Patents

Literature

69results about How to "Reduce free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Economic anti-saltpetering inside and outside walls facing mortar

The invention provides an inside and outside walls facing mortar with little saltpetering phenomenon in use and less price; the facing mortar comprises the following components by weight percent: 30-40% of silicate cement, 15-25% of inert filler, 40-50% of sand, 1.0-2.0% of high active mineral filler and 3.0-5.0% of additives. The preparation method of the facing mortar of the invention adopts common silicate cement as cementitious material, and adds high active metakaolin with small particle size to react with excessful calcium hydroxide in the cement and obtain CSH gel so that the existing free Ca<2+> in the cement is greatly reduced, the compactibility of the facing mortar layer is increased and the external water is hard to enter; in addition, a defined amount of nanoscale water repellent agent is added in the mortar so that the channel of external water into the mortar is blocked, double barriers are formed between each other and the generation conditions of saltpetering can be well restrained. The facing mortar of the invention has reasonable formula, simple construction, and lower production cost which is greatly less than that of the existing anti-saltpetering mortar, thus being applicable to the inside and outside walls decoration of common houses or factories.

Owner:广东龙湖科技股份有限公司

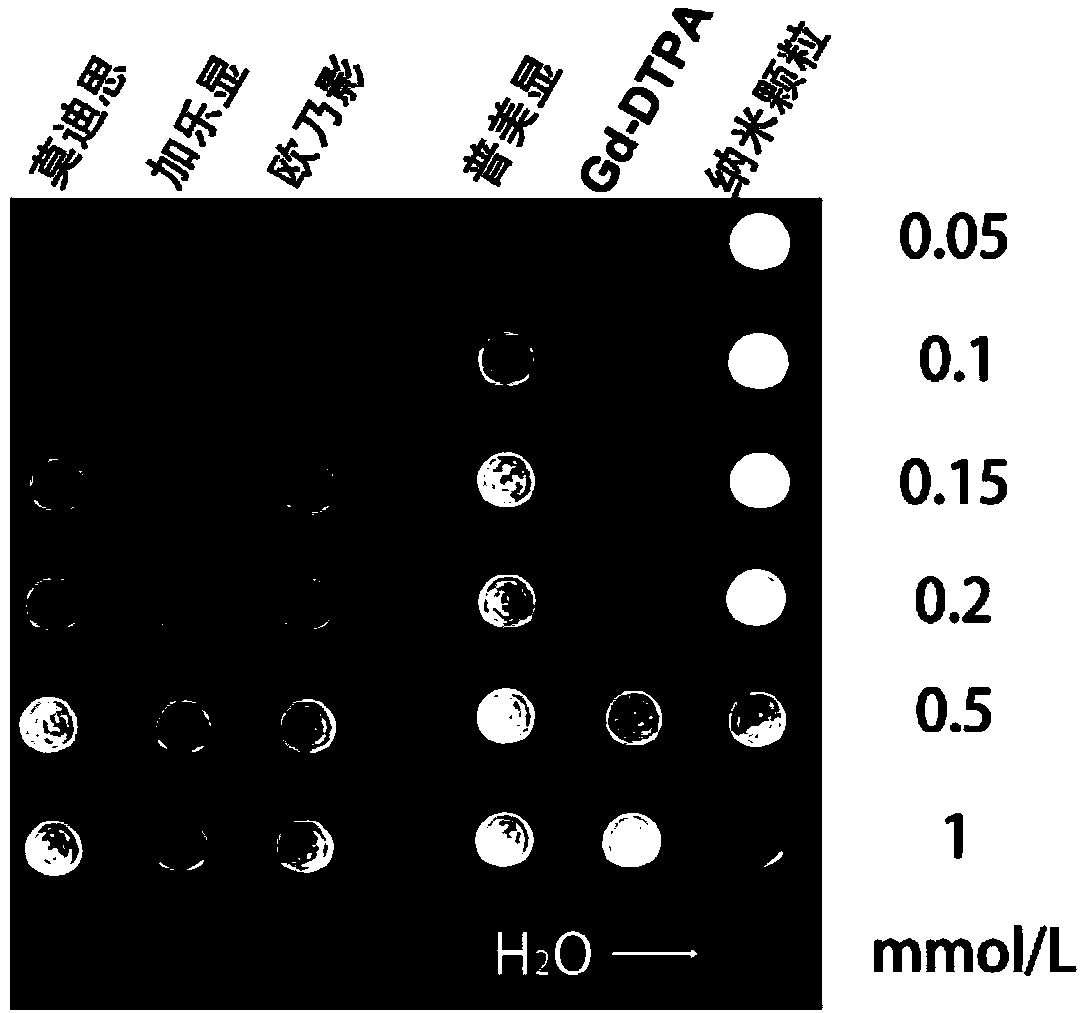

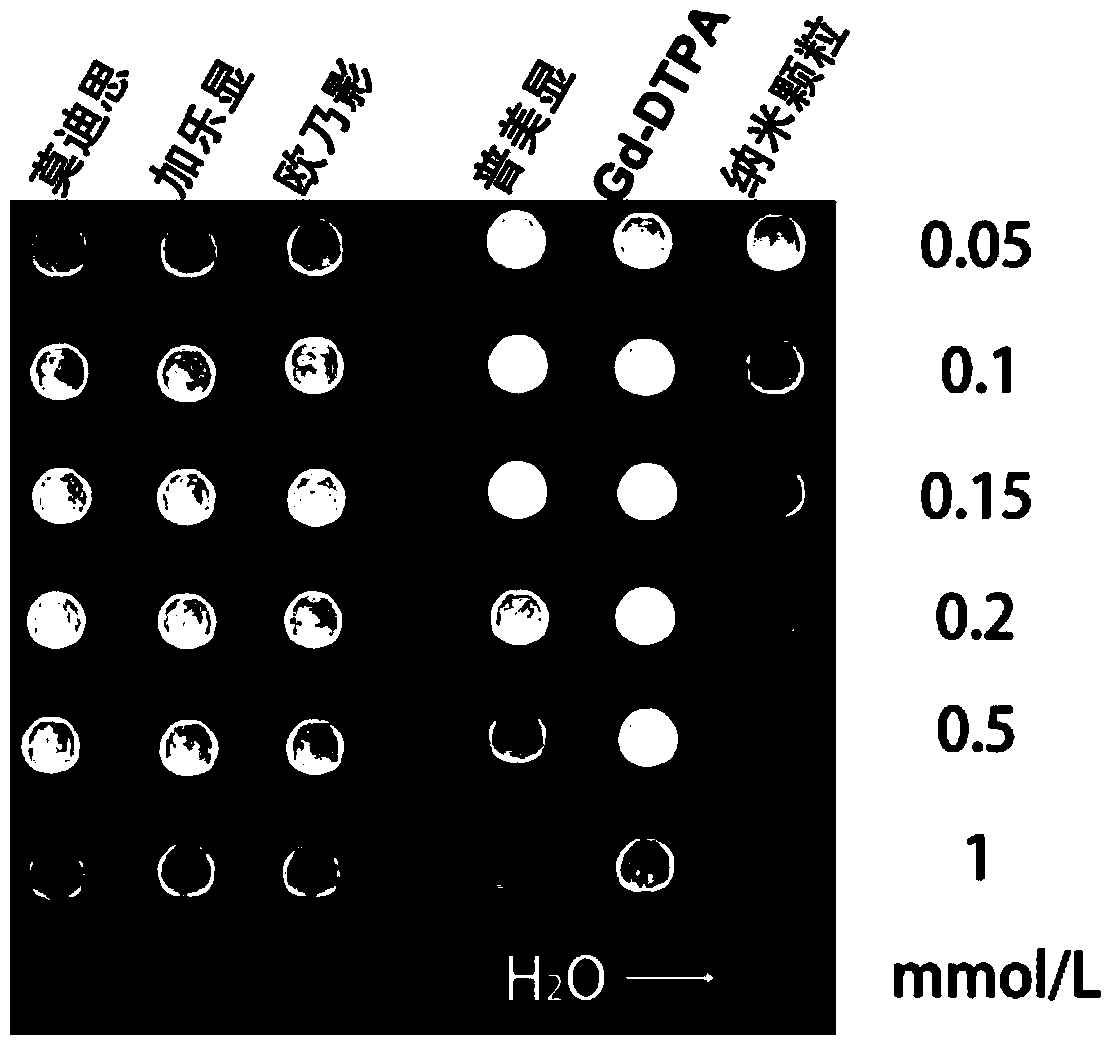

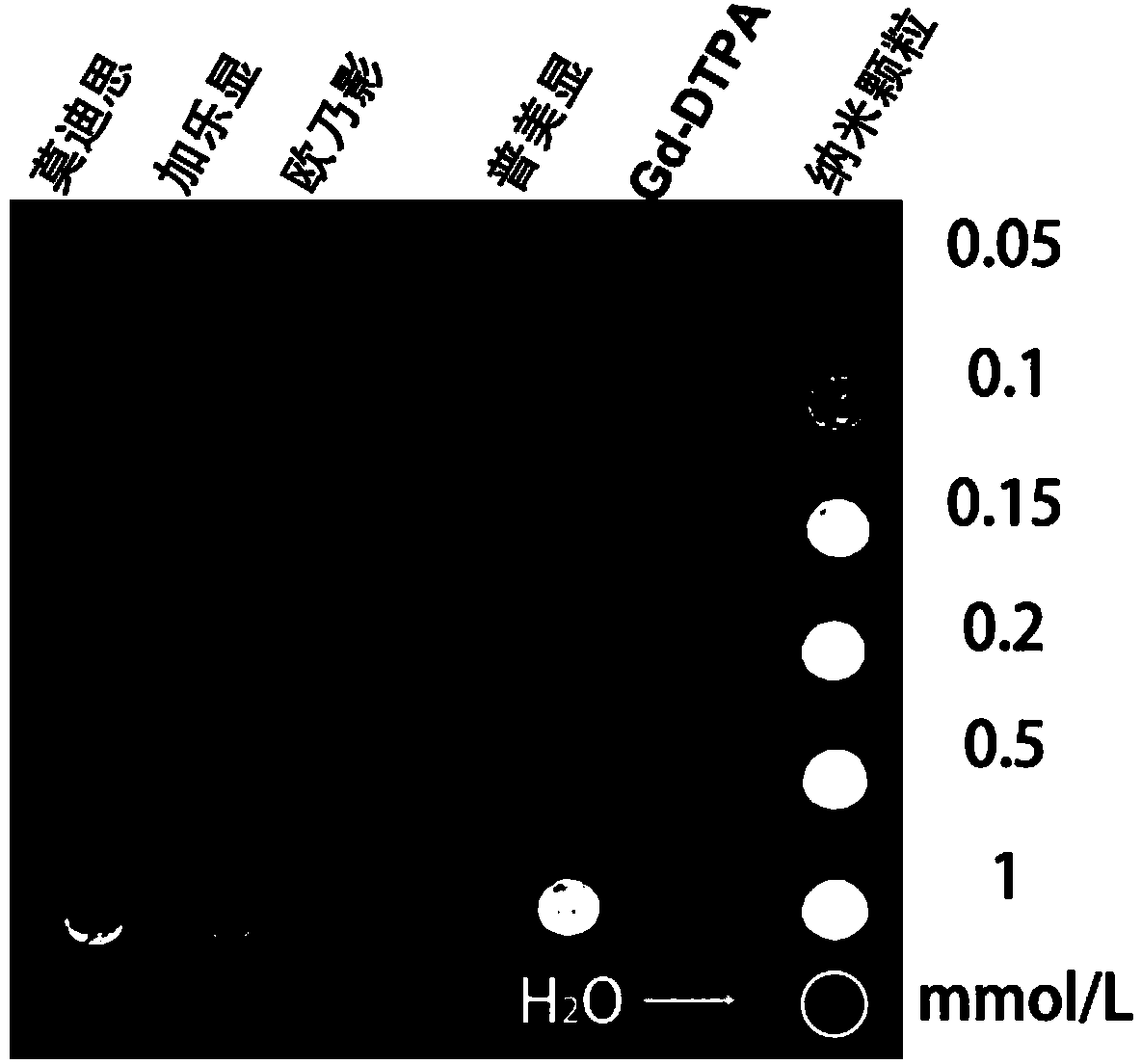

Rare earth-based nanoparticle magnetic resonance contrast agent and preparation method thereof

InactiveCN104043138AShorten the relaxation timeProlong circulation time in the bodyDispersion deliveryNMR/MRI constrast preparationsResonanceGadolinium

The invention relates to a rare earth-based nanoparticle magnetic resonance contrast agent and a preparation method thereof. The rare earth-based nanoparticle magnetic resonance contrast agent are rare earth-based inorganic nanoparticles having the surface coated with a hydrophilic ligand, firstly rare earth-based nanoparticles are obtained through a high-temperature oil phase reaction, and then the surface is coated with hydrophilic molecules to obtain the rare earth-based nanoparticle magnetic resonance contrast agent. Compared with a conventional clinical contrast agent, the magnetic resonance contrast agent has the relaxation rate greatly improved, is good in imaging effect, low in required injection dose, and relatively long in time staying in a body. In addition, a rigid structure of the inorganic nanoparticles can effectively reduce the free possibility of gadolinium ions. The rare earth-based nanoparticle magnetic resonance contrast agent has the advantages of simple preparation method, good repeatability and stable property, and easily realizes clinical commercial applications.

Owner:PEKING UNIV

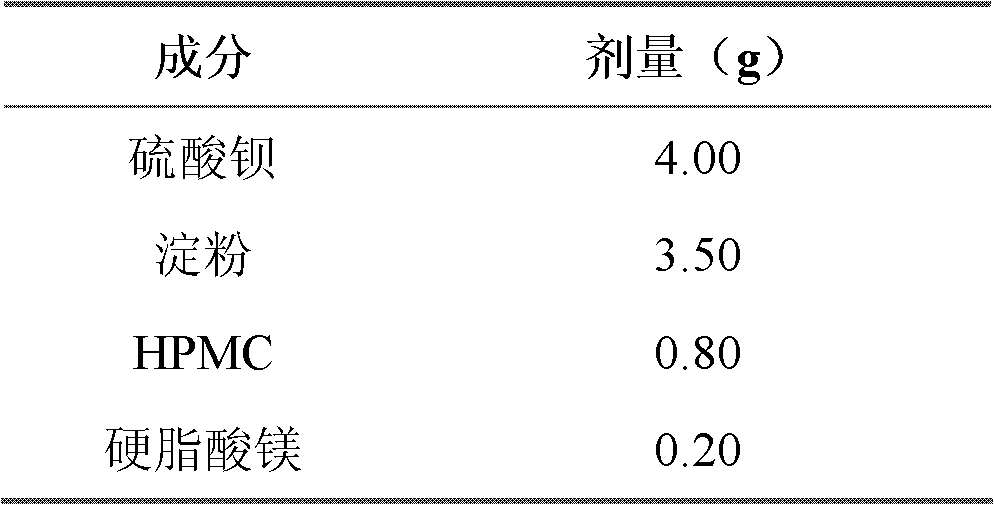

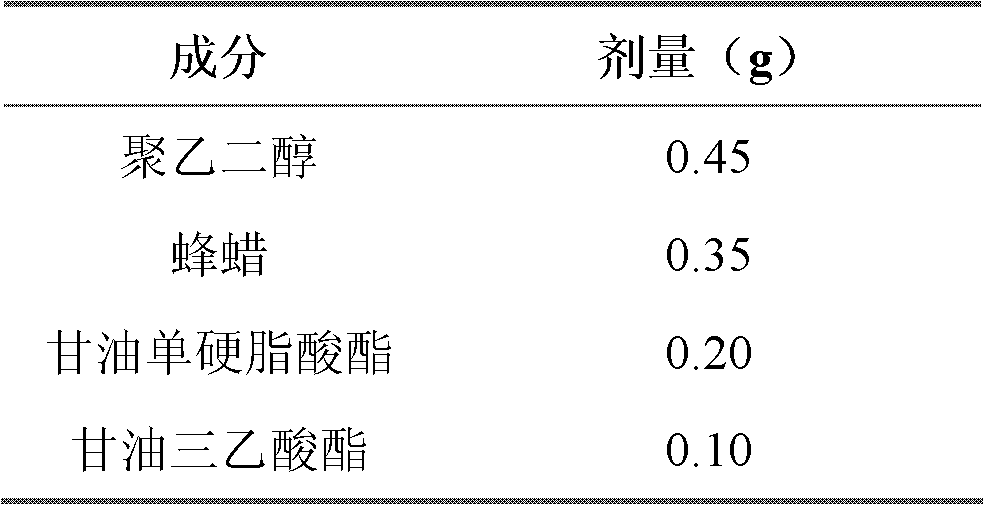

Gastrointestinal transit disorder diagnosis composition and use thereof

InactiveCN102091335AReduce the number of inspectionsRelieve painEchographic/ultrasound-imaging preparationsX-ray constrast preparationsGastrointestinal transitGastrointestinal obstructions

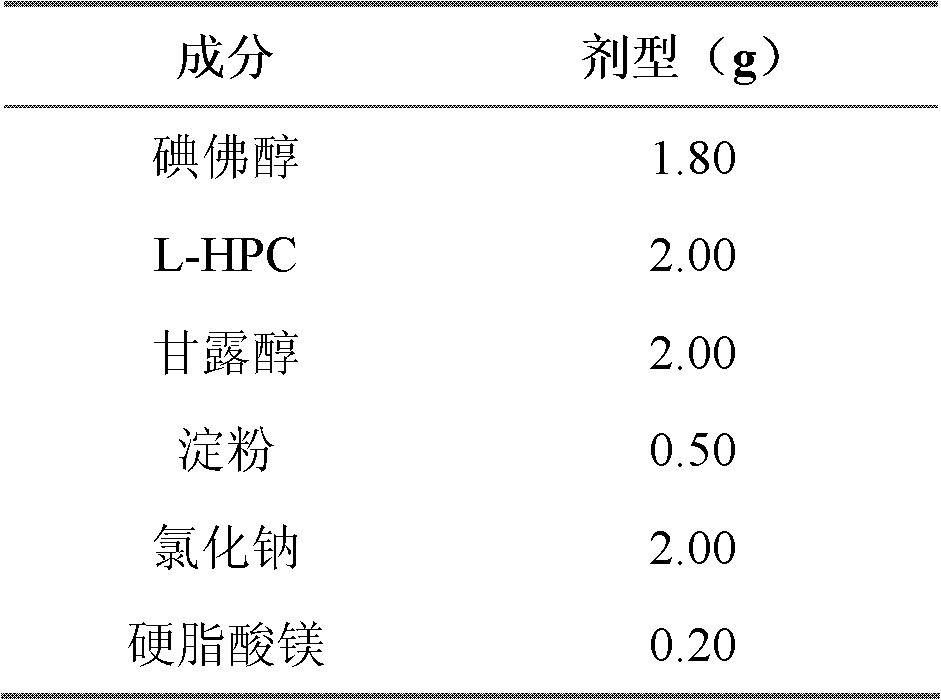

The invention discloses a gastrointestinal transit disorder diagnosis composition. The composition which can disintegrate at fixed time and fixed position in the gastrointestinal tract consists of an inner body, an outer layer covering the inner body and a gastrointestinal transit disorder diagnosis probe material which is mixed in the inner body or / and the outer layer. According to the evaluation of information on the probe marker material-containing preparation, such as position in the gastrointestinal tract, retention and image characteristics after disintegration, after a receiver takes the composition orally, the composition can be used for the diagnosis, positioning and degree and property judgment of clinic gastrointestinal transit disorder, such as gastrointestinal obstruction caused by benign and malignant occupation, and the identification and diagnosis of gastrointestinal transit disorder, such as redundant colon and irritable bowel syndrome.

Owner:张发明

Asphalt modifier and industrial production method and application thereof

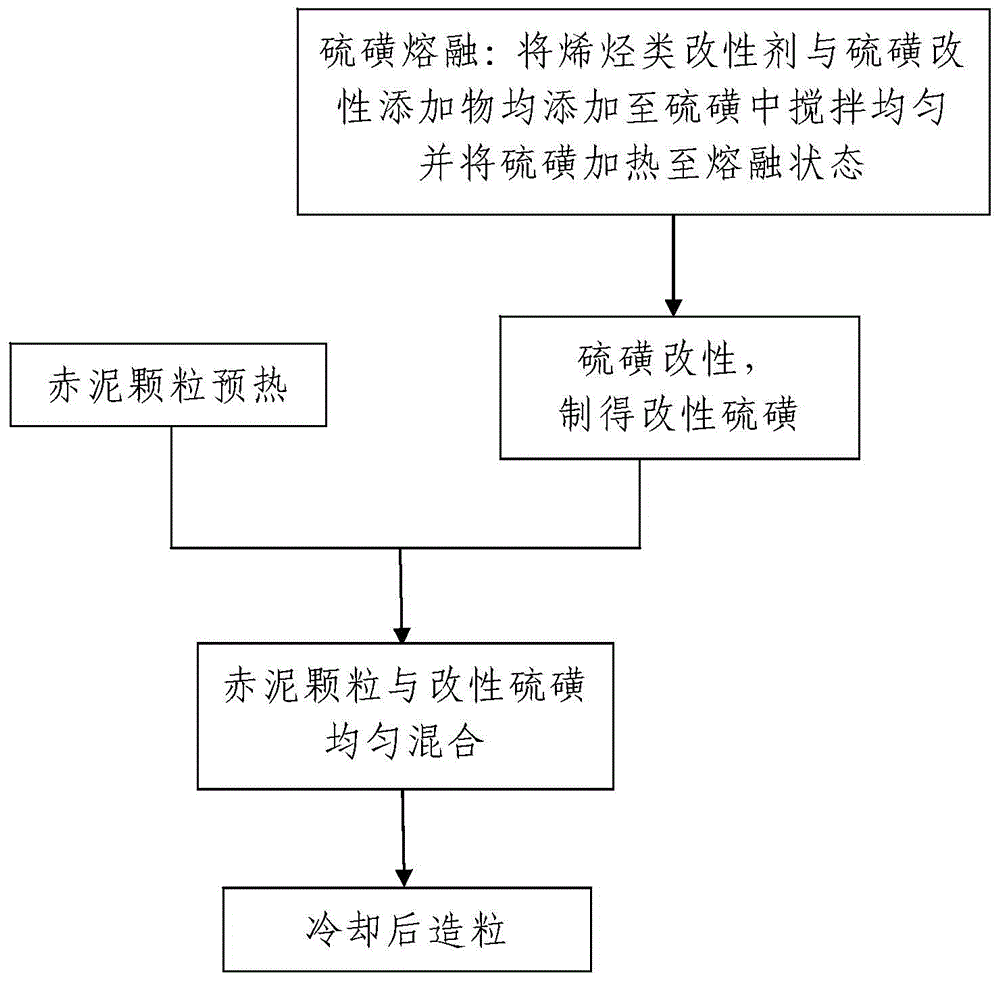

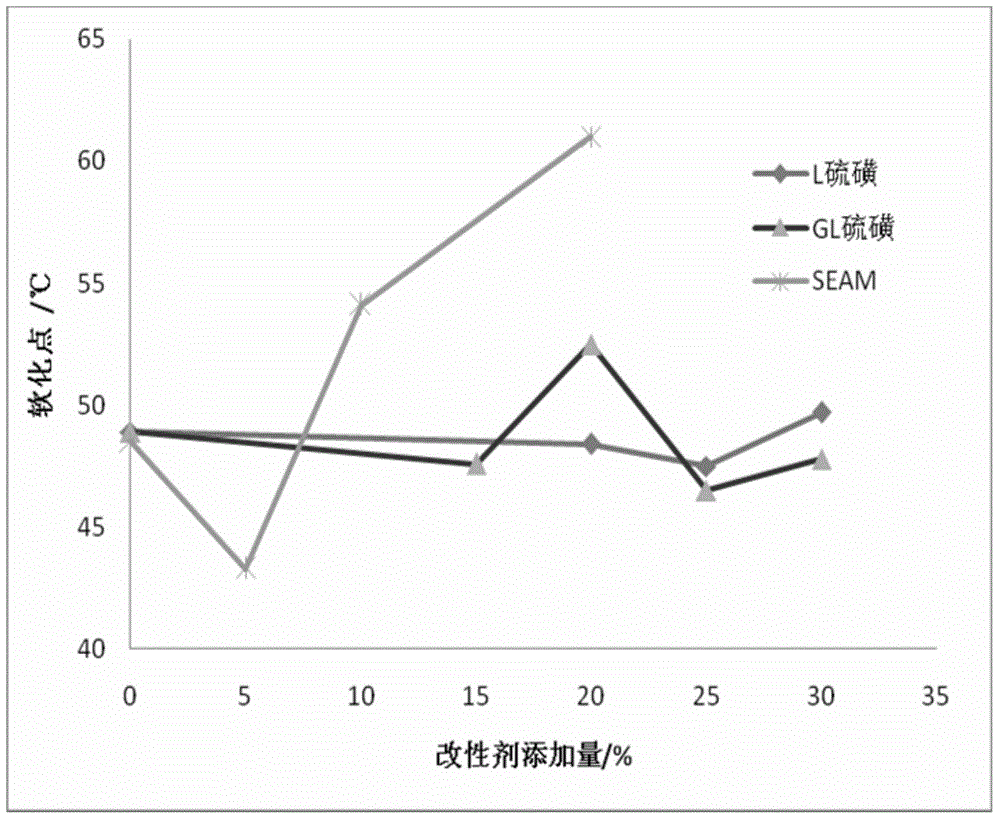

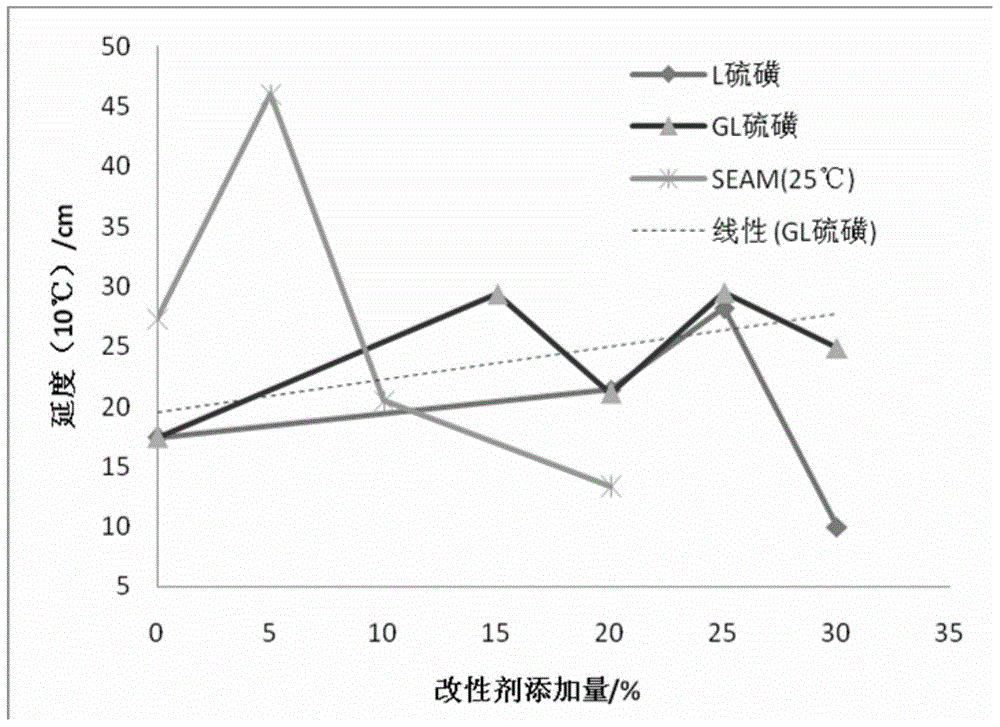

The invention discloses an asphalt modifier and an industrial production method and application thereof. The asphalt modifier is prepared by uniformly mixing modified sulfur and red mud particles. The industrial production method comprises the following steps: 1, preparing the modified sulfur, namely performing sulfur fusion and sulfur modification; and 2, adding the red mud particles. In the industrial production method, the modified sulfur is prepared in a way that an olefin modifier and a sulfur modification additive are added into sulfur for modifying sulfur; a weight ratio of the olefin modifier to sulfur is 2-6:100, and a weight ratio of the red mud particles to the sulfur is 10-30:100. The application process of the asphalt modifier comprises the following steps: I, preheating raw materials; and II, mixing, namely mixing the preheated asphalt modifier, mineral aggregate and matrix asphalt. The asphalt modifier adopted in the production method is simple in production process, low in construction cost, incombustible, safe to use and excellent in performance, the amount of discharged atmospheric pollutants in the production and application process is small, comprehensive performance of the modified asphalt concrete is excellent, and industrial waste red mud can be effectively utilized.

Owner:XIAN UNIV OF SCI & TECH

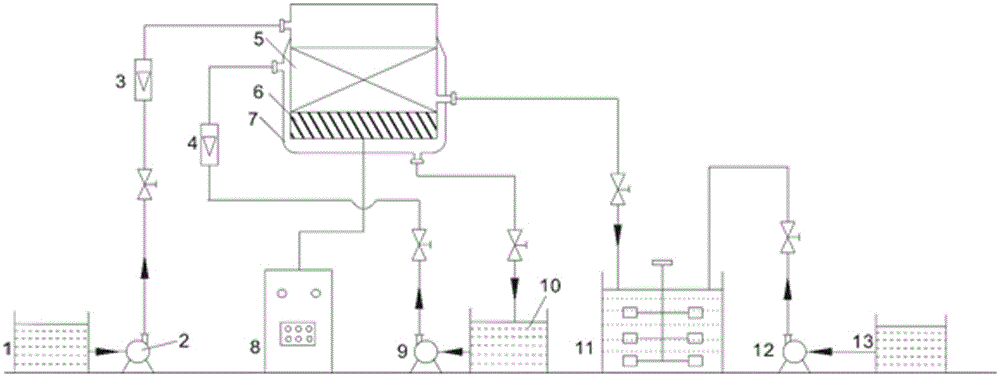

Method and device for treating nitrobenzene wastewater through ultrasonic wave/iron-carbon micro-electrolysis-Fenton oxidation method

PendingCN105884098APromote passivationAvoid churnWater/sewage treatment with mechanical oscillationsWater contaminantsElectrolysisFenton reagent

The invention belongs to the technical field of treatment of nitrobenzene wastewater, and particularly relates to a method and device for treating nitrobenzene wastewater through an ultrasonic wave / iron-carbon micro-electrolysis-Fenton oxidation method. The problems in the prior art that efficiency is low when organic pollutant in wastewater is treated only through ultrasonic waves, when a traditional iron-carbon micro-electrolysis-Fenton method is directly used for treating wastewater, along with delay of treating time, due to passivation of iron-carbon micro-electrolysis filler, the treating efficiency is greatly lowered, and anodic reaction is weakened are solved. The method comprises the steps that nitrobenzene wastewater is treated through ultrasonic waves and iron-carbon micro-electrolysis, and nitrobenzene difficult to degrade is reduced to be aniline easy to degrade; after micro-electrolysis is finished, wastewater is placed into a stirring reaction pool, H2O2 is added into wastewater to be combined with Fe2+ in wastewater to form a Fenton reagent, and wastewater is further oxidized and degraded. The reaction speed of iron-carbon micro-electrolysis is improved by 6-10 times on the whole, the concentration of free Fe2+ in wastewater is improved by 5-8 times, and H2O2 needed by the follow-up Fenton oxidization method is greatly reduced.

Owner:ZHONGBEI UNIV

Color-light consistent pure cotton bleached bright adhesive interlining and production method thereof

ActiveCN105133314AUniform shadeReduce freeSucessive textile treatmentsGarmentsCoated surfaceInterlining

The invention discloses a color-light consistent pure cotton bleached bright adhesive interlining and a production method thereof; the adhesive interlining is uniform and consistent in color and light, and the surface of a coating layer is bright; the content of free and hydrolyzed formaldehyde is not more than 35 mg / kg; the adhesive interlining stripping strength is not less than 20 N; the dimensional change rate in the warp and weft direction after water washing is -0.8% to +0.5%. The adhesive interlining is uniform and consistent in color and light and bright in surface, the quality grade of the adhesive interlining is enhanced, point leakage, coating leakage and other defect points can be easily detected during visual inspection, so as to ensure that defective products are not produced due to point leakage and coating leakage during clothing pressing, the content of free and hydrolyzed formaldehyde is low, the adhesive interlining stripping strength is high, the shrinkage rate in the warp and weft direction is small, and the production method is easy to operate.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD +1

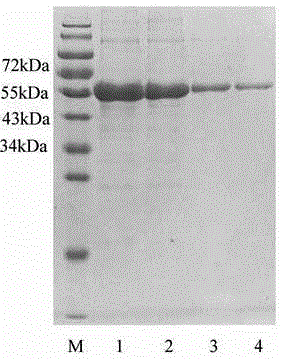

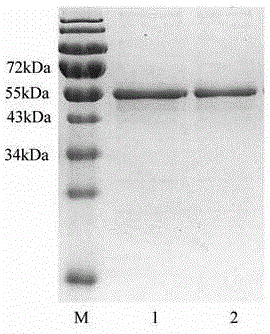

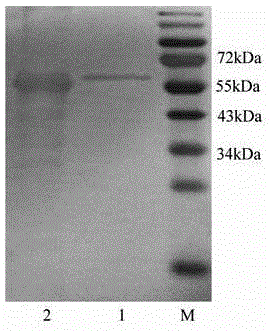

Chemiluminescence detection kit of swine foot-and-mouth disease 3ABC and 2C antibodies

ActiveCN106596932AHigh purityDetection of high sensitivityChemiluminescene/bioluminescenceEscherichia coliSerum ige

The invention discloses a chemiluminescence detection kit of swine foot-and-mouth disease 3ABC and 2C antibodies and belongs to the field of immunological detection. The kit comprises a chemiluminescent immunoreaction plate, an enzyme-labeled antibody, a serum diluent, a chemiluminescent substrate, a chemiluminescent enhancer and a PBST washing liquid, and is characterized in that the chemiluminescent immunoreaction plate is a milky white opaque polystyrene 96-well plate, the bottom in each one of the wells is coated with a 3ABC-2C fusion protein, the enzyme-labeled antibody is a HRP-rabbit anti-pig lgG antibody, the serum diluent comprises Tween-20, bovine serum albumin and a lysate of escherichia coli, the chemiluminescent substrate comprises luminol and bovine serum albumin, and the chemiluminescent enhancer comprises IPP, H2O2 and Tween-20. Compared with CLIA only coated with a 3BAC antibody and the commercial common ELISA kit, the chemiluminescence detection kit has higher sensitivity, specificity and diagnostic ability and good repeatability and stability.

Owner:LANZHOU INST OF VETERINARY SCI CHINESE ACAD OF AGRI SCI

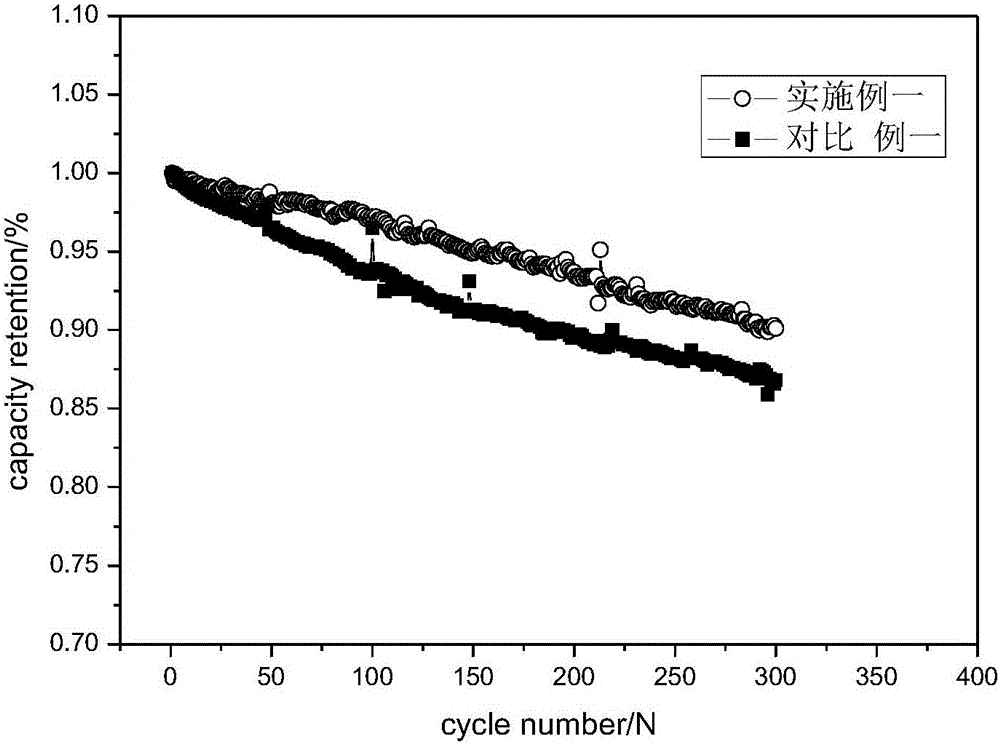

Positive electrode plate and preparing method thereof and lithium ion battery

InactiveCN105118958AReduce oxidative decompositionPromote migrationSecondary cellsNon-aqueous electrolyte accumulator electrodesHigh temperature storageEngineering

The invention relates to a positive electrode plate and a preparing method thereof and a lithium ion battery. The positive electrode plate aims at solving the problems that for a positive electrode plate in the prior art, under the situation of high charging voltage, the battery circulation performance and the high-temperature storage performance are poor. The positive electrode plate comprises a positive electrode current collector and a positive electrode material layer attached to the surface of the positive electrode current collector. A poly-dopamine layer is further attached to the surface of the positive electrode material layer. Meanwhile, the invention discloses the preparing method of the positive electrode plate and the lithium ion battery with the positive electrode plate. The battery circulation performance and the high-temperature storage performance of the lithium ion battery prepared from the positive electrode plate are excellent under the situation of high changing voltage.

Owner:SHENZHEN 3SUN ELECTRONICS

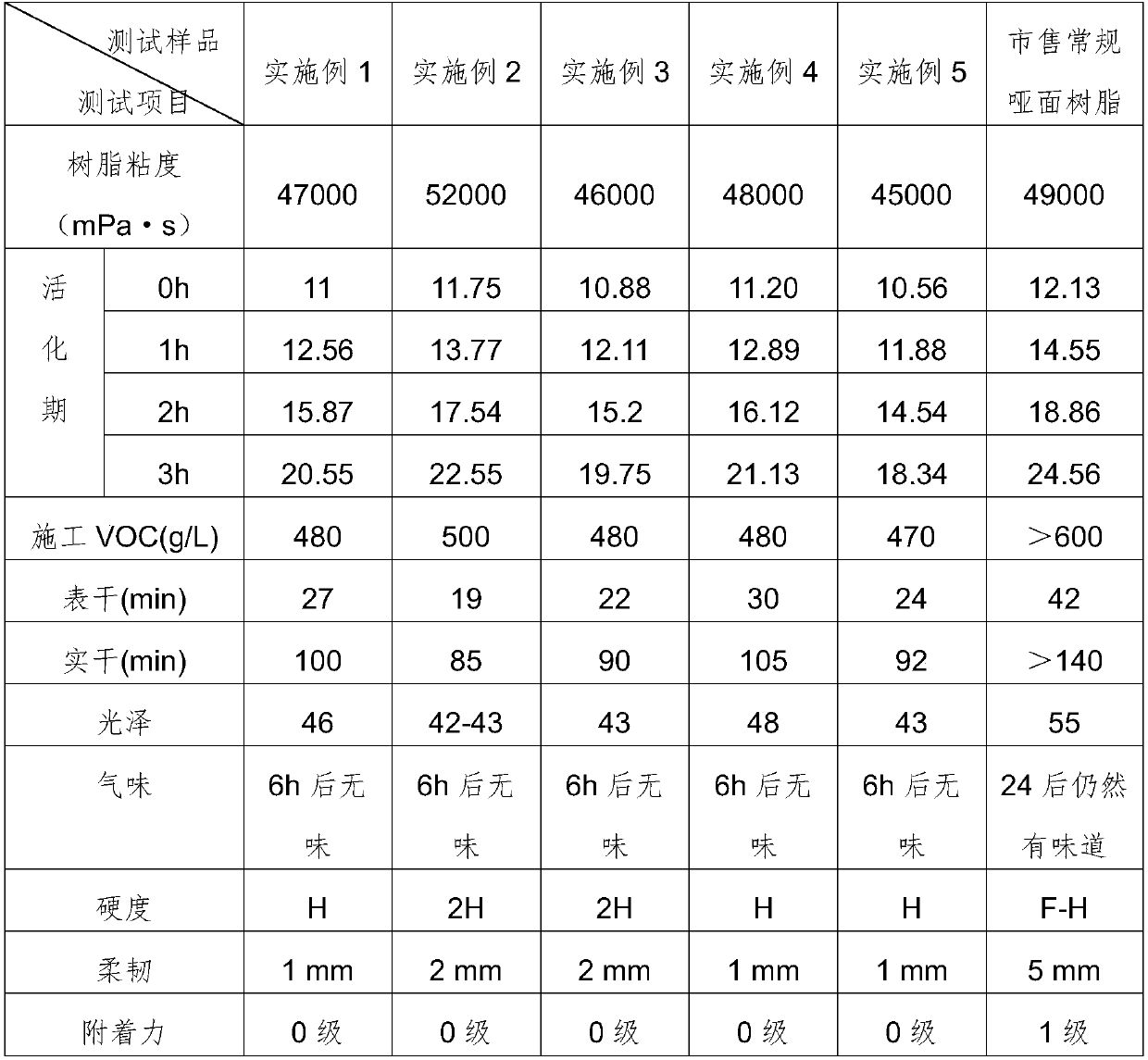

Preparation method of odor-less fast-dry alkyd resin

The invention relates to the field of alkyd resin, in particular to a preparation method of odor-less fast-dry alkyd resin. The odor-less fast-dry alkyd resin comprises, by weight, 9-15 parts of fattyacid, 5-12 parts of castor oil, 20-28 parts of polyhydric alcohols, 24-33 parts of organic acid, 2-5 parts of reflux solvents, 0.05-0.2 part of antioxidant additives and 23-27 parts of diluting solvents. The preparation methods includes: by a step-by-step feeding method, subjecting fatty acid, a part of organic acid and a part of polyhydric alcohols to esterification reaction, and adding in castor oil, the rest organic acid and the rest polyhydric alcohols to perform esterification reaction, so as to obtain the odor-less fast-dry alkyd resin. The alkyd resin has the advantages of fast drying,high solvent release property, less odor, high hardness, scratch resistance and the like, further has excellent flexibility without adding of other flexible resin and accordingly can improve production efficiency and have high competitiveness in application of modern furniture factories.

Owner:ANHUI SKSHU PAINT CO LTD

Safety treatment method for fluorine-containing solid waste

ActiveCN105130346AAvoid pollutionPlay the role of binding the fluorine-containing solid waste residueSolid waste managementWater insolubleFluorine containing

The invention relates to a safety treatment method for fluorine-containing solid waste. According to the method, a calcium compound is added into the fluorine-containing solid waste, and a composition fluorine ions in the fluorine-containing solid waste and calcium ions in the calcium compound form a water-insoluble compound calcium fluoride, so that free fluorine ions in the fluorine-containing solid waste are greatly reduced, and the phenomenon that the fluorine ion content of the fluorine-containing solid waste is large and the fluorine-containing solid waste is easily dissolved in soil and groundwater to cause pollution in the prior art is avoided; a curing agent is added to achieve the effect of bonding the fluorine-containing solid waste, and meanwhile, a layer of low-permeability substance is formed on the surface of the fluorine-containing solid waste to limit the transfer of harmful compositions, mainly the fluorine ions, in the fluorine-containing solid waste, so that soil and underground pollution is also avoided.

Owner:韩素梅

Pure cotton bleaching bright adhesive interlining and production method thereof

ActiveCN104544646AImprove the quality levelHigh peel strengthFibre treatmentGarmentsInterliningShrinkage rate

The invention discloses a pure cotton bleaching bright adhesive interlining and a production method of the adhesive interlining. The surface of a coating is bright, the peeling strength of hot melt adhesive points is greater than or equal to 16N, the warp and weft direction water washing dimension variation rate is -1.0 percent to 0.5 percent, and the free and hydrolysis formaldehyde is less than or equal to 40 mg / kg. The pure cotton bleaching bright adhesive interlining and the production method have the advantages that the surface of the adhesive interlining is bright, the quality and the grade of the adhesive interlining are improved, flaws such as leaking points and missed coating can be easily inspected during the appearance inspection, the generation of unqualified products due to leaking points and missed coating is enabled to be avoided during garment press ironing, the peeling strength of the adhesive interlining is high, the warp and weft direction shrinkage rate is low, the free and hydrolysis formaldehyde is low, and the operation of the production method is easy.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD +1

Method for preparing acetic acid and acetic anhydride respectively or synchronously

ActiveCN101659607AAvoid productiveAvoid the pitfalls of acetic anhydrideOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylic preparation from carbon monoxide reactionAcetic anhydrideAccelerant

The invention discloses a method for preparing an acetic acid and an acetic anhydride respectively and synchronously, which is characterized in that: a methanol, a methylacetate or a mixture of the methanol and the methylacetate and a mixed gas of carbon monoxide and hydrogen are reacted at 150 to 250 DEG C and 2.0 to 6.0 MPa; and a catalyst system used in the reaction comprises a mixture of rhodium or one of rhodium compounds and iridium or one of iridium compounds, a methyl iodide, at least one selected from mixtures of an amino acid and an amino acid derivative, the amino acid or the aminoacid derivative, and an accelerant. The method for preparing the acetic acid and the acetic anhydride in the invention has the advantages of: (1) reducing the generated tar, (2) reducing substance content of the acetic anhydride product, and (3) improving the stability of the catalyst system in the invention and avoiding the precipitation phenomenon. Due to the fact that the reaction system has no water, the corrosion to devices is also reduced.

Owner:SHANGHAI HUAYI ENERGY CHEM

High-temperature molten steel slag treating method

InactiveCN102534066AWide range of raw materialsLow costRecycling and recovery technologiesSlagElectric furnaces

The invention relates to a high-temperature molten steel slag treating method. A modifying agent with main components containing calcium oxide, silicon oxide and aluminum oxide is added, therefore the molar ratio of calcium oxide, silicon oxide and aluminum oxide in modified steel slag meets one or two kinds of CaO:SiO2=2.5-3:1 or CaO:SiO2:Al2O3=25-30:15-22:1, and the steel slag forms a stable spinel structure. In the method, the raw materials of the modifying agent of the steel slag have wide sources, the cost is low, the manufacture process is simple, and the method is suitable for converters, main frequency furnaces and arc furnaces to produce various kinds of steel slag. The steel slag is modified, the stability of the steel slag is good, and free calcium oxide and aluminum oxide in the steel slag can be preferentially reduced. The steel slag forms the stable spinel structure, so that the application scope of the steel slag is expanded.

Owner:HENAN UNIV OF SCI & TECH

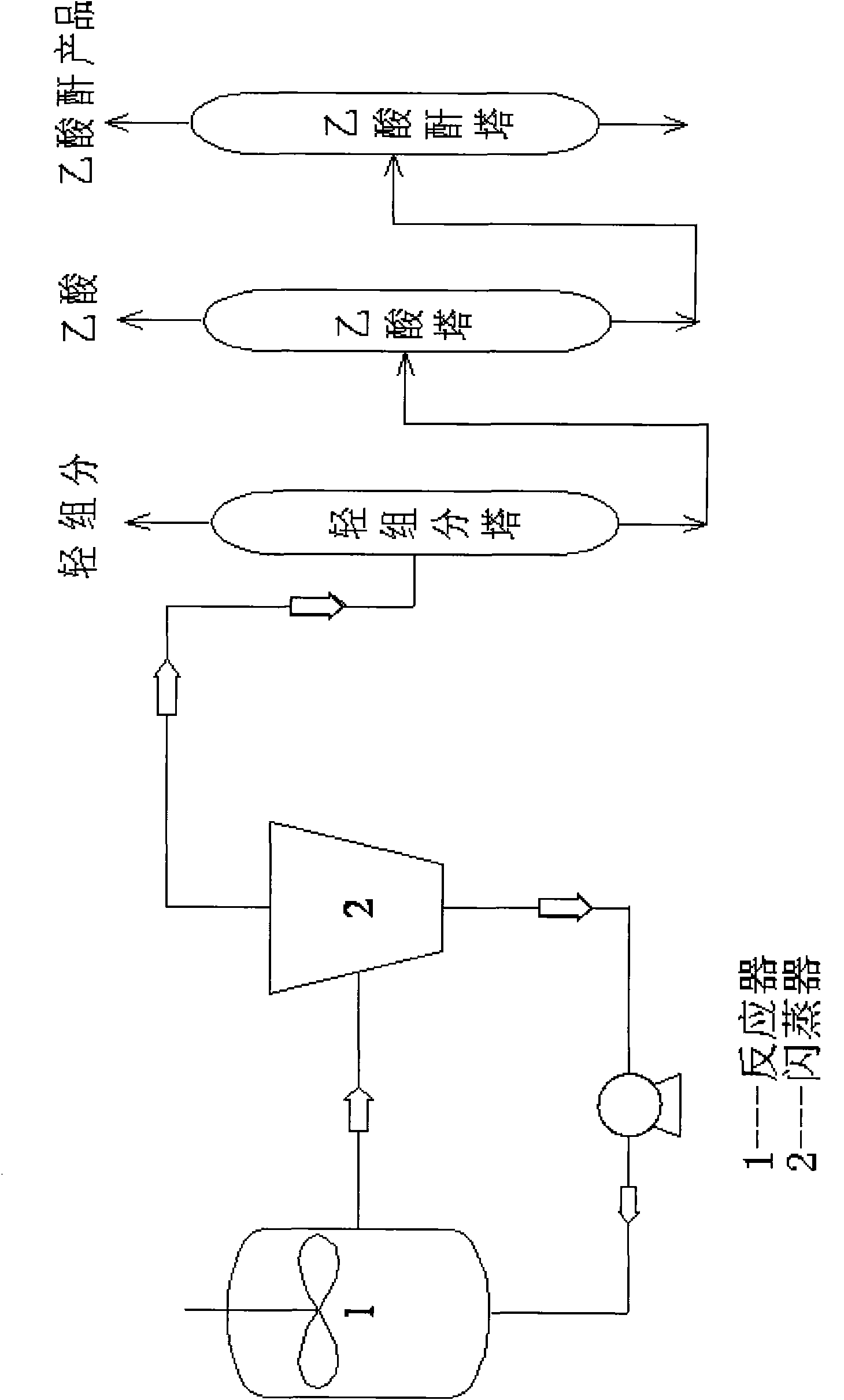

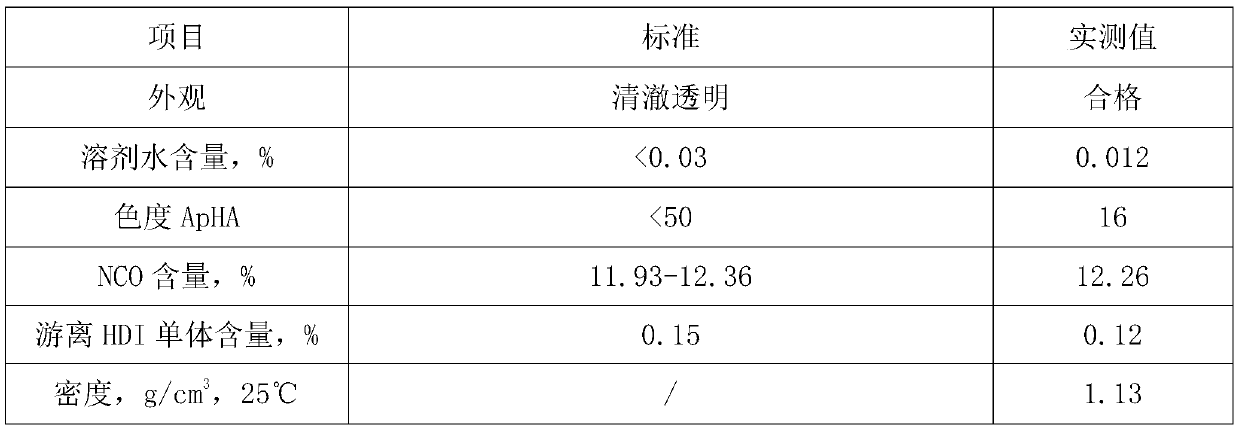

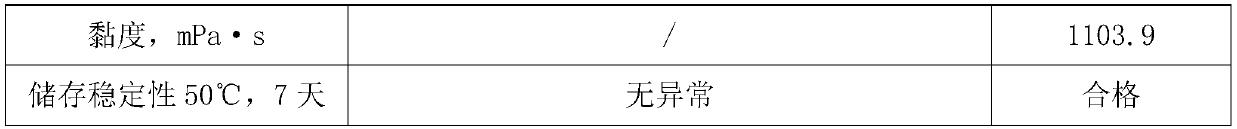

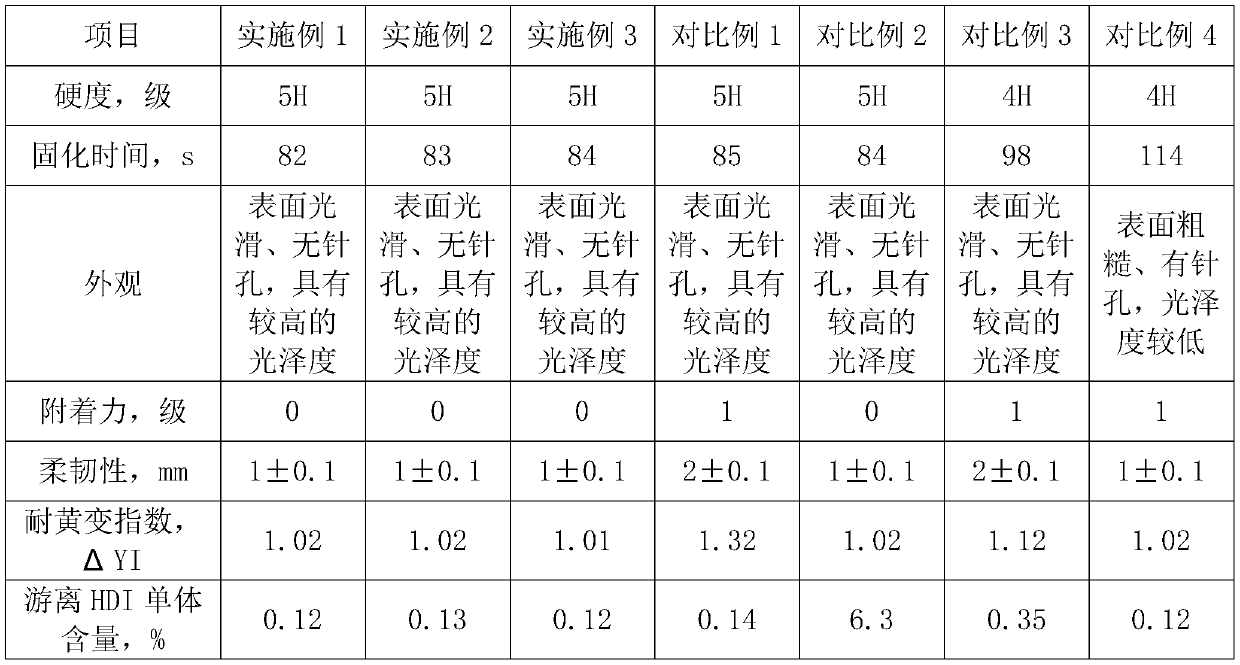

Preparation method of polyurethane curing agent

InactiveCN109824863AImprove stabilityImprove liquidityPolyurea/polyurethane coatingsOrganic solventNitrogen

The invention discloses a preparation method of a polyurethane curing agent and belongs to the technical field of curing agents. The preparation method includes following steps: S1, under protection of nitrogen, enabling oxygen content in a reaction environment to be less than or equal to 1%, and stirring hexamethylenediisocyanate prepolymer, ester solvent, aromatic hydrocarbon organic solvent anddispersant at normal temperature and normal pressure for 20-30min to obtain a mixture; S2, adding a water remover into the mixture, continuing stirring for 5-10min, and using a screen with 100-400 meshes for filtering to obtain the polyurethane curing agent. Through cooperation of the dispersant and the solvent, agglomeration of the hexamethylenediisocyanate prepolymer can be reduced, dispersityof the prepolymer can be improved, and fluidity of the curing agent can be improved.

Owner:SHANGHAI INABATA FINE CHEM CO LTD

Preparation method of prussian blue or prussian blue analogue coated pigment

ActiveCN107365513ASmall specific surface areaReduce adsorptionInorganic pigment treatmentHydrated aluminaPrussian blue

Owner:林一中

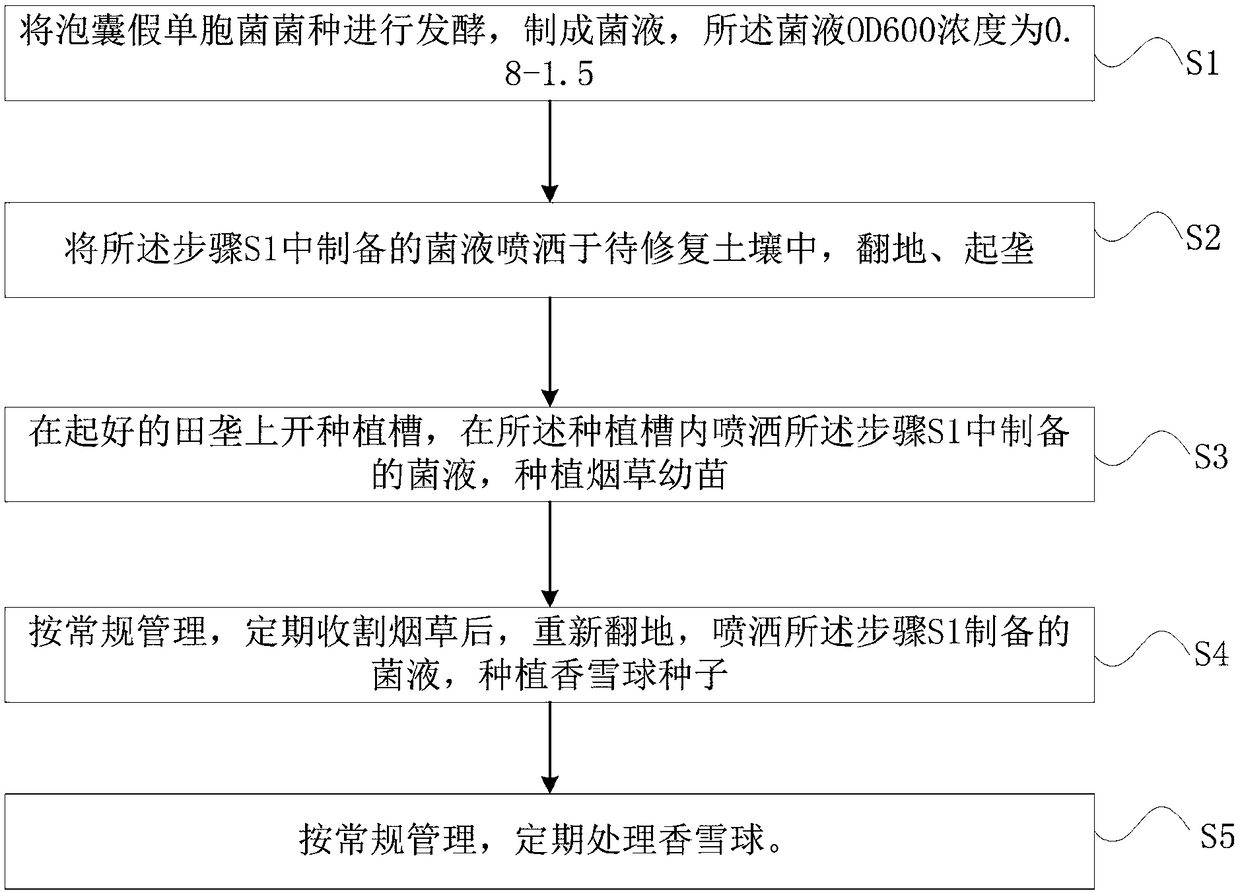

Method of promoting phytoremediation of soil nickel pollution by utilizing pseudomonas vesicularis

InactiveCN109108068AReduce the content of nickel ionsReduce freeContaminated soil reclamationNicotiana tabacumPseudomonas tolaasii

The invention discloses a method of promoting phytoremediation of soil nickel pollutionby utilizing pseudomonas vesicularis, wherein the method of promoting soil nickel pollution with phytoremediationby utilizing the pseudomonas vesicularis comprises the following steps of performing fermentation on a pseudomonas vesicularis strain to prepare a bacterium liquid, wherein the OD600 concentration ofthe bacterium liquid is 0.8-1.5; spraying the bacterium liquid in soils to be repaired, and performing ploughing and ridging; forming a groove on a ridged ribbing, spraying the bacterium liquid, andplanting tobacco seedlings; according to conventional management, after periodically harvesting tobacco plants, performing ploughing again, spraying the bacterium liquid, and planting sweet alyssum seeds; and according to conventional management, periodically treating sweet alyssum. The method provided by the invention can repair nickel polluted soils and is high in planting economic benefit at the same time.

Owner:HUNAN XISI ECOLOGY TECH

Method for preparing composite membrane of high polymer Nano materal

InactiveCN1539868AImprove scratch resistanceGood anti-adhesion effectPhotosensitive material auxillary/base layersComposite filmPolymer science

A composite film used as the protecting film of photosensitive silver halide material is prepared from high-molecular material and nanoparticles chosen from silicon oxide, aluminium oxide and zinc oxide. Its advantage are high water and light penetrability, low surface viscosity, good antistatic action, and high strength.

Owner:NANYANG NORMAL UNIV

Antibacterial outer shell used for automotive electronic igniter

The invention discloses an antibacterial outer shell used for an automotive electronic igniter. The outer shell comprises the following raw materials in parts by weight: 125-135 parts of a main material, 1-2 parts of isopropyl tri(dioctylpyrophosphate) titanate, 0.5-1.2 parts of maleic anhydride, 1-5 parts of a composite antibacterial agent, 5-10 parts of precipitated barium sulfate, 2-6 parts ofheavy calcium carbonate, 1-6 parts of calcined kaolin, 2-4 parts of graphene, 1-2 parts of trimethylethoxysilane, 2-4 parts of a dispersant, 1-2 parts of an anti-aging agent, and 1-2 parts of a defoaming agent, wherein the composite antibacterial agent is prepared by the following processes: performing uniform mixing on houttuynin and toluene, adding a hydrogen peroxide aqueous solution dropwise,raising the temperature, performing stirring, performing extraction by adopting dichloromethane, collecting an organic phase, performing evaporation to dryness, adding nano zinc oxide, nano silver oxide, sepiolite powder and water, performing mixing, raising the temperature, performing stirring, raising the temperature, continuing stirring, performing cooling, performing filtering, performing washing, and performing drying to obtain the composite antibacterial agent.

Owner:蚌埠泰欣电子科技有限公司

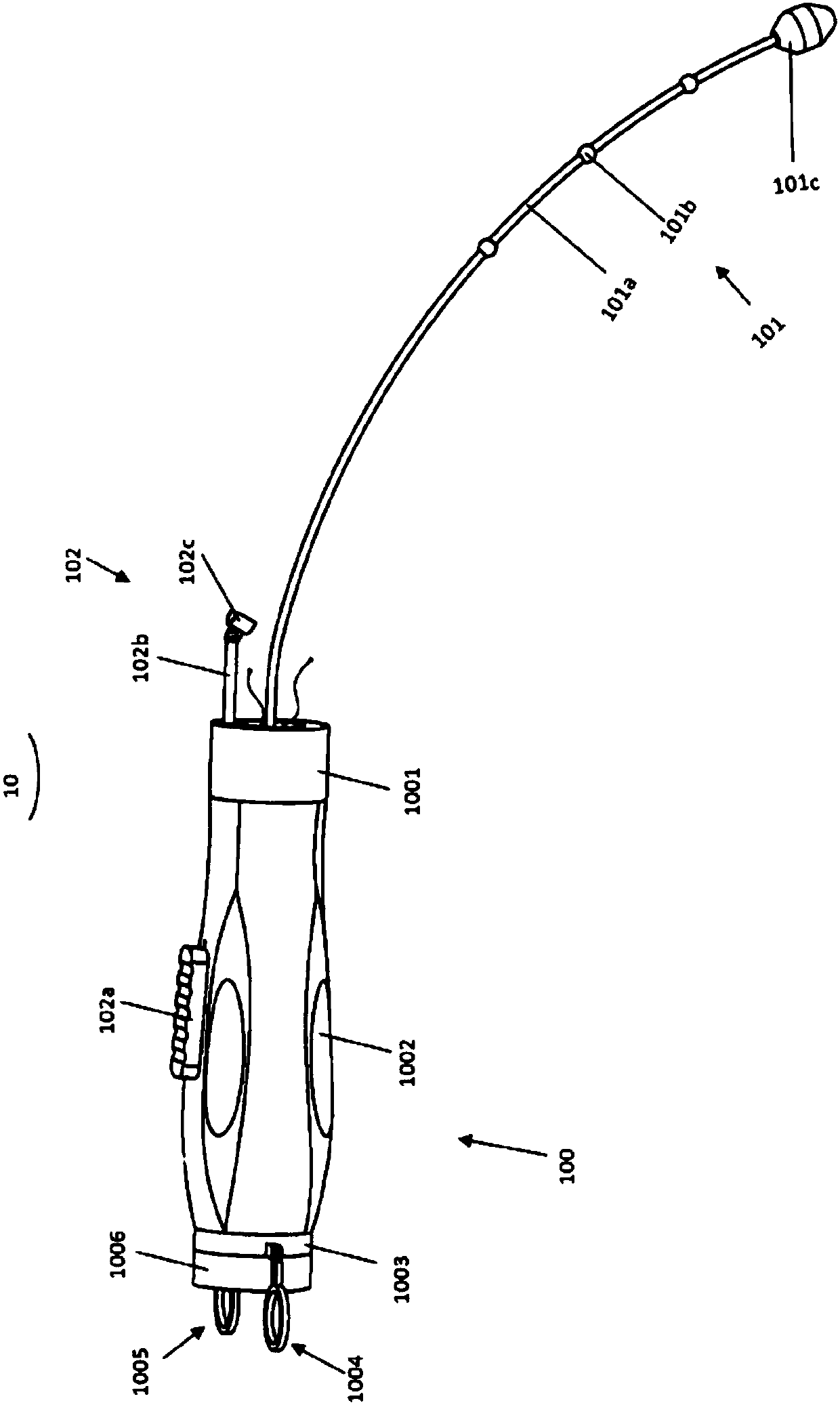

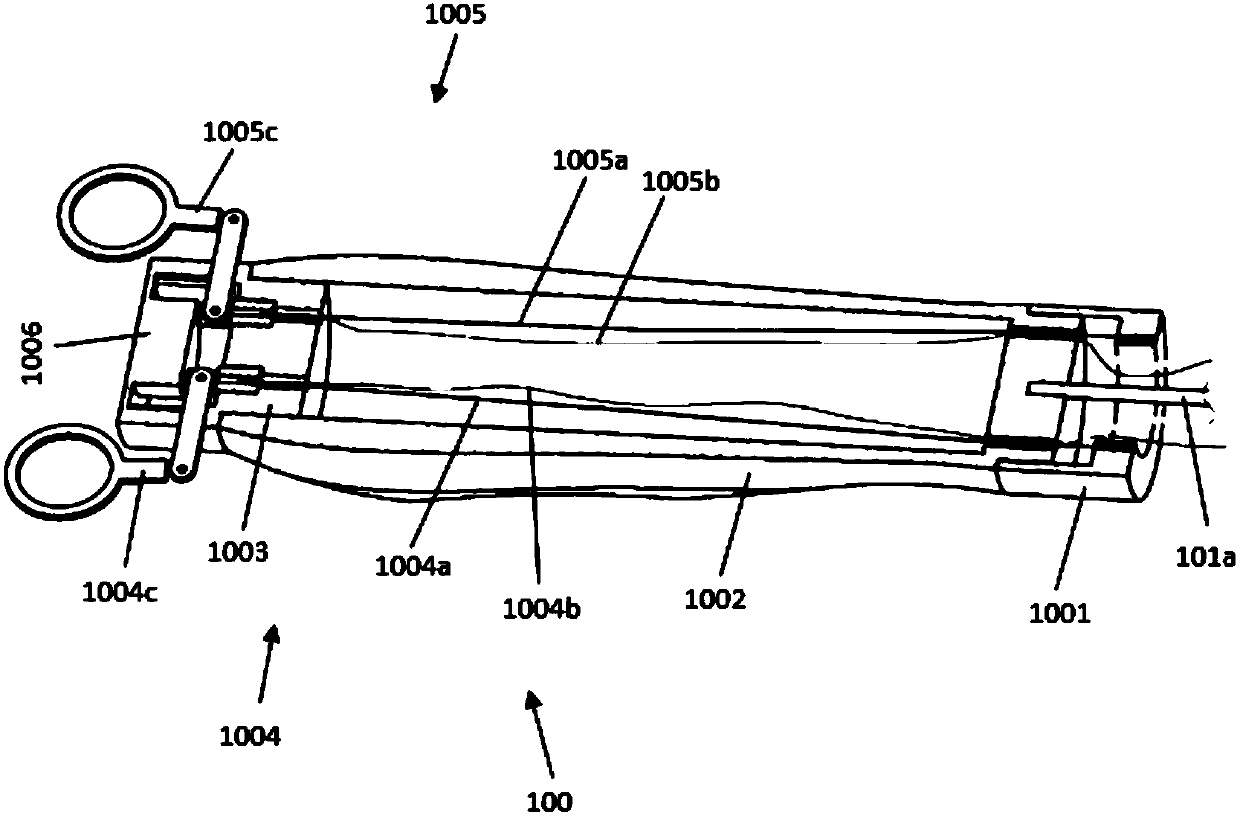

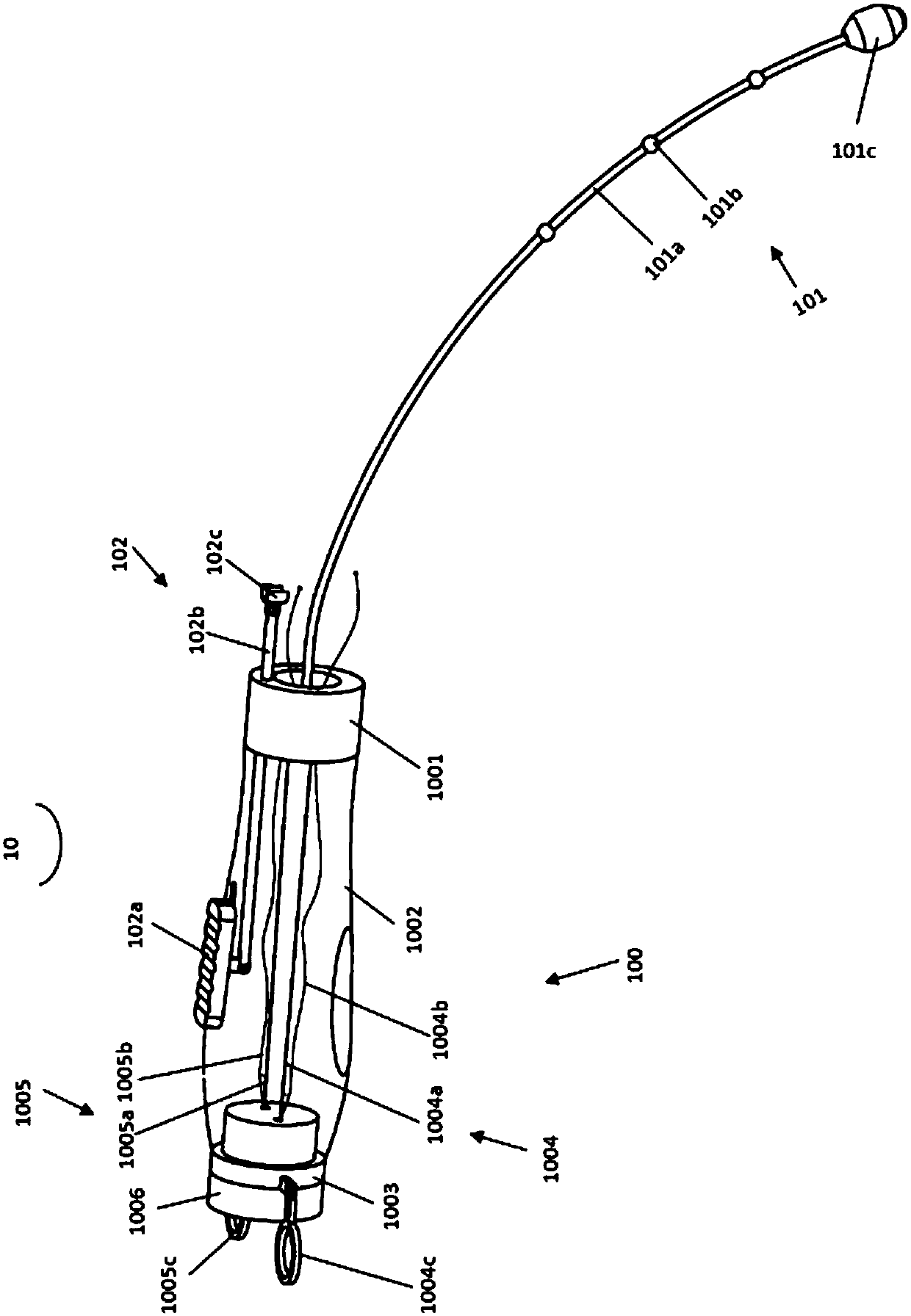

Intraoperative stent delivery system and use method thereof

The invention provides an intraoperative stent delivery system and an use method thereof. The intraoperative stent delivery system is used for loading and delivering the intraoperative stent. The intraoperative stent delivery system comprises a main body operating handle, a main body lining bar and a branch swing mechanism; the main body lining bar is arranged at the front end of the main body operating handle; the branch swing mechanism is also arranged at the front end of the main body operating handle; the main body operating handle comprises a front end cover, a middle handle, a rear end cover, a main body stent release portion, a branch support release portion and a lock cover; the main body lining bar comprises a bending bar, a limit ball and a guide head; and the branch swing mechanism comprises a sliding block , a transmission bar and a U-shaped ring. The invention also includes a method by using the system to deliver the intraoperative stent. The system can be used for delivering and releasing the single branch intraoperative stent so that the single branch intraoperative stent can solve the problem that the intraoperative stent is difficult to be matched with branch vessels, especially for the anastomosis with the left subclavian artery, accordingly the dissociation, the blocking and the anastomosis of the super-aortic branch vessels can be reduced or avoided so as toreduce the difficulty of surgery as well as the trauma of the surgery.

Owner:北京有卓正联医疗科技有限公司

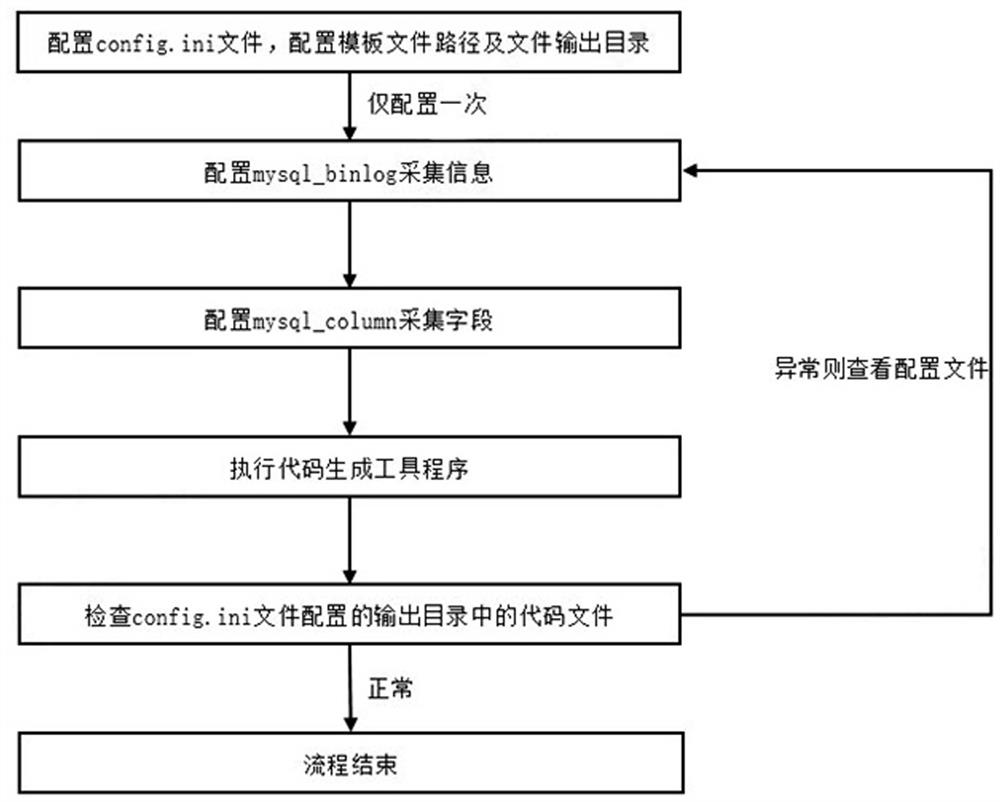

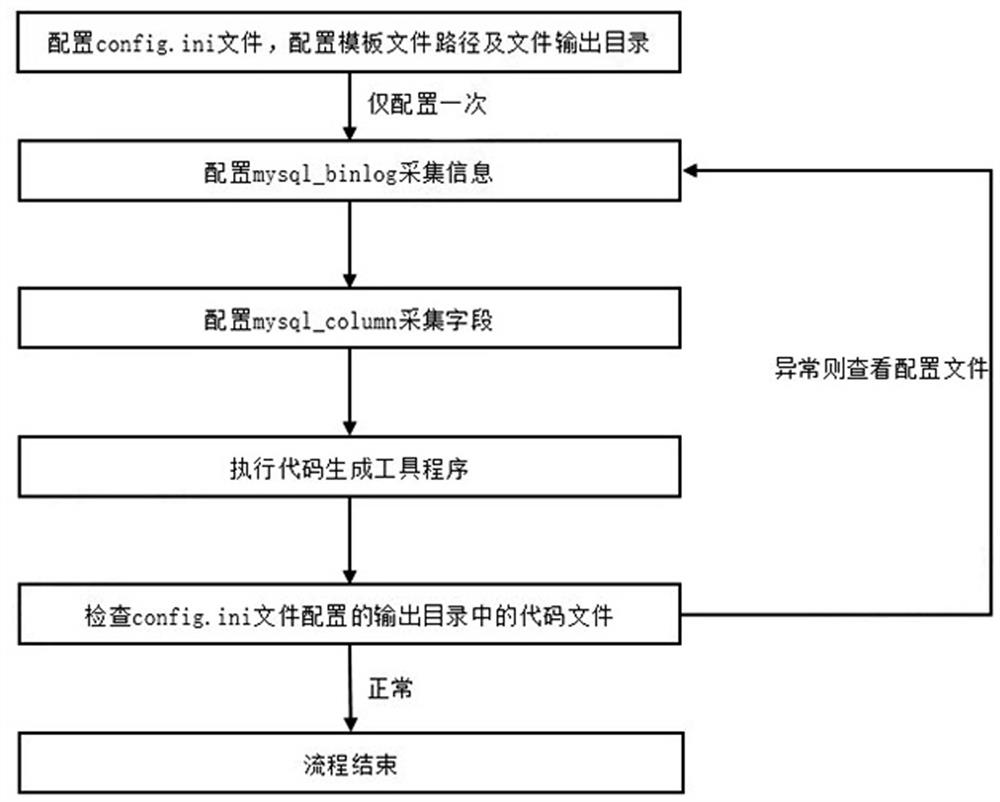

Real-time collection method applied to MYSQL BINLog change data

InactiveCN113961570ARealize automatic generationReduce the process of manually writing acquisition scriptsText processingRelational databasesSoftware engineeringMaintenance management

The invention discloses a real-time collection method applied to MYSQL BINLog change data, and belongs to the technical field of big data. The method comprises the following steps: 1, configuring database connection information and acquisition field information of an MYSQL database to be acquired in Excel, and configuring a configuration file for analyzing an Excel template position, Flink SQL script output file configuration information and execution environment configuration information; 2, executing an Flink mysql script tool, and automatically generating an Flink CDC acquisition script; and 3, uploading the Flink CDC acquisition script to each Flink client node to execute task release. The collection codes are automatically generated through simple configuration and tools, complex and frequent real-time collection research and development tasks are achieved, the collection tasks are integrated in an existing real-time application platform, cluster resources are fully utilized, unified operation and maintenance management is achieved, and the maintenance cost is reduced.

Owner:SICHUAN XW BANK CO LTD

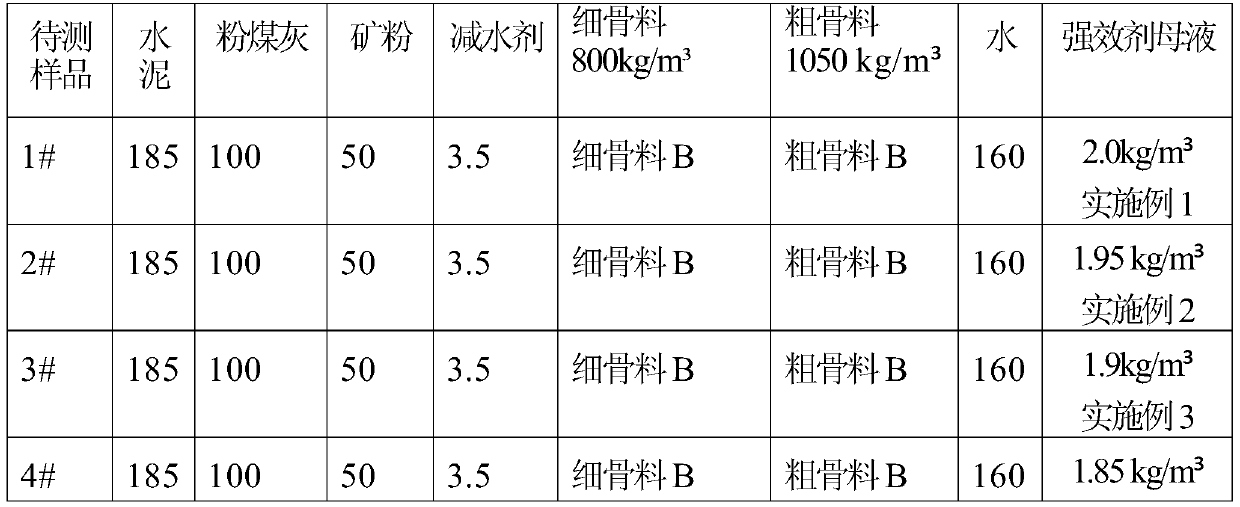

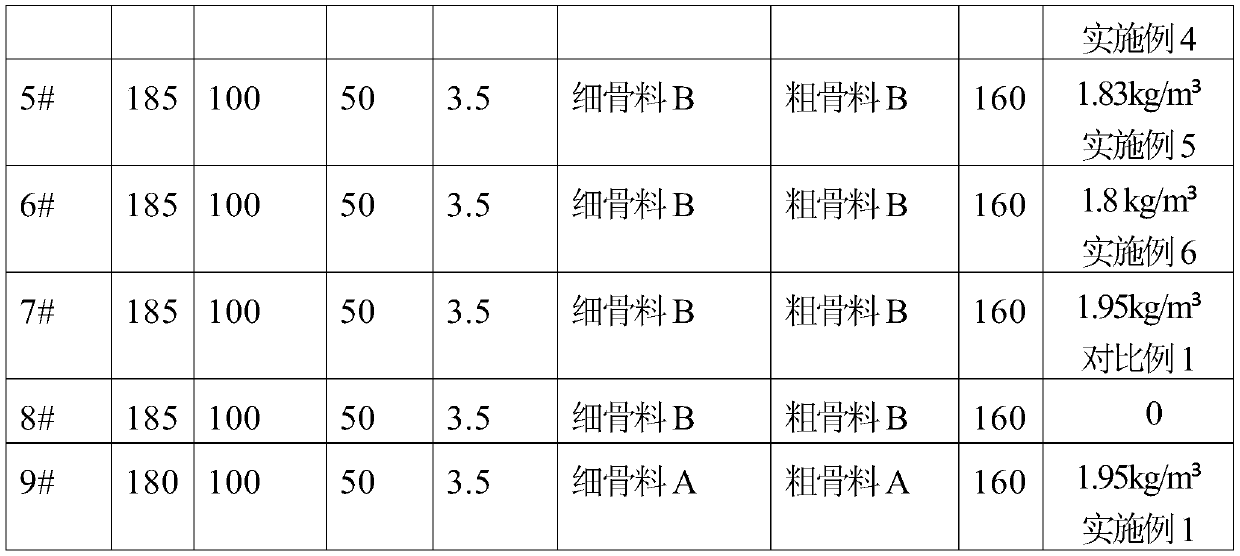

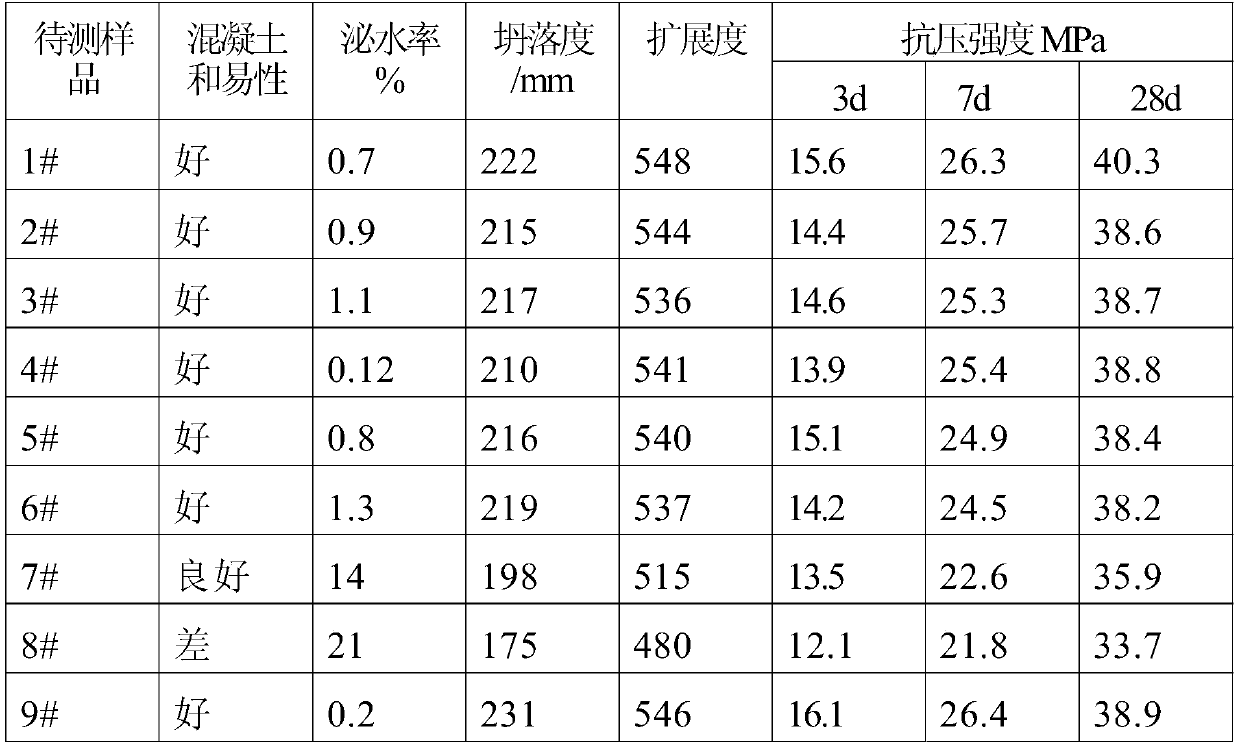

Intensifier suitable for concrete prepared from manufactured sand and preparation method of mother solution thereof

The invention relates to an intensifier suitable for concrete prepared from manufactured sand. The intensifier is prepared from the following components in parts by weight: 1 to 8 parts of TPEG, 8 to20 parts of triethanolamine, 4 to 15 parts of gellan gum, 3 to 10 parts of polyisoprene rubber latex, 3 to 10 parts of modified starch, 6 to 20 parts of sodium lignin sulfonate and 1 to 8 parts of filler. Compared with the prior art, the concrete intensifier has the advantages that the dosage of the modified starch and water is adjusted, and a proper amount of gellan gum and polyisoprene rubber latex is added, so that the thickening and water retention functions of the product on the concrete are improved on the basis of an original technique, the bad effects of multiple edges and corners andhigh mud and powder content of the manufactured sand on the concrete workability are improved, the sensitivity to use of water reducing agents such as polycarboxylic acid and the like in the manufactured sand concrete is reduced, the workability of the manufactured sand concrete is obviously improved, the bleeding and segregation phenomena are relieved, the homogeneity of the manufactured sand concrete is increased, and the strength dispersion of a solidification body of the manufactured sand concrete is reduced.

Owner:广东基业长青建筑科技有限公司

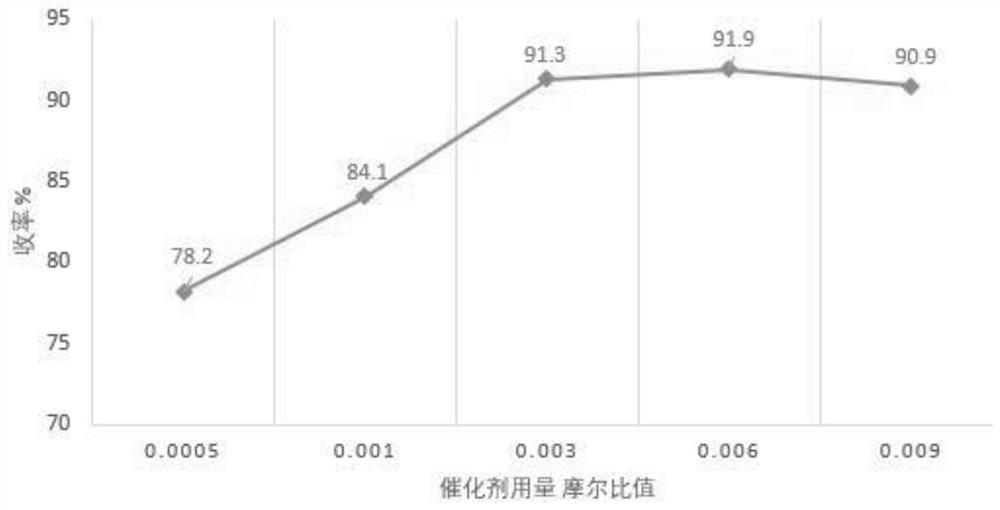

Preparation method of p-hydroxyl biphenol

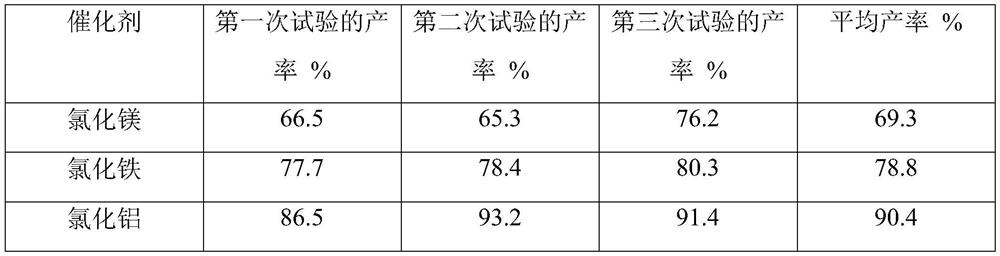

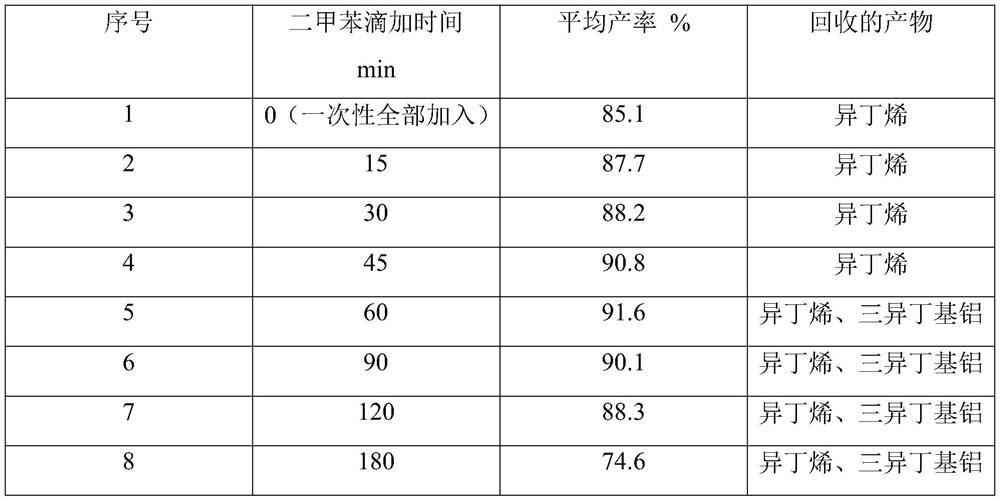

ActiveCN112142570AGood reaction selectivityReduce freeOrganic chemistryOrganic compound preparationXylyleneTert butyl phenol

The invention discloses a preparation method of p-hydroxyl biphenol, which adopts a two-step method to prepare a target product, and comprises the following steps: carrying out oxidative coupling reaction and reduction reaction on 2,6-di-tert-butyl phenol, recrystallizing to obtain white powder, adding a catalyst, dropwise adding xylene, and carrying out tert-butyl removal reaction to obtain the target product. By selecting the catalyst and dropwise adding xylene to capture tert-butyl, free tert-butyl in the reaction liquid is reduced, complete reaction is promoted, isomers or byproducts whichare difficult to remove are not generated, and the obtained product is easy to purify. Few types of reagents are added in the preparation process, xylene and isobutene obtained by reaction can be recycled, and the yield and purity of the finally obtained product are very high.

Owner:威海金泓高分子有限公司 +1

Production method for hardenability steel and hardenability steel

InactiveCN105624363AAccurately control the dosageReduce freeProcess efficiency improvementElectric furnaceAluminateSlag

The invention provides a production method for hardenability steel. The production method comprises the steps that 1, in the electric furnace smelting step, the tapping C content is precisely controlled to be below 0.04%, due to the fact that the carbon-oxygen equilibrium is constant at a certain temperature, after the C content is reduced, the oxygen content is kept to be at a high level, precise controlling over the using amount of ferroaluminum of a deoxidizing agent is facilitated during deoxidizing at the next step, and then the quantity of a Ca element can be controlled during calcium treatment on generated aluminate; 2, in the LF furnace refining step, special refining deoxidizing slag is adopted, the ratio of the Ca to Al in the adopted refining slag system is 1.6-1.8, and the free Ca element can be reduced by precisely controlling the ratio of the Ca to the Al; 3, in the VD refining step, bottom blowing of Ar gas is adopted, the pressure of the Ar gas is 0.20-0.40 MPa, floating of inclusion is facilitated through bottom blowing of the Ar gas, and calcium compounds are promoted to be removed from molten steel; and 4, in the continuous casting step, the superheat degree is controlled to be within 30 degrees in the casting process, and floating of the calcium compounds in the molten steel is facilitated through the low superheat degree.

Owner:SUZHOU SUXIN SPECIAL STEEL +2

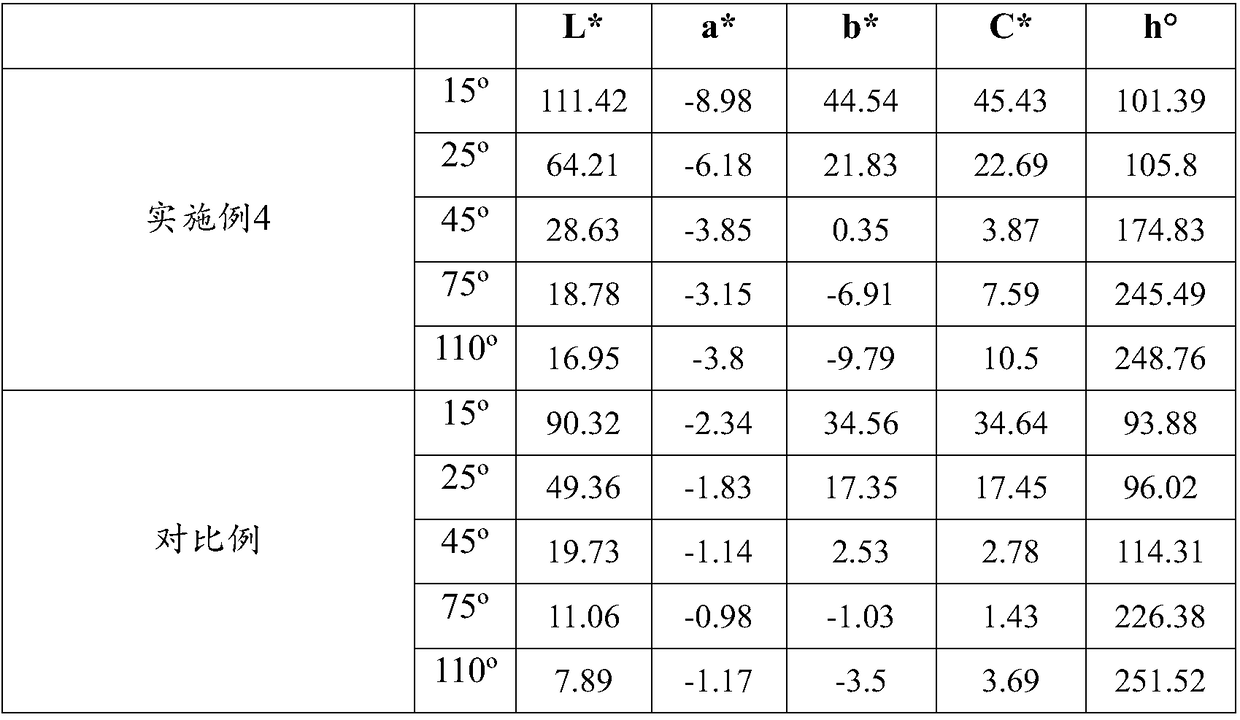

High-chroma glass-based pearlescent pigment as well as preparation method and application thereof

InactiveCN108707348ASolve the equilibrium matching of adsorption speedSolving Balanced MatchesPigment treatment with organosilicon compoundsTitanium ionHue

The invention provides a high-chroma glass-based pearlescent pigment as well as preparation method and application thereof. In the preparation method, stannous chloride is adopted for treatment to increase the surface active points, then a silane coupling agent with amino is adopted for further chemical grafting treatment to improve the surface adsorption capacity; since the amino functional grouphas remarkably strong complexing power on iron and titanium ions, the balance matching of the metal ions between the hydrolysis speed and the base material surface adsorption speed is further solved.The treated glass base material is greatly improved in the coating rate as well as the chroma. With the same particle size and the same hue, the coating rate of the treated glass base material is increased by about 10%, and the chroma and brightness are obviously improved. The high-chroma glass-based pearlescent pigment is applied to the fields of paint, coating, plastics, leather coloring, wallpaper, powder coating and cosmetics.

Owner:FUJIAN KUNCAI MATERIAL TECH

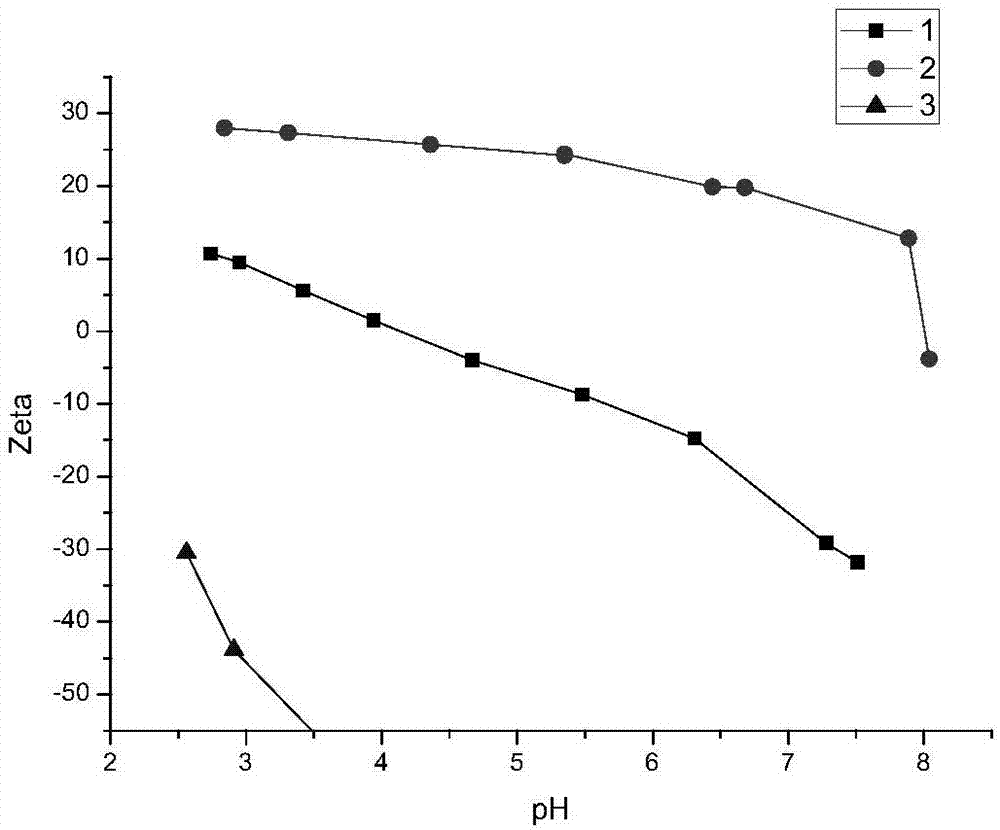

Preparation method for manganese violet coated pigment

ActiveCN107383938AFree controlImprove qualityCosmetic preparationsToilet preparationsZeta potentialSorbent

The invention relates to a preparation method for a manganese violet coated pigment. The method comprises the following steps: (1) depositing an adsorbent precursor on a substrate under the condition of system pH being 2-10, wherein the dosage (based on the volume of the generated adsorbent) thereof is 0.1-10% of the weight of the substrate; (2) adding a silane coupling agent under the condition of system pH being 2-10, wherein the dosage is 0-5% of the weight of the substrate; (3) adding Zeta potential regulating agent under the condition of system pH being 2-10, wherein the dosage is 0-10% of the weight of the substrate; (4) adding manganese purple pulp under the condition of system pH being 2-4, wherein the dosage (based on manganese violet pigment) is 0.1-10% of the weight of the substrate; (5) adding Zeta potential regulating agent under the condition of system pH being 2-4, wherein the dosage is 0-10% of the weight of the substrate; (6) adding a silane coupling agent under the condition of system pH being 2-4, wherein the dosage is 0-5% of the weight of the substrate; and (7) filtering, washing and drying, thereby acquiring the manganese violet coated pigment, wherein the step (3) and the step (5) meet the requirement that the dosage of the Zeta potential regulating agent is not equal to 0 at the same time. The free of the color paste of the pigment prepared according to the method cannot occur easily.

Owner:林一中

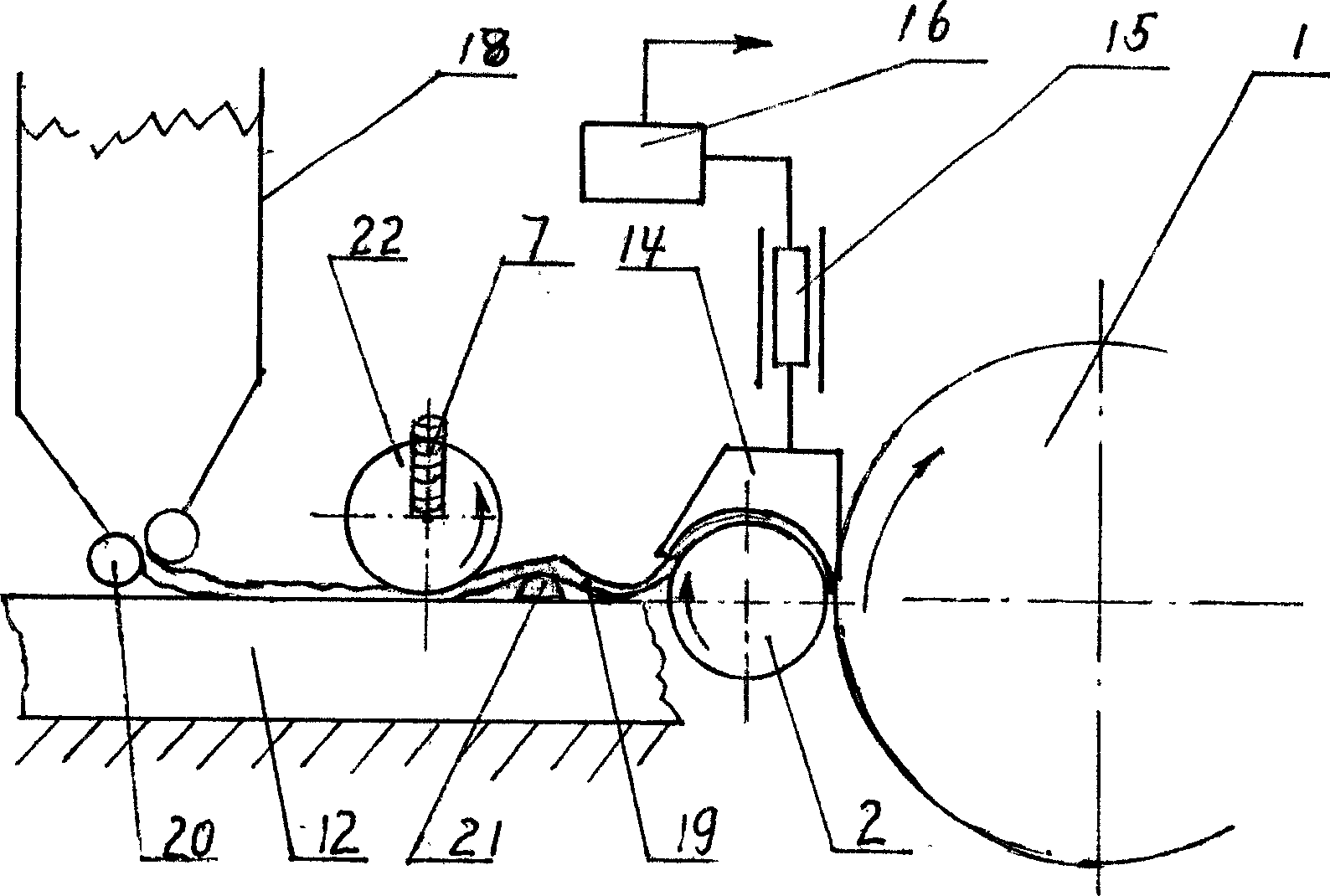

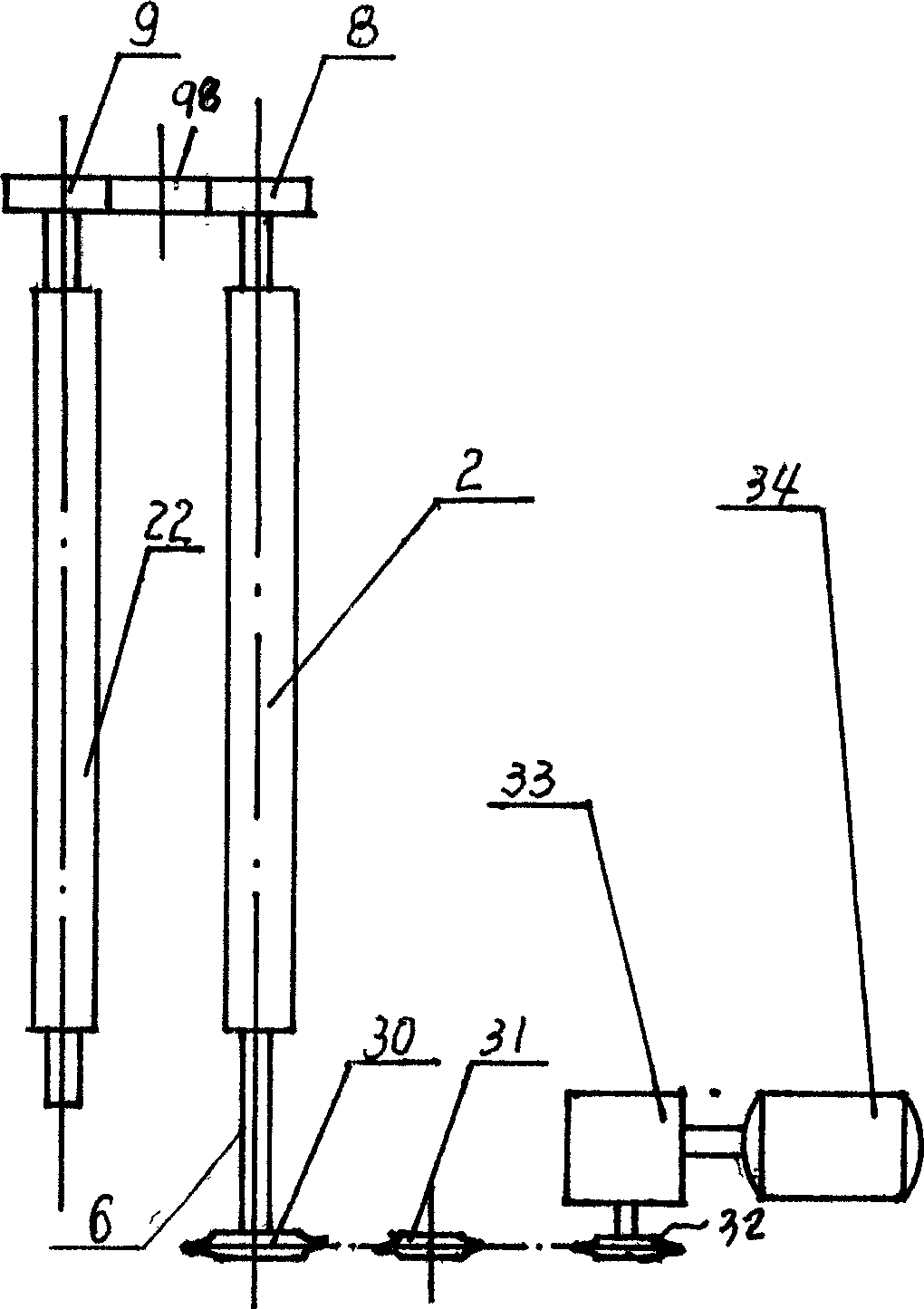

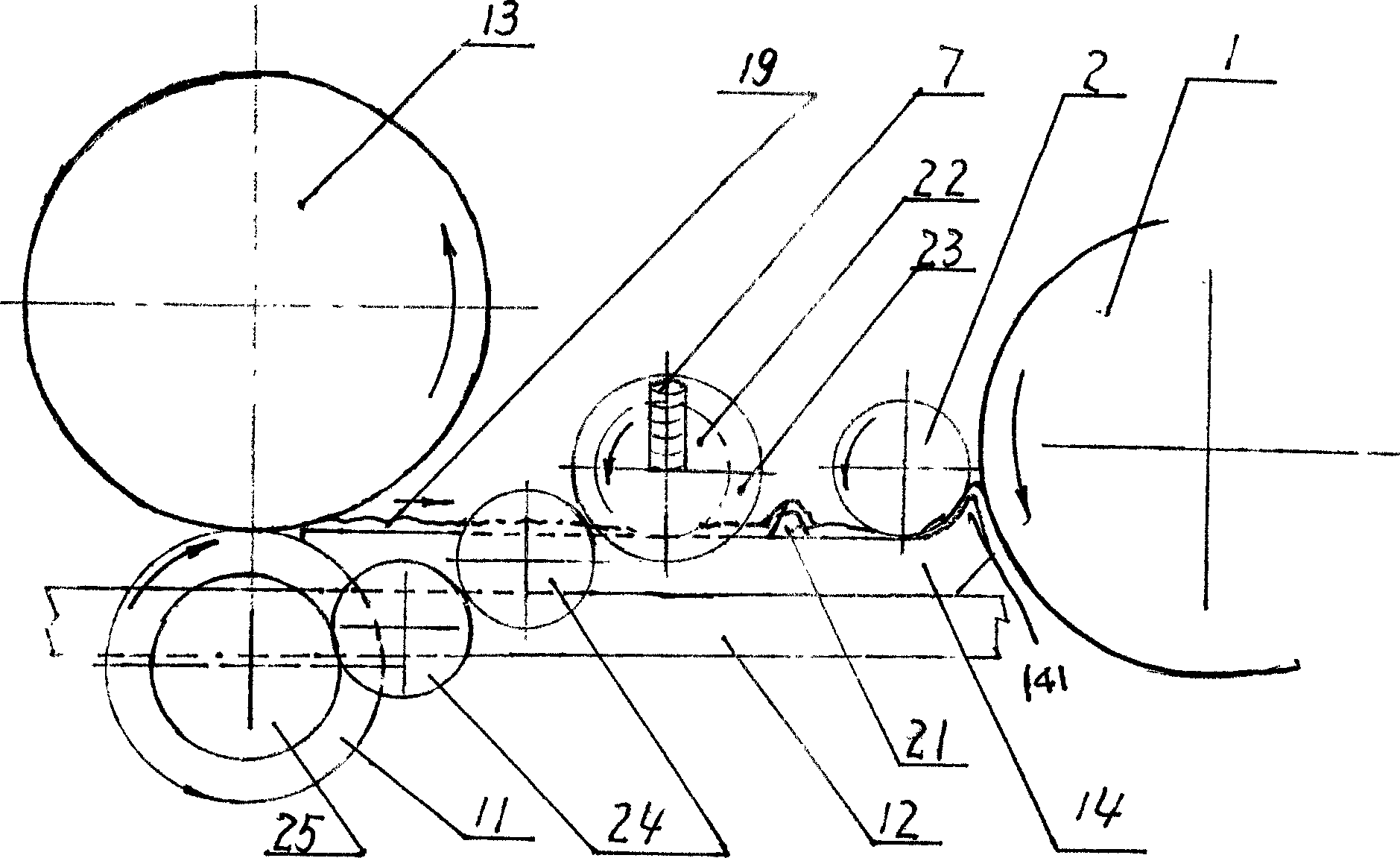

Feeder of carding machine

InactiveCN1779005AOptimize structural configurationIncrease projection lengthCarding machinesFiberEngineering

A receiver device of the cotton opener includes the rack, the driver, the roller of the cotton feeding and the cotton output part, which are the cotton box and the output roller. The cotton feeding bed is installed on the feeding roller, which is installed into the rack; the cotton feeding bed and the feeding roller form the feeding jaw; the friction roller is installed on the friction roller device, which is between the feeding roller and the output roller. The device can be used to all kinds of the cotton opener.

Owner:天津天鼎纺织集团有限公司 +1

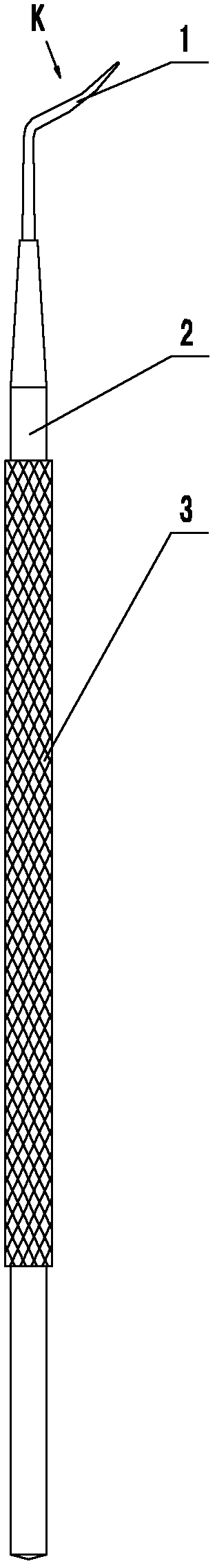

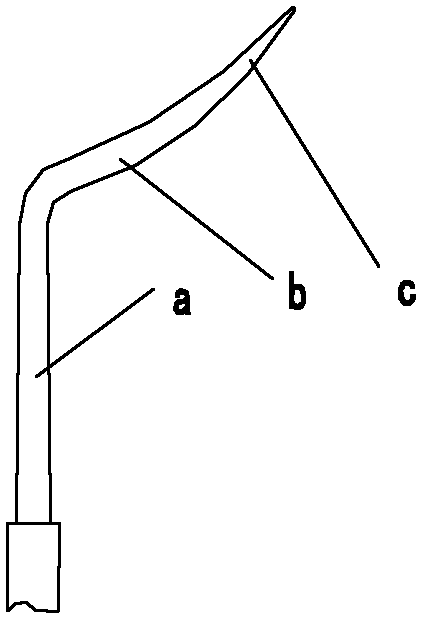

Microscopic flap lifting device used in LASIK (laser-assisted in situ keratomileusis) operation for femtosecond flap making

InactiveCN102600010ASurgical operation safetyReduce breakageEye treatmentLaser assistedSeparation process

The invention relates to a microscopic flap lifting device used in LASIK (laser-assisted in situ keratomileusis) operation for femtosecond flap making, comprising a flap lifting part and a handle, wherein the flap lifting part is fixedly arranged on the upper end of the handle; the flap lifting part includes a straight rod section, an arc section and a flat spade section which are manufactured integrally and connectedly; the lower end of the straight rod section is coaxially connected with the upper end of the handle, the upper blunt angle turning of the straight rod section is connected with the arc section, the section diameter and conical degree of the arc section become smaller gradually, the terminal end of the arc section is connected with the flat spade section with oval tips, and the cross section of the flat spade section is centrally thick and peripherally thin in shape. The microscopic flap lifting device disclosed by the invention can thoroughly separate corneal stroma flaps and reduce corneal flap damage, corneal flap dissociation and other complications during separation process, and is helpful for completely lifting the flap; meanwhile, the oval flat chisel section can reduce separation difficulty caused by opaque bubble layer (OBL) and reduce the damage on corneal tissue caused by repeated operation, and is helpful for post-operative wound recovery.

Owner:王雁 +2

Method for preventing and controlling formaldehyde pollution in decoration engineering

PendingCN110354440AReduce freeAchieve inhibitionGas treatmentDispersed particle separationAdhesivePollution

The invention relates to the field of formaldehyde removal in interior decoration, and discloses a method for preventing and controlling formaldehyde pollution in decoration engineering. The method comprises the following steps: 1, adding a formaldehyde stabilizer to a decoration auxiliary material, and performing stirring to achieve uniformity before construction, wherein the decoration auxiliarymaterial is a coating and / or an adhesive; 2, spraying a formaldehyde blocking agent on the exposed surfaces or the cut and notched surfaces of wood products used in the decoration during the construction, wherein the formaldehyde blocking agent is used for blocking the release of formaldehyde in the wood products; and 3, detecting and calculating the total release amount of formaldehyde in rooms,and spraying a formaldehyde cracking agent in the rooms after the construction. Different formaldehyde prevention and control technologies are used to prevent and control the indoor formaldehyde content at different stages in the decoration process, so the method reduces the superposed release of formaldehyde, effectively decomposes and converts a tiny amount of the residual released formaldehydefor a long term, and ensures that the decorated house after is safe and environmentally friendly and is suitable for people to live.

Owner:湖北天亚环境科技有限公司

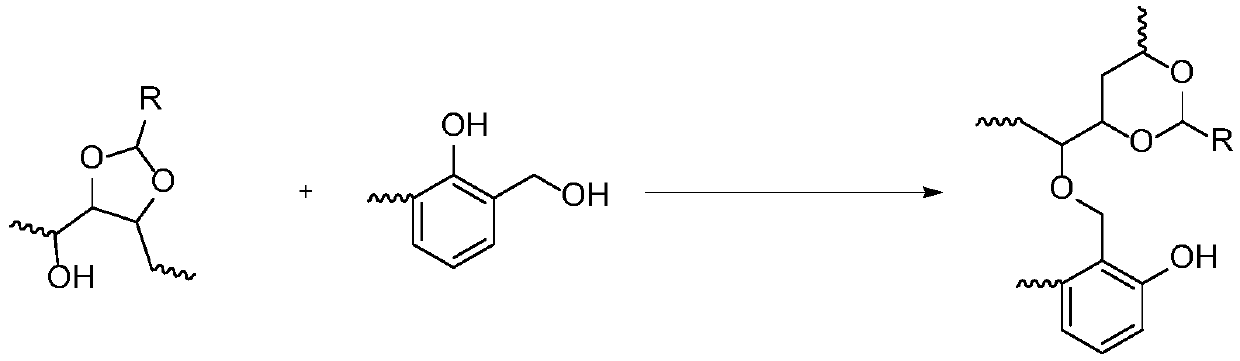

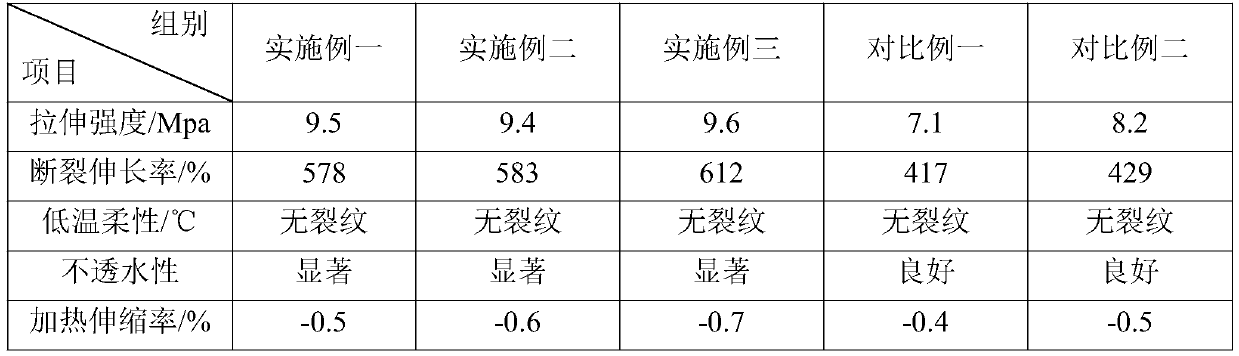

High-strength environment-friendly waterproof polyurethane coating and preparation method thereof

PendingCN110256947AReduce freeImprove securityPolyurea/polyurethane coatingsPolyesterEnvironmental resistance

The invention discloses a high-strength environment-friendly waterproof polyurethane coating and a preparation method thereof. The high-strength environment-friendly waterproof polyurethane coating comprises the following raw materials by weight: modified polyurethane, hydrophilic modified polyisocyanate, polyester polyol, potassium tripolyphosphate, zinc stearate, a filler, butyl acetate, a film forming aid, an antifoaming agent, a leveling agent, a dispersing agent and a catalyst, wherein the hydrophilic modified polyisocyanate is POSS-modified polyethylene glycol-modified polyisocyanate. The waterproof polyurethane coating comprehensively prepared from modified components through mixing in steps is more environmentally friendly and has better film properties, and the prepared waterproof polyurethane coating can meet the requirements for high strength and water resistance; and the coating with better performance is liquid at normal temperature, and is convenient to use, easy to store, simple in preparation process and low in cost.

Owner:FOSHAN SHUNDE HESHENG CHEMICAL INDUSTRIAL CO LTD

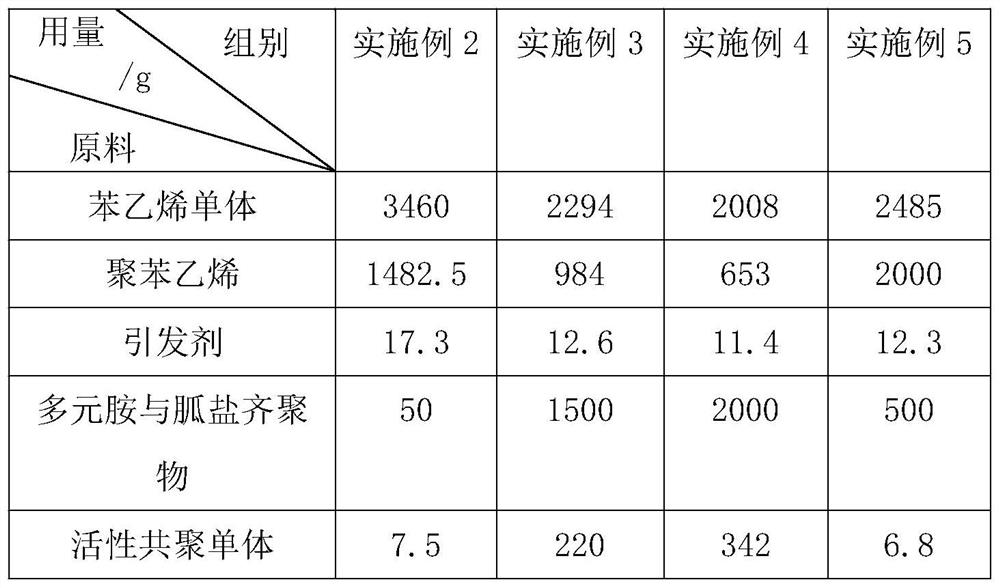

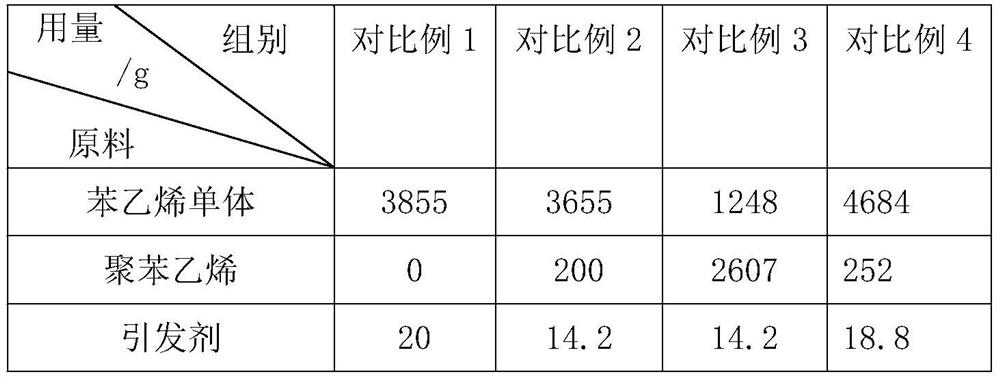

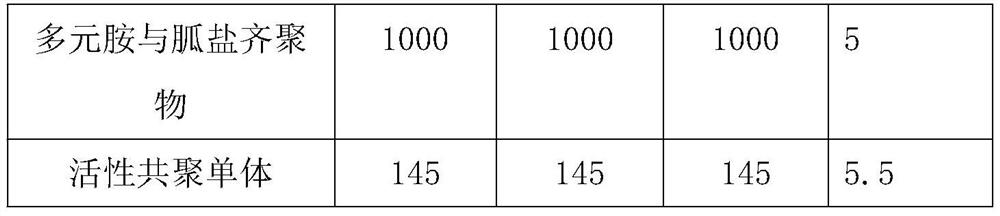

Long-acting antibacterial polystyrene resin and preparation method thereof

Owner:USEON NANJING EXTRUSION MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com