High-strength and high-hardness medium-chromium ferritic stainless steel and manufacturing method thereof

A high-hardness, high-strength technology, used in temperature control and other directions, can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

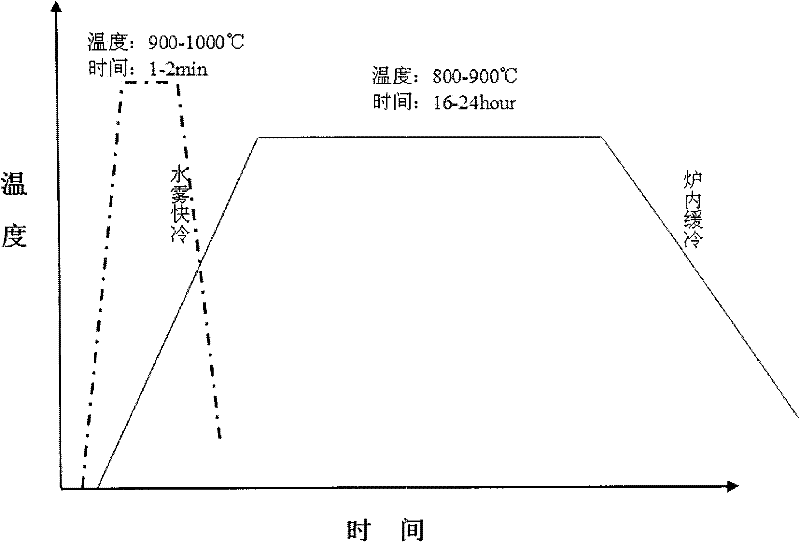

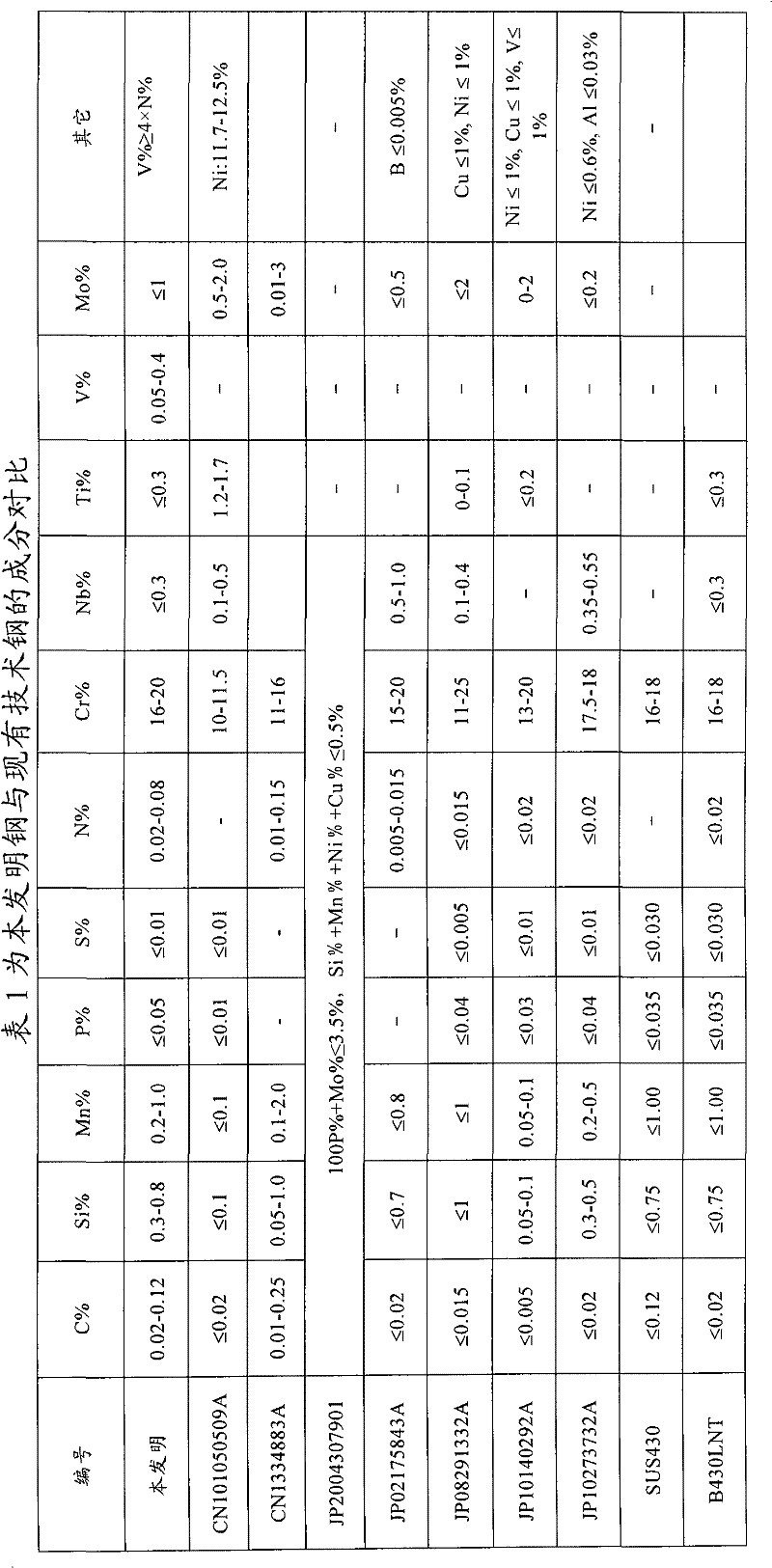

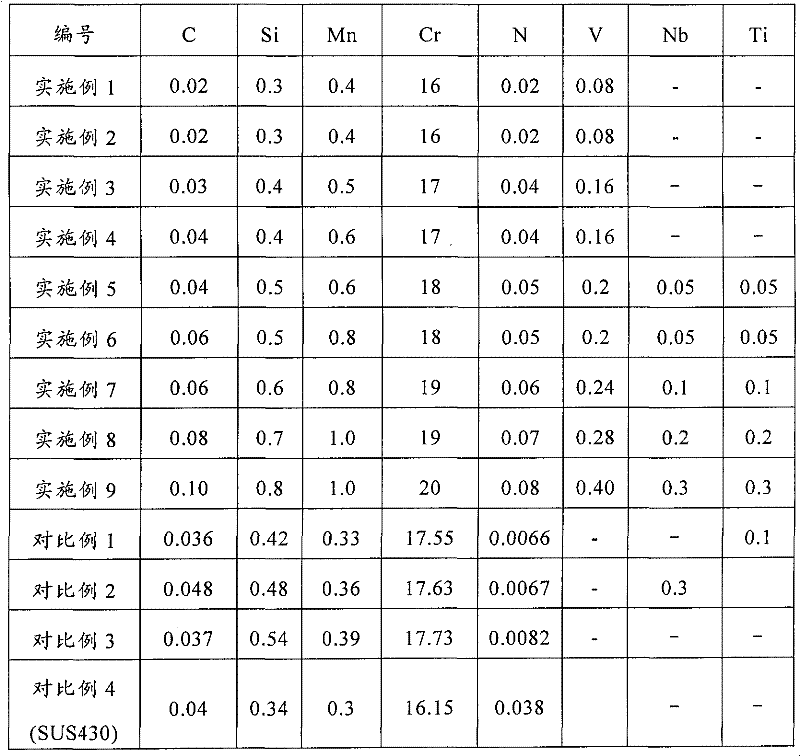

[0033] Carry out electric furnace+AOD two-step method smelting according to the composition of embodiment 1 in table 3, and according to figure 1 The process route and the process parameters in Table 2 are obtained after casting→hot rolling→BAF bell furnace annealing→pickling→cold rolling→APC cold annealing and pickling. Among them, the finishing temperature of hot rolling is controlled at 800°C, and the hot rolling annealing is as follows: figure 1 As shown by the solid line in the middle, the annealing temperature is controlled at 820°C, the time is controlled at 16 hours, and the cooling method is slow cooling in the furnace; while the cold rolling annealing is as follows figure 1 As shown by the dotted line in the middle, the annealing temperature is controlled at 850°C, the time is 1 minute, and the annealing method adopts water mist rapid cooling. Its performance is shown in Table 4.

Embodiment 2

[0035] Carry out electric furnace+AOD two-step method smelting according to the composition of embodiment 2 in table 3, and according to figure 1 The process route and the process parameters in Table 2 are obtained after casting→hot rolling→BAF bell furnace annealing→pickling→cold rolling→APC cold annealing and pickling. Among them, the finishing temperature of hot rolling is controlled at 850°C, and the hot rolling annealing is as follows: figure 1 As shown by the solid line in the middle, the annealing temperature is controlled at 900°C, the time is controlled at 18 hours, and the cooling method is slow cooling in the furnace; while the cold rolling annealing is as follows figure 1 As shown by the dotted line in the middle, the annealing temperature is controlled at 850°C for 2 minutes, and the annealing method adopts water mist rapid cooling. The properties are shown in Table 4.

[0036] table 3

[0037]

Embodiment 3

[0039] Carry out electric furnace+AOD two-step method smelting according to the composition of embodiment 3 in table 3, and according to figure 1 The process route and the process parameters in Table 2 are obtained after casting→hot rolling→BAF bell furnace annealing→pickling→cold rolling→APC cold annealing and pickling. Among them, the finishing temperature of hot rolling is controlled at 900°C, and the hot rolling annealing is as follows: figure 1 As shown by the solid line in the middle, the annealing temperature is controlled at 800°C, the time is controlled at 20 hours, and the cooling method is slow cooling in the furnace; while the cold rolling annealing is as follows figure 1 As shown by the dotted line in the middle, the annealing temperature is controlled at 900°C, the time is 1 minute, and the annealing method adopts water mist rapid cooling. Its performance is shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com