Manufacturing method of double-metal composite chilled cast-iron roll

A technology of chilled cast iron and a manufacturing method, which is applied in the field of manufacturing bimetallic composite chilled cast iron rolls, can solve problems such as insufficient roll tensile strength, roll hardness fluctuations, and large variation ranges, and achieve strong tensile strength and hardness fluctuations The effect of small amplitude and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now with reference to the accompanying drawings, give an example:

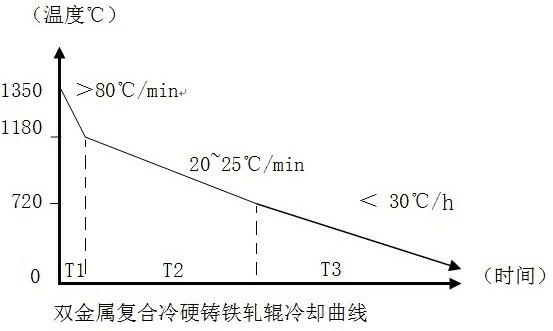

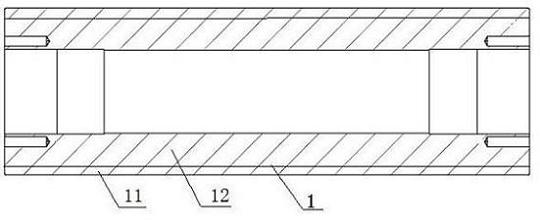

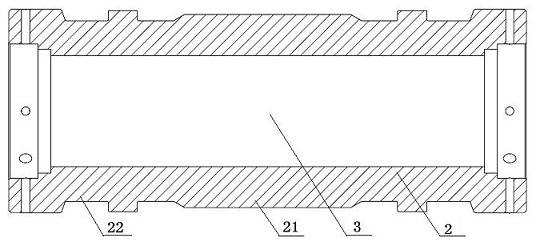

[0019] Such as figure 2 As shown, a bimetal composite chilled cast iron roll 1 with an outer diameter of 250mm, an inner hole of 100mm, and a length of 1000mm is to be produced, the outer layer of chilled cast iron wear-resistant material 11 is 10-20mm in depth, and the outer layer of chilled cast iron wear-resistant material The hardness of 11 is 450~490HB, the hardness difference of the roll body is within 30HB, the outer diameter of the casting billet is 258mm, the inner hole is 85~90mm, the length is 1020mm, and the outer layer of chilled cast iron wear-resistant material 11 is 14~24mm in depth. The chilled cast iron wear-resistant material 11 on the outer layer of the roll 1 weighs about 150 kg, and the supporting gray iron material 12 on the inner layer weighs about 200 kg. The matrix structure of the outer chilled cast iron wear-resistant material 11 is as follows: the content of carbide is 40-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com