Patents

Literature

196 results about "Argon oxygen decarburization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Argon oxygen decarburization (AOD) is a process primarily used in stainless steel making and other high grade alloys with oxidizable elements such as chromium and aluminum. After initial melting the metal is then transferred to an AOD vessel where it will be subjected to three steps of refining; decarburization, reduction, and desulfurization. AOD was invented in 1954 by the Lindé Division of The Union Carbide Corporation (which became known as Praxair in 1992).

High carbon high silicon martensite stainless steel billet and preparation method thereof

InactiveCN101967610AGuaranteed performanceSmall temperature fluctuationsProcess efficiency improvementElectric furnaceStress concentrationElectric arc furnace

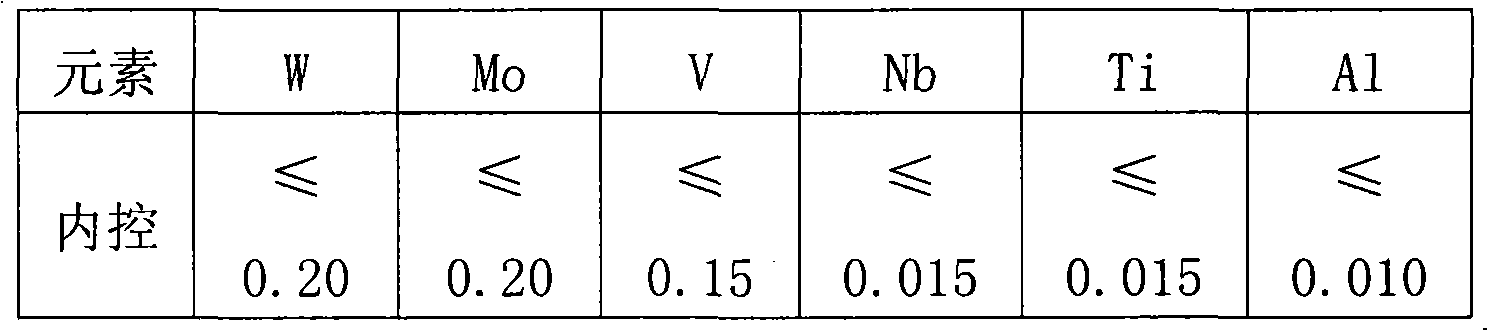

The invention provides a high carbon high silicon martensite stainless steel billet. The steel billet is characterized by comprising the following components by weight percent: 0.41-0.47% of C, 2.80-3.20% of Si, 0.50-0.80% of Mn, 8.50-9.20% of Cr, 0.30% or less of Ni, 0.028% or less of P, 0.005% or less of S, 0.20% or less of W, 0.20% or less of Mo, 0.15% or less of V, 0.015% or less of Nb, 0.015% or less of Ti, 0.010% or less of Al and the balance Fe and inevitable impurities. The invention also provides a preparation method of the high carbon high silicon martensite stainless steel billet. The method comprises the following steps: performing primary smelting with an electric arc furnace (EAF), performing argon-oxygen decarburization (AOD) smelting, refining with a low frequency (LF) furnace, performing continuous casting, annealing and rolling. The method of the invention has simple operation, can stably control the quality of the continuous casting billet, completely suppresse cracks, overcome the defect of concentration of stress and increase the casting yield and quality stability of the martensite stainless steel.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

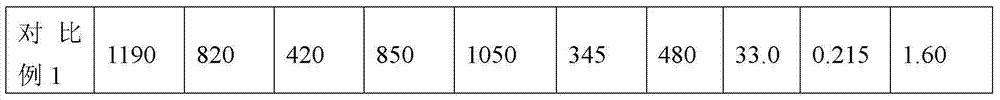

Ultrahigh-strength and high-toughness welded cast steel

InactiveCN101074472AGood effectImprove hardenabilityHeat treatment process controlSmelting processUltimate tensile strength

A high-strength and high-toughness welding cast steel consists of C 0.12-0.17 wt%, Si 0.10-0.50 wt%, Mn 0.8-1.2 wt%, S+P<=0.025 wt%, Ni 4.00-4.50 wt%, Cr 0.7-1.2 wt%, Mo 0.40-0.50 wt%, V 0.04-0.08 wt%, Cu 0.20-0.40 wt% and iron residue. The process is carried out by selecting electric furnace + AOD duplex smelting process, pouring and heating to obtain final product. The yield strength reaches above 800 MPa, V-shaped notch impact reaches above 55J at -20 degree. It can be used for ship, ocean and petrochemical industries.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Duplex stainless steel and manufacturing method thereof

The invention relates to duplex stainless steel. The duplex stainless steel comprises the following chemical components in percent by weight: 0.01-0.08% of C, 0.2-1.0% of Si, 1.5-3.5% of Mn, 19.0-21.0% of Cr, 1.2-2.8% of Ni, 0.08-0.18% of N, less than or equal to 0.5% of Mo, less than or equal to 1.0% of W, less than or equal to 1.0% of Cu and the balance of Fe and inevitable impurities; PREN (Pitting Resistance Equivalent Number) is 20-24, the martensitic temperature Md formed by strain induction is 60-130 DEG C. A manufacturing method comprises the following steps of: selecting vacuum induction smelting in an electric furnace, argon oxygen decarburization (AOD) or electric furnace, argon oxygen decarburization (AOD), external refining and LF (Ladle Furnace) smelting; carrying out die casting or continuous casting on molten steel, controlling the superheat degree to be 20-50 DEG C in die casting, matching with fast cooling, preventing nitrogen from escaping, and controlling the overheat degree to be 20-50 DEG C and the plate blank casting speed to be 0.8-2m / min; and putting a die-casting blank or a continuous casting blank into a heating furnace for heating to 1100-1250 DEG C, preserving the heat for 0.5-1.5 hours, processing the die-casting blank or the continuous casting blank on a forging production line or a hot-rolling mill group to the needed thickness, then carrying out annealing at the speed of 0.5-2.5min / mm and the temperature of 1030-1150 DEG C. The obtained duplex stainless steel has excellent corrosion resistance and TRIP effect.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Method for manufacturing low-carbon TWIP steel through AOD (argon oxygen decarburization) furnace

ActiveCN103468874AEase of mass productionRaw materials are easy to getProcess efficiency improvementManufacturing technologySlag

The invention belongs to the field of metal smelting, and mainly relates to smelting manufacturing technology of low-carbon TWIP steel through an AOD (argon oxygen decarburization) furnace. The smelted TWIP steel comprises the following components in percentage by weight: 0%-0.06% of C, 20%-30% of Mn, 2.0%-3.0% of Si, 2.5%-3.5% of Al, and the balance of Fe. The particular technology procedures comprises the following steps: 1), the AOD furnace is adopted for oxygen decarburization process, once the carbon in the liquid steel is lower than 0.03%, the liquid steel is subject to alloying; 2), after the TWIP steel is subject to manganese alloying, ferrosilicon or / and metal aluminium is adopted to perform reduction reaction on manganese oxide, so that the yield of metal manganese is increased; the oxidation heat of silicon or / and aluminium is adopted to regulate the temperature of the liquid steel and compensate temperature drop of the liquid steel generated by the manganese alloying of the TWIP steel. The method is high in manufacturing efficiency, low in cost, stable in operation and easily-mastered in technology; the main raw material is easily accessible, and no specific requirement is needed; the realization of large-scaled industrialized production is facilitated.

Owner:UNIV OF SCI & TECH BEIJING

Method for smelting stainless steel with high chrome melts and dephosphorized melted iron

ActiveCN102766799AStable furnace conditionsEase of industrial productionSS - Stainless steelArgon oxygen decarburization

The invention relates to a method for smelting stainless steel with high chrome melts and dephosphorized melted iron. The method includes the steps that a medium frequency induction furnace melts high carbon ferro chrome into high chrome melts; a converter provides the dephosphorized melted iron; the high chrome melts and the dephosphorized melted iron provided by the converter are mixed and added into an argon oxygen decarburization (AOD) refining furnace for decarburization, argon blowing and refining; a low temperature shift (LTS) furnace heats the mixture and components are adjusted; and continuous casting is performed. The method is short in smelting time and the consumption of auxiliary materials is low.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Ferro-titanium alloying method for titaniferous stainless steel

The invention relates to a ferro-titanium alloying method for titaniferous stainless steel, which comprises the following steps of: I) after slagging off and AOD (Argon Oxygen Decarburization) tapping, removing slag and keeping the thickness of the remained slag being not more than 50mm; II) making a slag steel bag again and hanging in an LF (Low Frequency) finery, adding lime and fluorite for making the slag again, blowing argon from bottom and powerfully stirring and slagging or electrifying and slagging; III) deoxidizing, adding aluminum powder in surface slag, keeping total bottom blowingflow being 600-1,000Nl / min, and stirring for 3-5min; IV) before discharging molten steel, starting to feed a silico-calcium line, and then softly stirring; and V) adding ferro-titanium for alloying, keeping the bottom blowing argon flow close to the side of a feeding port being 500-700 Nl / min and the one away from the side of the feeding port being 100-200Nl / min, adding 2.5-3.5kg ferro-titanium in a ton of molten steel, keeping the bottom blowing flow being 200-300 Nl / min per piece and stirring, and then adjusting the total flow of bottom blowing double-tube being not more than 200NL / min, andsoftly stirring. According to the ferro-titanium alloying method for titaniferous stainless steel, the titanium-feeding time is short and a crystallizer water port is prevented from being plugged during a continuous casting process.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Production method of integral special-shaped heavy forging made of austenitic stainless steel

ActiveCN103350173AImprove surface qualityImprove hot workabilitySS - Stainless steelArgon oxygen decarburization

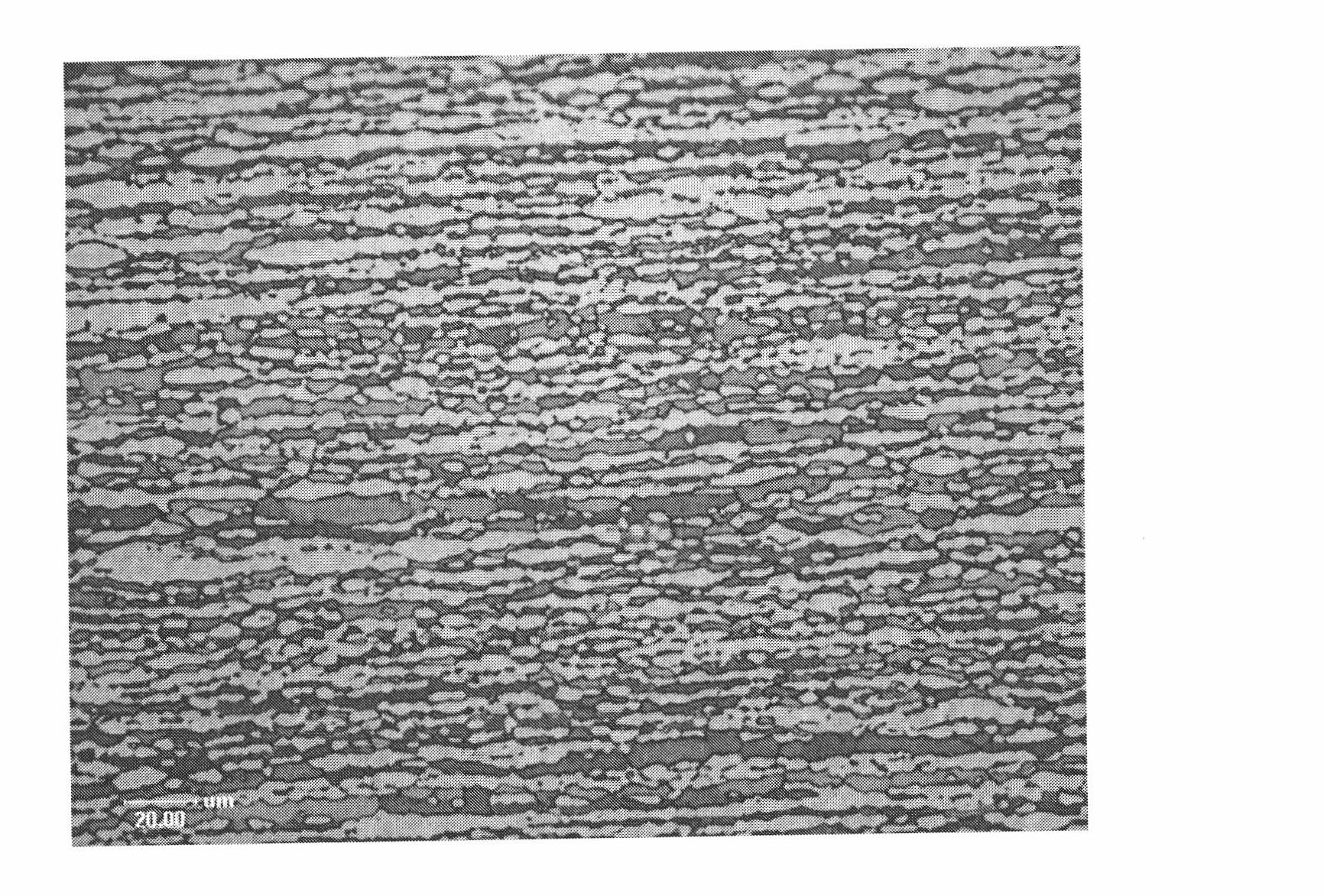

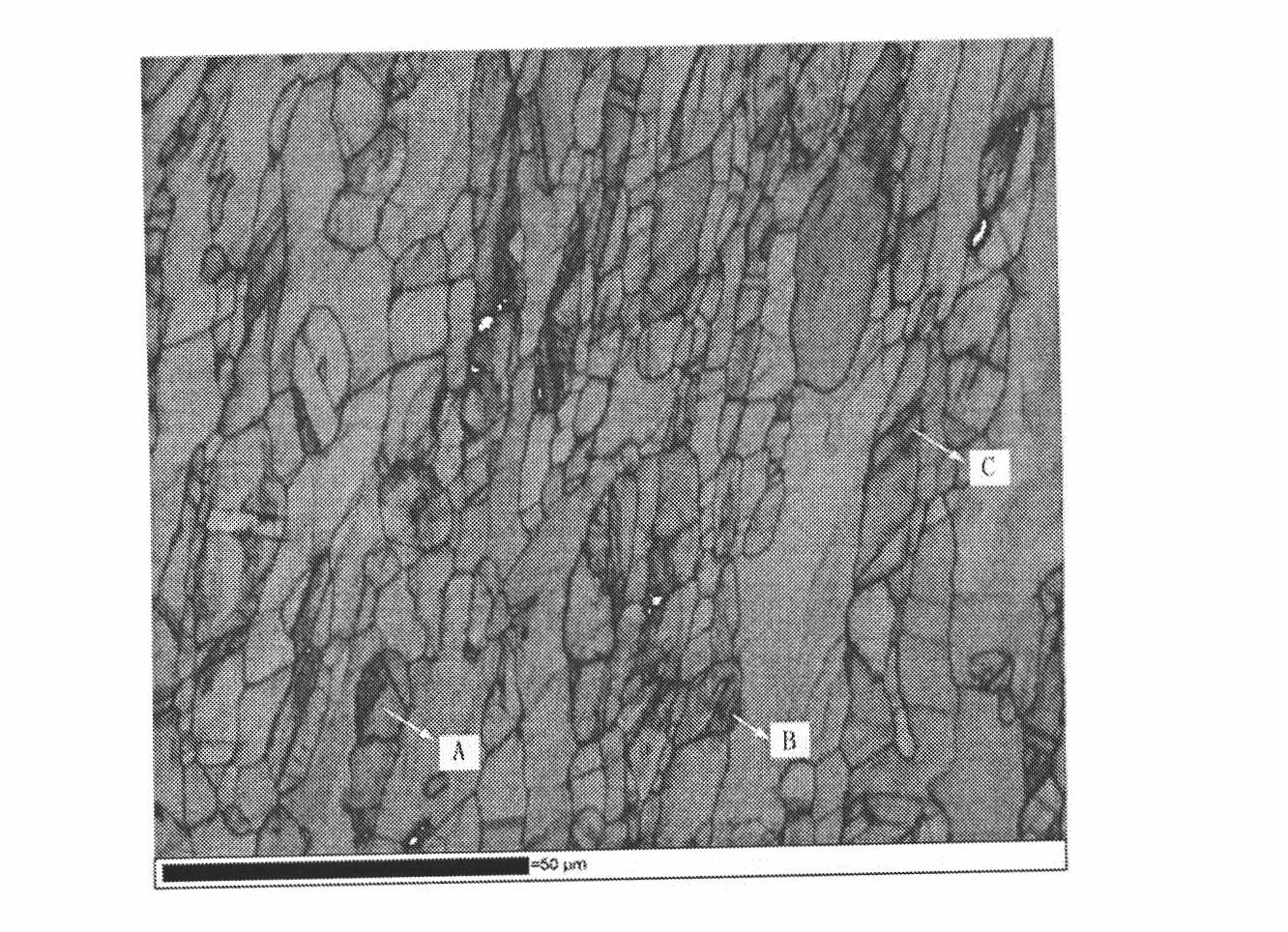

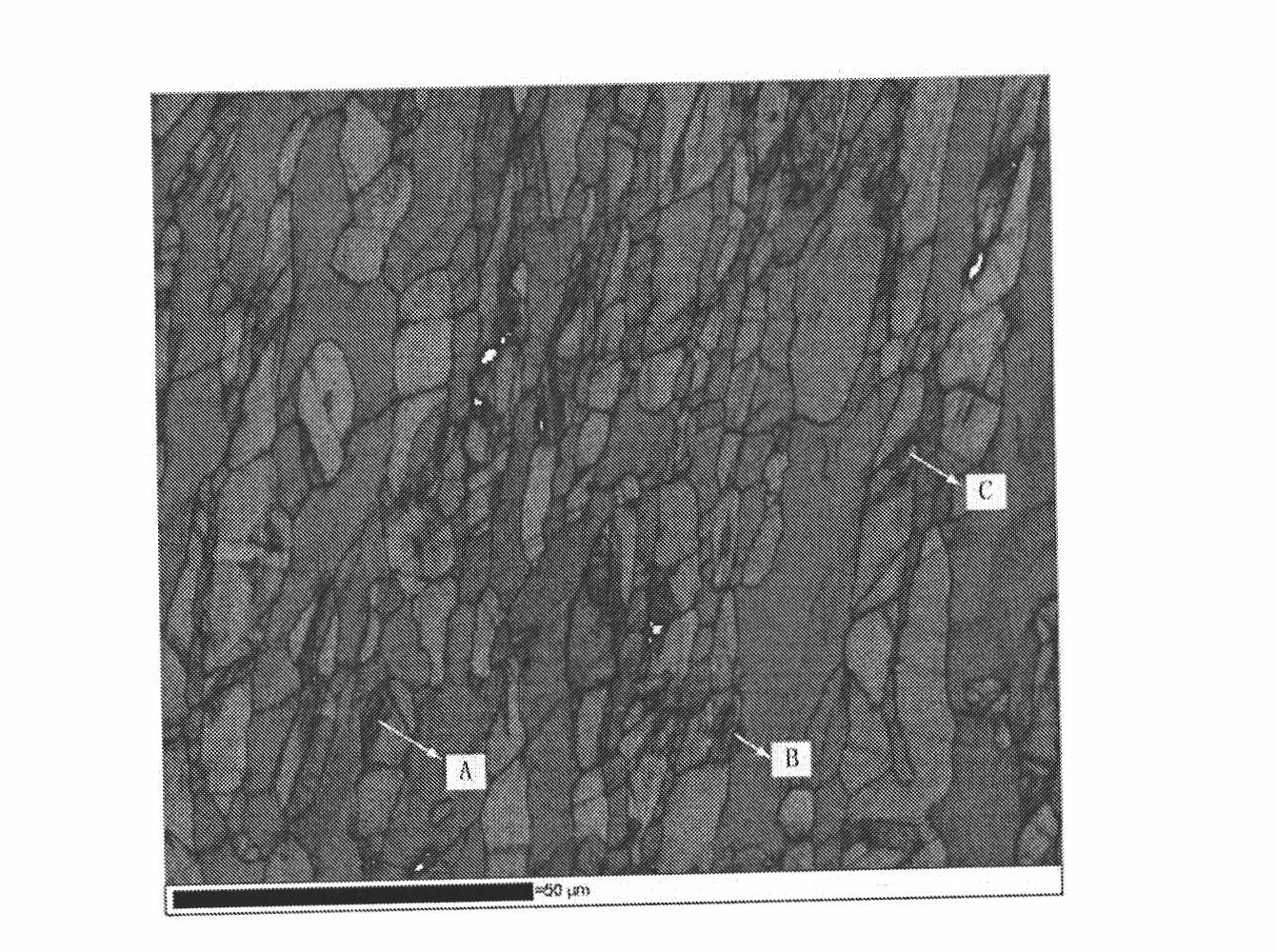

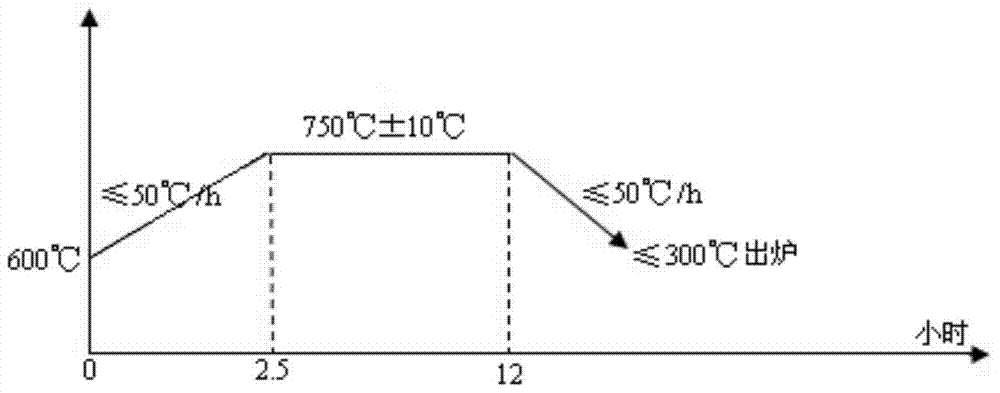

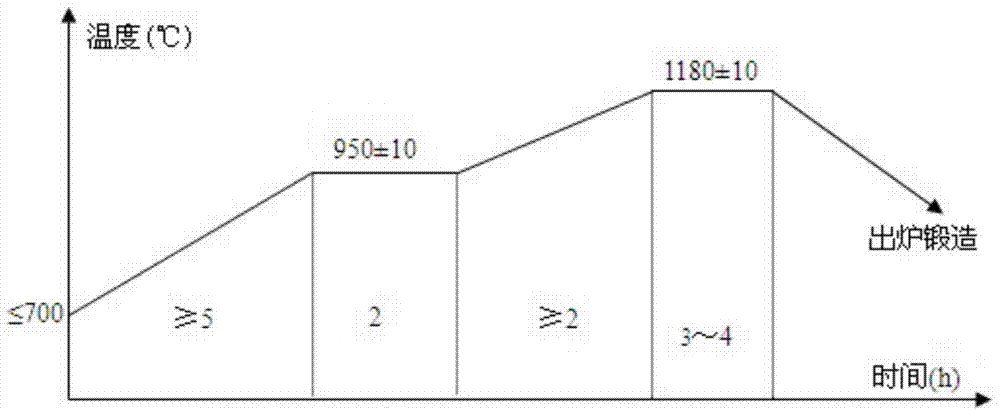

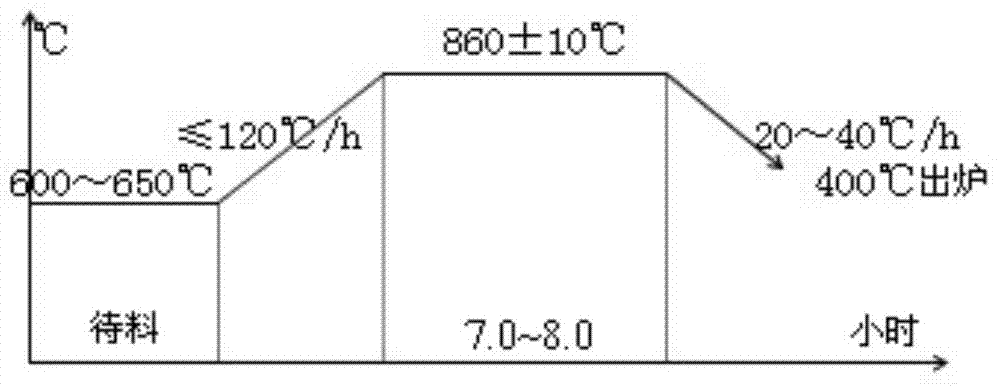

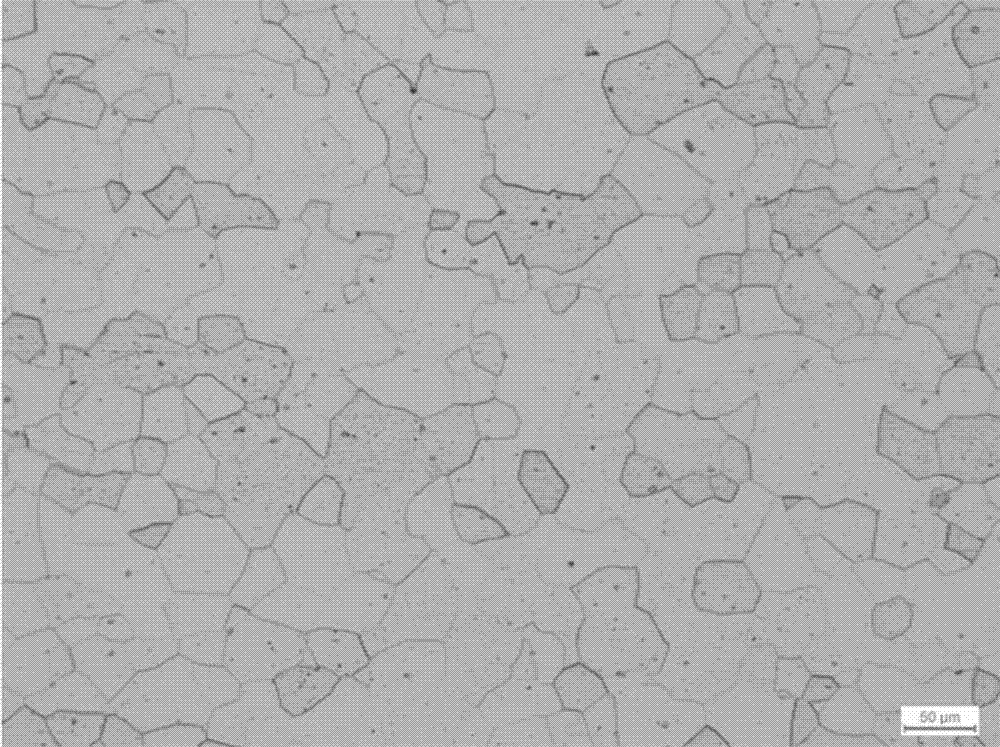

The invention discloses a production method of an integral special-shaped heavy forging made of austenitic stainless steel, and belongs to the technical field of stainless steel machining. The process comprises the following steps of smelting which combines an electric furnace, AOD (argon oxygen decarburization) and electroslag remelting, hammer cogging, upsetting, stretching, remelting heating and forging, heat treatment, machining, cold bending or hot bending machining, heat treatment and the like. Electroslag ingot surface quality is improved through surface grinding, and an electroslag ingot casting-state structure is broken through hammer cogging, so that the hot-working character of billet steel is improved, the electroslag ingot is restrained from hammer cogging, and conditions are provided for following large-deformation upsetting and stretching. The steel ingot crystal grain size is refined through repeated large-deformation upsetting and stretching processes, recrystallized grains are restrained from abnormal growth through controlling of last flame path remelting heating temperature, forging deformation and final heat treatment process, coarse crystals and mixed crystals are avoided, the forging structure is refined, and the crystal grain size reaches a 4.0 grade or high.

Owner:CENT IRON & STEEL RES INST

Desulfurization and deoxidation process for smelting stainless steel in small-capacity AOD (Argon Oxygen Decarburization) furnace by double-slag process

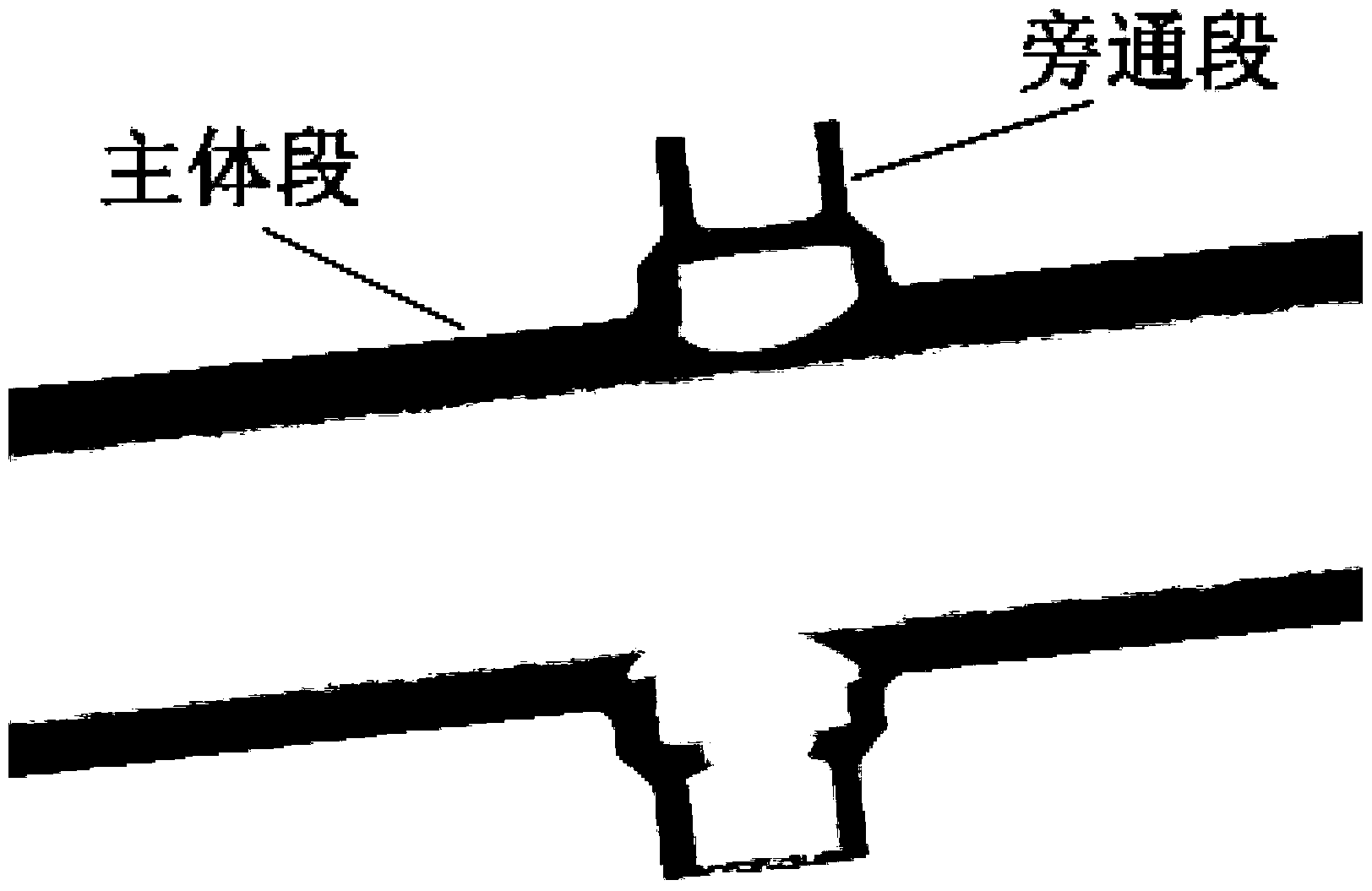

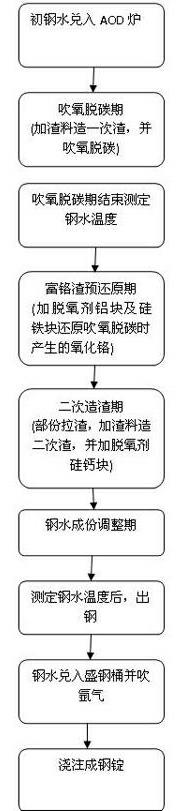

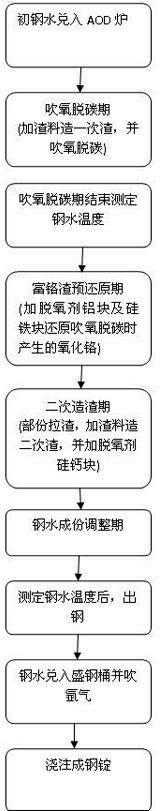

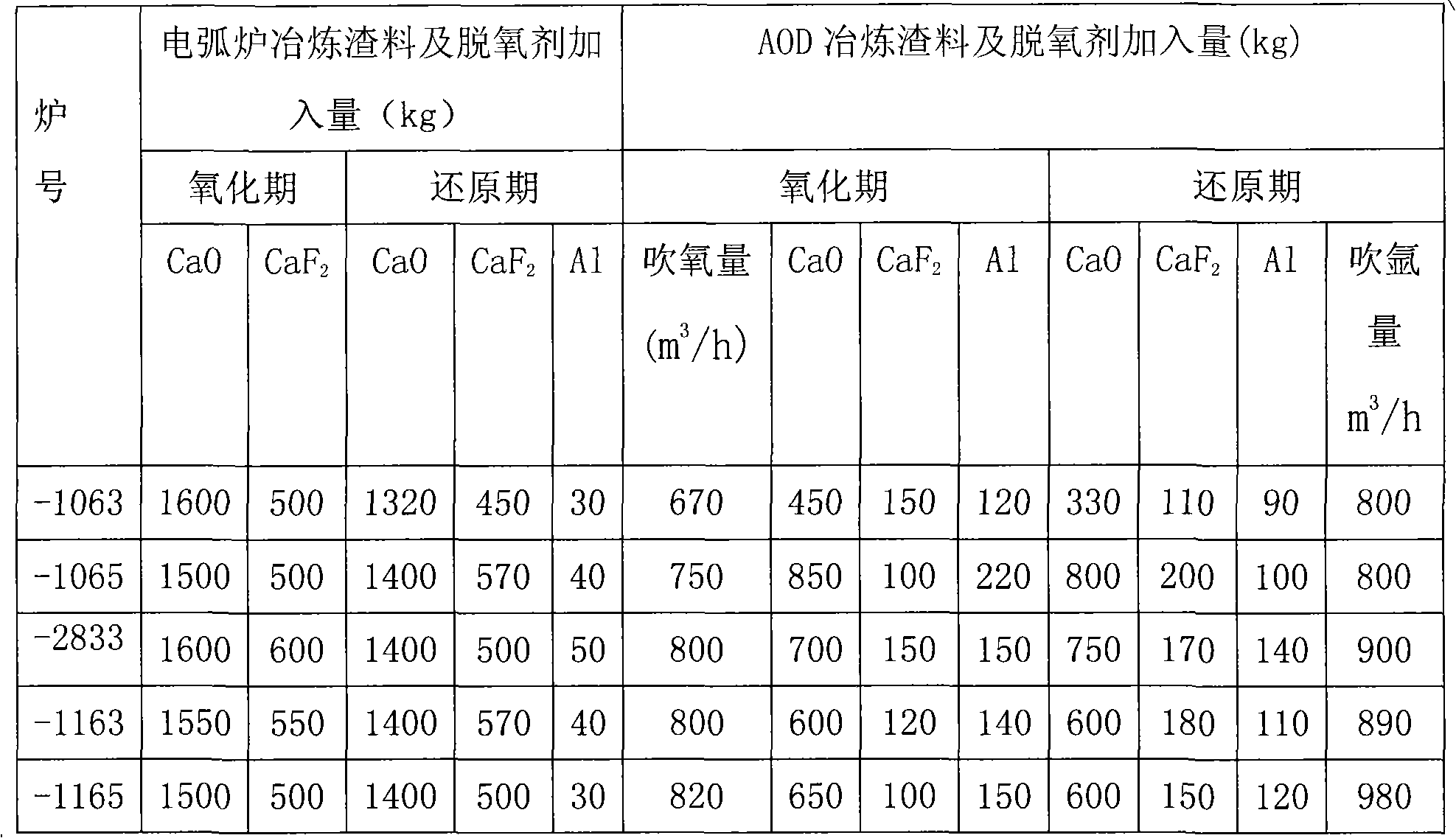

The invention relates to a desulfurization and deoxidation process for smelting stainless steel in a small-capacity AOD (Argon Oxygen Decarburization) furnace by a double-slag process, which is characterized in that the capacity of the AOD furnace is smaller than or equal to 10 tons; and the desulfurization and deoxidation process comprises the following steps of: after initial molten steel is added into the AOD furnace, entering the oxygen blowing and decarburization period, adding slag for primary slag-making and carrying out oxygen blowing and decarburization; after the end of the oxygen blowing and the decarburization, entering the rich chromium residue prereduction period, adding a deoxidizing agent to reduce chromium oxide generated in the oxygen blowing and the decarburization, controlling the temperature of the molten liquid within 1700-1820 DEG C after the end of rich chromium residue prereduction; entering the secondary slag-making period, partially slagging off, controllingthe basicity of slag subjected to secondary slag-making within 1.8-3.8 and controlling the time of argon or nitrogen blowing during the secondary slag-making period to be more than or equal to 2 minutes; then entering the molten steel component adjusting period and adjusting molten steel components; and steel-tapping, controlling the steel-tapping temperature within 1570-1670 DEG C, adding moltensteel into a molten steel holding barrel and pouring the molten steel into an steel ingot. By utilizing the process, the contents of sulphur and oxygen can be remarkably reduced, so that high-alloy super austenitic stainless steel, ultra-low carbon double-phase stainless steel and other high-end stainless steel for cold or hot processing can be successfully smelted.

Owner:HAIYAN ZHONGDA METAL ELECTRONIC MATERIAL CO LTD

Ultra-low carbon high-purity industrial pure iron and manufacturing method thereof

The invention discloses an ultra-low-carbon (ULC) high-purity industrial pure iron and a production method thereof. The invention is mainly characterized in that: the ULC high-purity industrial pure iron contains chemical elements in weight percentage as follows: C is less than or equal to 0.008 percent, Si is less than or equal to 0.05 percent, Mn is less than or equal to 0.05 percent, S is less than or equal to 0.002 percent, P is less than or equal to 0.005 percent, and Al is less than or equal to 0.055 percent. The materials with the proportions of the above chemical compositions are smelted for dephosphorization and desulfurization in an arc furnace, blown with oxygen for decarbonization by AOD (argon-oxygen decarburization), and desulfurized under high temperature and high alkalinity, and finally cast into steel ingots; therefore, the purity of the steel ingots produced by the method can reach 99.5 to 99.7 percent. The maraging steel trial produced by the pure iron of the invention can reach the best level of the steels in China; the pure iron produced by the method of the invention can also improve the performance of other steels such as 00Ni12Cr5Mo3AlTiVA, and push the research and development of high-purity steels.

Owner:宝武特种冶金有限公司

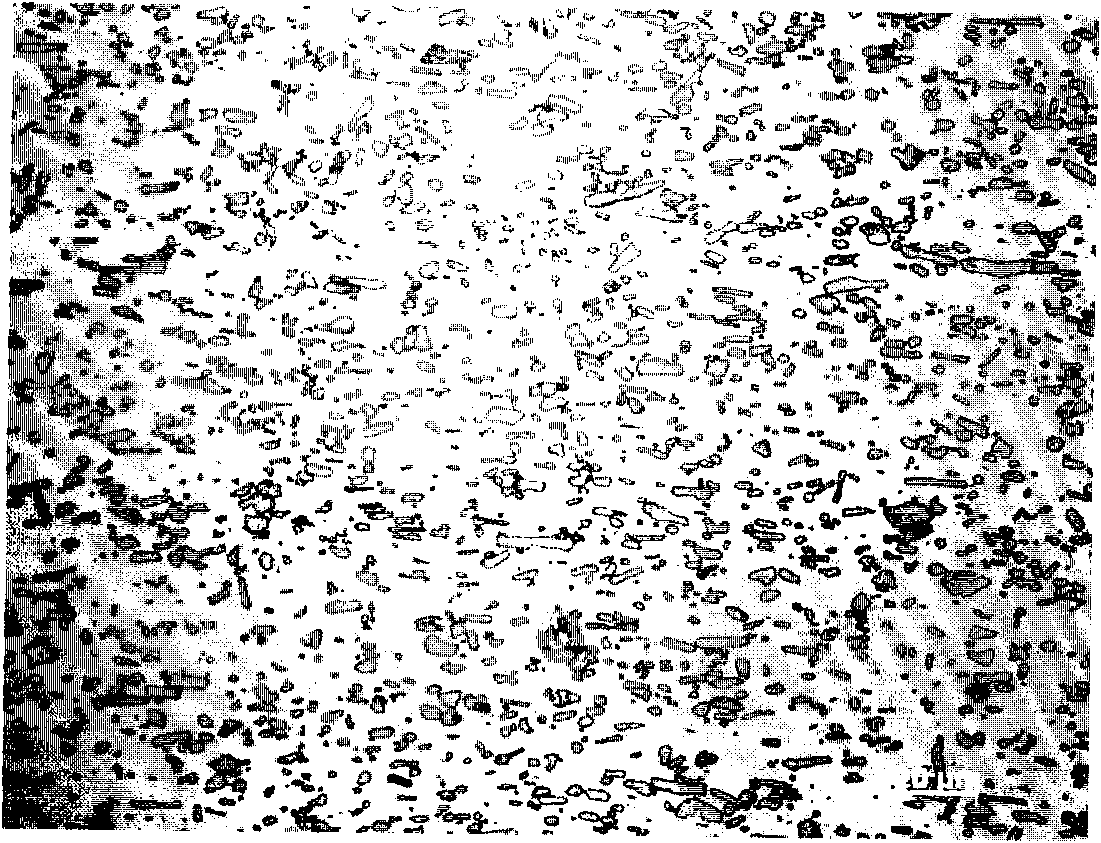

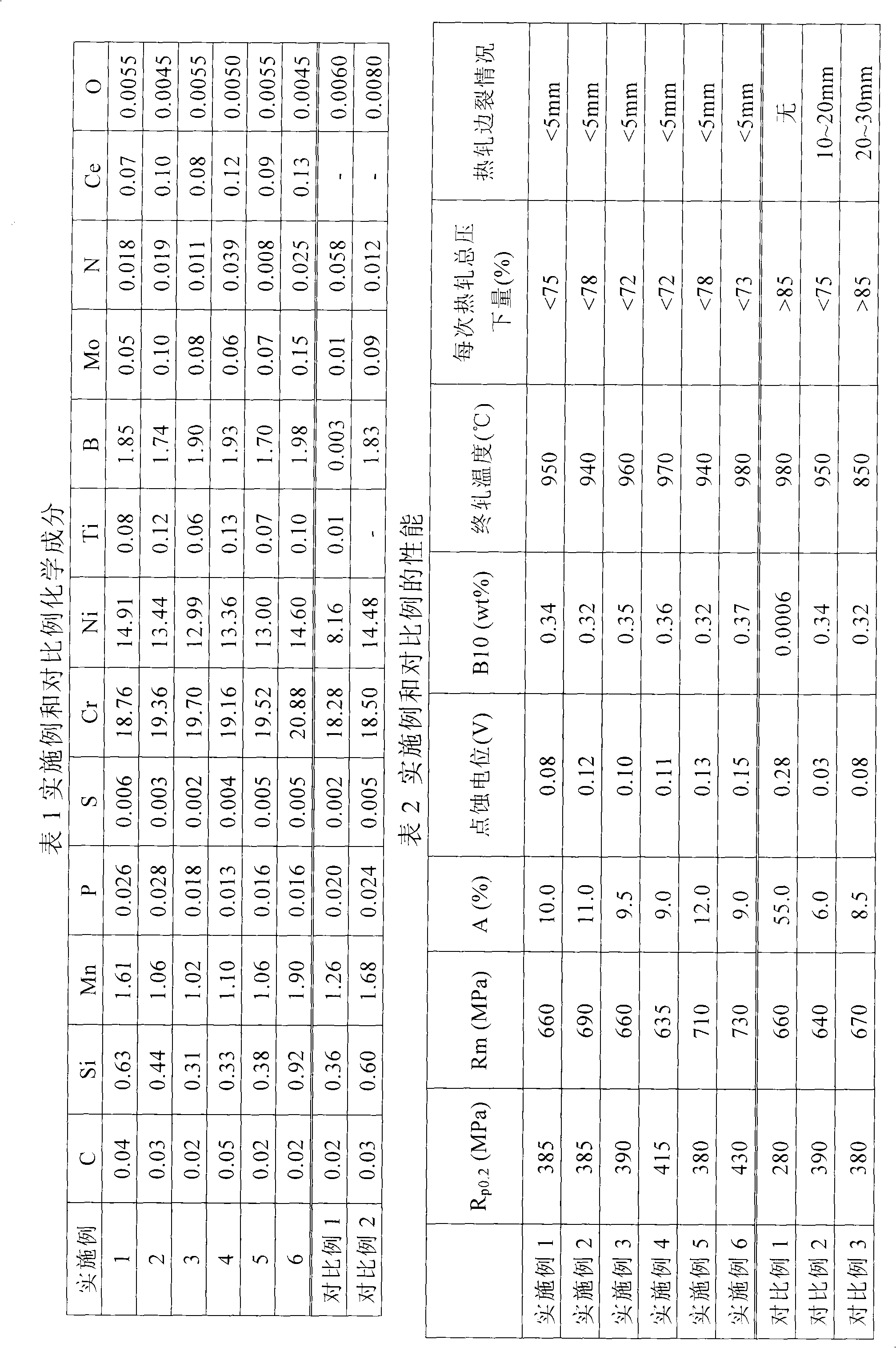

High boron content austenite stainless steel and preparation method thereof

InactiveCN102051531APromote absorptionImprove mechanical propertiesRoll force/gap control deviceTemperature control deviceElectric arc furnaceArgon oxygen decarburization

Owner:BAOSTEEL STAINLESS STEEL

Method for producing high-purity stainless steel

The invention relates to a method for producing a high-purity stainless steel. The method comprises the following steps: molten raw materials are put in an argon oxygen decarburization (AOD) refining furnace to be decarburized, reduced and desulfurized, so that molten steel is obtained; then the molten steel is delivered to a steel ladle; and the molten steel is continuously cast, wherein the treatment of the AOD refining furnace comprises the following steps: after the oxygen blowing decarburization is finished, ferrosilicon is put, meanwhile, slagging and desulfurizing are carried out, the desulfurizing is finished until the S content in the furnace is smaller than 0.01wt%, steel is tapped into the steel ladle from the AOD refining furnace for the first time, after the steel ladle is slagged off, the molten steel is added into the AOD refining furnace again to be slagged again, oxygen is blown, the slag basicity is controlled within the range of 1.4-1.8, argon is then blown, the molten steel is stirred until the S content in the furnace is smaller than 0.01%, and the steel is tapped from the AOD refining furnace again so as to obtain the molten steel. The method adopts the AOD refining furnace, a double-slagging method is adopted, and hard slag inclusions are prevented from being produced, and thus, the high-purity stainless steel is produced.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

Low-alloy high-strength cast steel for low temperature and preparation method thereof

InactiveCN103194687AEasy to useSufficient low temperature toughnessManganeseArgon oxygen decarburization

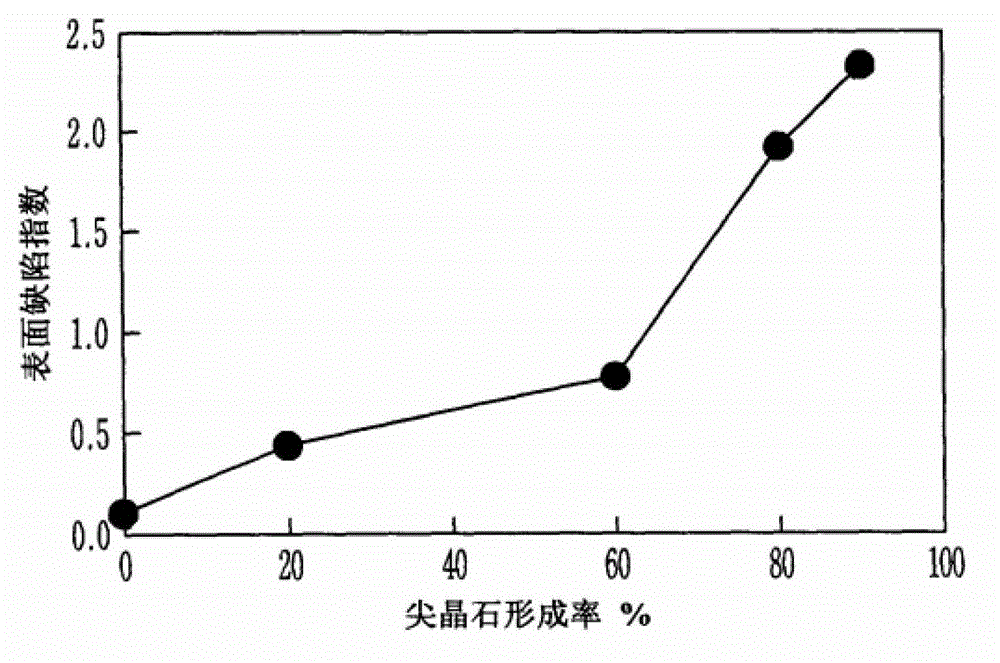

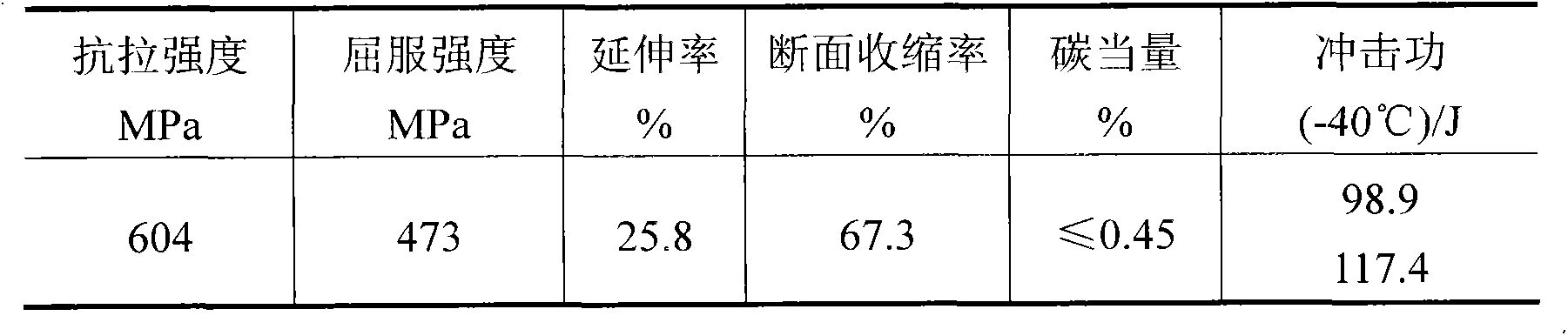

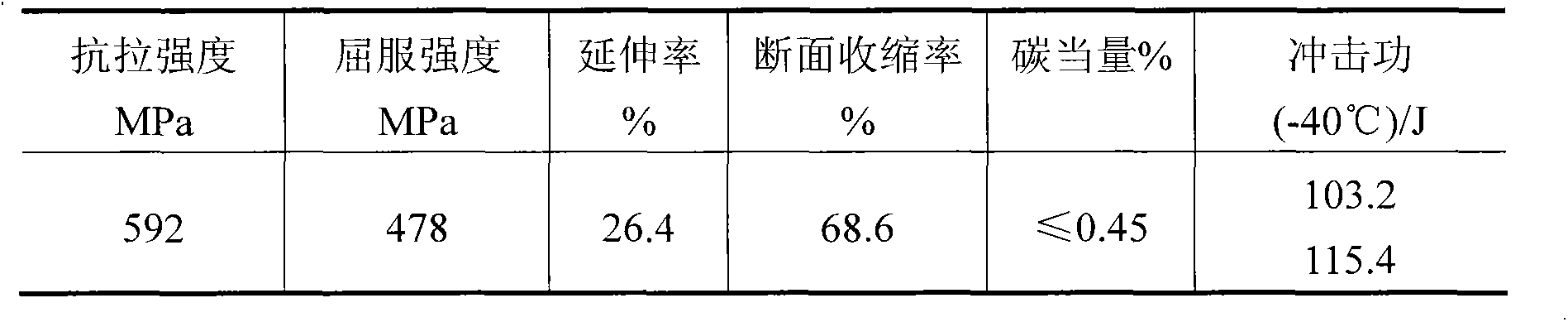

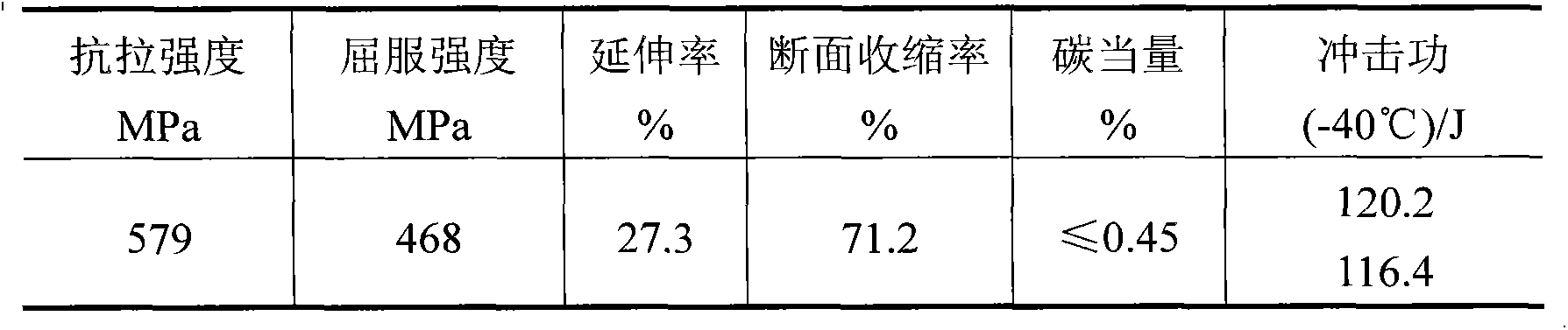

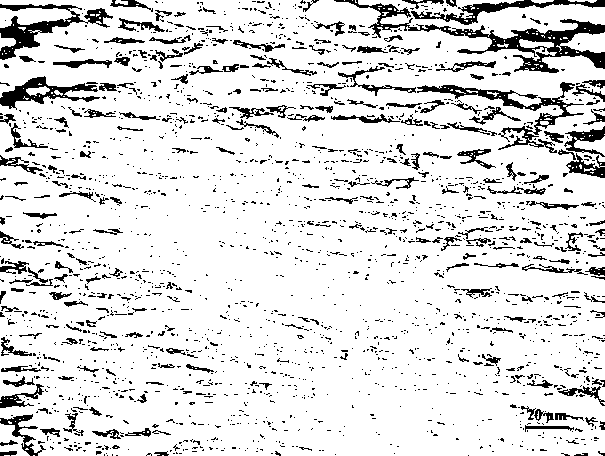

The invention discloses a low-alloy high-strength cast steel for low temperature, and the cast steel comprises the following components in percentage by weight: 0.10%-0.15% carbon, 0.30%-0.60% of manganese, 0.10%-0.50% of silicon, 0%-0.015% of phosphorus, 0%-0.025% of sulfur, 1.0%-1.4% of nickel, 0.20%-0.35% of chromium, 0.20%-0.35% of molybdenum, 0.03%-0.06% of vanadium, 0%-0.01% of copper, 0%-0.08% of aluminum and the balance of iron. The low-alloy high-strength cast steel is prepared through electric furnace and argon oxygen decarburization duplex smelting and pouring and normalizing and high-temperature tempering treatment. The cast steel disclosed by the invention achieves the tensile strength of 570-590 Mpa, the yield strength of 460-475 MPa, the elongation percentage of 25%-27%, the area reduction percentage of 67%-70%, the carbon equivalent less than or equal to 0.45% and the impact energy of 110J at -40 DEG C, has the advantages of high strength, good toughness, excellent low-temperature toughness and welding property especially, less alloy element addition, simple heat treatment process and lower cost and is especially suitable for manufacturing high-strength steel casting materials which have severe requirements on low-temperature toughness and welding.

Owner:CENT SOUTH UNIV

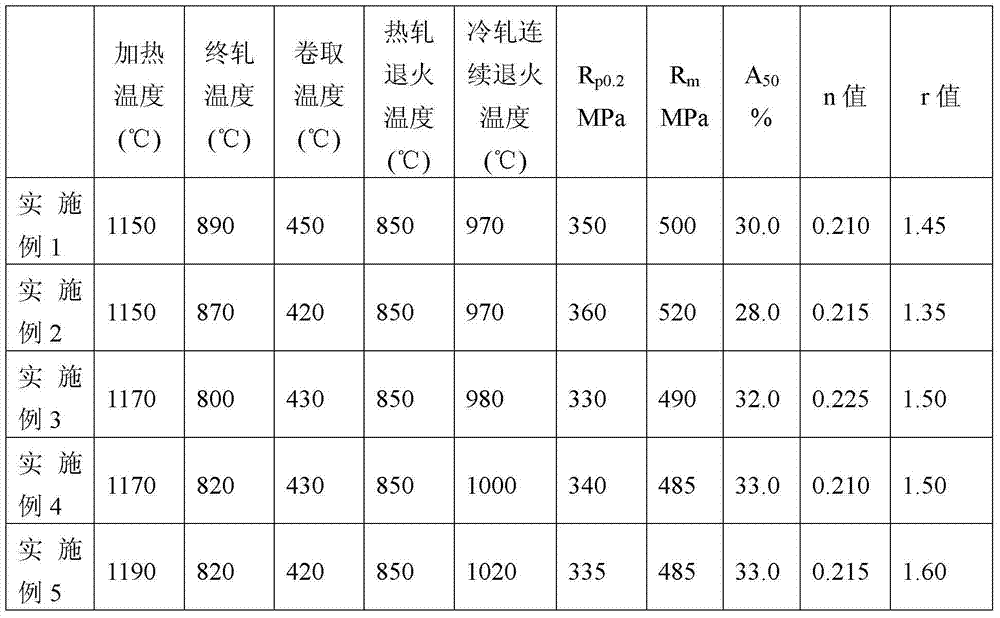

Nickel-saving type double-phase stainless steel and preparation process thereof

ActiveCN103014559AEasy to produceImprove high temperature plasticityHigh carbonIntermediate frequency

The invention relates to a preparation process of nickel-saving type double-phase stainless steel, comprising the following steps of: 1) controlling components of a mother solution in an electric furnace as follows: more than 1.0% of C, less than 1.0% of Si, 12-21% of Cr, 1.5-1.9% of Ni and less than 0.025% of P, controlling a tapping temperature at 1580-1630 DEG C, and mixing the mother solution in the electric furnace with a high-carbon ferro-chrome mother solution in an intermediate-frequency furnace to form a mixed mother solution, wherein the high-carbon ferro-chrome mother solution contains the following components of 6-10% of C, less than 0.5% of Si, less than 0.06% of P, 62-72% of Cr and the balance of iron; and 2) blending the mixed mother solution into an AOD (Argon Oxygen Decarburization) furnace to carry out oxygen blowing and decarburization, nitrogen blowing and component adjustment, refining in a steel ladle refining furnace and adding a micro-alloy into the components, and finally adjusting, wherein the adjusted chrome-nickel equivalence ratio is more than or equal to 2.2. The chrome-nickel equivalence ratio is properly controlled to be good for forming double-phase stainless steel high-temperature ferrite so that heat machining is carried out in a single-phase region to the greatest extent; and furthermore, the preparation process is good for the high-temperature plasticity of the double-phase stainless steel.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

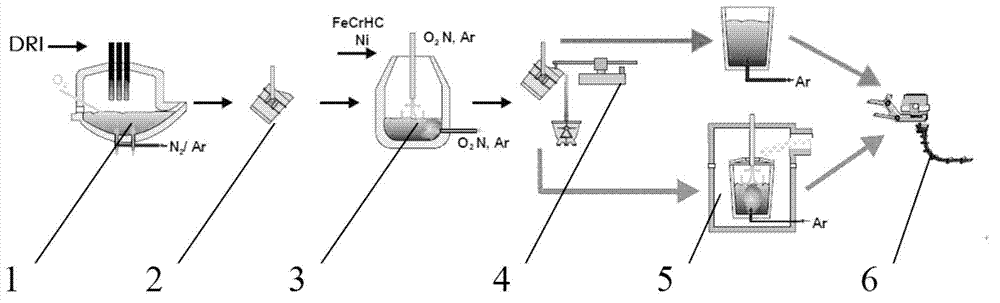

Method for smelting stainless steel by direct reduced iron

The invention relates to a method for smelting stainless steel by direct reduced iron, and belongs to the technical field of stainless steel smelting. The method includes the process steps: melting the direct reduced iron by an electric furnace; refining and alloying the iron by an AOD (argon oxygen decarburization) furnace; refining the iron by the AOD furnace; and continuously casting the iron.Compared with a traditional stainless steel smelting method, the method has the advantages that product quality is high, the content of oxygen, nitrogen, hydrogen and impurities in the steel is low, the P content can be controlled below 0.02%, the variety range is wide, low-carbon and ultra-low-carbon stainless steel, low-P stainless steel and ultra-pure ferrite stainless steel can be produced, and the comprehensive yield of chromium is improved by about 5% as the electric furnace is only used for melting the direct reduced iron and providing high-temperature crude molten steel.

Owner:BEIJING SHOUGANG INT ENG TECH

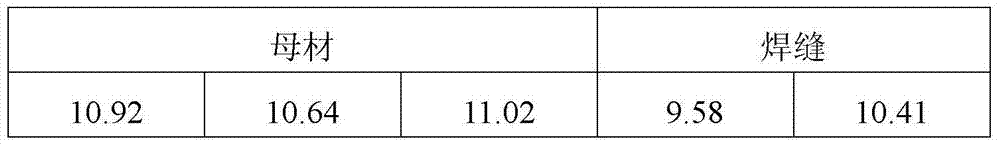

High-performance and high-nitrogen austenitic stainless steel for non-magnetic drill collar and manufacturing method thereof

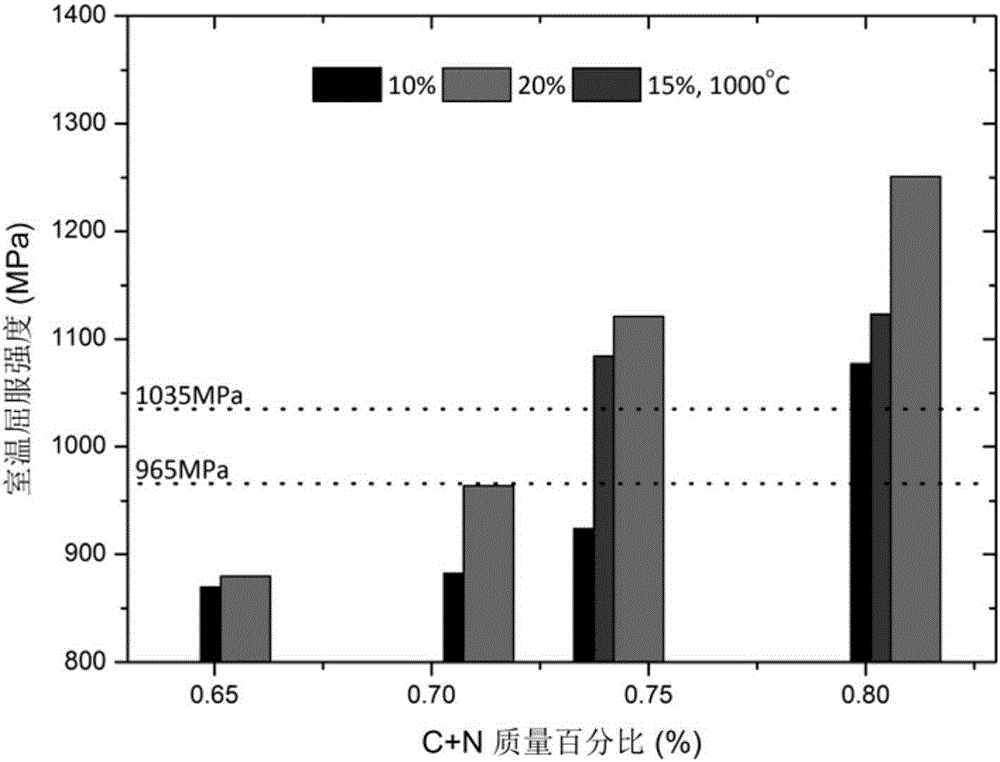

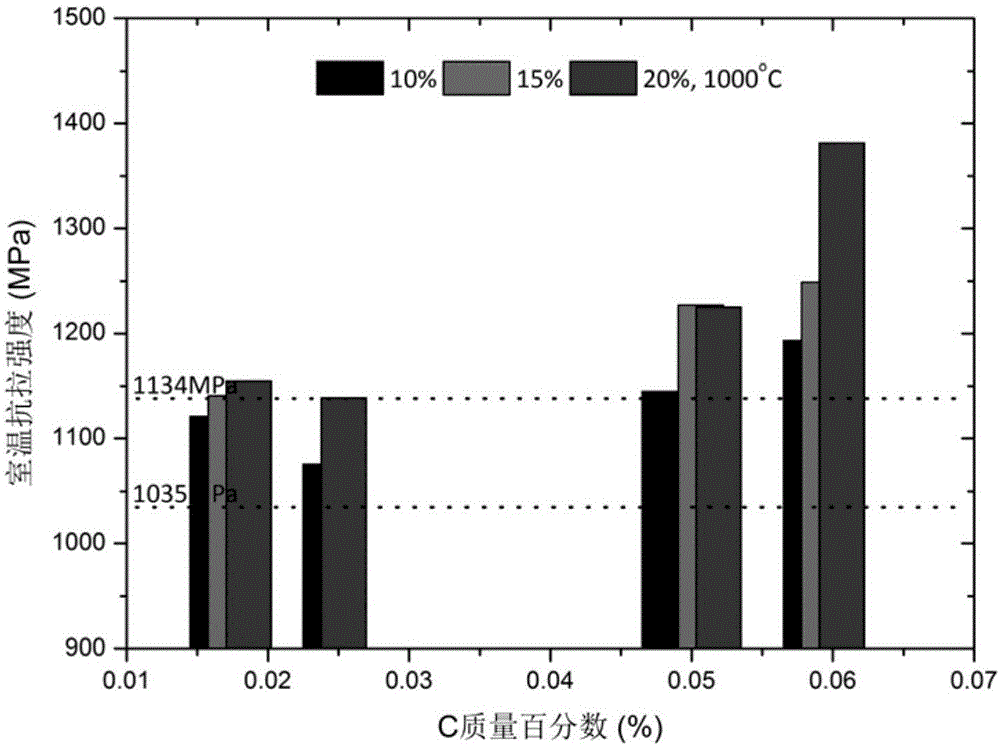

ActiveCN104264071AAvoid sensitive temperature rangesReduce manufacturing costDrilling rodsDrilling casingsRoom temperatureNon magnetic

The invention provides high-performance and high-nitrogen austenitic stainless steel for a non-magnetic drill collar and a manufacturing method thereof, and belongs to the technical field of stainless steel. The stainless steel comprises components in percentage by weight as follows: larger than or equal to 21.5% and smaller than or equal to 22.5% of Cr, larger than or equal to 0.5% and smaller than or equal to 1.5% of Mo, smaller than or equal to 0.040% of C, larger than or equal to 0.65% and smaller than or equal to 0.75% of N, larger than or equal to 0.40% and smaller than or equal to 0.50% of Nb, larger than or equal to 1.95% and smaller than or equal to 2.05% of Ni, larger than or equal to 16.0% and smaller than or equal to 17.0% of Mn, smaller than or equal to 0.20% of Si, smaller than or equal to 0.020% of P, smaller than or equal to 0.010% of S and the balance of Fe, wherein the sum of weight percentage of Cr, a product obtained by multiplying the weight percentage of Mo by 3.3 and a product obtained by multiplying the weight percentage of N by 16.0 is larger than or equal to 33.0%. The manufacturing method of the high-performance and high-nitrogen austenitic stainless steel comprises the steps as follows: smelting by an electric furnace, argon oxygen decarburization for secondary refining, electroslag remelting, cogging by a fast forging machine, forming by a radial forging machine and water cooling treatment. The high-performance and high-nitrogen austenitic stainless steel for the non-magnetic drill collar has the advantages of good room-temperature strength as well as excellent spot corrosion resistance and intercrystalline corrosion resistance.

Owner:CENT IRON & STEEL RES INST

Method for smelting stainless steel by high-chrome melt and dephosphorized pre-melt

InactiveCN102766726AShorten smelting timeReduce smelting tasksElectric furnaceSS - Stainless steelArgon oxygen decarburization

The invention relates to a method for smelting stainless steel by high-chrome melt and dephosphorized pre-melt. The method includes the steps of I, melting high-chrome material in an medium frequency induction furnace to obtain high-chrome melt; II, using an electric furnace to provide dephosphorized pre-melt; III, adding mixture of the high-chrome melt and the dephosphorized pre-melt for AOD (argon oxygen decarburization); IV, slagging in an LTS (ladle treatment station); V, adjusting alloy composition, slagging and refining by the LTS or an LF (ladle furnace); and VI continuous casting. By the method, whole-line metal yield is increased, yield of chrome is increased from 93% to 96%, average AOD smelting time is shortened by 10 minutes, and power consumption is low.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

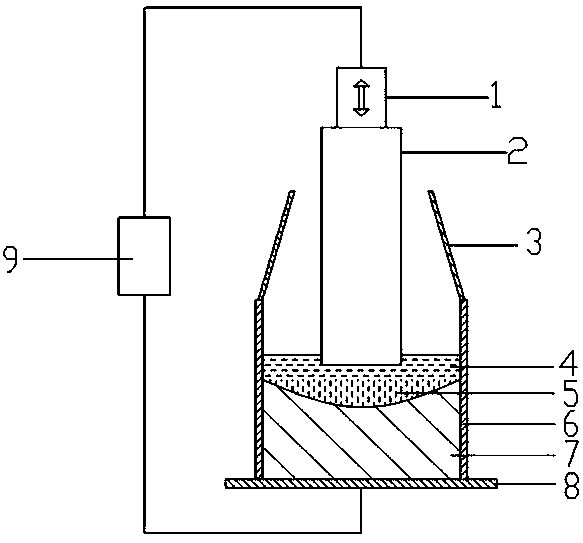

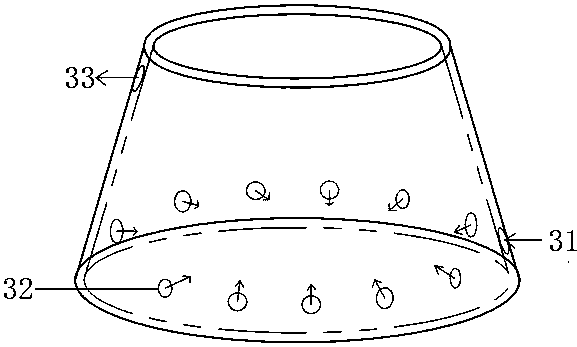

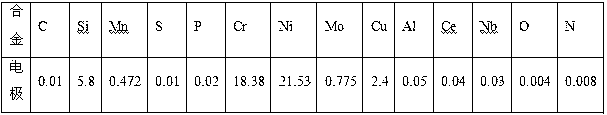

Manufacturing method of high silicon stainless steel for resisting high temperature concentrated sulphuric acid and equipment thereof

ActiveCN107312937AReduce entryUniform compositionIncreasing energy efficiencyIntermediate frequencyChemical element

The invention relates to a manufacturing method of high silicon stainless steel for resisting the high temperature concentrated sulphuric acid and equipment thereof. Firstly, ingredients of chemical elements of a steel ingot are designed, and a round-shaped electrode is smelted through the technology of intermediate frequency induction furnace primary smelting and argon oxygen decarburizing furnace refining; and the steel ingot is smelted through the technology of electro slag remelting (ESR). The equipment of the manufacturing method of the high silicon stainless steel for resisting the high temperature concentrated sulphuric acid includes the electrode and a liquid slag pool; a protection cover is arranged above the liquid slag pool, an inner cavity is formed in the protection cover, and the electrode is arranged in the inner cavity; an inner wall air outlet hole for inert gas is formed in the bottom of the protection cover, a main air inlet hole for the inert gas is formed below the side face, and a main air inlet hole for the inert gas is formed above the side face. The high silicon stainless steel prepared by the method and the equipment is high in concentrated sulphuric acid corrosion resistance under a high temperature environment, and the corrosion rate of the high silicon stainless steel is lower than 0.08mm / year in a H2SO4 solution with the concentration of 98% at the temperature of 150 DEG C.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Driving rod of driving mechanism of nuclear power station control rod and preparation method thereof

InactiveCN103789684AReach mechanicalMeet the requirementsNuclear energy generationReactors manufactureElectricityNuclear power

The invention discloses a driving rod of a driving mechanism of a nuclear power station control rod and a preparation method of the driving rod. The preparation method comprises the following steps: 1) selecting raw materials, smelting by using an electric furnace, refining in AOD (Argon Oxygen Decarburization) and refining by using an LF (Low Frequency) furnace so as to obtain molten iron; 2) casting the molten iron into an electrode; 3) remelting the electroslag of the electrode to obtain a steel ingot, wherein the steel ingot comprises the following components in percentage by weight: less than or equal to 0.150% of C, less than or equal to 1.00% of Mn, less than or equal to 1.00% of Si, less than or equal to 0.030% of S, less than or equal to 0.030% of P, less than or equal to 0.50% of Ni, 11.50-13.50% of Cr, less than or equal to 0.06% of Co, less than or equal to 0.001% of B and the balance of Fe; 4) fogging the steel ingot into a tube blank, hot-rolling and hot-drilling the tube blank so as to obtain a pierced billet; and 5) processing the pierced billet into the driving rod of the driving mechanism of the nuclear power station control rod. When being used in a CRDM (Control Rod Drive Mechanism), the CRDM driving rod prepared according to the method disclosed by the invention is ideal in wear-resistance and free of deflection or deformation and has certain rigidity when being meshed with a hook claw and can be safely operated under the condition of load, the service life meets the CRDM design provision and the national standard requirements, the quality also meets the advanced level of similar products in other countries, and domestication of the CRDM driving rod is achieved.

Owner:中广核工程有限公司 +1

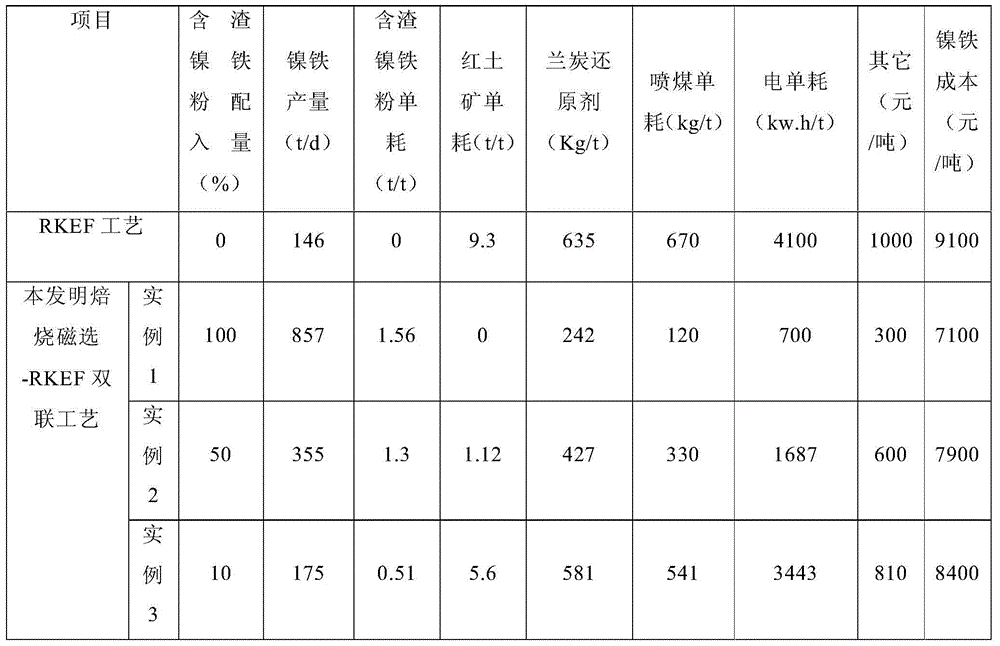

Double-combined method for producing ferronickel through magnetic separation-rotary kiln electric furnace (RKEF)

PendingCN105463185ALow costConforms to the requirements for the composition of molten nickel iron into the furnaceProcess efficiency improvementSlagCombined method

The invention provides a double-combined method for producing ferronickel through a magnetic separation-rotary kiln electric furnace (RKEF). The double-combined method comprises the steps that lateritic ore is subjected to roasting reduction in a roasting rotary kiln to form magnetic iron slag ore; products obtained through magnetic concentration are subjected to RKEF rotary kiln burdening; after being preheated and prereduced in a RKEF rotary kiln, the iron slag ore and the products are together added into an electric furnace in a hot charging mode for heating melting and further reduction; and slag-iron separation is achieved, and crude liquid ferronickel is obtained. The double-combined method has the beneficial effects that slag is separated through a magnetic separation working procedure, so that a large amount of electric energy is saved; meanwhile, selected ferronickel powder obtained through concentration is added, so that the productivity of RKEF is improved, the cost of each ton of liquid high ferronickel is significantly reduced, and the crude liquid ferronickel meeting the composition requirements of into-furnace crude liquid ferronickel for argon oxygen decarburization furnace (AOD) smelting of stainless steel can be produced.

Owner:广西北港新材料有限公司

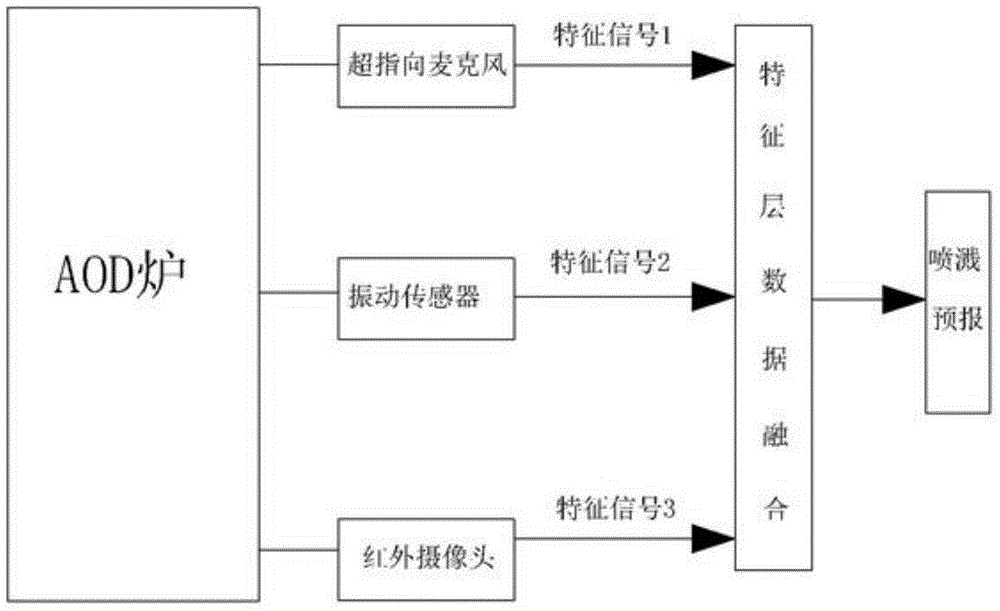

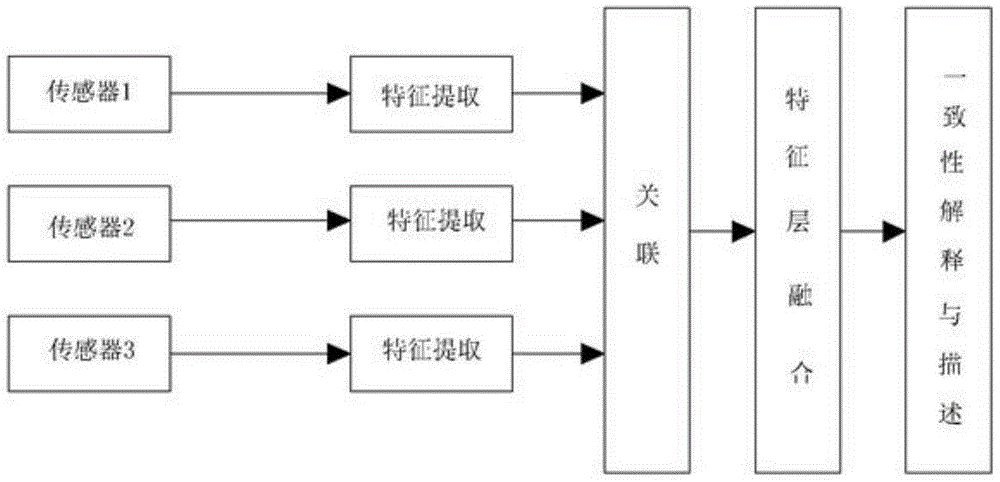

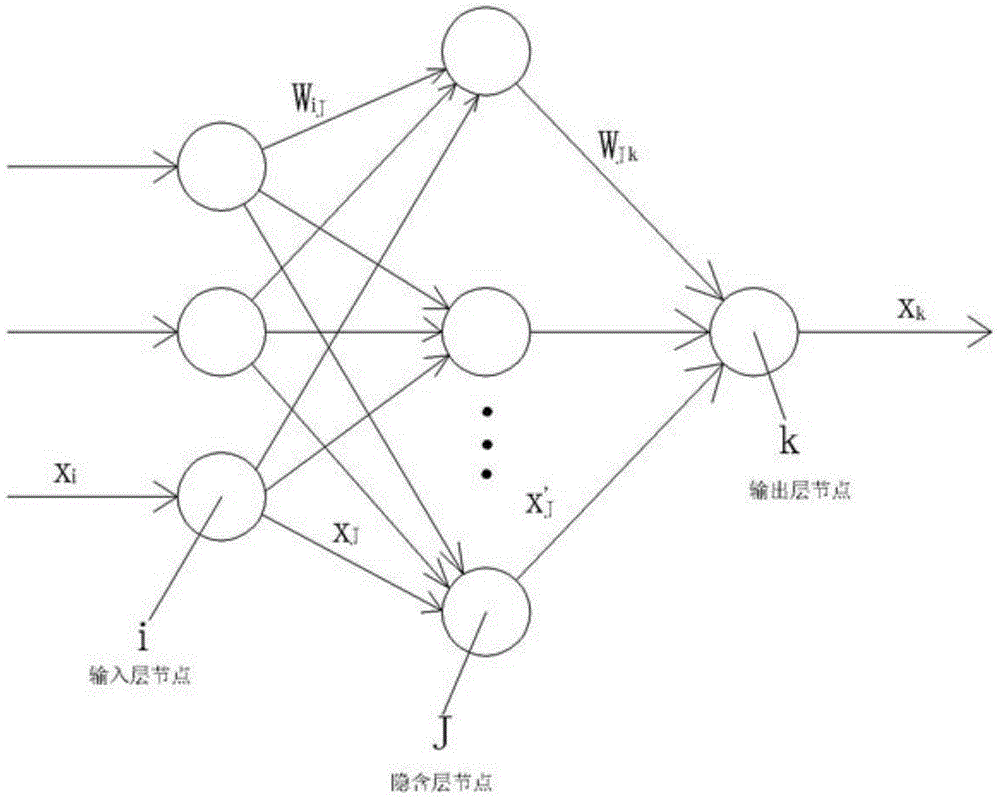

Method for fusing information of spatter predictive analyzers for AOD (argon oxygen decarburization) furnaces

InactiveCN104894335AIncrease uncertaintyImproving the Accuracy of Splash ForecastingBiological neural network modelsCharacter and pattern recognitionResearch ObjectNetwork on

The invention discloses a method for fusing information of spatter predictive analyzers for AOD (argon oxygen decarburization) furnaces. The method has the advantages that spatter occurred in smelting procedures is used as a research object for low-carbon ferrochromium smelting production procedures of the AOD furnaces, features of in-furnace audio signals, furnace mouth flame images and furnace body vibration signals which are acquired in fields are extracted on the basis of deep analysis on spatter occurrence mechanisms in the smelting procedures, the feature-level signals are fused by the aid of a process for fusing data of BP (back propagation) neural networks on the basis of feature level fusion, accordingly, the most reasonable judgment results can be obtained, occurrence of spatter in the low-carbon ferrochromium smelting production procedures of the AOD furnaces can be accurately predicted by the aid of the method, the alloy yield can be increased, and the production safety can be guaranteed.

Owner:CHANGCHUN UNIV OF TECH

Ferritic stainless steel for tubular heat exchangers and manufacturing method thereof

The invention relates to a ferritic stainless steel for tubular heat exchangers and a manufacturing method thereof. The ferritic stainless steel comprises the following chemical components in percentage by weight: at most 0.015% of C, at most 0.020% of N, at most 0.5% of Si, at most 0.5% of Mn, at most 0.035% of P, at most 0.01% of S, 22-24% of Cr, 1.5-3.0% of Mo, 0.0050-0.050% of Al, and the balance of Fe and inevitable impurities, wherein 10(C+N)<=(Nb+Ti)<=0.6%. The manufacturing method comprises the following steps: smelting by an arc furnace+AOD (argon oxygen decarburization)+VOD (vacuum oxygen decarburization) three-step process, carrying out continuous casting to obtain a continuous casting blank, and carrying out hot rolling, acid washing, cold rolling, annealing, acid washing and the like to obtain the high-weldability cold-rolled stainless steel sheet strip. The high-weldability cold-rolled stainless steel sheet strip is suitable for manufacturing welded tubes with higher requirements for corrosion resistance and flaring performance; and the flaring ratio is up to higher than 35%.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Titanium-containing ferritic stainless steel smelting method

ActiveCN103924157AAvoid cloggingPrevent or inhibit the formation ofReduction treatmentTitanium alloy

The invention discloses a titanium-containing ferritic stainless steel smelting method. The titanium-containing ferritic stainless steel smelting method comprises the following steps: (1) carrying out phosphorous removal treatment on molten iron in a phosphorous removal converter; (2) carrying decarburization, denitrification and reduction treatment on molten steel in an AOD (Argon Oxygen Decarburization) converter; (3) tapping the molten steel to a steel ladle; (4) moving the steel ladle to a LF furnace, and then weakly blowing argon; (5) carrying out calcium treatment on a silicon-calcium feeding line; (6) hoisting the steel ladle to a slagging station so as to slag furnace clinker; (7) moving the steel ladle to the LF furnace again so as to carry out titanium alloying; (8) slagging again in the LF furnace; (9) slugging, and heating; (10) carrying out argon blowing treatment in the LF furnace; (11) confirming components and temperature; (12) weakly blowing the LE furnace, and moving out of the LF furnace; and (13) carrying out continuous casting. The titanium-containing ferritic stainless steel smelting method has the advantages that the content of C and N can be controlled at a relatively low level under the condition that vacuum treatment equipment is not provided, meanwhile, the formation of harmful occluded foreign substances such as magnesium and aluminum in the production process is prevented or inhibited, the product quality is improved, the blockage of tundish water gaps is prevented in a continuous casting process, and the smooth production is ensured.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

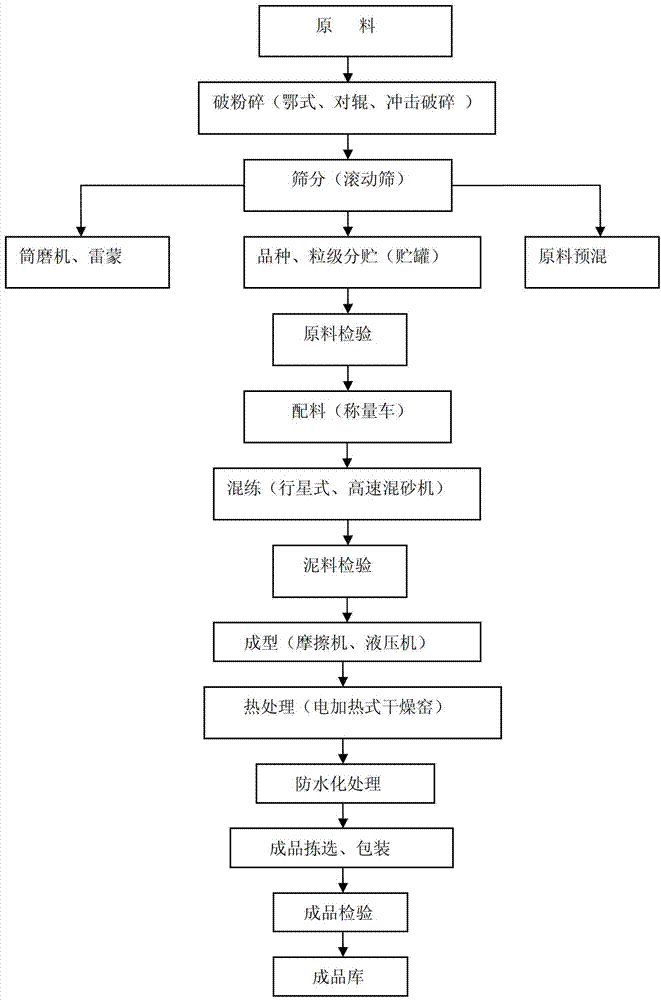

Magnesium-calcium-titanium-carbon brick and preparation method thereof

InactiveCN102765951AImprove thermal shock resistanceSolve the shortcomings of the large change rate of the reburning lineCalcium in biologyHexamethylenetetramine

The invention relates to the field of fireproof materials, particularly to a magnesium-calcium-titanium-carbon brick and a preparation method of the brick. The brick is characterized in comprising the following raw materials based on weight: sintered dolomite sand, fused magnesite, graphite, asphalt powders, anhydrous resin, urotropine, an antioxidant and industrial titanium dioxide. Compared with the prior art, the magnesium-calcium-titanium-carbon brick has the following beneficial effects: (1) the brick can be widely applied to various external refining devices such as LF (ladle furnace), VAD (vacuum arc degassing) furnace, VOD (vacuum oxygen decarburization) furnace, AOD (argon oxygen decarburization) furnace, RH (recirculation degassing) furnace, GOR (gas oxidation refining) furnace, ASEA-DKF and K-OBM-S, thereby having wide application value; (2) the brick can resist against corrosion, endure peeling, and has good high-temperature vacuum stability, and the product is small in re-burning line change, good in thermal shock stability, and not limited by intermittent usage conditions; (3) the product has excellent hydration resistance; and (4) the brick does not contain water or need any external water, so that the magnesium-calcium fireproof material can be effectively protected from hydration, and the brick is especially fit for matching with the magnesium-calcium fire brick.

Owner:营口青花耐火材料股份有限公司

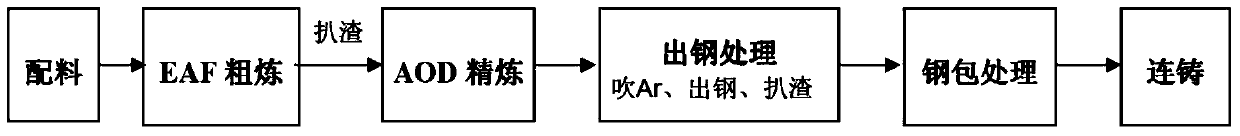

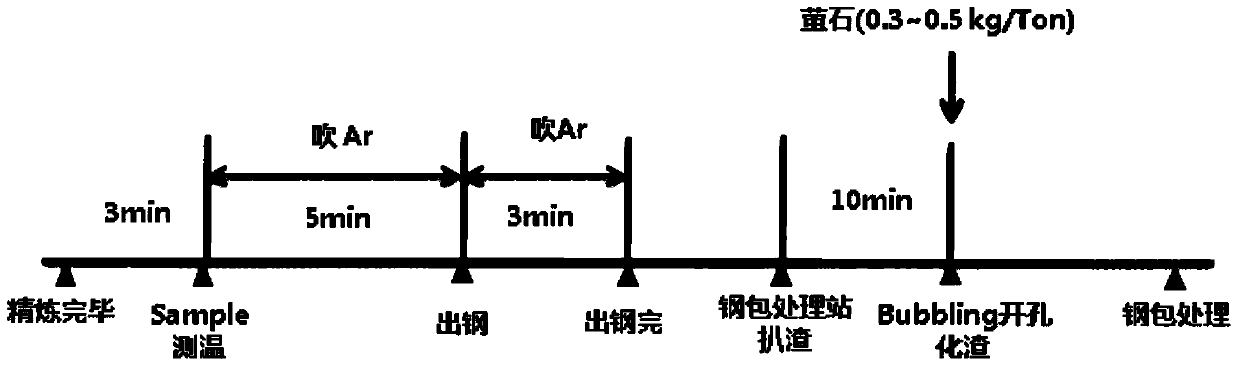

Preparation method of Ti-containing low-nitrogen stainless steel

The invention provides a preparation method of Ti-containing low-nitrogen stainless steel. The preparation method comprises the following steps: subjecting raw materials to mixing, electric furnace coarse smelting, AOD (argon oxygen decarburization) furnace refining, tapping treatment, ladle treatment and continuous casting, thus obtaining Ti-containing low-nitrogen stainless steel, wherein the step of tapping treatment at least comprises the sub-steps of blowing argon into a ladle after AOD furnace refining is completed, tapping molten steel and steel slag from an AOD furnace to the ladle 5-10 minutes later, and continuously blowing argon into the ladle until tapping is completed. The nitrogen uptake of the molten steel after AOD furnace tapping can be effectively reduced by adopting the preparation method, thus reducing precipitation of inclusions such as TiN and the like so as to improve the continuous casting level and improve the surface quality of the stainless steel.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

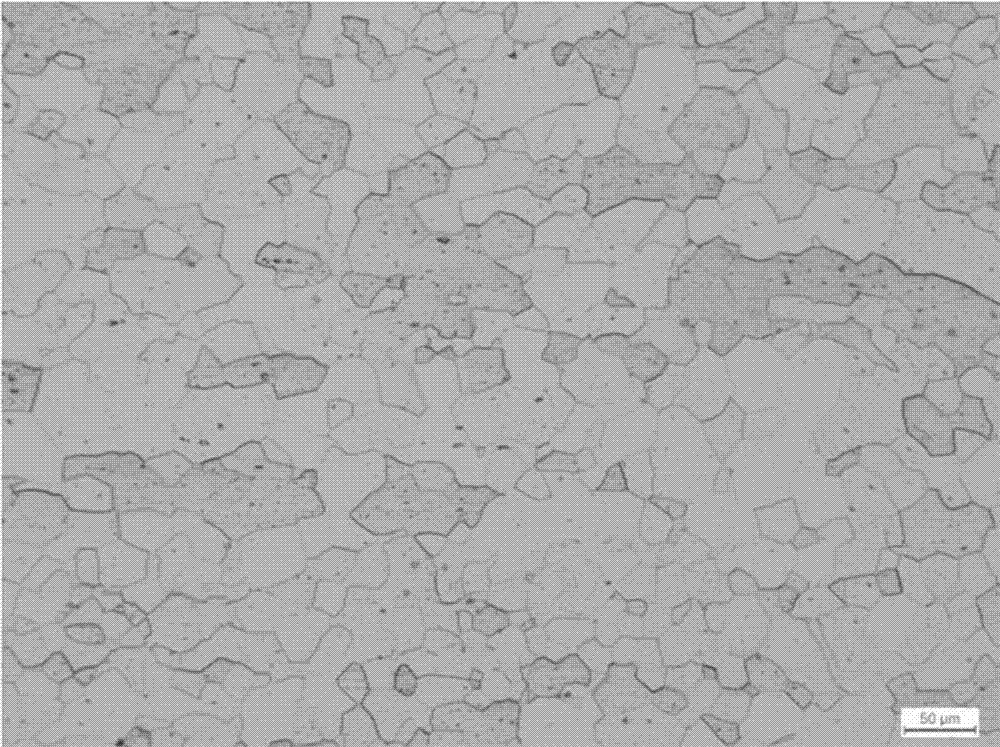

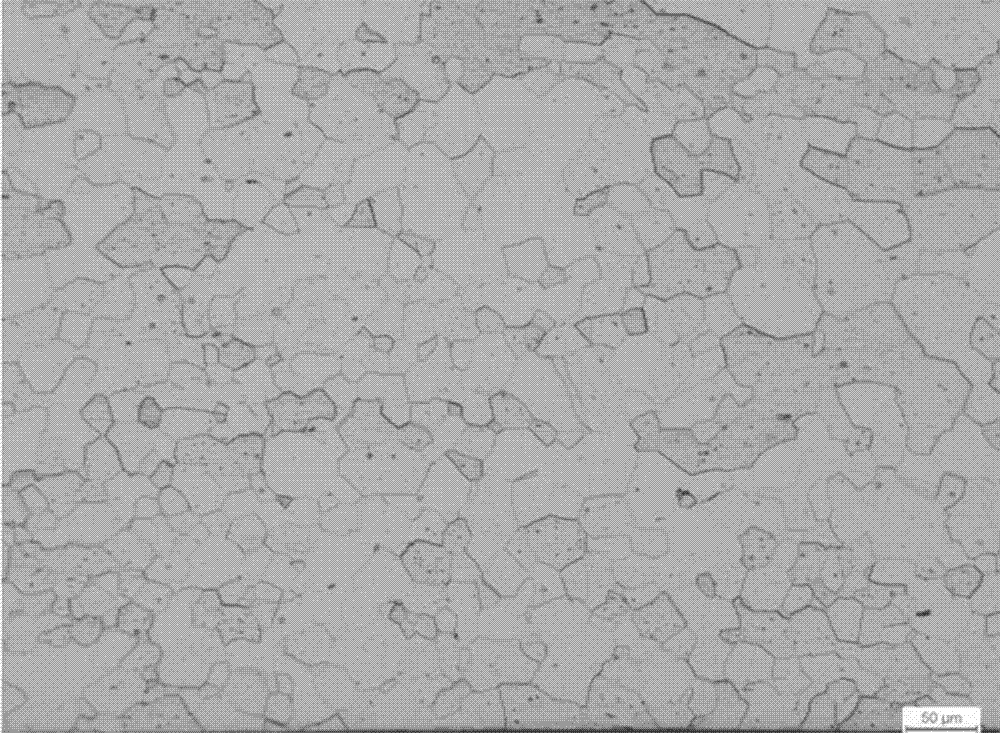

High-strength and high-hardness medium-chromium ferritic stainless steel and manufacturing method thereof

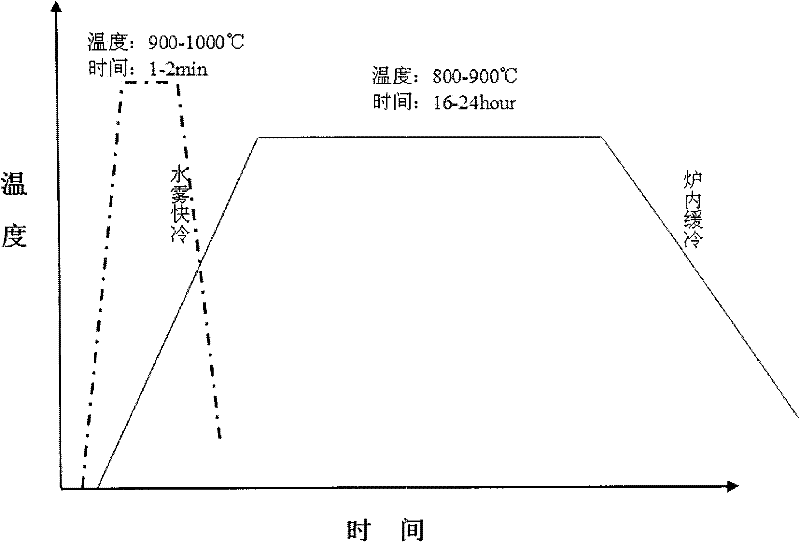

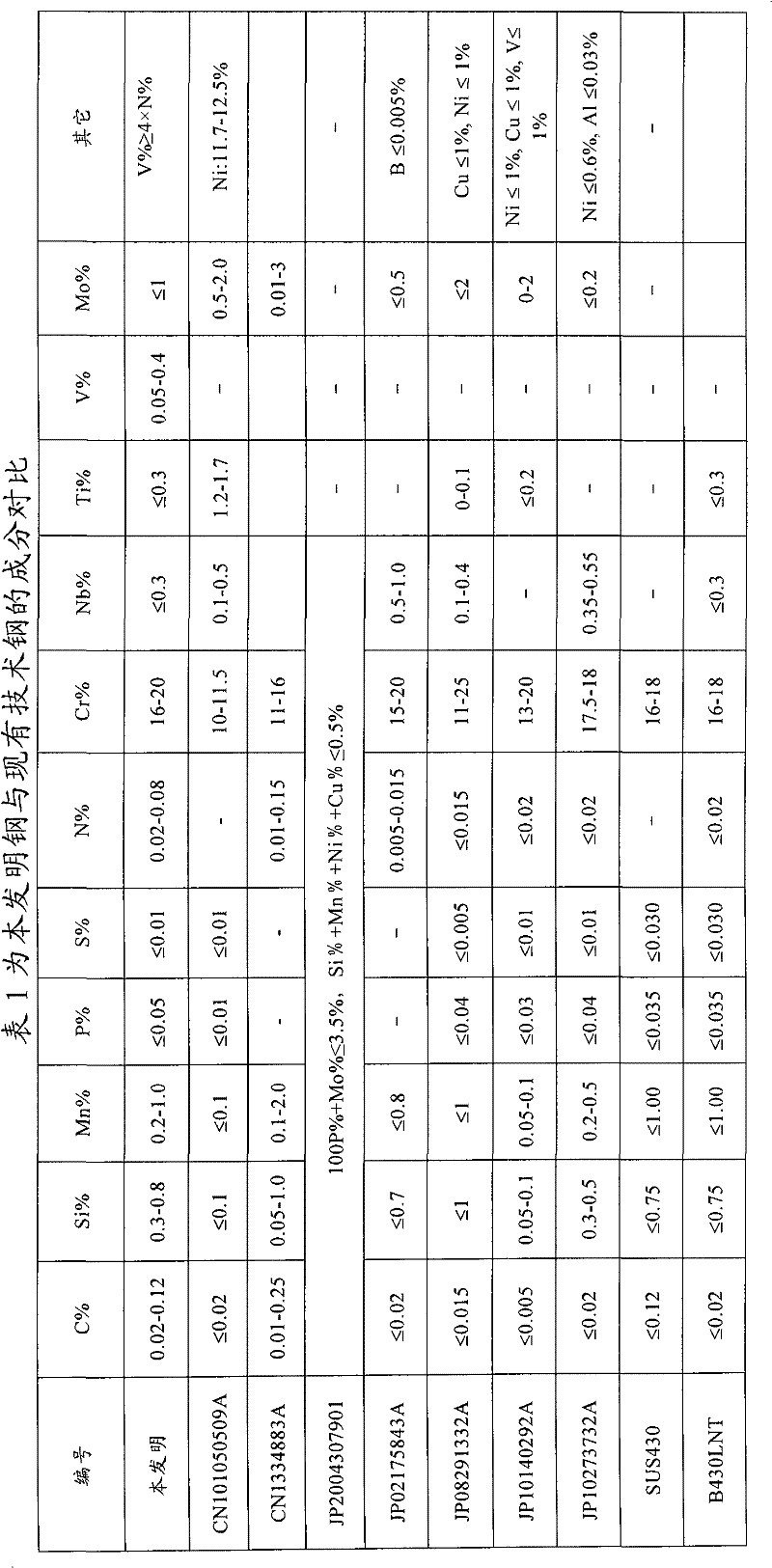

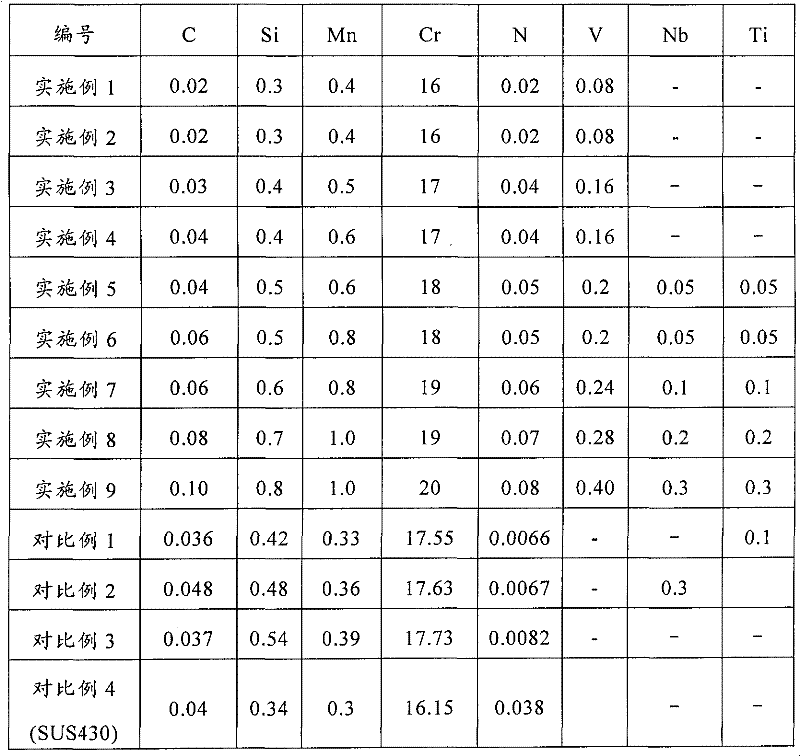

The invention relates to high-strength and high-hardness medium-chromium ferritic stainless steel, which comprises the following chemical components in weight percentage: 0.02-0.10 percent of C, 0.30-0.80 percent of Si, 0.40-1.0 percent of Mn, 16.0-20.0 percent of Cr, 0.02-0.08 percent of N, 0-0.3 percent of Ti, 0.08-0.4 percent of V, 0-0.3 percent of Nb and the balance Fe and unavoidable impurities, wherein V percent is not less than 4*N percent. A manufacturing method for the ferritic stainless steel comprises the following steps of: electric furnace and argon oxygen decarburization two-step smelting, casting, hot rolling, cover annealing, acid washing, cold rolling and cold-annealing acid washing, wherein the finish rolling temperature of the hot rolling is controlled to between 800 DEG C and 950 DEG C; the annealing temperature of the hot rolling is controlled to between 800 DEG C and 900 DEG C; the annealing time is 16-24 hours; an in-furnace slow cooling mode is adopted to serve as a cooling mode; the annealing temperature of the cold rolling is controlled to between 900 DEG C and 1000 DEG C, the annealing time is 1-2 minutes, and a spray rapid cooling mode is adopted to serve as the cooling mode. The tensile strength of the obtained steel is 450-600MPa, the yield strength is 250-350MPa, the Vickers hardness is 145-170, and the coefficient of elongation is 30-40 percent.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

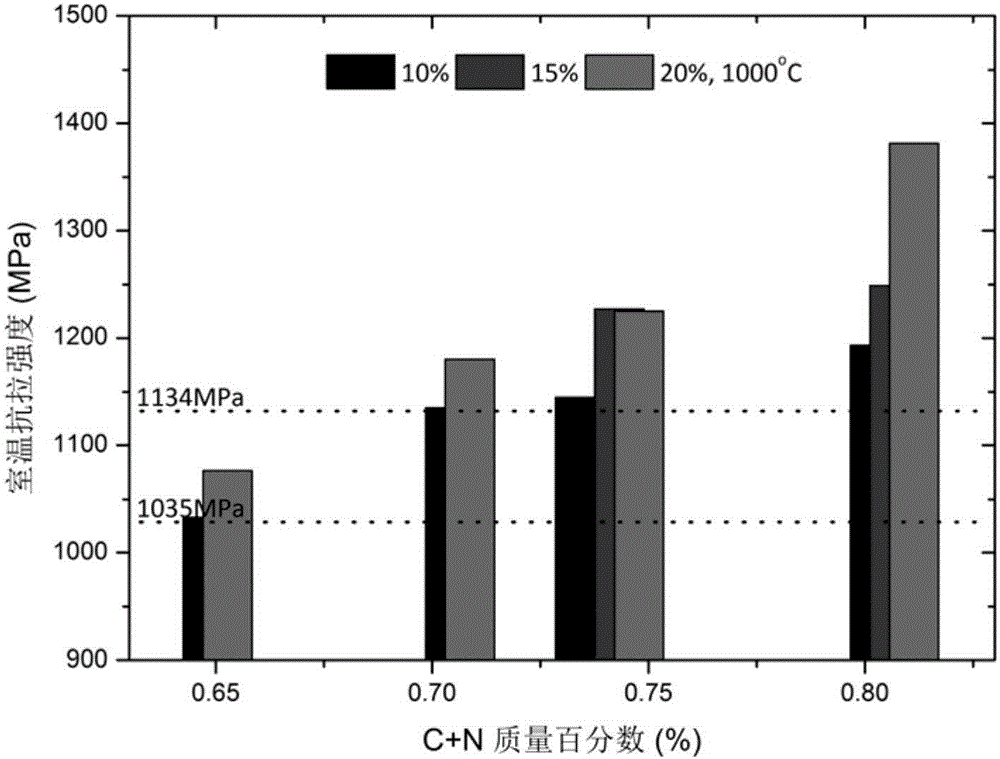

Novel high-nitrogen austenitic stainless steel for non-magnetic drill collar and manufacturing method of novel high-nitrogen austenitic stainless steel

ActiveCN106702290AAvoid the sensitive temperature range that is easy to generateImprove intergranular corrosion resistanceNon magneticWater cooling

The invention relates to novel high-nitrogen austenitic stainless steel for a non-magnetic drill collar and a manufacturing method of the novel high-nitrogen austenitic stainless steel, and belongs to the technical field of stainless steel materials. The stainless steel comprises, by weight, 22.15-23.50% of Cr, 0.56-0.68% of Mo, 0.047-0.060% of C, 0.70-0.81% of N, 0.95-2.14% of Ni, 16.20-16.94% of Mn, 0.17-0.24% of Si, 0.008-0.010% of P, 0.008-0.012% of S, and the balance Fe, wherein the C+N is greater than or equal to 0.747% but smaller than or equal to 0.836% by weight, and Cr+3.3*Mo+16.0*N is greater than or equal to 35.0% by weight. The manufacturing method comprises the steps of non-vacuum induction melting, argon oxygen decarburization external refining, cogging by a quick forging press, molding by a radial forging machine, and water-cooling treatment. The novel high-nitrogen austenitic stainless steel for the non-magnetic drill collar has the advantages of excellent indoor temperature strength and intercrystalline corrosion resistance.

Owner:CENT IRON & STEEL RES INST

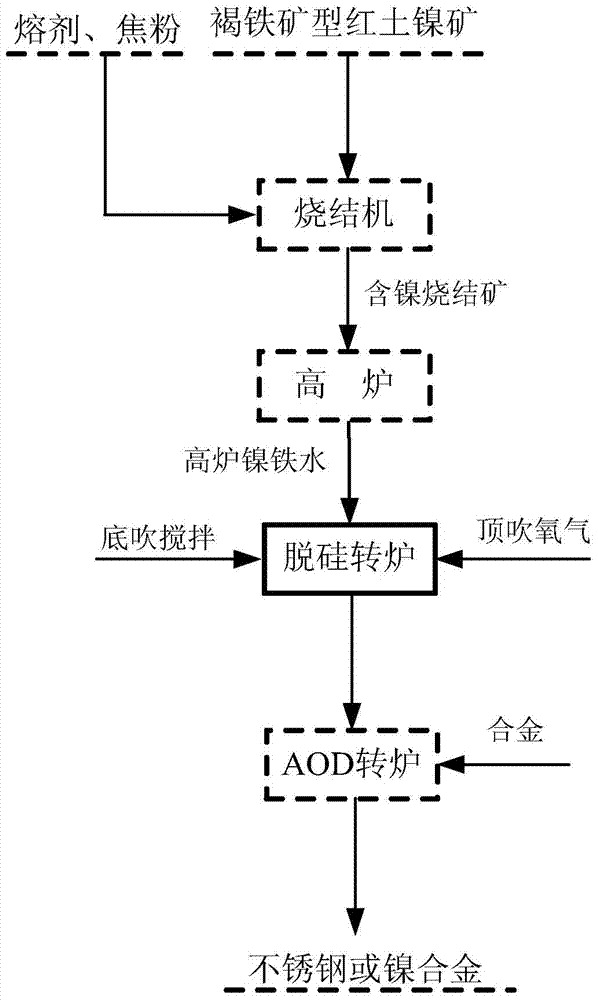

Method for producing phosphorus weathering resistant steel from limonitic laterite ore

ActiveCN103343291AImproved method of producing weathering steelRich sourcesBlast furnace detailsProcess efficiency improvementElectrical steelPhosphor

The invention provides a method for producing phosphorus weathering resistant steel from limonitic laterite ore. The method comprises steps of preparing ore; preparing sinter; carrying out blast furnace iron making; implementing argon oxygen decarburization (AOD) refining; performing LF (Ladle Furnace) refining; after obtaining molten weathering resistant steel, continuously casting the molten steel into a slab or a billet through a slab or billet continuous casting machine, or furthermore, implementing controlled rolling to the obtained slab or billet through a continuous mill group, so as to produce weathering resistant steel profile or slab. The method has the beneficial effects that the adopted raw material, namely limonitic laterite ore containing nickel and phosphor, is abundant in source and cheap in price, thus saving resource, relieving environmental pollution, recycling waste material and realizing comprehensive utilization; a blast furnace greater than 300m<3> can be used for melting the limonitic laterite ore containing nickel and phosphor, so as to realize long-term large-scale production and improve the production efficiency; the production process of the weathering resistant steel omits a process of converter or electric steel making, thus greatly reducing the production cost of the weathering resistant steel.

Owner:前海索新发展科技(深圳)有限公司

Manufacturing method of magnesium-calcium regeneration brick

The invention relates to a manufacturing method of a magnesium-calcium regeneration brick. The manufacturing method comprises the following steps of: preparing waste magnesium-calcium bricks which are just discharged and removed from each refining furnace, cleaning the waste magnesium-calcium bricks up, and then storing the waste magnesium-calcium bricks in a dry and airtight environment; putting the waste magnesium-calcium bricks into a kiln in time and rapidly calcining, and then crushing the calcined magnesium-calcium bricks to obtain waste magnesium-calcium brick granule sand; and carrying out die pressing and firing on the waste magnesium-calcium brick granule sand instead of a great mass of new magnesium-calcium sand raw materials to obtain a regenerated magnesium-calcium brick product. According to the manufacturing method, the quality of crushed materials of the waste magnesium-calcium bricks is similar to that of the new magnesium-calcium sand and the waste magnesium-calcium bricks can substitute the new magnesium-calcium sand, and therefore the addition amount of the waste magnesium-calcium brick granules in the fired magnesium-calcium brick is greatly increased. Proved by practices, the addition amount of the waste magnesium-calcium brick granules in the regenerated magnesium-calcium brick can reach 50-75 percent, and the regenerated magnesium-calcium brick reaches the performance level of the original magnesium-calcium brick, therefore, refractories of AOD (Argon Oxygen Decarburization), VOD (vacuum oxygen debikeburization) and other refining furnaces can be circularly recycled, the purpose of zero emission is reached, the consumption of dolomite ore sources is effectively reduced, and the cost and the environmental pollution degree are lowered.

Owner:HUZHOU MINGDE REFRACTORY MATERIAL

Method for adding nitrogen into stainless steel used for thermonuclear fusion reactor

The invention relates to a method for adding nitrogen into stainless steel used for a thermonuclear fusion reactor. The method comprises the following steps of: I, pouring molten steel meeting requirements of an AOD (argon oxygen decarburization) furnace into the AOD furnace to be smelted; II, carrying out a process for controlling nitrogen component of the AOD furnace, namely blowing argon and stirring before tapping, wherein argon blowing-in amount target value Y is calculated according to the following formula: Y=17.5e-0.002X, X (ppm) is the target nitrogen content of a product, and Y (cubic meter per ton of steel) is amount of argon blown into the molten steel; and III, carrying out an LF (ladle furnace) process, comprising the steps of pouring the molten steel into an LF, controlling LF bottom blowing nitrogen flow to be 0.2-1.0L / min per ton of steel when the nitrogen content of the molten steel is at the target range requirement, carrying out LF furnace nitrogen bottom blowing to increase nitrogen content when the nitrogen content of the molten steel is lower than target requirement, wherein the amount of nitrogen blown into the molten steel is calculated according to the following formula: W=K / (2.0*m), K is nitrogen content added value required by the product, m is time for blowing nitrogen, and W is flow rate of nitrogen blown into the molten steel; and tapping when composition requirement of the molten steel is met. By applying the method for adding nitrogen provided by the invention, the nitrogen content can be easily controlled to be within the target range.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Molten iron desilication method for stainless steel smelting

ActiveCN103614609ALow Si content requirementEnough reaction spaceManufacturing convertersIRON PREPARATIONSFerrosilicon

The invention provides a molten iron desilication method for stainless steel smelting, which comprises the following steps: 1. blast furnace molten iron preparation: mixing and sintering laterite-nickel ore, adding the laterite-nickel ore into a blast furnace, and smelting while ensuring the blast furnace tapping temperature to be at least 1350 DEG C; 2. transportation: transporting the high-temperature nickeliferous high-silicon molten iron of the blast furnace to a desilication converter in the one-step or metal mixer form; 3. carrying out desilication, decarburization, dephosphorization and desulfurization on the nickeliferous high-silicon molten iron in the desilication converter, and carrying out desilication treatment on the molten iron in a top / bottom blowing mode, wherein the mass percent of silicon in the desilicated molten iron is not greater than 0.20%; and 4. final product smelting: after finishing converting, charging the semisteel from the desilication converter into an AOD (argon oxygen decarburization) furnace while adding alloy into the AOD furnace, and finishing the final smelting of stainless steel. The desilication technique has low requirements for Si content in the molten iron, provides sufficient reaction space for desilication, effectively prevents splashing, creates favorable dynamic conditions for desilication, and meanwhile, can perform dephosphorization and desulfurization.

Owner:BERIS ENG & RES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com