Method for fusing information of spatter predictive analyzers for AOD (argon oxygen decarburization) furnaces

A fusion method and analyzer technology, applied in the direction of instruments, biological neural network models, character and pattern recognition, etc., can solve the problems of difficult real-time control, high price, and reduced real-time forecast accuracy, so as to improve fault tolerance and prediction Accuracy, ensuring production safety, and improving the effect of forecasting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The method of the present invention is:

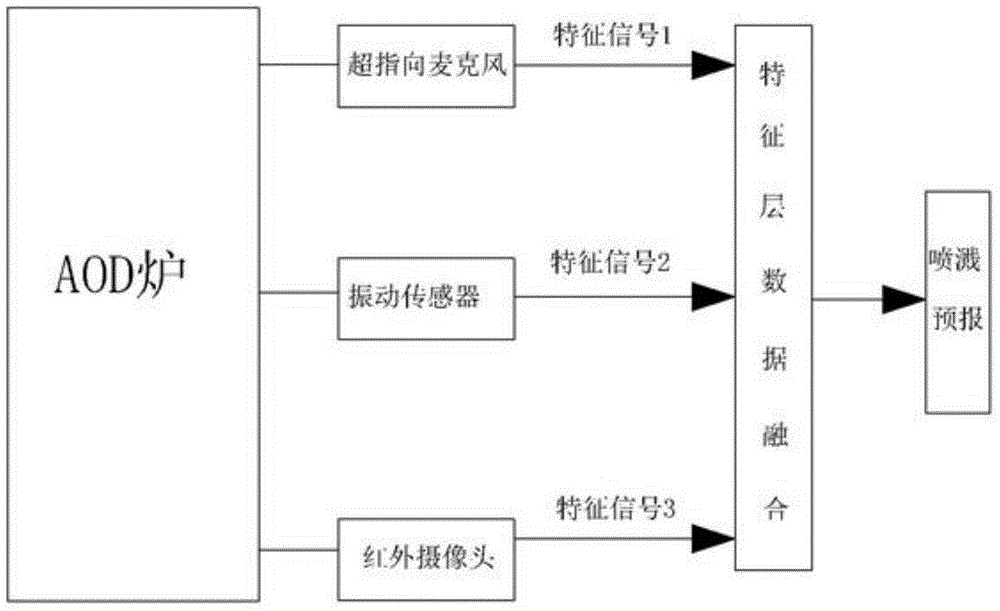

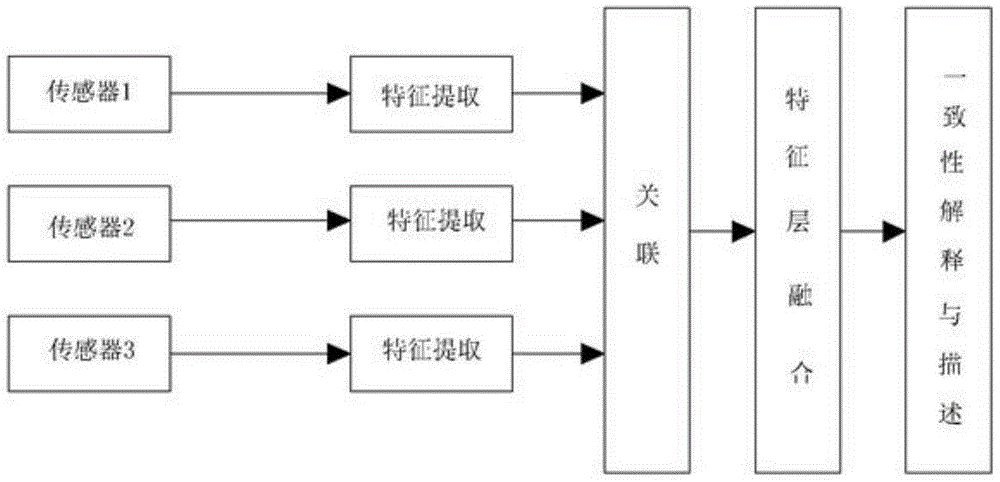

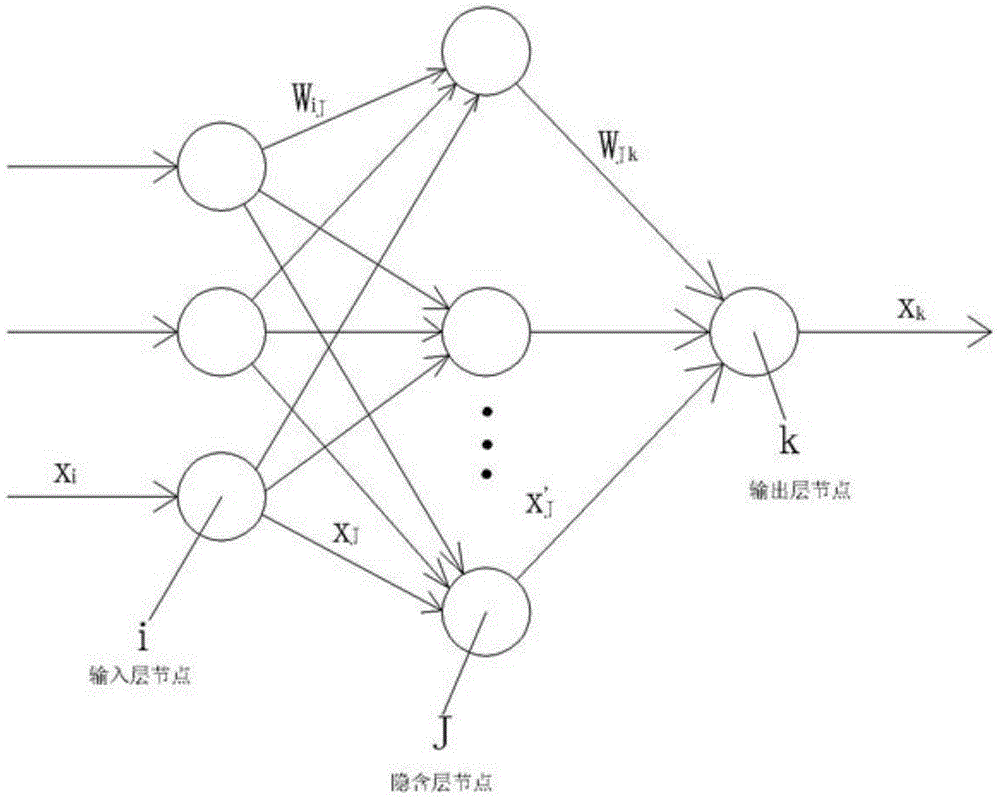

[0066] 1. Firstly, the audio signal in the furnace, the vibration signal of the furnace body and the flame image signal of the furnace mouth are collected respectively by using a super-directional microphone, a vibration sensor, and an infrared camera. After hardware preprocessing, the multi-function acquisition card is sent to the industrial computer; Combined with the wavelet packet method to extract the features of the signal, and extract useful information for judging the occurrence of splashing; finally, the data fusion method based on BP neural network is used for feature-level signal fusion. The signal acquisition and processing structure is as follows: figure 1 shown.

[0067] 2. For one-dimensional sound and vibration signals, first compare and analyze their FFT spectra to compare the overall frequency characteristics of the two; then perform time-domain wavelet packet spectrum analysis to observe their time-frequency v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com