Production technology of spring steel 60Si2Mn hot-rolled wire rod for automotive suspension

A production process and technology for hot-rolled wire rod, which is applied in the field of production process of spring steel 60Si2Mn hot-rolled wire rod for automobile suspension, can solve the problems of high heating temperature, long heating time, increase production cost, etc., and achieve uniform chemical elements. , Optimize the rolling speed and ensure the effect of the time in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

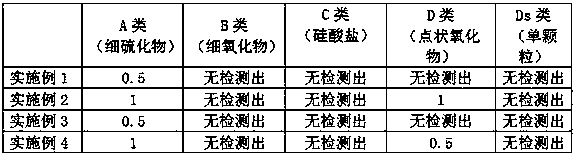

Embodiment 1

[0026]The production process of spring steel 60Si2Mn hot-rolled wire rod for automobile suspension in this embodiment includes molten iron pretreatment, converter smelting, LF refining, RH vacuum treatment, continuous casting, billet opening, billet grinding, and wire rod rolling processes. The specific process The steps are described below:

[0027] (1) Hot metal pretreatment process: after hot metal pretreatment, S: 350ppm;

[0028] (2) Converter smelting process: the ratio of scrap steel in the converter is controlled at 15%; when tapping the steel, the infrared slide plate + slag-stopping cone is used to strictly control the slag, and 12.0kg / t steel SiMn and 17.0kg / t steel SiMn are added during the tapping process Ferrosilicon precipitation deoxidation and alloying, adding synthetic refining slag 3.0kg / t steel along the steel flow when 1 / 2 of the steel is tapped;

[0029] (3) LF refining process: use aluminum-free deoxidation, add 1.1kg / t steel SiC diffusion deoxidation, ...

Embodiment 2

[0039] The production process of spring steel 60Si2Mn hot-rolled wire rod for automobile suspension in this embodiment includes molten iron pretreatment, converter smelting, LF refining, RH vacuum treatment, continuous casting, billet opening, billet grinding, and wire rod rolling processes. The specific process The steps are described below:

[0040] (1) Hot metal pretreatment process: after hot metal pretreatment, S: 320ppm;

[0041] (2) Converter smelting process: the ratio of scrap steel in the converter is controlled at 19%; when tapping the steel, the infrared slide plate + slag-stopping cone are used to strictly control the slag, and 13.0kg / t steel SiMn and 18.0kg / t steel SiMn are added during the tapping process Ferrosilicon precipitation deoxidation and alloying, adding synthetic refining slag 3.0kg / t steel along the steel flow when 1 / 2 of the steel is tapped;

[0042] (3) LF refining process: use aluminum-free deoxidation, add 1.1kg / t steel SiC diffusion deoxidation...

Embodiment 3

[0051] The production process of spring steel 60Si2Mn hot-rolled wire rod for automobile suspension in this embodiment includes molten iron pretreatment, converter smelting, LF refining, RH vacuum treatment, continuous casting, billet opening, billet grinding, and wire rod rolling processes. The specific process The steps are described below:

[0052] (1) Hot metal pretreatment process: after hot metal pretreatment, S: 350ppm;

[0053] (2) Converter smelting process: The scrap ratio of the converter is 13%; when tapping the steel, the infrared slide plate + slag-stopping cone double block is used to strictly control the slag, and 10.0kg / t steel SiMn and 15.0kg / t steel silicon are added during the tapping process Iron precipitation deoxidation and alloying, adding synthetic refining slag 3.5kg / t steel along the steel flow when 1 / 2 of the steel is tapped;

[0054] (3) LF refining process: use aluminum-free deoxidation, add 1.1kg / t steel SiC diffusion deoxidation, add 5.2kg / t st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com