Nickel-saving type double-phase stainless steel and preparation process thereof

A technology of duplex stainless steel and preparation process, applied in the field of nickel-saving duplex stainless steel, can solve the problems of strengthening the difference in strength and reducing the overall performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, the preparation process of nickel-saving duplex stainless steel includes the following steps.

[0046] 1) In the Consteel electric furnace, the composition of the mother liquor is controlled at C: 1.72%, Si: 0.65%, Cr: 14.5%, Ni: 1.8%, P: 0.018%, and the tapping temperature is controlled at 1610°C. The mother liquor can be made of stainless steel waste, Manufactured from high quality steel scrap, ferronickel and ferrochrome. The mother liquor in the electric furnace and the high-carbon ferrochrome mother liquor in the intermediate frequency furnace are mixed to form a mixed mother liquor. The composition of the high-carbon ferrochrome mother liquor is C: 6%, Si: 4%, P: 0.05, Cr: 62%, and the rest is iron.

[0047] 2) Transfer the mixed mother liquor into the AOD furnace for oxygen decarburization, nitrogen blowing and composition adjustment; then refine in the ladle refining furnace and add microalloy composition for final adjustment, after adjustmen...

Embodiment 2

[0055] The nickel-saving duplex stainless steel prepared in Example 1 comprises the following components in weight percent:

[0056] C: 0.035%; Si: 0.3%; Mn: 4.0%; Cr: 19%; Ni: 1.0%; Mo: 0.25%; N: 0.20%; Cu: 0.2%; S: 0.001%; P: 0.035%; O: 0.005%; B: 0.005%; Ca: 0.005%; Al: 0.001%; REM: 0.005;

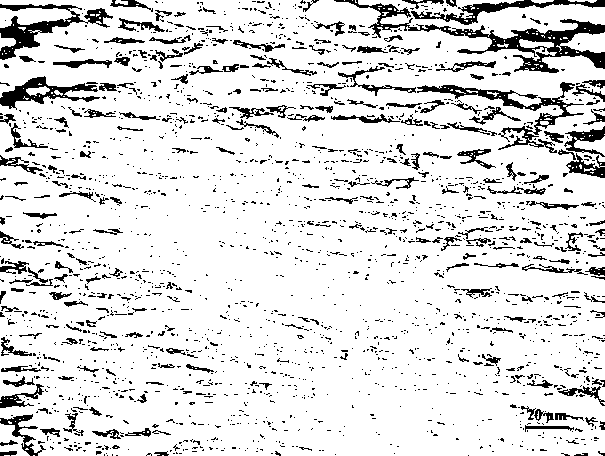

[0057] figure 2 The gray is the ferrite structure, and the bright white is the austenite structure. It can be seen that the phase boundary is smooth and there is no obvious precipitated phase. image 3 It shows the surface quality of stainless steel after pickling, and it can be seen that the quality of the surface is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com