft manufactured through the forging process is small in carbide segregation and uniform in distribution; no crack is generated, and the quality of the product is good; and grains cannot grow up anew, carbide cannot gather, and use performance is good.

Owner:ANHUI RUIJIE FORGING

Ledeburite malleable cast iron with high tenacity

InactiveCN107541643ANovel componentsThe production process is reasonable and clearSolid state diffusion coatingStress concentrationLedeburite

The ledeburite malleable cast iron with high toughness belongs to the field of casting technology. It is composed of the following raw materials in mass percentage, C 0.07%, Si 0.25%, Mn 0.2%, S 0.01%, P 0.02%, Cr 2.2%, Mo 1.2%, V 0.65%, Nb 0.12%, RE 0.08%, Ni 0.14%, W 0.36%; the rest is Fe and impurities. The composition of the invention is novel, the service life is greatly improved, the use cost is greatly reduced, the use range is expanded, and the large impact load can be effectively solved. Surface carburizing treatment is carried out on it, and surface quenching treatment is carried out after carburizing, and its toughness and fatigue strength have been greatly improved. The stress on the surface is reduced, and the service life of malleable cast iron has been greatly improved, which meets the needs of various stress concentrations and high impact loads.

Owner:田静

A kind of preparation method of high-speed tool steel

The invention relates to the field of hot processing of steel, and to a method for preparing high-speed tool steel. A method for preparing high-speed tool steel, which method includes the following process steps: 1) heating the ledeburite high-speed tool steel billet material to be processed to the liquidus line T L above, to completely melt it; 2) Cool the material to T L ~T S Insulate the solid-liquid two-phase zone between them to obtain a semi-solid structure with a solid phase ratio of more than 70%; 3) Deform the material in the solid-liquid two-phase zone with a forging ratio of more than 1.5; 4) Cool the material to the solidus line T S At the following temperatures, continue to implement deformation with a forging ratio of 1.5 or more, and it will be obtained. By implementing deformation in the solid-liquid two-phase region, the present invention can effectively break dendrites formed during the solidification process of high-speed tool steel, reduce dendrite segregation, inhibit the precipitation of liquid carbides, achieve a homogenized structure, and improve comprehensive mechanical properties. , the purpose of extending service life.

Owner:NORTHEASTERN UNIV LIAONING

High-hardness and high-abrasion-resistance high tungsten ledeburite gear steel and preparation method thereof

InactiveCN107435124AExtended service lifeImprove internal mechanical propertiesFurnace typesProcess efficiency improvementLedeburiteWear resistance

The invention discloses a high-hardness and high-abrasion-resistance high tungsten ledeburite gear steel and a preparation method thereof and belongs to the technical field of powder metallurgy. The high-hardness and high-abrasion-resistance high tungsten ledeburite gear steel is composed of the following raw materials of, by mass, 1. 8% of C, 0.5% of Si, 0.25% of Mn, 0.015% of S, 0.025% of P, 2.5% of Cr, 1.25% of Mo, 0.8% of V, 0.16% of Nb, 0.05% of Re, 0.12% of Ni, 0.30% of W and the balance Fe and impurities. The high-hardness and high-abrasion-resistance high tungsten ledeburite gear steel can replace cold working die steel such as Cr12MoV steel and D2 steel, the toughness and abrasion resistance of a die are improved, the service life is greatly prolonged so as to reduce the use cost and expand the use range, the problems of poor toughness, tipping or breaking and poor abrasion resistance under special use environments such as the large impact load, the high working speed, high precision and the long life can be effectively solved, and the use requirements of multiple high bearing and high rotating speed occasions are met.

Owner:鲍凡凡

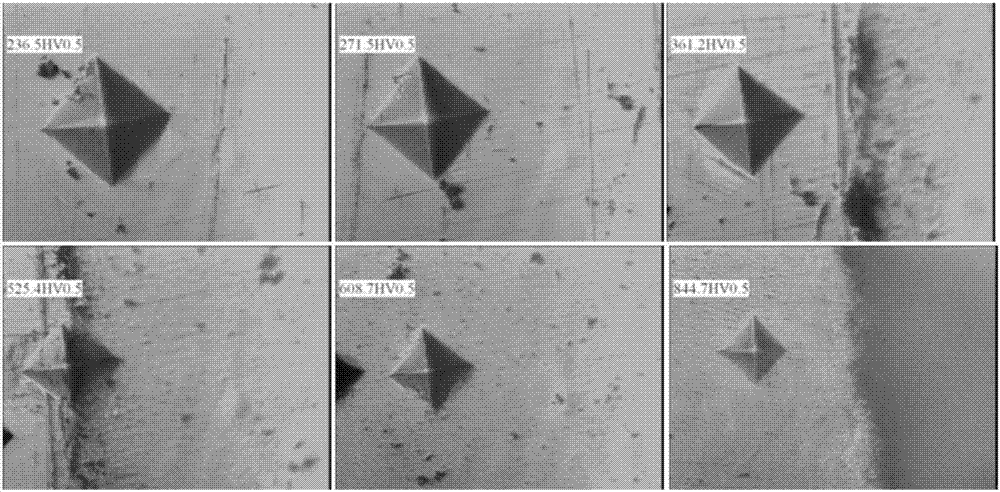

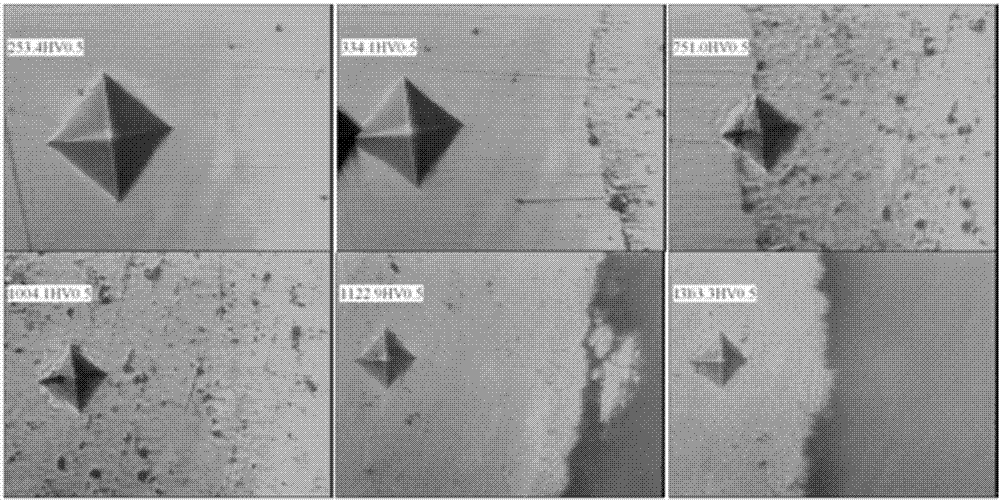

Abrasion-resistant alloy cast iron

The invention discloses abrasion-resistant alloy cast iron, comprising the following components in percentage by weight: 3.1-3.5% of carbon, 1.9-2.5% of silicon, 0.4-0.9% of copper, 0.4-0.6% of manganese, 0.2-0.4% of chromium, 0.1-0.4% of molybdenum, 0.1-0.15% of sulphur, 0.1-0.15% of phosphorus, 0.05-0.2% of vanadium, 0.04-0.07% of boron, and the balance of iron and impurities. Different numbers of cast iron of boron-containing cementite or ledebrite structures in a metallographic structure can be obtained. The micro-hardness of the boron-containing cementite is HV960-1280. The alloy cast iron disclosed by the invention has a special abrasion-resistant structure and the abrasion resistance is greatly improved.

Owner:广东扬山联合精密制造股份有限公司

Camshaft argon arc remelting production and machining process

The invention discloses a camshaft argon arc remelting production and machining process. The camshaft machining process includes the following steps that a strip round material is placed on a punch to be cut off; the cut-off round material is placed in a heating device to be preheated, and the round material is heated to 900 DEG C to 1000 DEG C in an induction mode, wherein the heating rate ranges from 70 DEG C / s to 80 DEG C / s; then a preheated camshaft is heated to 1000 DEG C to 1200 DEG C in an induction mode, wherein the heating rate ranges from 50 DEG C / s to 60 DEG C / s; thermal refining is conducted, and hardness is made to range from 28 HRC to 30 HRC; the heated material is placed in a forming die, and the material is formed through punch forging; then under the arc high-temperature effect, tiny molten pools are formed on the surface of a cam through protection of argon laminar flow, after arc transfer, the molten pools are chilled through heat absorption of a workpiece, fine ledeburite tissue is obtained, and turning and deburring are conducted. The grains of the camshaft are fine, abrasion resistance of the camshaft is higher than that of chilled cast iron, mechanization is easy to achieve, quality is stable, the rejection rate is low, and cost is low.

Owner:ANQING JIAN AUTO PART FORGING & ROLLING

Material with high resistance to wear

Owner:BOHLER EDELSTAHL GMBH & CO KG

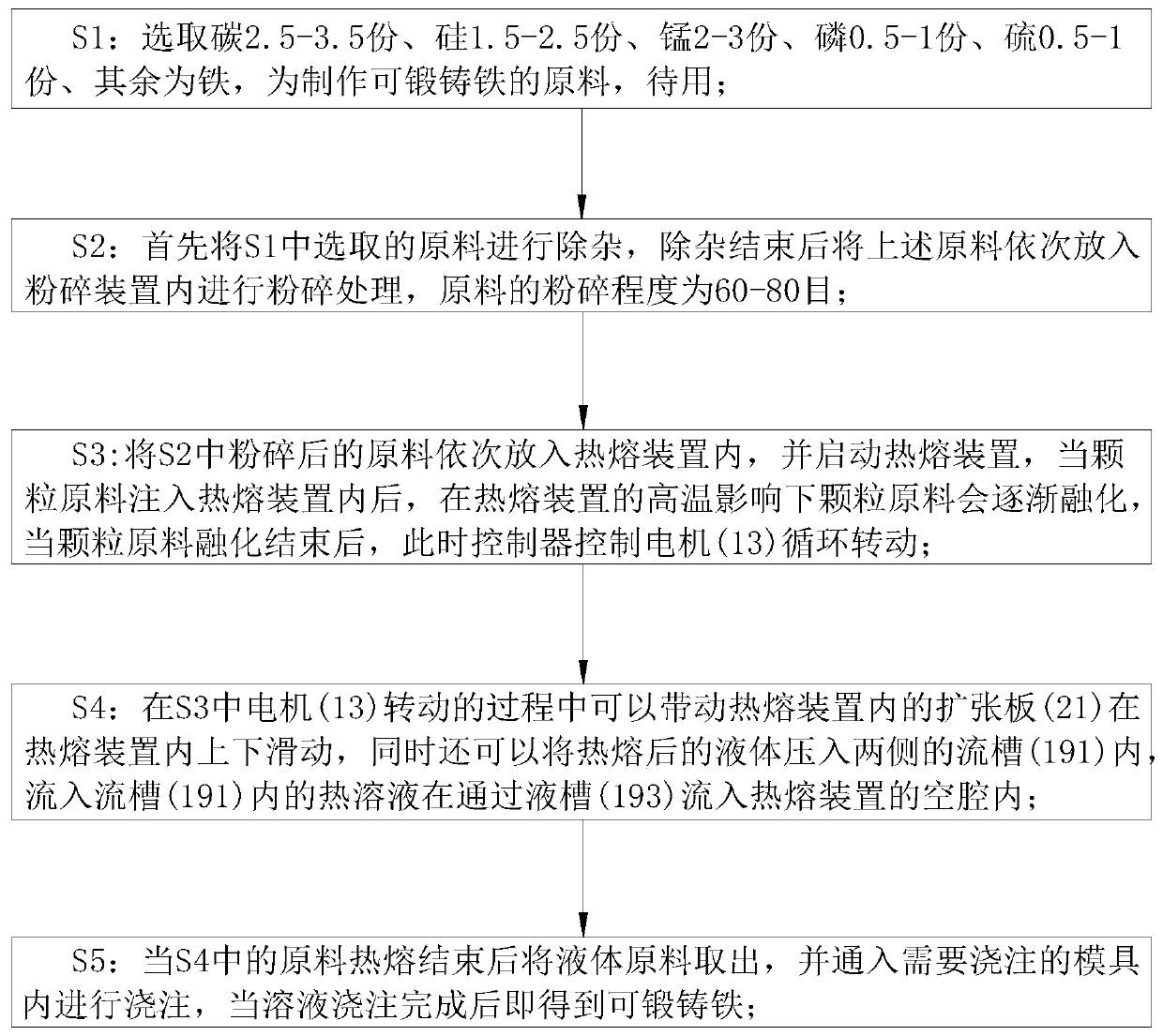

High-toughness ledeburite malleable cast iron

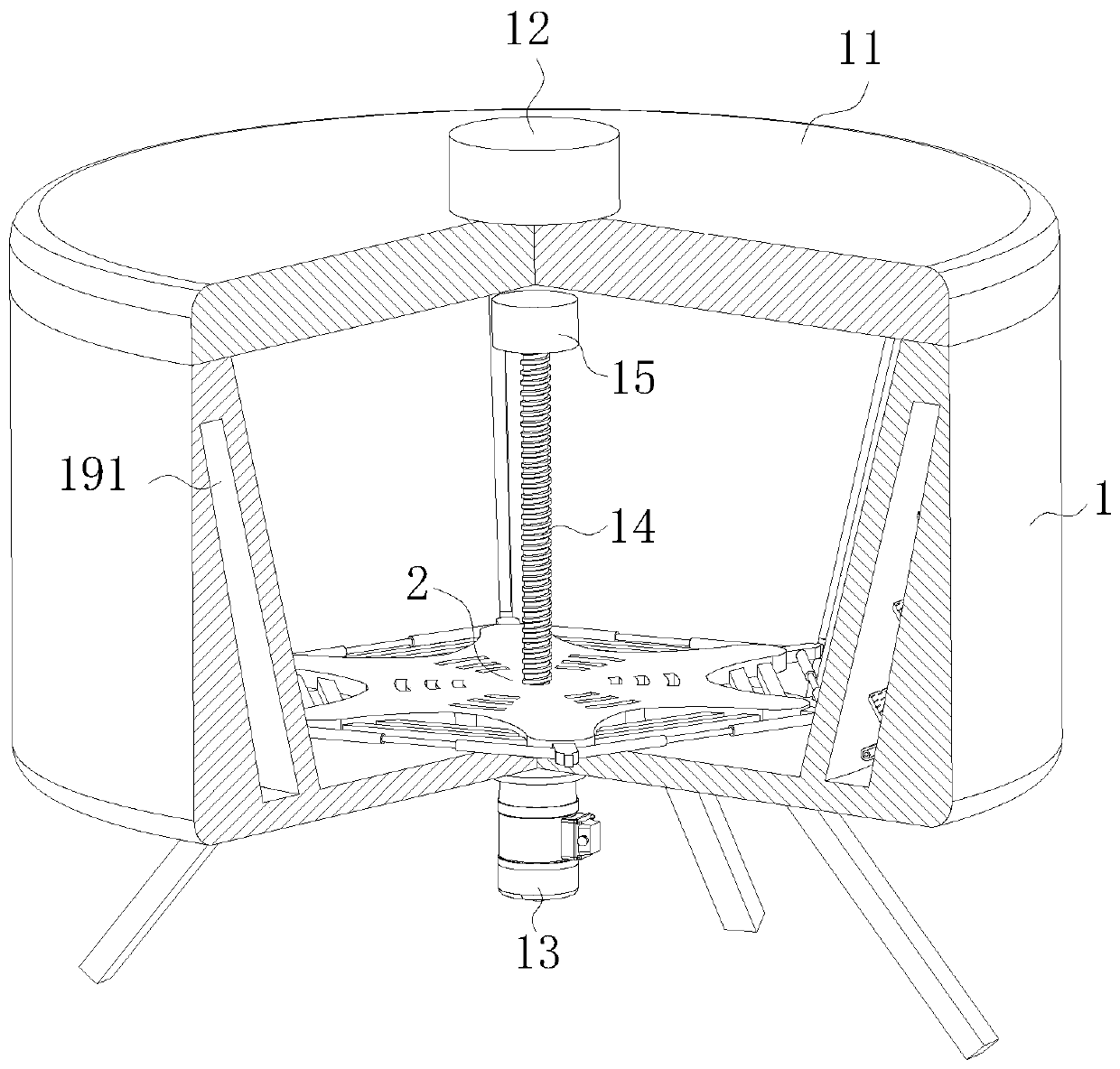

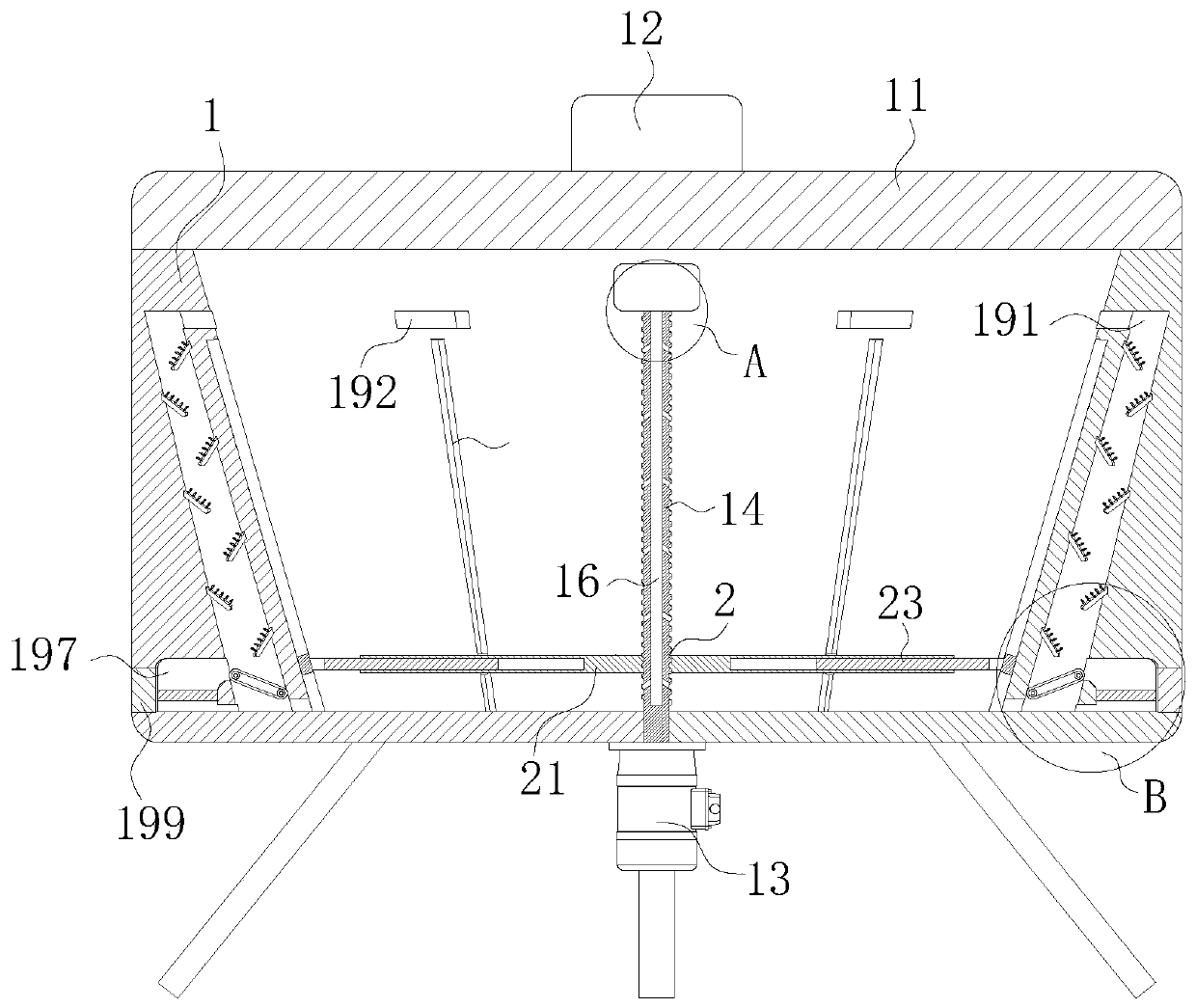

The invention belongs to the technical field of malleable cast iron, and particularly relates to high-toughness ledeburite malleable cast iron. The hot melting device comprises a hot melting box and an impurity removing mechanism; a box cover is mounted on the top end surface of the hot melting box; a supercharger is installed on the upper surface of the box cover and electrically connected with the controller through a wire; a cavity in the hot melting box is designed to be inclined; and the bottom end surface of the hot melting box is fixedly connected with a motor; a lead screw is fixedly connected to a driving shaft of the motor. The device is mainly used for solving the problems that according to an existing hot melting device, a raw material is usually placed in the hot melting device for hot melting, then gas doped in a raw material is exhausted in a stirring mode, however, the gas doped in a raw material cannot be completely exhausted in the mode, a cavity exists in poured malleable cast iron, and the casting quality of the malleable cast iron is influenced; and meanwhile, impurities in molten iron need to be manually removed in the hot melting process of the raw material,so that a certain danger is caused to workers, and meanwhile, the impurities are not thoroughly removed.

Owner:山东惠宇汽车零部件有限公司 +1

Ledeburite steel compression roller shell with high wear resistance

The invention discloses a ledeburite steel compression roller shell with high wear resistance. The raw material of the compression roller shell is ledeburite steel, the ledeburite steel comprises thefollowing components of, in percentage by weight, 1.2%-2.3% of carbon, 3.5%-13% of chromium and the balance silicon, manganese, iron, molybdenum, vanadium, tungsten and impurity elements; representative marks of the ledeburite steel include Cr8, Cr12, Cr5Mo1V, Cr12W, Cr12MoV and Cr12Mo1V1 in GB / T1299-2014; tempered martensite, carbides and retained austenite exist in the metallographic structure of the ledeburite steel compression roller shell; and the carbides comprise eutectic carbides and eutectoid carbides. According to the ledeburite steel compression roller shell, the high wear resistance of the eutectic carbides is utilized to enhance the wear resistance of the compression roller shell, so that the service life of the compression roller shell is prolonged.

Owner:LIYANG JINKUN FORGING & MACHINING

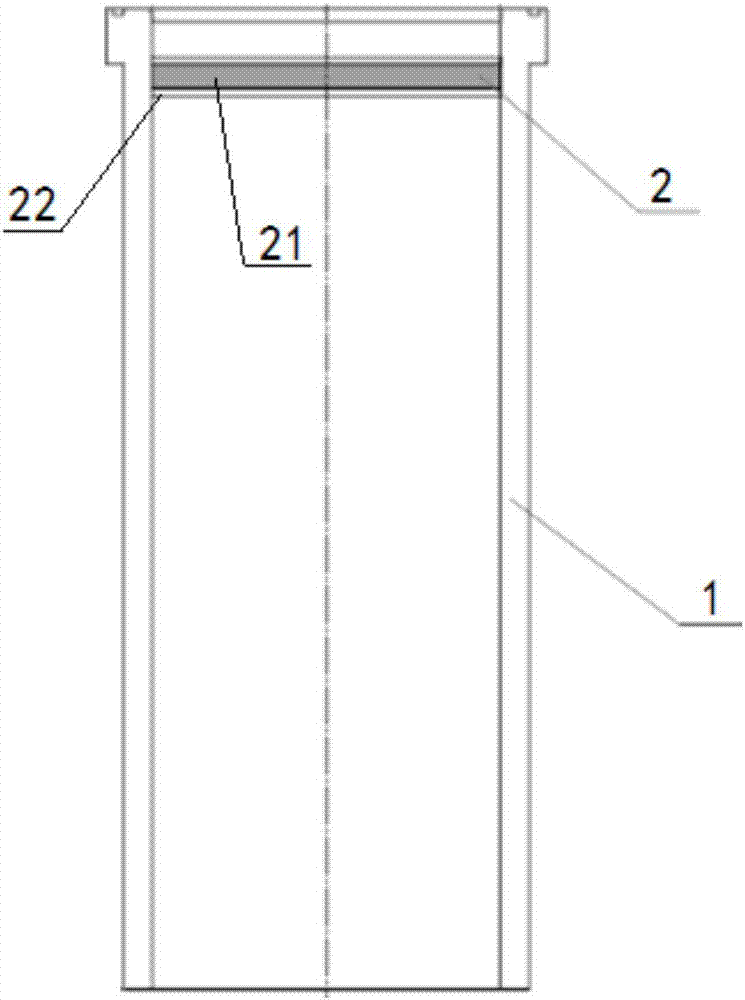

Surface micro-melting treated cylinder jacket and preparation method thereof

The invention belongs to the technical field of cylinder jackets and specifically relates to a method for treating a cylinder jacket by virtue of surface micro-melting. According to the method, the outer circular surface of the cylinder jacket finished product is scanned by use of a laser beam or a plasma beam; the power density of the laser beam or the plasma beam is within the range of 14.5-21KW / cm2, and the scanning speed is within the range of 28-36mm / s; after finishing scanning, the temperature is just reduced to the room temperature by virtue of natural cooling. The outer circular surface of the cylinder sleeve finished product is most of a perlite structure having the hardness of 220-260HB; after the micro-melting treatment, the surface is formed into a ledeburite structure or mixed ledeburite and trace martensite structures, and the hardness of the surface is remarkably improved and can be within the range of 470-480HB (approximately above 49HRC).

Owner:ZYNP GRP

Spinneret device for spinning machine

The invention relates to a spinneret device for a spinning machine.Wire guide holes are formed in the spinneret device.The spinneret device for the spinning machine is characterized by comprising a body and an inorganic polymer anti-corrosive coating layer fixedly arranged on the body, wherein the body is composed of a ledeburite portion, a tempered martensite portion and a widmanstatten structure portion, and the inorganic polymer anti-corrosive coating layer is made of a nano-plating toughened membrane.The body is prepared from, by weight, 50-100 parts of ledeburite portion, 30-40 parts of tempered martensite portion and 10-20 parts of widmanstatten structure portion, and preferably, the body is prepared from, by weight, 50 parts of ledeburite portion, 40 parts of tempered martensite portion and 10 parts of widmanstatten structure portion.The spinneret device for the spinning machine cannot be contaminated with grease, and therefore the situation that shutdown maintenance operation is conducted in order to remove oil and grease is avoided.

Owner:CHANGSHU SUHONG MACHINERY

A laser repair method for the surface of ball-ground cast iron

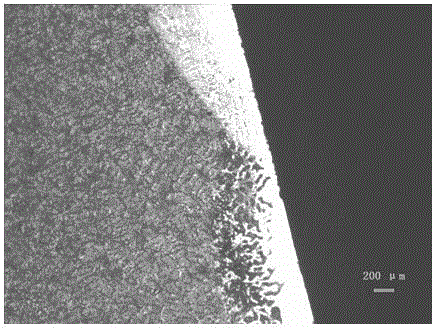

ActiveCN105177569BNo crack defectLittle thermal impactMetallic material coating processesLedeburiteDuctile iron

The invention provides a method for laser repairing the surface of spheroidal cast iron, comprising the following steps: 1) preparing powder material for laser repairing spheroidal cast iron; 2) pretreating the area to be clad; 3) preheating the base material; 4) Multi-layer cladding is carried out on the damaged part of the surface of the spheroidal cast iron. The single layer thickness of the cladding layer is 1.2-1.3mm. 2mm; 5) After cladding, the nodular cast iron is cooled to room temperature, and the colorant is sprayed to check whether there are crack defects; 6) The cladding repair layer of the nodular cast iron is machined to remove the protruding coating on the outer surface of the damaged part. The cladding area formed by this method has no crack defects and has little thermal influence on the base material. The interface between the cladding layer and the ductile cast iron base material shows a discontinuous melting trend, and the interface is a typical jagged shape. The bonding strength is high and the interface is avoided. Cracks occur due to the formation of continuously transformed ledeburite.

Owner:WUHAN HGLASER ENG CO LTD

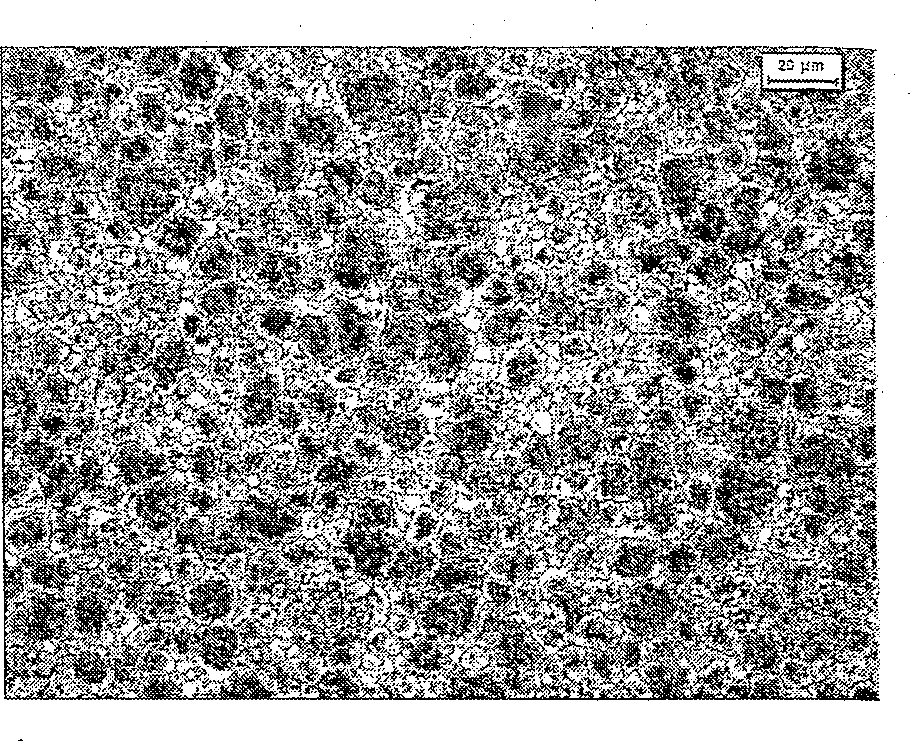

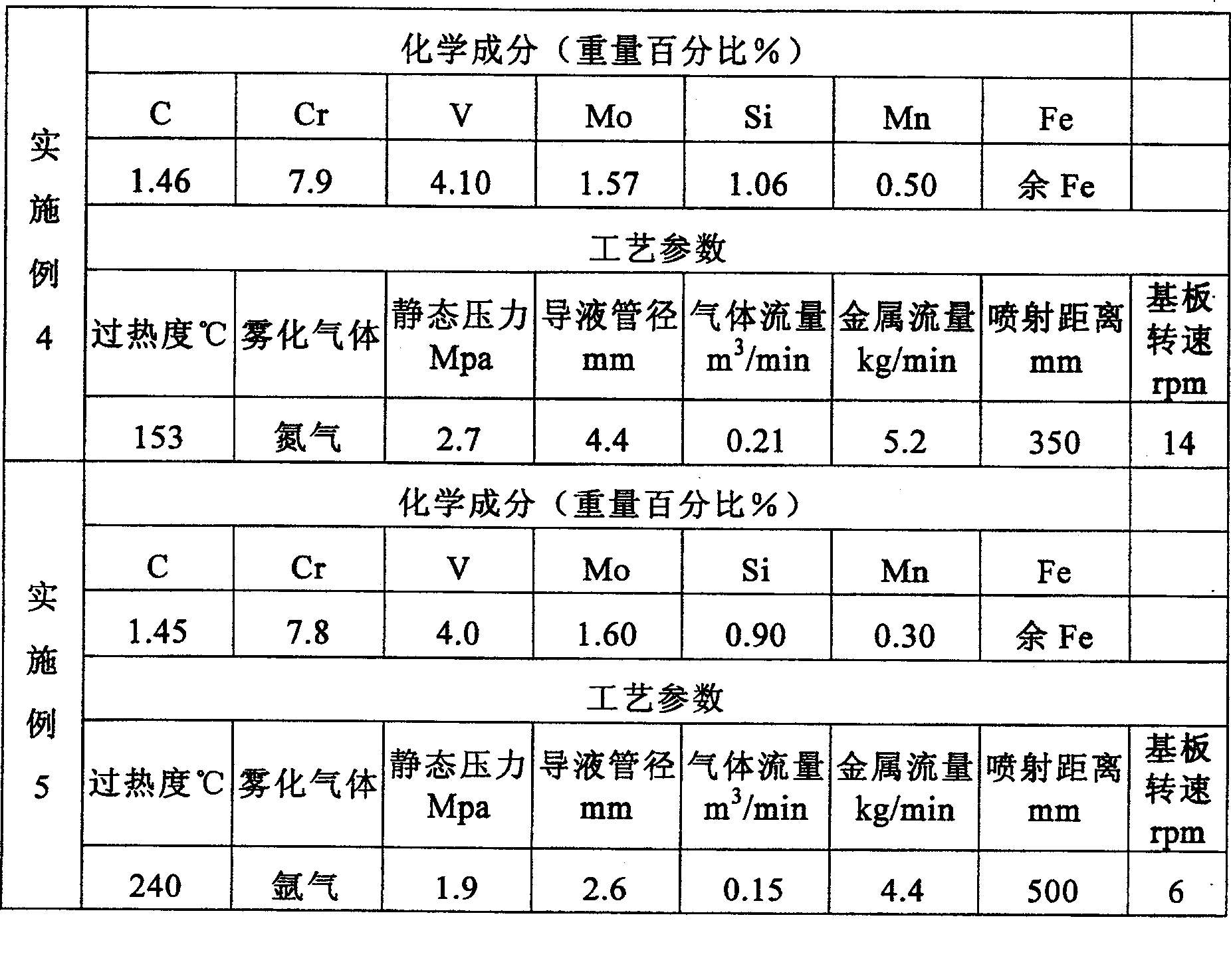

Technical method for preparing cold work die steel in high alloy through jetting deposition

This invention discloses a method for preparing high-alloy cold-working die steel by injection deposition. The method comprises: (1) preparing molten high-alloy cold-working die steel; (2) preparing high-alloy cold-working die steel green body by atomization deposition in inert gas when the temperature reaches required overheating degree. The components of molten high-alloy cold-working die steel are: C 1.45-1.55 wt.%, Cr 7.8-8.2 wt.%, V 3.9-4.1 wt.%, Mo 1.4-1.6 wt.%, Si 0.9-1.1 wt.%, Mn 0.3-0.5 wt.%, and Fe. Since atomization deposition is utilized, the obtained green body has tiny and uniform microstructure without macroscopic precipitation. The grain sizes of the green body are 2-10 mums, and the green body can be directly hot-rolled without forging. The method can avoid the occurrence of eutectic ledeburite, and has such advantages as simple process, low cost and low energy consumption.

Owner:BAOSHAN IRON & STEEL CO LTD

Malleable wear-resistant alloy cast iron

The invention discloses malleable wear-resistant alloy cast iron. The malleable wear-resistant alloy cast iron comprises the following components by weight percent: 2.4-2.8% of carbon, 1.1-1.5% of silicon, 0.4-0.6% of manganese, 0.15-0.2% of sulfur, 0.8-0.1% of phosphorus, 0.05-0.2% of vanadium, 0.04-0.07% boron and the balance of iron and impurities. The malleable wear-resistant alloy cast iron has both forging machinability and wear resistance. Different amounts of boron-containing cementite or ledeburite in the metallographic structure is formed in the cast iron, wherein the micro-hardness of the boron-containing cementite is HV960-1280. The malleable wear-resistant alloy cast iron has a special wear-resistant structure, thus the wear resistance is extremely increased. In addition, after the cast iron is annealed, the forging machinability becomes good.

Owner:广东扬山联合精密制造股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com