Manufacturing method of high silicon stainless steel for resisting high temperature concentrated sulphuric acid and equipment thereof

A manufacturing method and stainless steel technology, applied in the direction of improving energy efficiency and process efficiency, can solve the problems of affecting the corrosion resistance of materials, low forging yield and high inclusion content, and achieve excellent high temperature sulfuric acid corrosion resistance. , Simple manufacturing process, uniform composition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

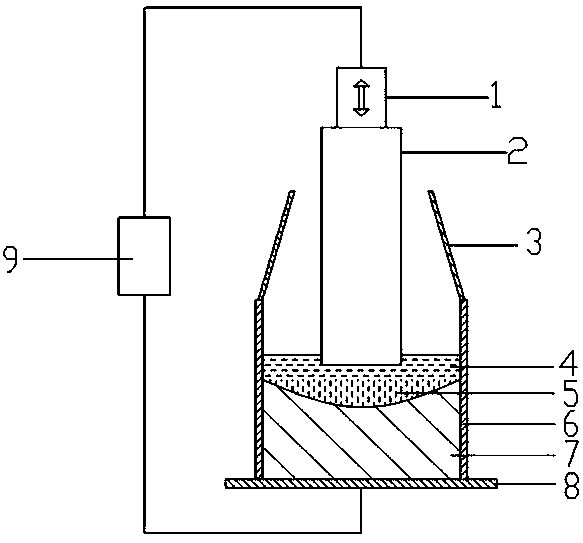

[0088] Example 1: A high-silicon stainless steel electroslag remelting ingot of Φ360 mm.

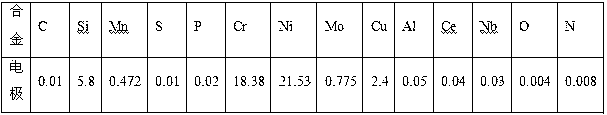

[0089] The first step is to smelt the consumable electrode by adopting the "medium frequency induction + AOD refining" process. The electrode specification is Φ260mm×2500mm. The chemical composition of the electrode is shown in Table 1.

[0090] Table 1 Electrode chemical composition (wt%)

[0091]

[0092] The second step is to polish the surface of the consumable electrode.

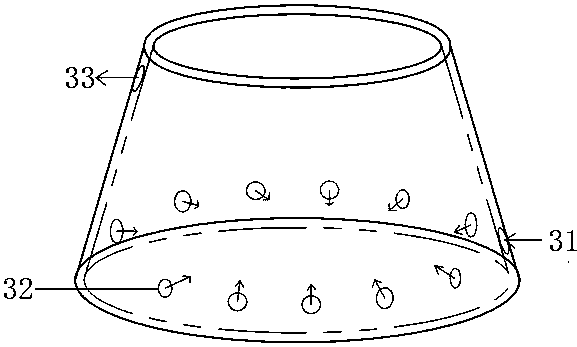

[0093] In the third step, according to the principle of thermodynamics, calculate the SiO required in the slag discharge system when the Si burning reaction reaches equilibrium. 2 theoretical content, then by SiO 2 Select the matching slag system for the theoretical content, the specific method is:

[0094] (1) In the stage of electroslag remelting, the electrode is inserted into the liquid slag and gradually melted, and the metal droplets pass through the slag pool, and the reaction occurs:

[0095] [Si]+2...

Embodiment 2

[0112] Example 2: Electroslag remelting ingot of high silicon stainless steel with Φ440 mm.

[0113] The first step is to smelt the consumable electrode by adopting the "medium frequency induction + AOD refining" process. The electrode specification is Φ310mm×3500mm. The chemical composition of the electrode is shown in Table 1.

[0114] Table 2 Electrode chemical composition (weight %)

[0115]

[0116] The second step is to polish the surface of the consumable electrode.

[0117] The third step is to calculate according to the method of implementation 1 The activity value of is: =0.04, then the theoretical molar concentration of SiO2 in the design slag system is 0.04, and the mass percentage is 3%.

[0118] The third step is to prepare slag. The slag system adopts CaF 2 、Al 2 o 3 , CaO, SiO 2 Quaternary slag system, the weight percentage of each component is 69%, 15%, 13%, 3% respectively, and the slag amount is 80kg. Put the slag separately into the electric f...

Embodiment 3

[0125] Example 3: Electroslag remelting ingot of high silicon stainless steel with a diameter of 560mm.

[0126] The first step is to smelt the consumable electrode by adopting the "medium frequency induction + AOD refining" process. The electrode specification is Φ420mm×3000mm. The chemical composition of the electrode is shown in Table 3.

[0127] Table 3 Electrode Chemical Composition (wt%)

[0128] alloy

C

Si

mn

S

P

Cr

Ni

Mo

Cu

Al

Ce

Nb

O

N

electrode

0.015

5.5

0.6

0.01

0.017

18.05

21.5

0.66

2.2

0.04

0.04

0.04

0.006

0.007

[0129] The second step is to polish the surface of the consumable electrode.

[0130] The third step is to calculate according to the method of implementation 1 The activity value of is: =0.05, then the SiO in the design slag system 2 The theoretical molar concentration is 0.05, and the mass percentage is 4%.

[0131] The third step is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average corrosion rate | aaaaa | aaaaa |

| Average corrosion rate | aaaaa | aaaaa |

| Average corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com