High-toughness ledeburite malleable cast iron

A ledeburite and high-toughness technology, applied in the field of high-toughness ledeburite malleable iron, can solve the problems of dangerous workers, inability to discharge, and the existence of cavities, so as to improve the degree of purity, improve the degree of diversion, and reduce the gas content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

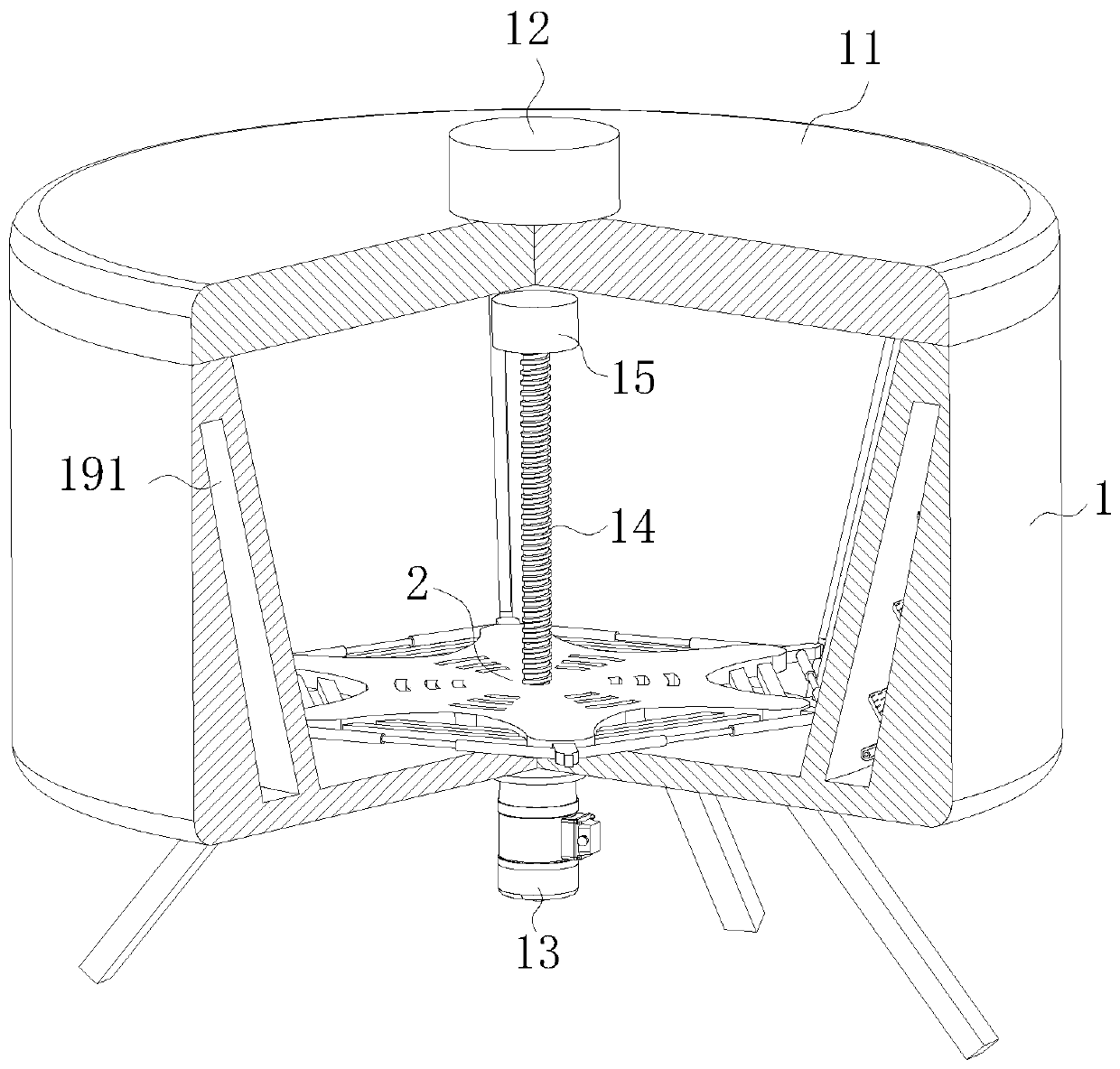

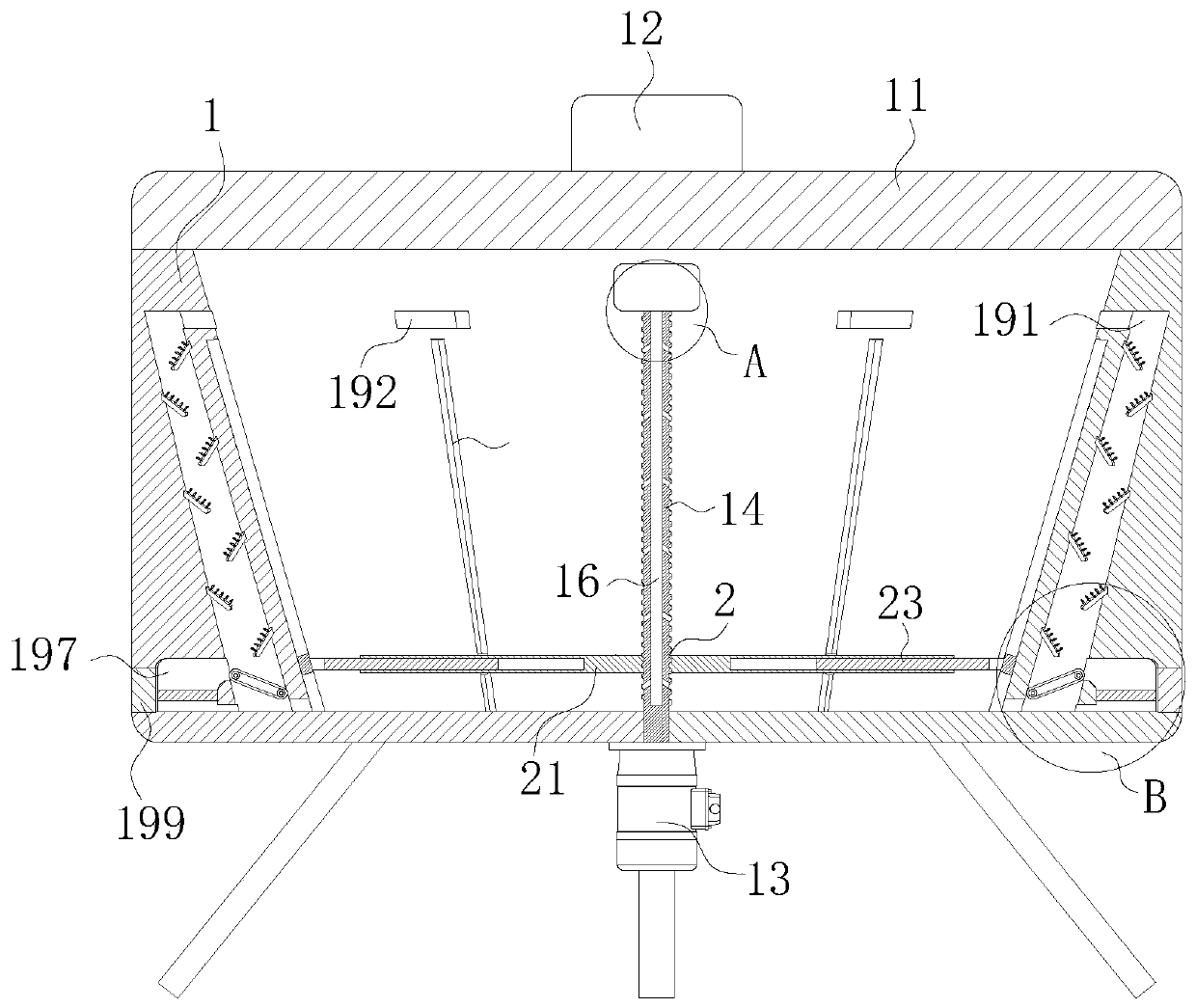

[0036] use Figure 1-Figure 6 A high-toughness ledeburite malleable cast iron according to one embodiment of the present invention will be described as follows.

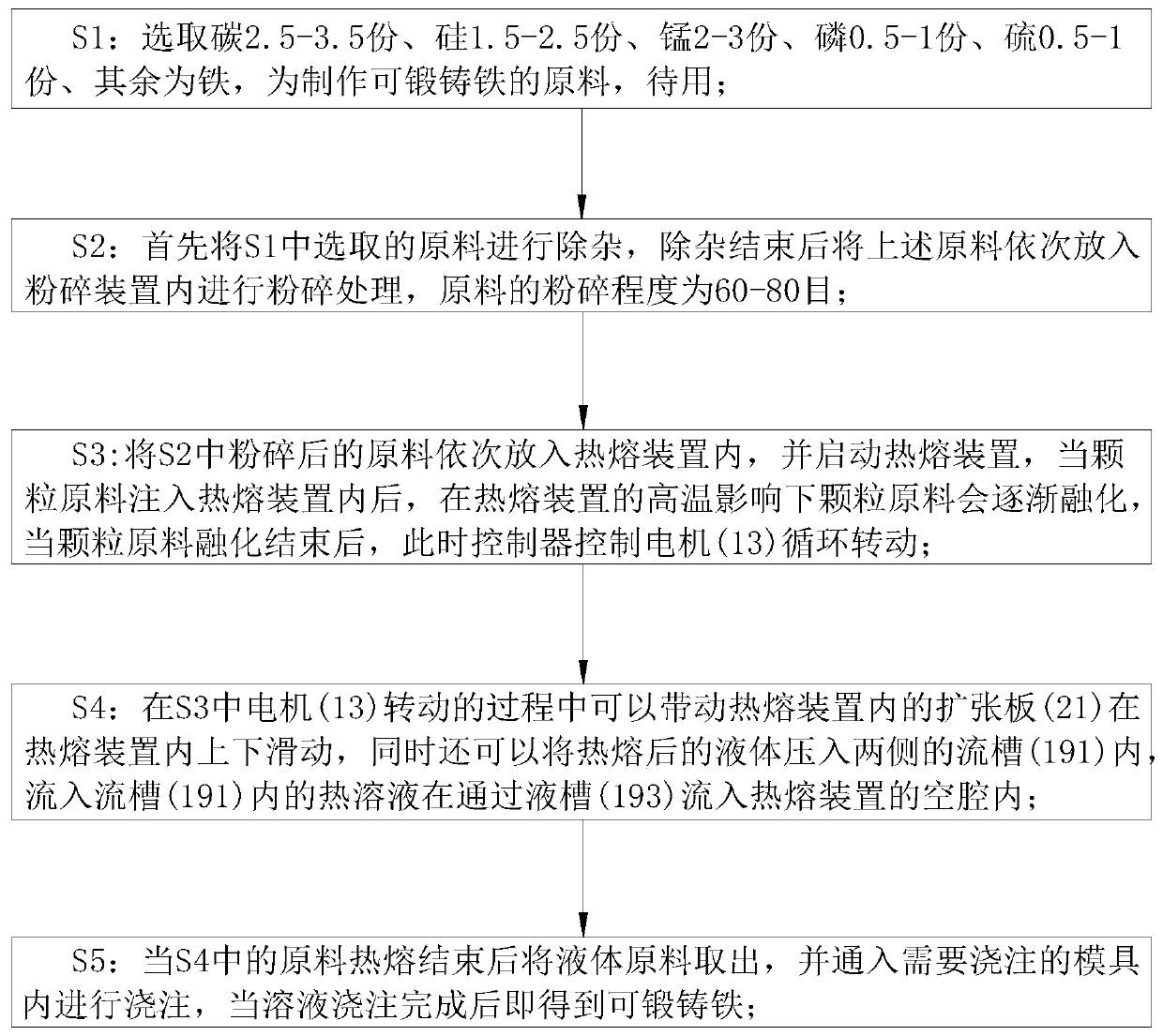

[0037] Such as Figure 1-Figure 6 Shown, a kind of high toughness ledeburite malleable cast iron of the present invention, the manufacturing process of this malleable cast iron comprises the following steps:

[0038] S1: Select 2.5-3.5 parts of carbon, 1.5-2.5 parts of silicon, 2-3 parts of manganese, 0.5-1 part of phosphorus, and 0.5-1 part of sulfur, and their combination is iron, which is the raw material for making malleable cast iron, which is to be used; select the above raw materials The produced ledeburite malleable cast iron not only has strong toughness, but also has strong mechanical strength;

[0039] S2: First remove impurities from the raw materials selected in S1. After the removal of impurities, put the above raw materials into a crushing device for crushing treatment. The crushing degree of the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com