Heat treatment technique of stainless steel for 410L containers

A stainless steel and container technology, applied in the field of stainless steel, can solve problems such as high cost and slow production rhythm, and achieve the effect of reducing production cost and speeding up production rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

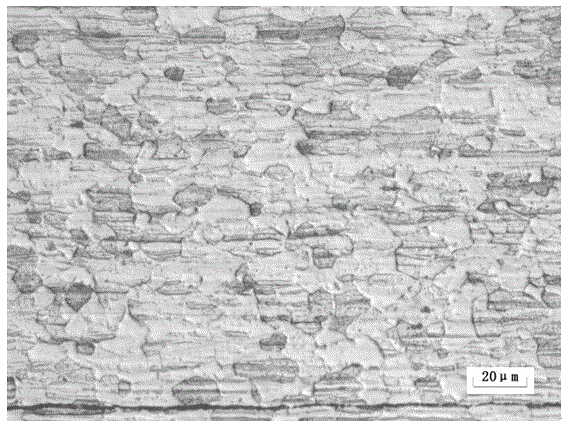

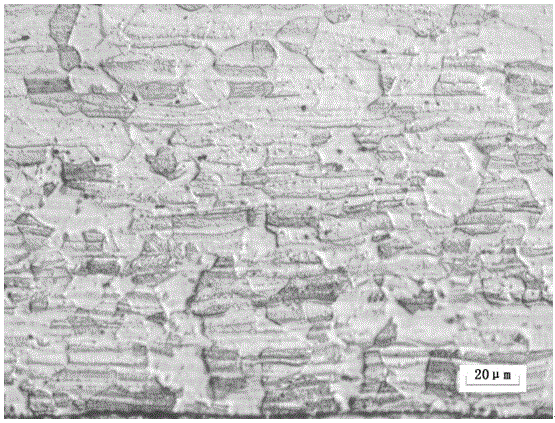

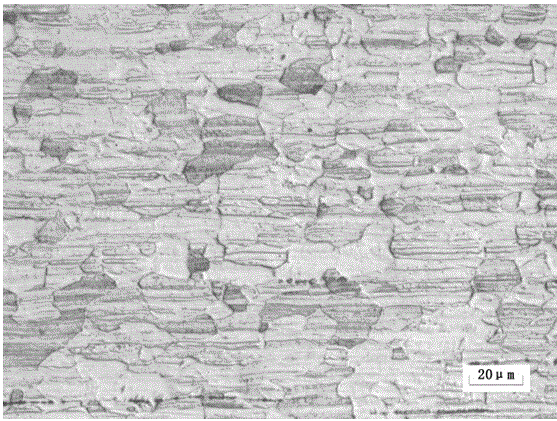

Image

Examples

Embodiment Construction

[0013] The stainless steel heat treatment process for 410L containers includes the following steps (take the thickness of 0.75mm*width of 1250mm and the coil weight of 18 tons as an example):

[0014] 1) The laminar flow cooling of the hot rolling process is not used, the coiling temperature control range: 800-840 ℃, the side blowing of the strip must be put into use, and the black coil off-line adopts the stack cooling process;

[0015] 2) The annealing process of the original bell furnace is cancelled;

[0016] 3) Cold wire heat treatment process: TV value 40±5 mm*m / min (0.75mm plate);

[0017] 4) Cold wire heat treatment process: target TV value 40 mm*m / min (0.75mm plate);

[0018] 5) Cold wire heat treatment process: material temperature 840±10°C (subject to material temperature in zone 7).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com