Novel anti-attrition and wear resistant cast iron and preparation method thereof

A wear-resistant cast iron, a new type of technology, applied in the field of alloy cast iron, can solve the problems of poor anti-friction lubrication effect, can not meet the requirements of anti-friction, etc., achieve the effect of improving anti-friction and anti-wear performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

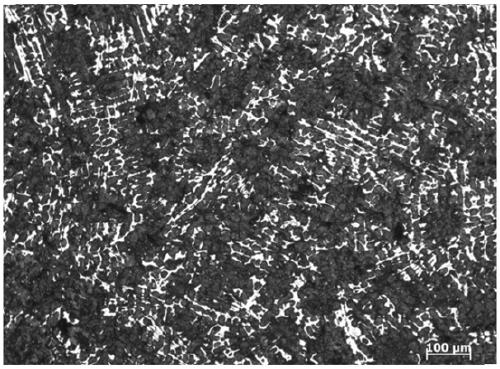

Embodiment 1

[0020] Embodiment 1: A kind of method for preparing antifriction, wear-resisting cast iron of this example, comprises the following several steps:

[0021] 1) Ingredients: return materials, steel scrap, pig iron, ferrosilicon, ferromanganese, ferrochrome, ferrovanadium, pure copper, ferrotitanium, ferrophosphorus according to C2.8%, Si 1.8%, Mn 0.5%, P 0.3%, Cr 1.2%, Ni 0.4%, Mo 0.1%, V 0.2%, Cu 0.5%, Ti 0.1%, S≤0.08%, and the balance is the weight percentage of Fe;

[0022] 2) Preheating, preheating the calculated scrap steel, pig iron, and returned materials in the intermediate frequency induction melting furnace in sequence;

[0023] 3) Melting: After melting the scrap steel, pig iron and returned materials in the intermediate frequency induction melting furnace, put in the calculated recarburizer, after the recarburizer is melted, add the deoxidizer for the first deoxidation, and then add the calculated quality For pure copper, when the temperature rises to 1460°C, add ba...

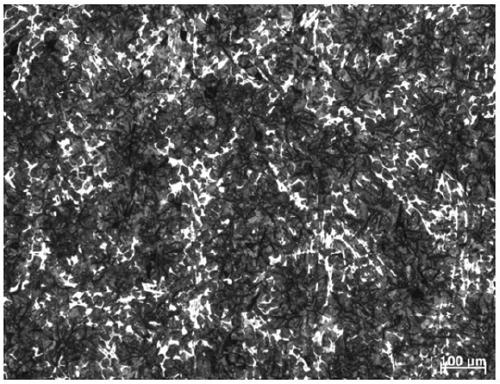

Embodiment 2

[0029] A kind of method for preparing antifriction, wear-resisting cast iron of this example comprises the following steps:

[0030] 1) Ingredients: Return materials, steel scrap, pig iron, ferrosilicon, ferromanganese, ferrochrome, ferrovanadium, pure copper, ferrotitanium, ferrophosphorus according to C3.5%, Si 2.7%, Mn 1.8%, P 0.7%, Cr 2.8%, Ni 0.6%, Mo 0.8%, V 1.6%, Cu 1.8%, Ti0.3%, S≤0.08%, and the balance is the weight percentage of Fe;

[0031] 2) Preheating, preheating the calculated scrap steel, pig iron, and returned materials in the intermediate frequency induction melting furnace in sequence;

[0032] 3) Melting: After melting the scrap steel, pig iron and returned materials in the intermediate frequency induction melting furnace, put in the calculated recarburizer, after the recarburizer is melted, add the deoxidizer for the first deoxidation, and then add the calculated quality For pure copper, when the temperature rises to 1380°C, add baked ferromanganese and f...

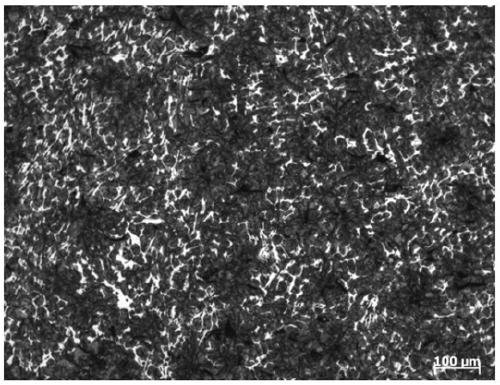

Embodiment 3

[0038] A kind of method for preparing antifriction, wear-resisting cast iron of this example comprises the following steps:

[0039] 1) Ingredients: Return materials, steel scrap, pig iron, ferrosilicon, ferromanganese, ferrochrome, ferrovanadium, pure copper, ferrotitanium, ferrophosphorus according to C3.2%, Si 2.2%, Mn 0.9%, P 0.4%, Cr 2.0%, Ni 1.3%, Mo 0.4%, V 0.9%, Cu 0.9%, Ti 0.4%, S≤0.08%, and the balance is the weight percentage of Fe;

[0040] 2) The second step: preheating, preheating the calculated scrap steel, pig iron, and returned materials in the intermediate frequency induction melting furnace in sequence;

[0041] 3) The third step: smelting: After melting the scrap steel, pig iron and returned materials in the intermediate frequency induction melting furnace, put in the calculated recarburizer, after the recarburizer melts, add a deoxidizer for the first deoxidation, and then add Calculate the quality of pure copper, and when the temperature rises to 1400°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com