Environment friendly casting coating as well as preparation method and using method thereof

An environmentally friendly and paint technology, applied in casting molding equipment, coatings, molds, etc., can solve the problem of too much attention paid to paint coating performance, and achieve the effects of storage resistance, low gas generation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

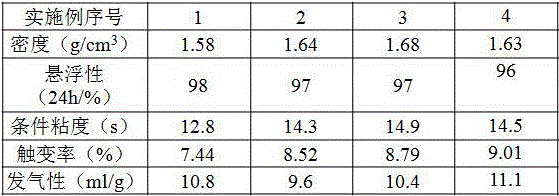

Examples

Embodiment 1

[0050] 1. Ratio of ingredients

[0051] Parts by weight of each composition in component A and component A are:

[0052] Secondary graphite 20 parts

[0053] 5 parts of fly ash

[0054] Kaolin 15 parts

[0055] Active zinc oxide 10 parts

[0056] Bentonite 6 parts

[0057] Parts by weight of each composition in component B and component B are:

[0058] 65 parts of isopropanol

[0059] 2-butoxyethanol 10 parts

[0060] Dibenzylidene sorbitol 5 parts

[0061] 6 parts hydrogenated castor oil

[0062] 20 parts phenolic resin

[0063] Titanate coupling agent 0.6 part

[0064] Parts by weight of each composition in component C and component C are:

[0065] Silica airgel 15 parts

[0066] Activated charcoal 2 parts

[0067] Carboxymethylcellulose 5 parts

[0068] Fly ash vitrified microspheres 8 parts

[0069]Among them, the specific surface area of silica airgel in component C is 450m 2 / g, the density is 55kg / m 3 . The particle size of nano titanium dioxide in c...

Embodiment 2

[0080] 1. Ratio of ingredients

[0081] Parts by weight of each composition in component A and component A are:

[0082] Secondary graphite 25 parts

[0083] 7.5 parts of fly ash

[0084] Kaolin 18 parts

[0085] Active zinc oxide 12 parts

[0086] Bentonite 7 parts

[0087] Parts by weight of each composition in component B and component B are:

[0088] 72 parts of isopropanol

[0089] 12 parts of 2-butoxyethanol

[0090] Dibenzylidene sorbitol 6.5 parts

[0091] 9 parts hydrogenated castor oil

[0092] 22 parts of phenolic resin

[0093] Titanate coupling agent 0.75 parts

[0094] Parts by weight of each composition in component C and component C are:

[0095] Silica airgel 17 parts

[0096] Activated charcoal 3 parts

[0097] Carboxymethylcellulose 6.5 parts

[0098] Fly ash vitrified microspheres 10 parts

[0099] Among them, the specific surface area of silica airgel in component C is 465m 2 / g, the density is 66kg / m 3 . The particle size range of nano...

Embodiment 3

[0110] 1. Ratio of ingredients

[0111] Parts by weight of each composition in component A and component A are:

[0112] Secondary graphite 22 parts

[0113] Fly ash 6 parts

[0114] Kaolin 16.5 parts

[0115] Active zinc oxide 11 parts

[0116] Bentonite 6.8 parts

[0117] Parts by weight of each composition in component B and component B are:

[0118] 77 parts of isopropanol

[0119] 14 parts of 2-butoxyethanol

[0120] Dibenzylidene sorbitol 8 parts

[0121] 8 parts hydrogenated castor oil

[0122] 25 parts of phenolic resin

[0123] Titanate coupling agent 0.75 parts

[0124] Parts by weight of each composition in component C and component C are:

[0125] Silica airgel 15 parts

[0126] Activated charcoal 4 parts

[0127] Carboxymethylcellulose 7 parts

[0128] Fly ash vitrified microspheres 10 parts

[0129] Among them, the specific surface area of silica airgel in component C is 465m 2 / g, the density is 66kg / m 3 . The particle size range of nano tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com