Improved Cr8 steel roll and preparation method thereof

An improved, rolling technology, applied in the direction of rolling, metal rolling, metal rolling, etc., can solve problems such as difficulty in determining the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

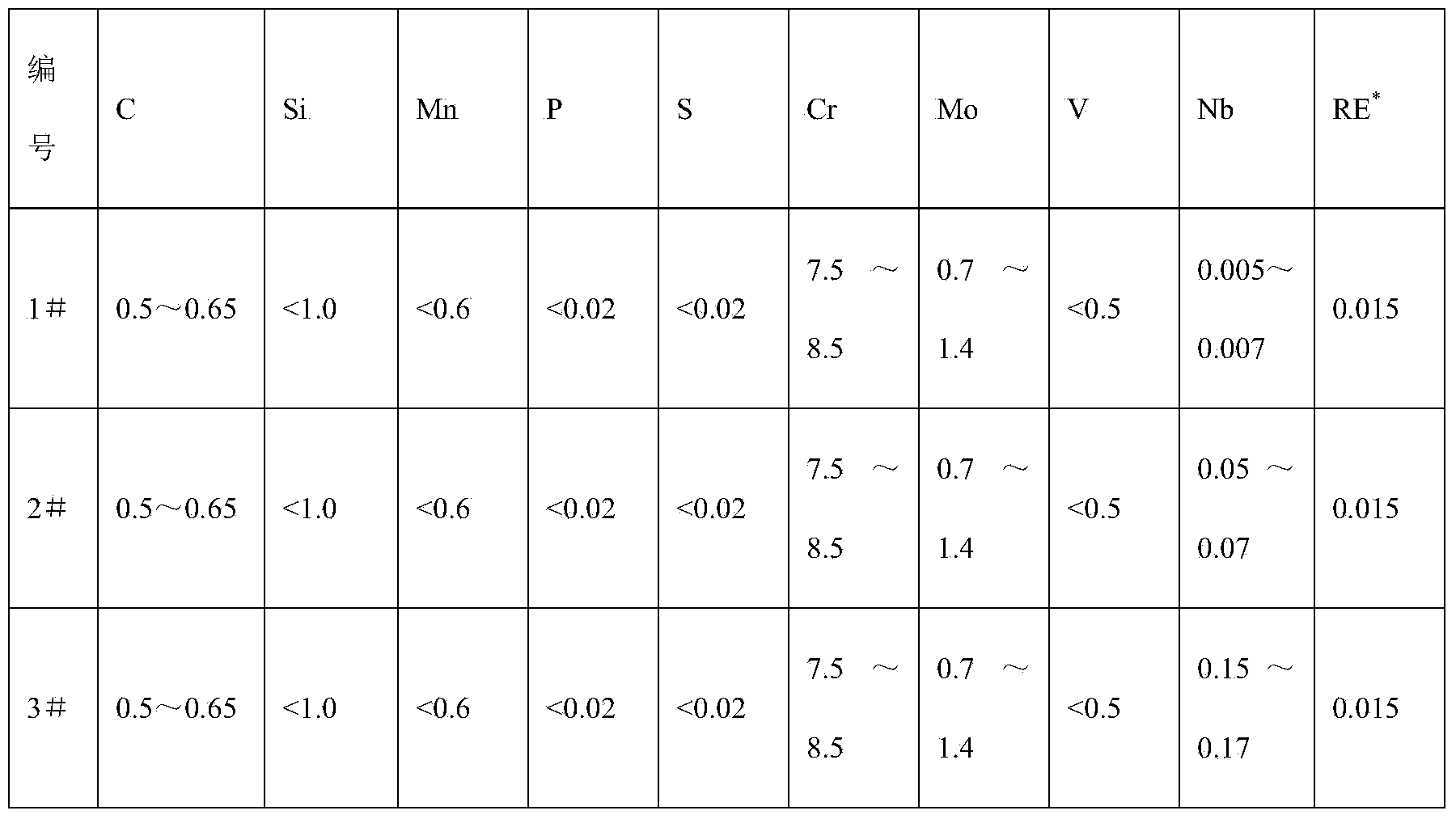

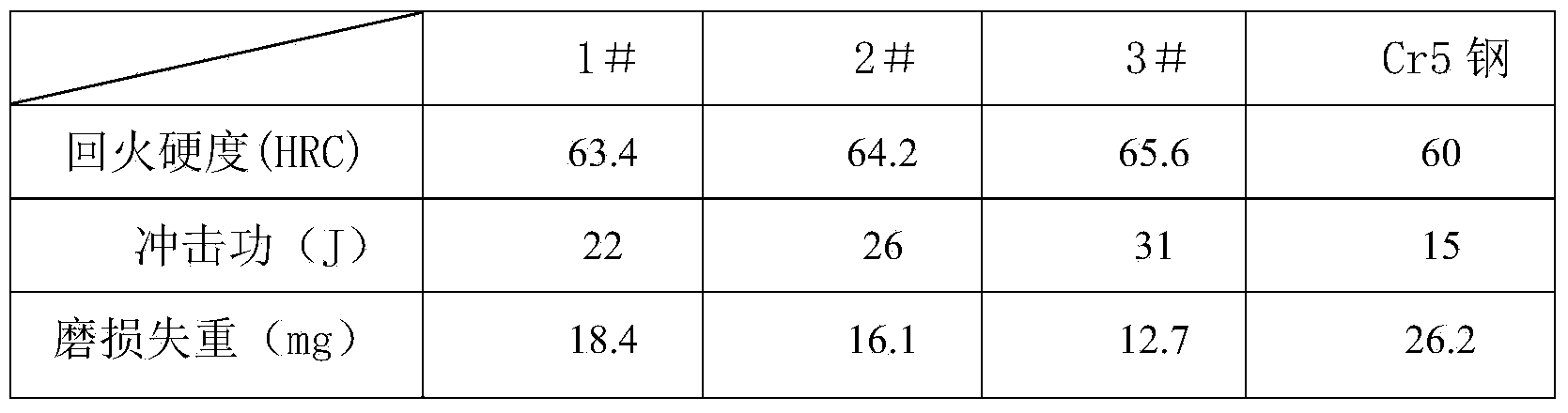

[0018] Examples The design weight percentages of the components of the improved Cr8 steel roll are shown in Table 1.

[0019] Table 1 Trial composition of improved Cr8 steel rolls (wt%)

[0020]

[0021] Improving the processing technology of the new Cr8 steel roll includes the following steps:

[0022] (1) Smelting: put scrap steel raw materials into vacuum induction furnace or electric arc furnace for melting, the melting temperature is 1500-1600°C, and alloy and deoxidizer are added in time during the melting process. The electric furnace steel is passed through the ladle refining furnace and the vacuum degassing furnace for secondary refining.

[0023] (2) Molten steel casting forming steel ingot: Preheat the steel ingot mold twice at 250-300°C, the casting temperature is 1460-1510°C, after 50 minutes of heat preservation, demoulding and heat preservation are slowly cooled, and it is released after 48 hours.

[0024] (3) Put the steel ingot as a consumable electrode i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com