High boron content austenite stainless steel and preparation method thereof

A technique for manufacturing austenitic stainless steel, applied in temperature control, rolling force/roll gap control, furnace type, etc., can solve problems affecting material surface quality, heavy welding workload, and easy welding cracks, etc., to achieve Good mechanical properties and neutron absorption performance, good neutron absorption performance, simple and effective production process

Inactive Publication Date: 2011-05-11

BAOSTEEL STAINLESS STEEL

View PDF4 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The hot rolling method of this patent is to reduce or avoid the high boron steel ingot or forging billet by welding the frame around the forging billet. The purpose of high-boron stainless steel hot-rolled edge cracking has achieved certain results, but this method requires the preparation of high-precision groove frame materials and a large amount of welding work, and the frame materials are easy to peel off during the rolling process, resulting in complex production processes and low production efficiency. Low

[0006] Japanese patent JP9269398 discloses a hot-working method for hot-rolling high-boron austenitic stainless steel. The ferrite content of the weld metal layer is 3-12vol.%, the boron content is less than 0.3wt.%, and the thickness is more than 3mm. Finally, it is hot-rolled after heat preservation at 1100-1200°C to reduce hot-rolling edge cracking, but this method In order to ensure a sufficient thickness of the surfacing layer, the number of welding workers is large and welding cracks are prone to occur. When welding cracks occur, t

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

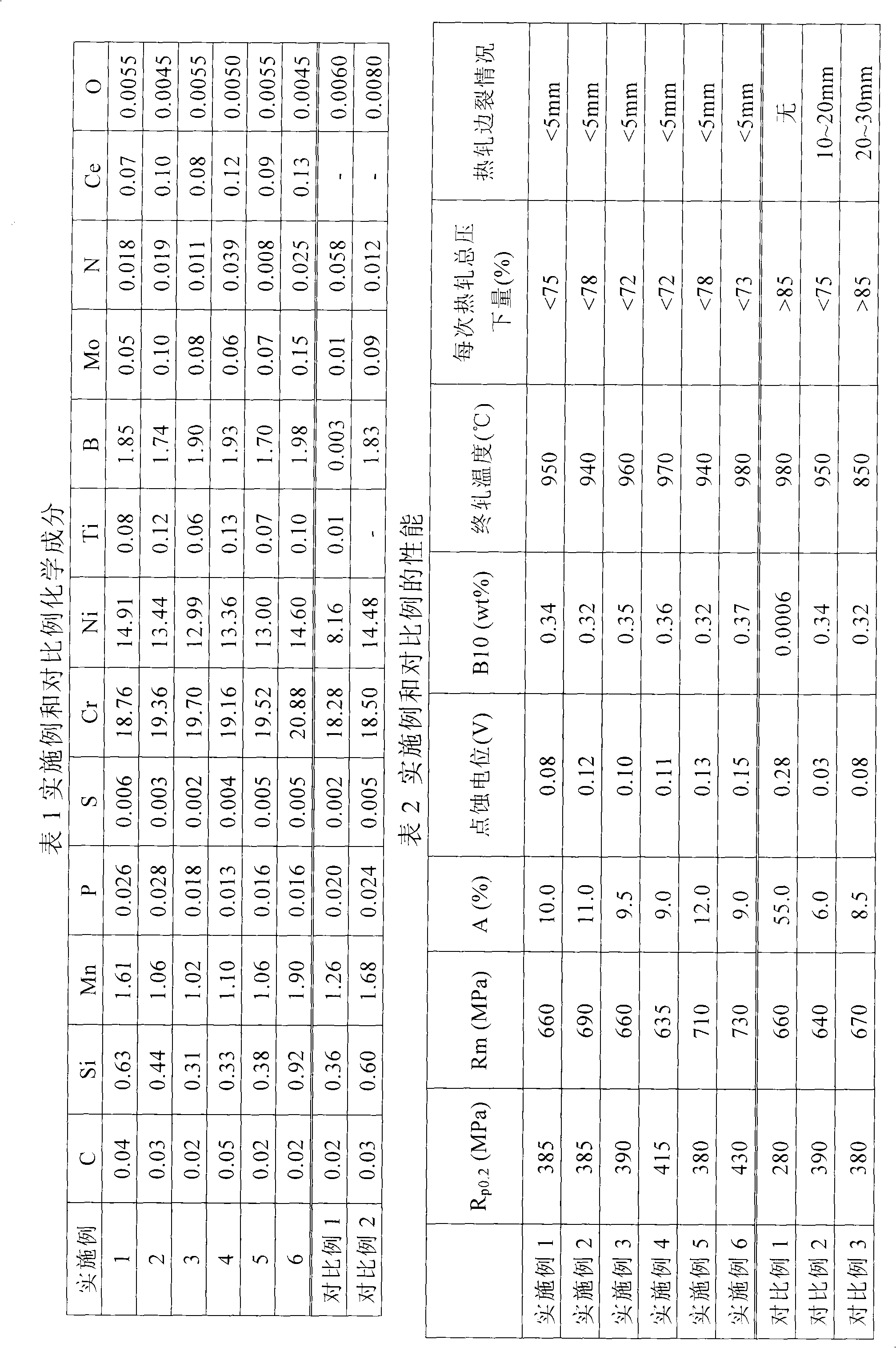

The invention relates to high boron content austenite stainless steel which comprises the following chemical components in percentage by weight: no more than 0.05% of C, 1.7-2.0% of B, no more than 1.0% of Si, no more than 2.0% of Mn, no more than 0.035% of P, no more than 0.030% of S, 12.5-15.0% of Ni, 18.5-21.0% of Cr, no more than 0.5% of Mo, no more than 0.05% of N, no more than 0.15% of Ti, no more than 0.0060% of O, no more than 0.15% of Ce and balance of Fe and inevitable impurities. The preparation method comprises the following steps: the vacuum induction furnace-vacuum consumable furnace technology or vacuum induction furnace-gas-shielded electroslag furnace technology or arc furnace-argon oxygen decarburization (AOD) smelting technology is adopted to smelt stainless steel, die casting is performed, and the cooling speed is greater than 30 DEG C/min; forging and hot rolling are adopted for hot working; and heat treatment and acid pickling are performed to obtain a hot-rolled product. The produced high boron stainless steel hot-rolled product has good mechanical property and neutron absorption property; and no special technological equipment is needed, the production technology is simple and effective, and the production efficiency is high.

Description

technical field [0001] The invention relates to a stainless steel manufacturing process, in particular to an austenitic stainless steel with high boron content and a manufacturing method thereof. Background technique [0002] With the increasingly serious problem of energy shortage in the world and the increasingly prominent environmental problems, green energy such as nuclear power has been paid more and more attention to and vigorously developed by countries all over the world. High-boron austenitic stainless steel has the advantages of excellent neutron absorption performance, long service life, stable and reliable performance, and no need for in-service inspection. It gradually replaces neutron absorption materials such as boron plastics and cadmium as spent fuel storage materials. Neutron absorbing materials are the first choice for grids, nuclear waste fuel storage and transportation containers, and have been widely used. [0003] In order to ensure that spent fuel re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/58C22C38/54C22C33/04C21C5/52C21C7/068B22D7/00B22D30/00C21D8/02B21B37/74B21B37/58

Inventor 余式昌马永柱

Owner BAOSTEEL STAINLESS STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com