Horizontal-drilling staged-fracturing pressure relief method for underground coal bed

A horizontal drilling and staged fracturing technology, which is applied in earthwork drilling, wellbore/well components, gas discharge, etc., can solve the problems of high gas outburst, rock burst, etc., and reduce the gas content and risk , Improve the effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

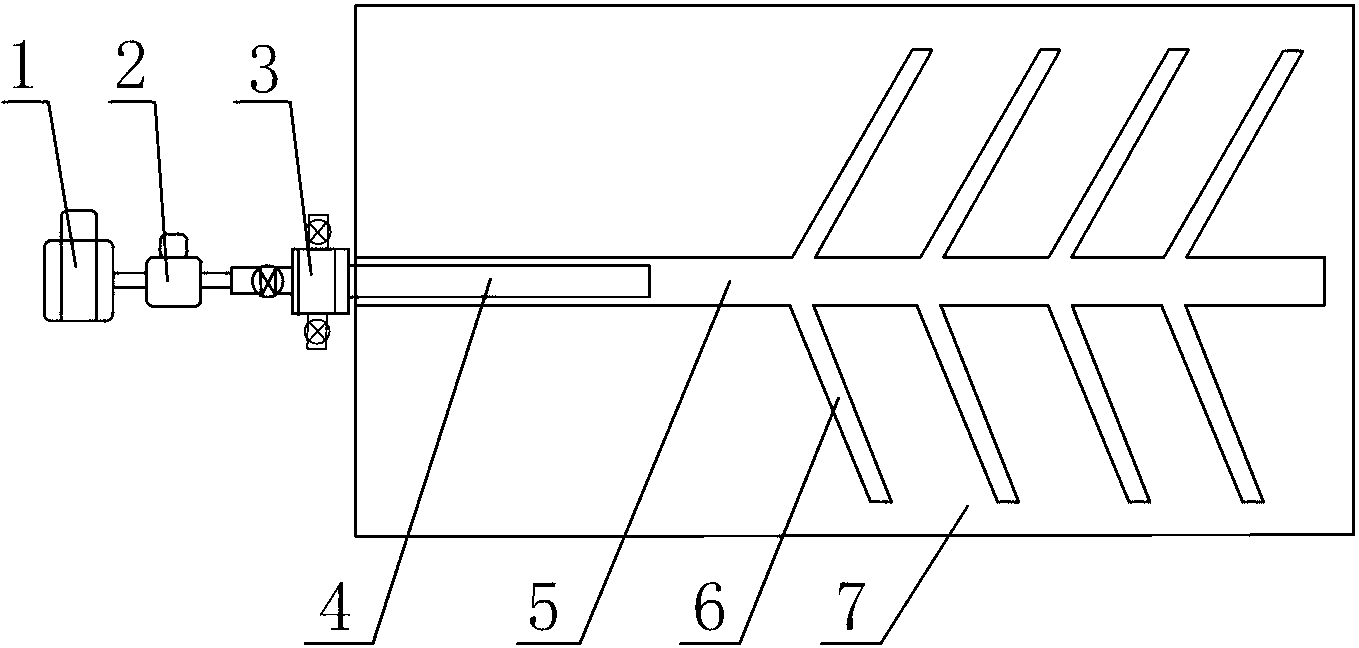

[0022] According to the characteristics of the coal seam structure of the coal seam face, when the coal seam has good pore geological conditions and good permeability, follow the figure 1 For implementation, the specific method is to drill a main horizontal hole 5 with a length of 500m----1000m with a Φ215.9mm drill bit in the coal seam face 7 of the underground, and then run a steel-grade N80 oil casing pipe with a diameter of Φ139.7mm and a wall thickness of 7.72mm. 4. Cement the well with G-grade cement, wait for setting and then enter Φ118mm*2 after 48 hours 。 The single-bent screw is drilled into the main horizontal hole 5. 8-10 branch holes of 100-200m are drilled. After the drilling is thoroughly cleaned, the pressure-resistant 70MPa high pressure seal is installed at the main horizontal hole 5 through the high-pressure pipeline Hole device 3, and connect the pump injection equipment 2 with a working pressure of 70MPa, and pour 1500m into the hole 3 Or more volume of 0.5% ...

Embodiment 2

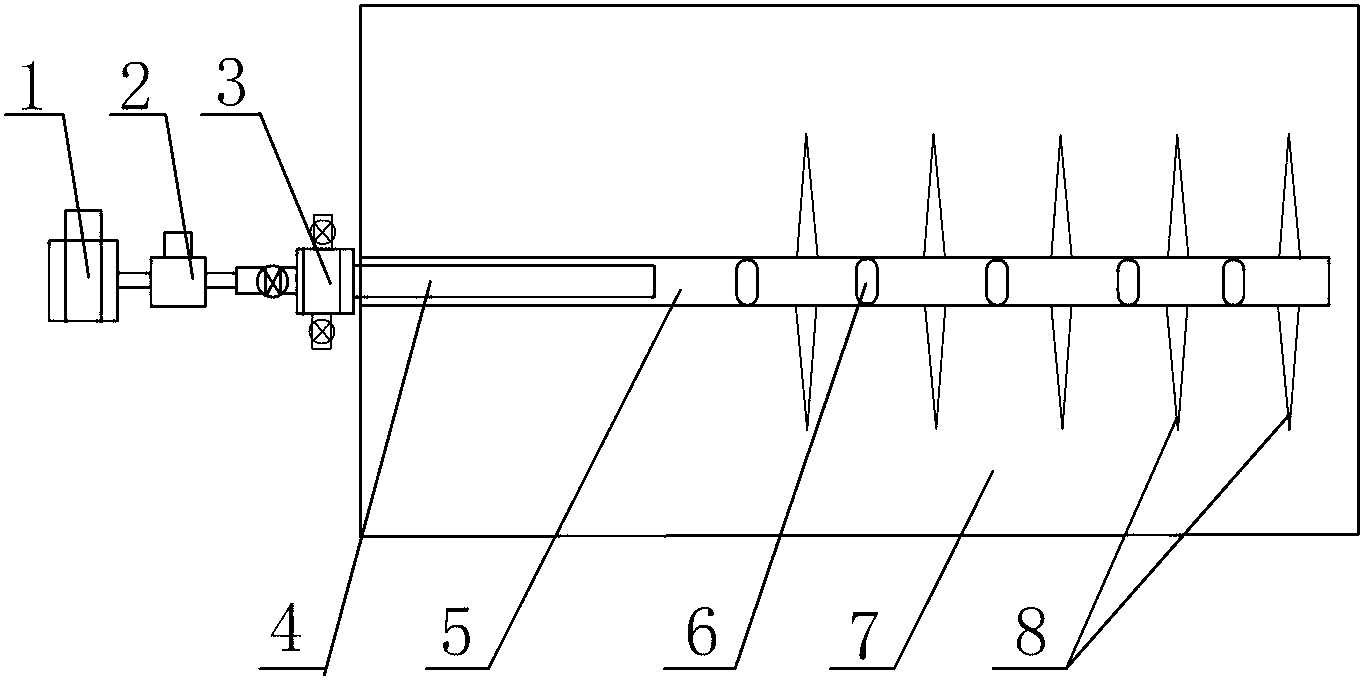

[0024] According to the characteristics of the coal seam structure of the coal seam face, in the case of poor pore-forming geological conditions and poor permeability, follow the figure 2 To implement, the specific method is to drill a main horizontal hole 5 with a length of 500m----1000m with a Φ215.9mm drill bit in the coal seam face 7 of the underground, and then run a steel-grade N80 oil casing pipe with a diameter of Φ139.7mm and a wall thickness of 7.72mm. 4. Cement the well with G-grade cement, wait for setting and then 48 hours later, run a Φ118mm screw, and then drill a 500-1000m horizontal borehole on the main horizontal hole 5. After thoroughly cleaning the borehole, enter the main horizontal hole 5. Install the pressure-resistant 70MPa high-pressure sealing device 3 through the high-pressure pipeline to connect the high-pressure pump injection equipment 2 with a working pressure of 70MPa, and then inject the polymer gel liquid with natural quartz sand proppant into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com