Patents

Literature

32results about How to "Good viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Raw material formula of bronzy sculpture

The invention discloses a raw material formula of a bronzy sculpture. The raw material formula of bronzy sculpture includes the following substances in parts by weight: 40-50 parts of paraffin wax, 20-30 parts of talcum powder, 15-20 parts of bronze powder, 5-8 parts of rosin, 10-15 parts of magnesium oxide, 2-5 parts of a flexibilizer and 1-3 parts of a catalyst, wherein the catalyst is selected from phosphate, sulphate and oxalic acid; the flexibilizer is selected from plant straw fine powder, glass fibres and organic fibres. The raw material formula of bronzy sculpture disclosed by the invention has the following beneficial effects: the raw material formula of bronzy sculpture is more time-saving and labour-saving while realizing a bronzy effect compared with the mode of producing a sculpture by virtue of water-based clay and then manually polishing; moreover, the raw material formula of bronzy sculpture is good in viscosity, not liable to crack, and convenient to store for a long time.

Owner:厦门鼎艺雕塑有限公司

Magnesium alloy boride iron illiminating flux and its production method

A deironing boride flux for Mg-alloy contains magnesium chloride, potassium chloride, sodium chloride, calcium chloride, calcium fluoride, barium chloride, and boron oxide and / or sodium borate as deironing agent. Its advantages are high power removing impurities and Fe from molten Mg-alloy, easy separation, and low cost.

Owner:SHANGHAI HAOHUA MOLD

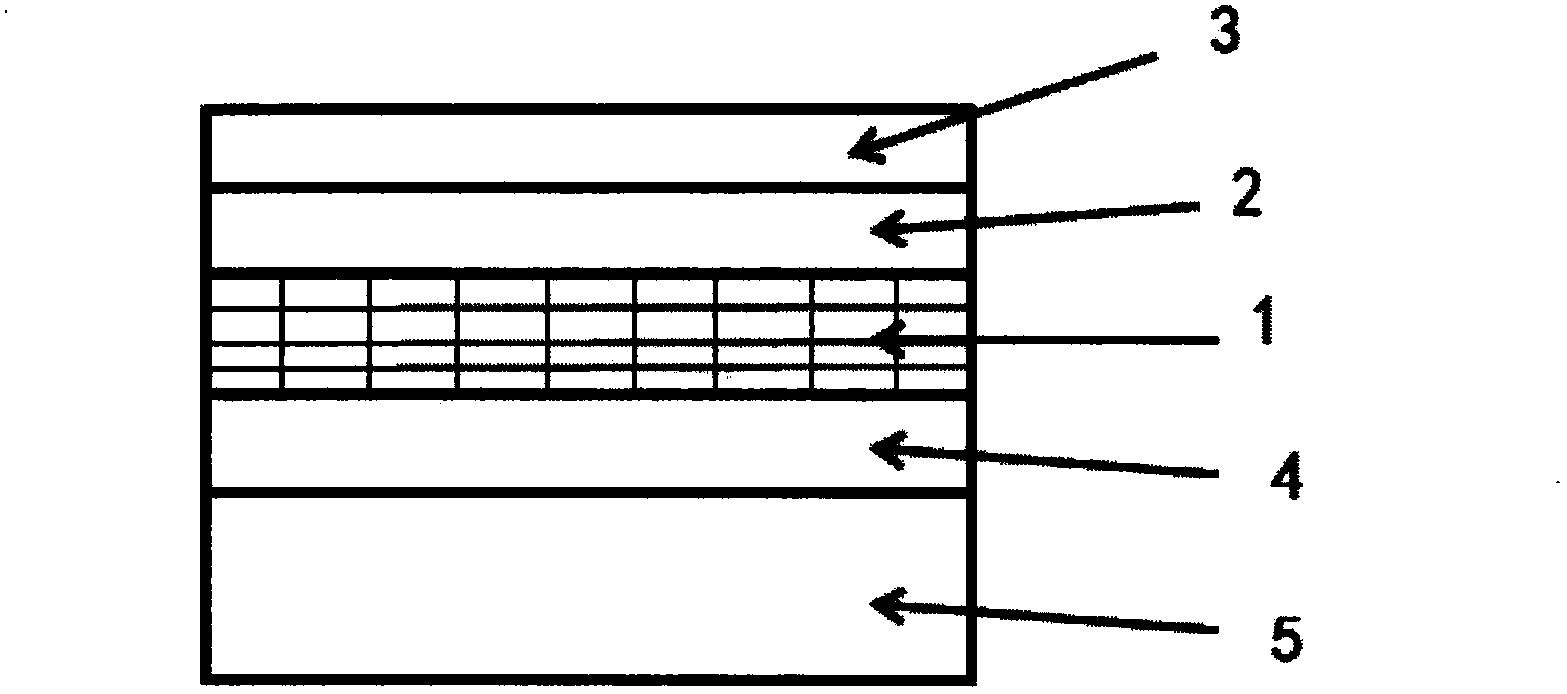

Pressure sensitive adhesive tape for high-temperature resistant masking and preparation method thereof

InactiveCN103571369AEliminate high temperature residual glueHigh peel strengthNatural rubber adhesivesFilm/foil adhesivesHot TemperaturePressure sensitive

The invention relates to a pressure sensitive adhesive tape for high-temperature resistant masking and a preparation method thereof. The pressure sensitive adhesive tape consists of a substrate layer, an isolator layer, a release agent layer, a primer layer and an adhesive layer, wherein the isolator layer and the release agent layer sequentially cover the upper surface of the substrate layer, and the primer layer and the adhesive layer sequentially cover the lower surface of the substrate layer. The pressure sensitive adhesive tape prepared by the invention, compared with the prior art, can avoid crack and residue when being peeled off after being roasted for 60 minutes at high temperature of 180 DEG C, and the adhesive property has strong adhesive property and can avoid a wrapping phenomenon when being used.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Carbon-free ladle brick and preparation method thereof

ActiveCN102515794ASolve the problem of non-scouring resistance and aggregate powder separationGood structural flexibilityThermal expansionConstruction aggregate

The invention discloses a carbon-free ladle brick and a preparation method thereof. The carbon-free ladle brick is prepared by using bauxite chamotte, a corundum raw material, magnesium oxide and alumina micro powder as main raw materials, adding iron oxide, a magnesium chloride solution, sodium hexametaphosphate and canary dextrin, mixing the above-mentioned materials by using special procedures, storing an obtained mixed for 30 min, carrying out compression molding and drying the mixture at a temperature of 200 DEG C for 24 h. According to the invention, iron oxide and alumina micro powder are enabled to exist in gaps between aggregate and powder and form hercynite with a low thermal expansion coefficient at a medium-high temperature, and no excess iron oxide enters into a matrix, which enables the ladle brick to have good high temperature stability and anti-stripping performance; therefore, the problem that molten steel carburetting caused by high temperature melting loss of a refractory brick influences smelting quality is overcome, and the prepared carbon-free ladle brick has excellent performances of high strength, washing resistance, a long service life, etc.

Owner:山西高科耐火材料股份有限公司

Oil sludge recovery device

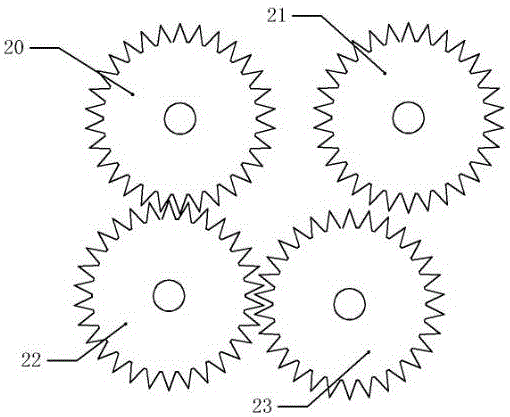

ActiveCN106734094AGood viscosityIncreased softness and plasticitySolid waste disposalMagnetic separationScrapMagnet

Owner:CHONGQING TENGTONG IND DESIGN

External preparation for treating androgens psilosis, seborrheic dermatitis and acne

InactiveCN101596318AGood viscosityGood sticky consistencyOrganic active ingredientsCosmetic preparationsPercutaneous absorptionSide effect

The invention provides an external prescription and a preparation process of a 5alpha-reductase inhibitor external preparation for treating androgen spsilosis , seborrheic dermatitis and acne (common comedo). In the prescription and the preparation process, a 5alpha-reductase inhibitor is used as a main medicine and a diluent antiseptic agent, a dissolve-helping moisturizing antiseptic agent, a dissolve-helping disinfecting agent, a softening percutaneous absorption promoter, an antiseptic disinfecting agent, diluent agent, and the like as auxiliary materials, wherein the 5alpha-reductase inhibitor which is originally and orally taken is prepared into an external solution to be directly applied on wounded parts so as to effectively treat the spsilosis, the seborrheic dermatitis and the acne and also reduce side effect caused in such a way that the 5alpha-reductase inhibitor is orally taken to treat the spsilosis. The invention has simple preparation process and good stability.

Owner:BEIJING PURUN BIOSCI DEV

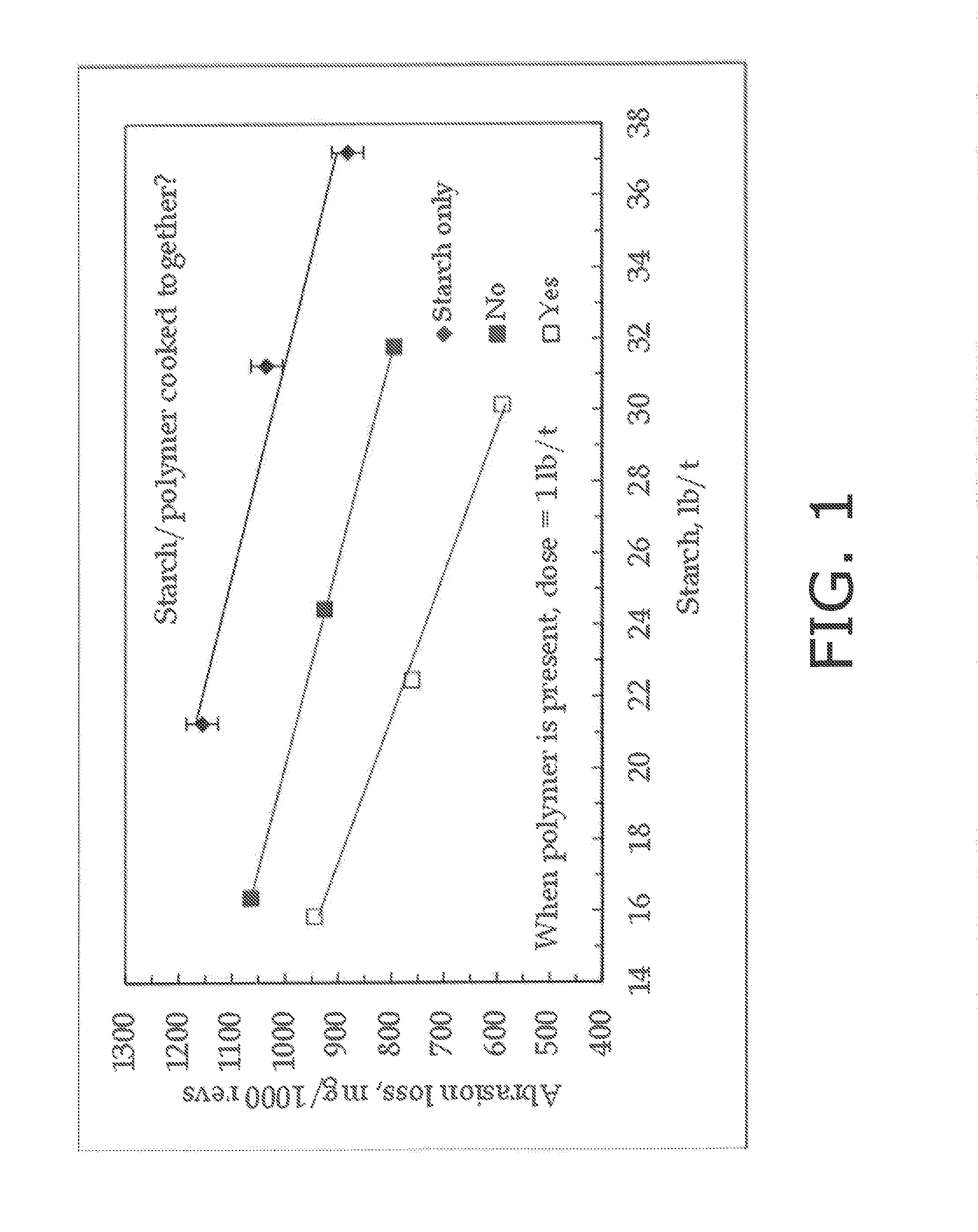

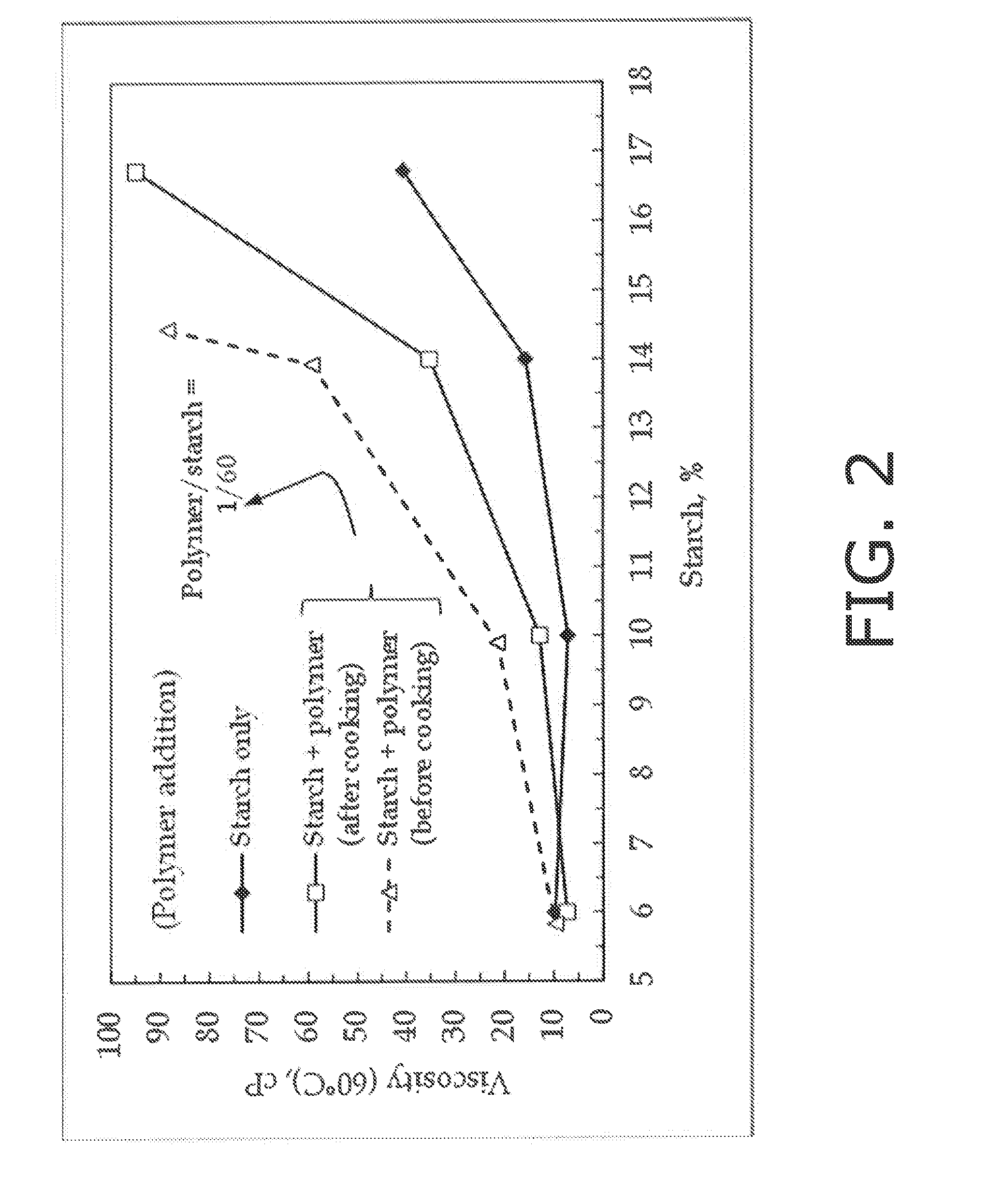

Method of increasing paper surface strength by using acrylic acid/acrylamide copolymer in a size press formulation containing starch

ActiveUS20140182799A1Good viscosityGood surface strengthNatural cellulose pulp/paperSpecial paperChemistrySynthetic polymer

The invention provides methods and compositions for increasing the strengthening effect of a starch coating on paper. The method involves contacting the starch with a synthetic polymer before the starch is cooked. This changes how the starch gelatinizes and how the polymer gets distributed on the paper resulting in greater paper surface strength.

Owner:ECOLAB USA INC

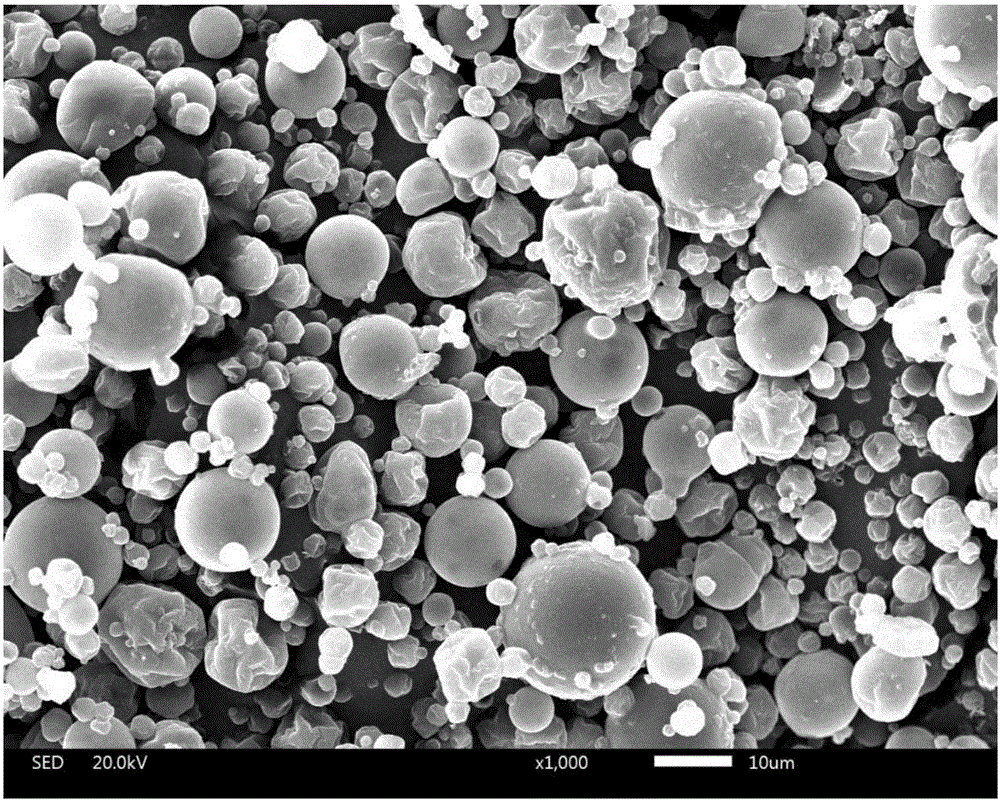

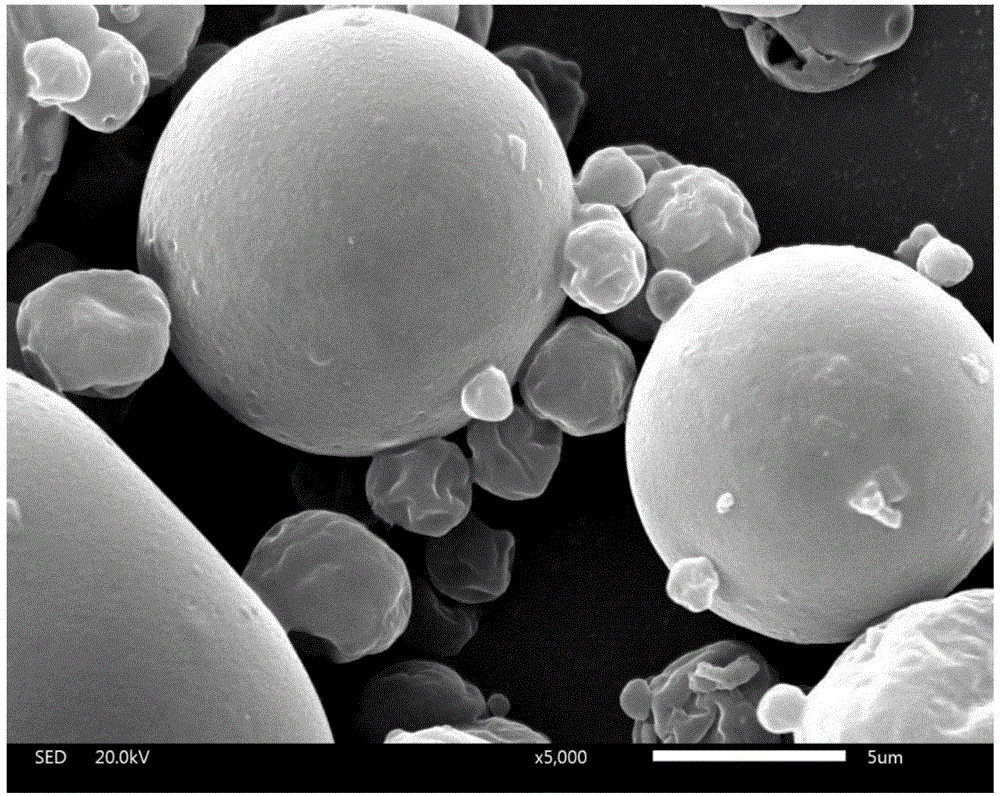

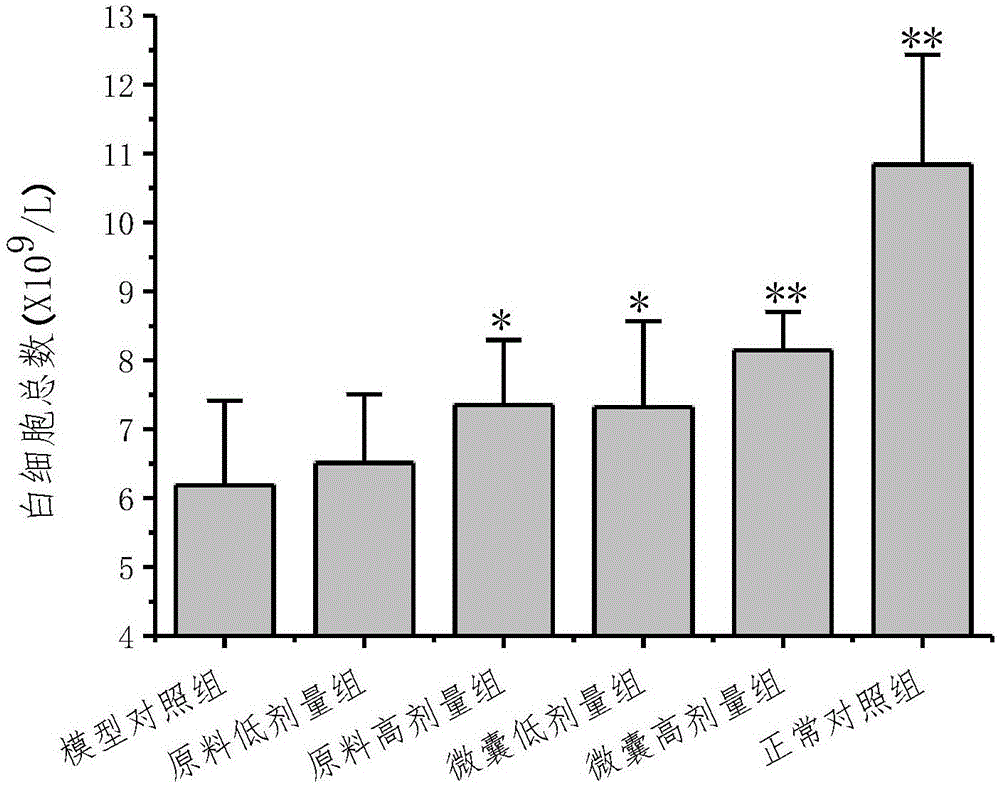

Ganoderma spore oil microcapsule powder and preparing method and application thereof

ActiveCN106580919ASpeed up evaporationFast film formationPharmaceutical non-active ingredientsImmunological disordersOCTENYLSUCCINIC ACIDBioavailability

The invention relates to the technical field of microcapsule powder, and discloses a ganoderma spore oil microcapsule powder and a preparing method and application thereof. The microcapsule powder comprises ganoderma spore oil and a wall material. The wall material comprises starch sodium octenylsuccinate and maltodextrin. According to the ganoderma spore oil microcapsule powder, starch sodium octenylsuccinate and maltodextrin are adopted as a composite wall material, microencapsulation is conducted on the ganoderma spore oil, not only does the ganoderma spore oil microcapsule powder have good dispersibility, but also times of adoption of homogenization are reduced in the processing process, meanwhile, bioavailability of the ganoderma spore oil can be improved, medicinal activity of the ganoderma spore oil is further improved, and immunity can be remarkably improved.

Owner:INFINITUS (CHINA) CO LTD

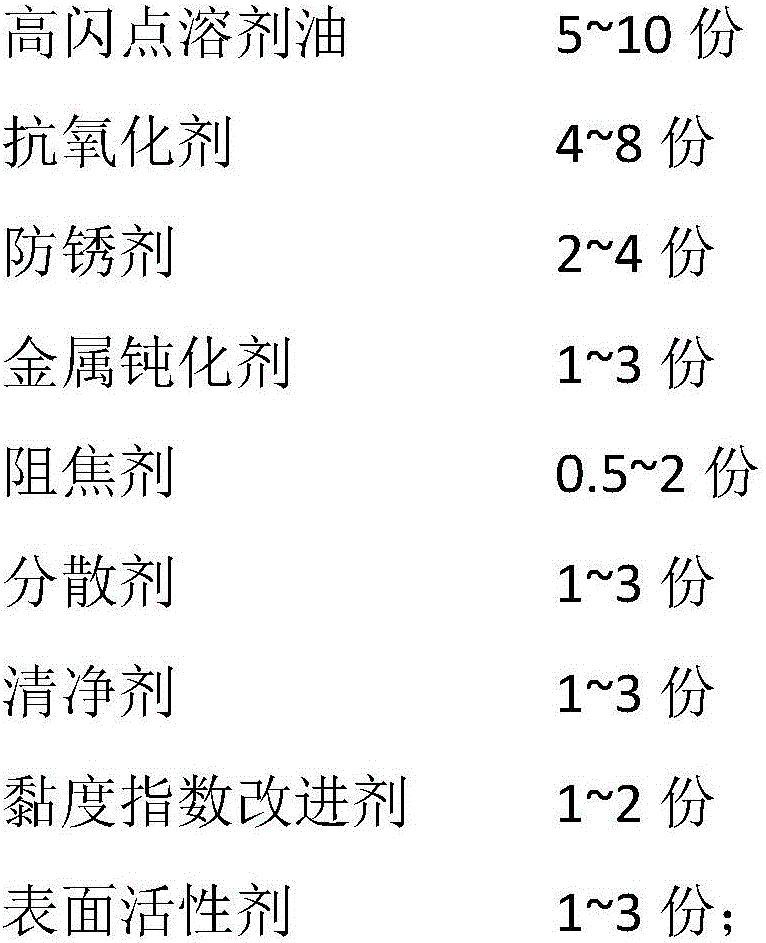

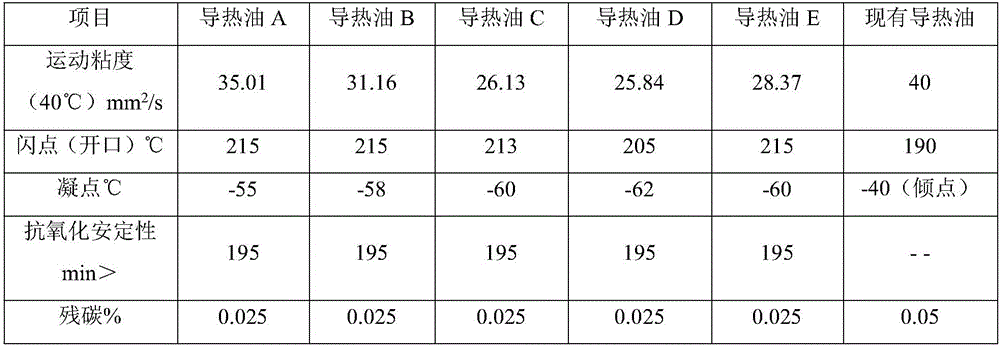

Environment-friendly conduction oil and preparation method thereof

InactiveCN106010464ALow excellentGood viscosityHeat-exchange elementsSolventEnvironmentally friendly

The invention belongs to the field of heat conduction, and in particular relates to an environment-friendly heat conduction oil and a preparation method thereof, including composite base oil, high flash point solvent oil, antioxidant, antirust agent, metal passivator, coke inhibitor, surfactant, Dispersant, detergent and viscosity index improver; preparation method: antioxidant, antirust agent, metal deactivator, scorch inhibitor, surfactant, dispersant, detergent and viscosity index improver according to the proportion of the components The agent is dissolved in high-flash point solvent oil; then the mixture obtained above is added to the composite base oil in proportion. The invention has the advantages of prolonging the service life and not being easy to coke, and can reduce the generation and discharge of low boiling substances, is safe and environment-friendly, and has a wide range of uses.

Owner:山东沾化莱斯特石油化工有限公司

Multiple-effect composite refining flux for removing impurities in aluminum and aluminum alloy melt and application

ActiveCN105803215AEvenly dispersedAccelerates the process of adsorbing slag inclusionsPowder mixtureSlag

The invention discloses a multiple-effect composite refining flux for removing impurities in aluminum and aluminum alloy melt. Raw materials of the multiple-effect composite refining flux comprise, by weight, 50%-70% of aluminum fluoride AlF3, 15%-25% of magnesium chloride MgCl2, 2%-10% of sodium borate Na2B4O7 and 1%-15% of potassium chloride KCl2. All the raw materials are dried industrial grade powder products, and the purities of all the raw materials reach 99.5% or above. After the matched raw materials are added into a ball mill for ball milling for 10-15 min, the raw materials are screened through a screen with the meshes being 100-325, and the powder mixture grain size distribution requirements are that 35%-50% of powder with the grain size being 90-125 [mu]m, 20%-25% of powder with the grain size being 60-90 [mu]m, 8%-10% of powder with the grain size being 40-60 [mu]m, and 35%-50% of powder with the grain size being smaller than or equal to 40 [mu]m. The prepared flux is packaged in a sealed mode for standby application after inspection. The multiple-effect composite refining flux provided by the invention has the good capacity for removing the metal impurities and oxide inclusion, the problem that metal impurities in the aluminum and aluminum alloy melt are over standard is solved, and the flux has the better impurity and slag inclusion removing capacity, and has the multiple effects and the multiple purposes.

Owner:广元中孚高精铝材有限公司

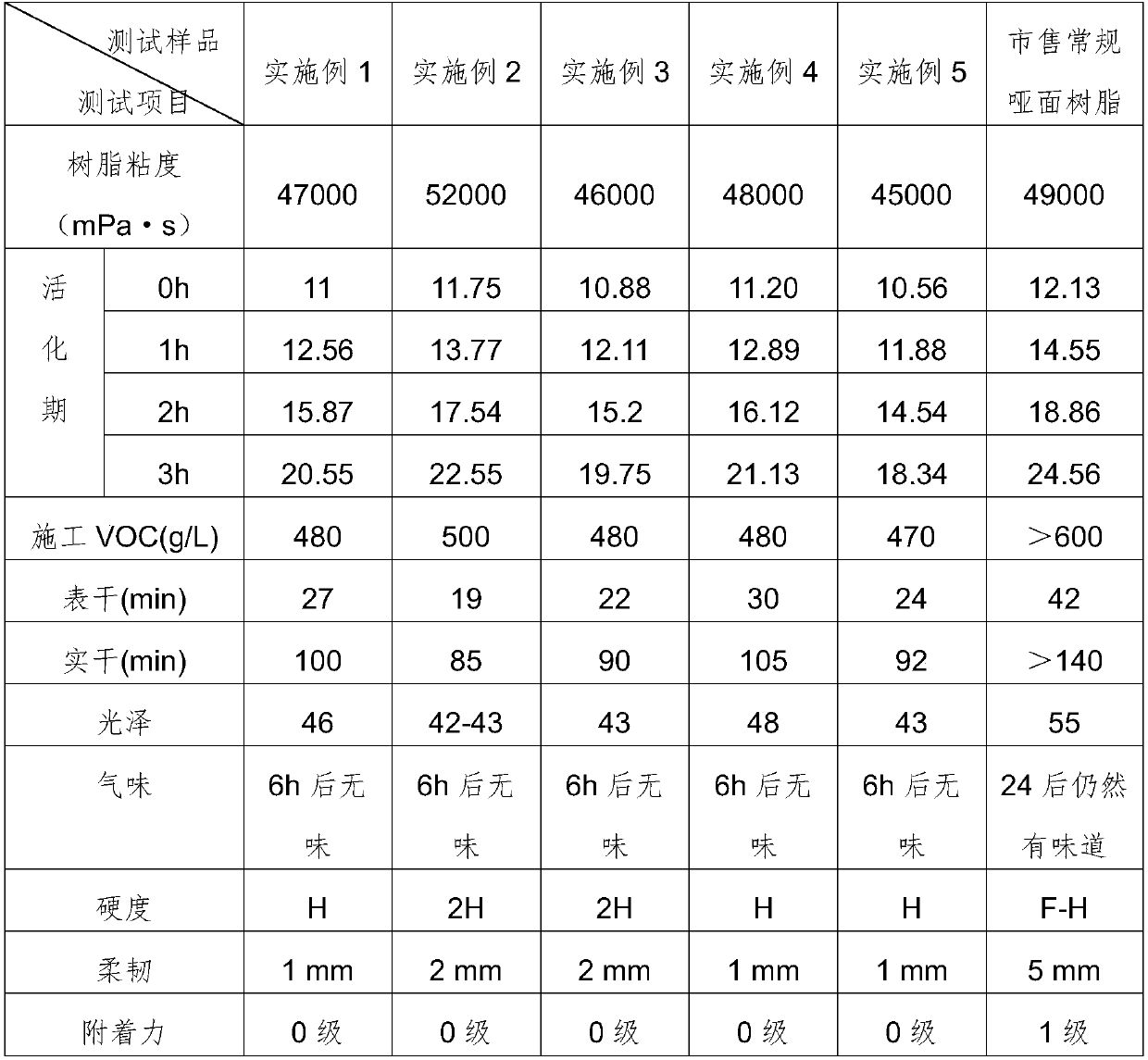

Preparation method of odor-less fast-dry alkyd resin

The invention relates to the field of alkyd resin, in particular to a preparation method of odor-less fast-dry alkyd resin. The odor-less fast-dry alkyd resin comprises, by weight, 9-15 parts of fattyacid, 5-12 parts of castor oil, 20-28 parts of polyhydric alcohols, 24-33 parts of organic acid, 2-5 parts of reflux solvents, 0.05-0.2 part of antioxidant additives and 23-27 parts of diluting solvents. The preparation methods includes: by a step-by-step feeding method, subjecting fatty acid, a part of organic acid and a part of polyhydric alcohols to esterification reaction, and adding in castor oil, the rest organic acid and the rest polyhydric alcohols to perform esterification reaction, so as to obtain the odor-less fast-dry alkyd resin. The alkyd resin has the advantages of fast drying,high solvent release property, less odor, high hardness, scratch resistance and the like, further has excellent flexibility without adding of other flexible resin and accordingly can improve production efficiency and have high competitiveness in application of modern furniture factories.

Owner:ANHUI SKSHU PAINT CO LTD

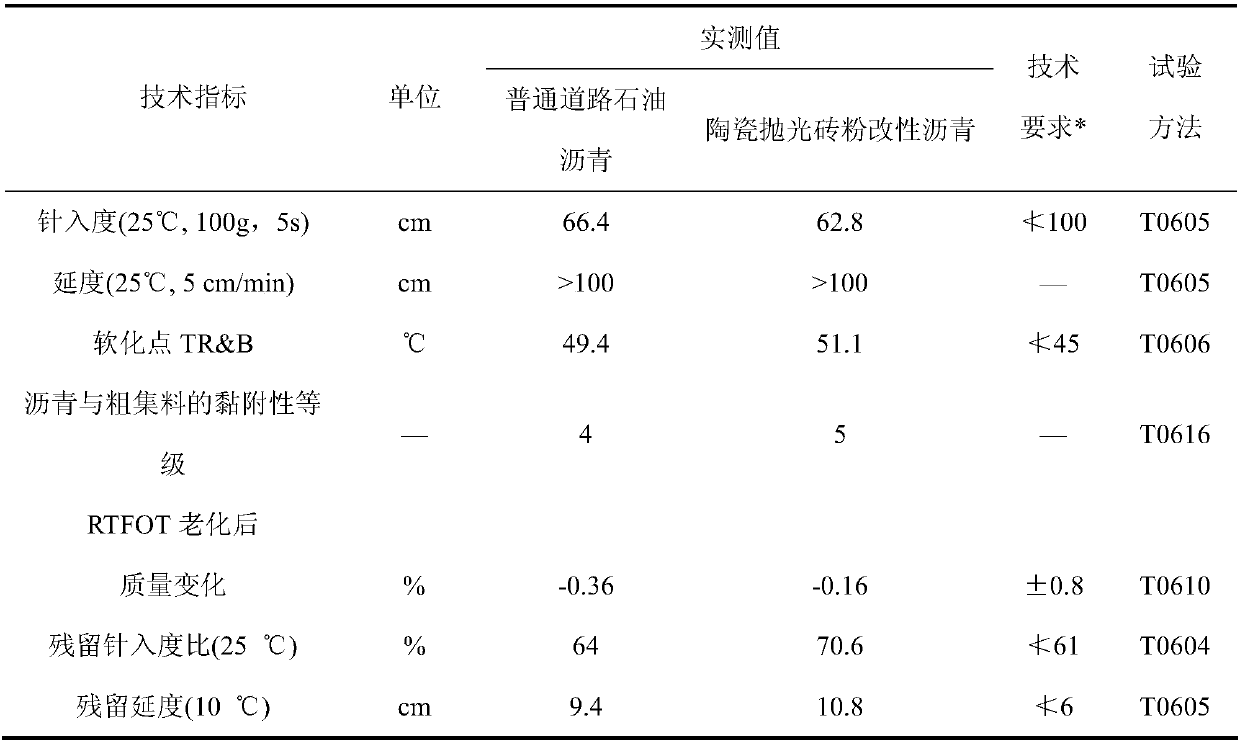

Ceramic-polished-tile-powder-modified asphalt made from industrial waste residue and preparation method of modified asphalt

The invention discloses ceramic-polished-tile-powder-modified asphalt made from industrial waste residue and a preparation method of modified asphalt. The method comprises drying ceramic polished waste residue, performing grinding and screening to obtain ceramic polished tile powder, performing surface modification to the ceramic polished tile powder with a silane coupling agent solution to obtainsurface-modified ceramic polished tile powder, mixing the surface-modified ceramic polished tile powder with common road asphalt, and performing heating melting, shearing stirring and delaying curingto make modified asphalt. Compared with common road asphalt, the modified asphalt has no obvious change in penetration, ductility and softening point, while has improved adhesion performance with aggregates, and is obviously improved in residual penetration and residual ductility, so that the road performance is obviously improved. Ceramic industrial solid waste is fully utilized, and pollution of the waste to the environment is greatly reduced. The preparation method is simple in process, stable in product quality, can be widely applied to laying of multiple grades of roads and building waterproofness, and has great economic benefit and social benefit.

Owner:HUNAN UNIV OF SCI & TECH

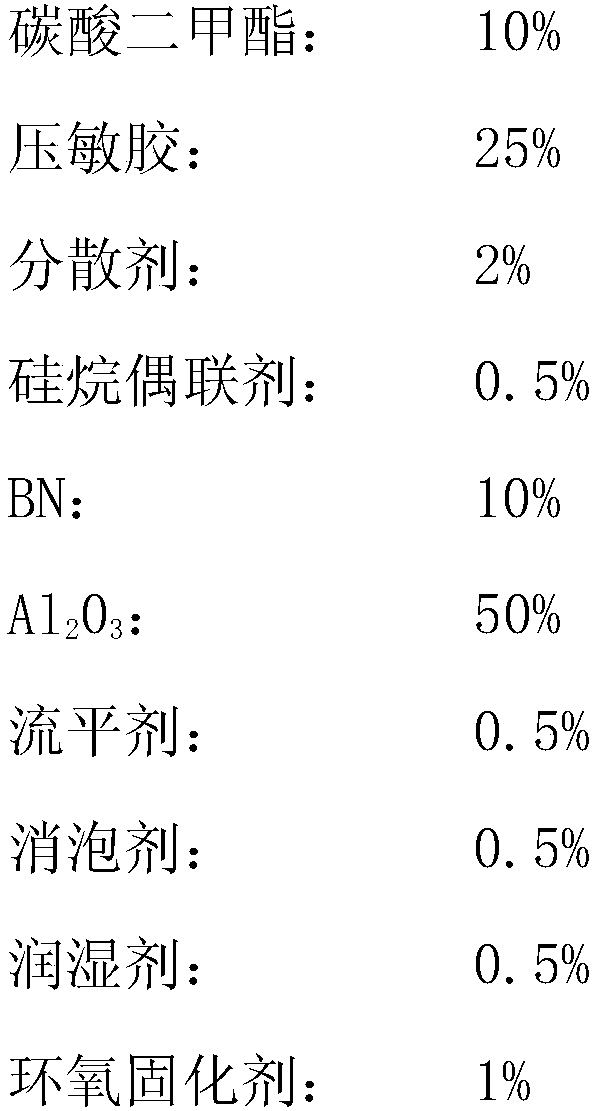

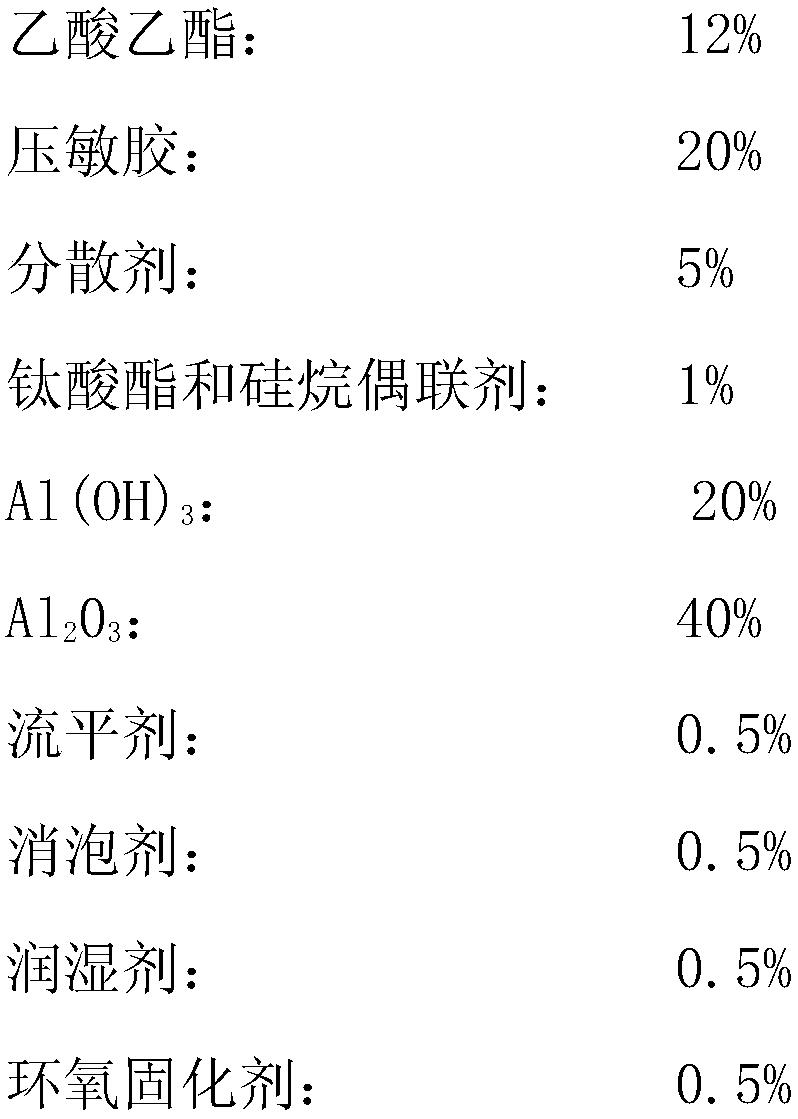

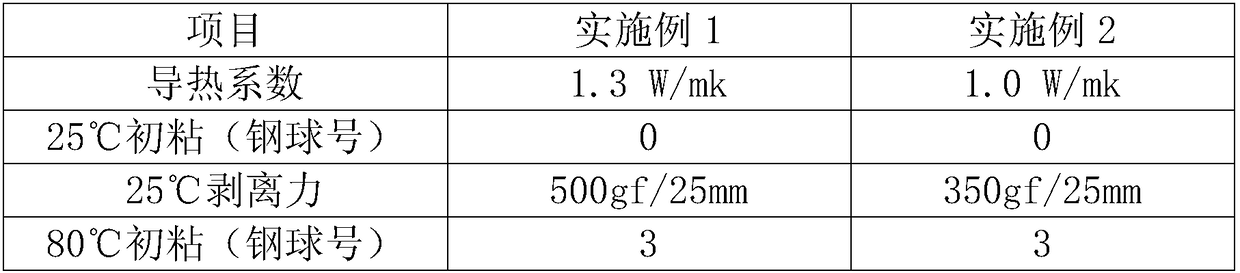

Preparation method of heat conducting glue with low viscosity and high thermal conductivity

InactiveCN108300373AIncrease stickinessGood repeatabilityNon-macromolecular adhesive additivesPressure sensitive film/foil adhesivesPolymer scienceFilling materials

The invention relates to a preparation method of a heat conducting glue with low viscosity and high thermal conductivity. The preparation method comprises following steps: weighing a dispersant and acoupling agent, adding a solvent to dilute the mixture, adding a heat conducting filling material, mixing the mixture for 2 minutes by a homogenizer; adding a pressure sensitive glue, mixing the mixture for 2 minutes by the homogenizer; adding an auxiliary agent, mixing the mixture for 1 minute by the homogenizer; adding a curing agent, mixing the mixture for 1 minute by the homogenizer; paintingthe mixture on two sides of a base material, and carrying out curing and drying to obtain the heat conducting glue. The heat conducting glue is made of different heat conducting filling materials, isprepared by a special technology, has a multilayer structure and low viscosity at a room temperature, can be repeatedly laminated, does not generate any residue, can be repeatedly used, and has excellent viscosity and heat conductivity at a high temperature, and the operability and high heat conductivity are perfectly combined.

Owner:SUZHOU ENBRIGHTECH

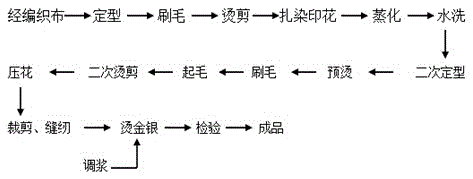

Gold-silver stamping process of gold stamping blanket

InactiveCN105648805AGood viscosityGood sizing rateOrnamental textile articlesPattern makingStamping processEngineering

The invention discloses a gold-silver stamping process of a gold stamping blanket, comprising the following main production steps: weaving warp knitted single cloth, high temperature setting, brushing, ironing and shearing, printing, ageing, washing, setting, high temperature pre-ironing, brushing, fuzzing, high temperature ironing and shearing, knurling, tailoring and sewing, thus obtaining a finished blanket. According to the gold-silver stamping process, pure color is adopted in printing, the influence of a multi-color pattern to gold-silver stamping powder is avoided, and the gold-silver stamping effect is good.

Owner:JIANGSU KINGDAY TEXTILE CO LTD

Casting alcohol-based coating

InactiveCN108817311AGood viscosityHigh viscosityFoundry mouldsFoundry coresLeveling effectMetallurgy

The invention discloses a casting alcohol-based coating which comprises, by weight, 10-25 parts of a refractory aggregate, 50-60 parts of a carrier, 2-7 parts of a binder, 10-15 parts of a suspensionagent, and 8-49 parts of additives. The casting alcohol-based coating has high viscosity, brush-ability, anti-sagging effect, leveling effect, permeability, suspensibility, coatability and thixotropy.

Owner:江苏赫芝电气有限公司

Composite salt-resistant thickening agent, and preparation method and application thereof

The invention discloses a composite salt-resistant thickening agent, which belongs to the field of daily chemicals. The composite salt-resistant thickening agent consists of xanthan gum, guar gum and sodium alginate, wherein the weight ratio of the xanthan gum to the guar gum to the sodium alginate is (5-8):(2-5):(1-3); and the composite salt-resistant thickening agent is prepared by the following steps of: dissolving the xanthan gum, the guar gum and the sodium alginate into water in turn; stirring and uniformly mixing; adjusting to the concentration for use by using water; and adjusting pH value to be 6 to 8; and heating at the temperature of between 50 and 80 DEG C for 10 to 60 minutes. The amount of the used thickening agent is 0.01 to 1.0 percent of the weight of the salt-containing daily chemical. The composite salt-resistant thickening agent has acid and alkali resistance, high temperature resistance, anti-freezing effect and does not have toxic or side effect, is excellently matched with a common surfactant (such as sodium alcohol ether sulfate AES, sodium ammonium dodecyl sulfate K12A and the like) in the daily chemical and has the advantages of simple manufacturing process, low technological condition and low comprehensive cost.

Owner:自贡市轻工业设计研究院有限责任公司 +1

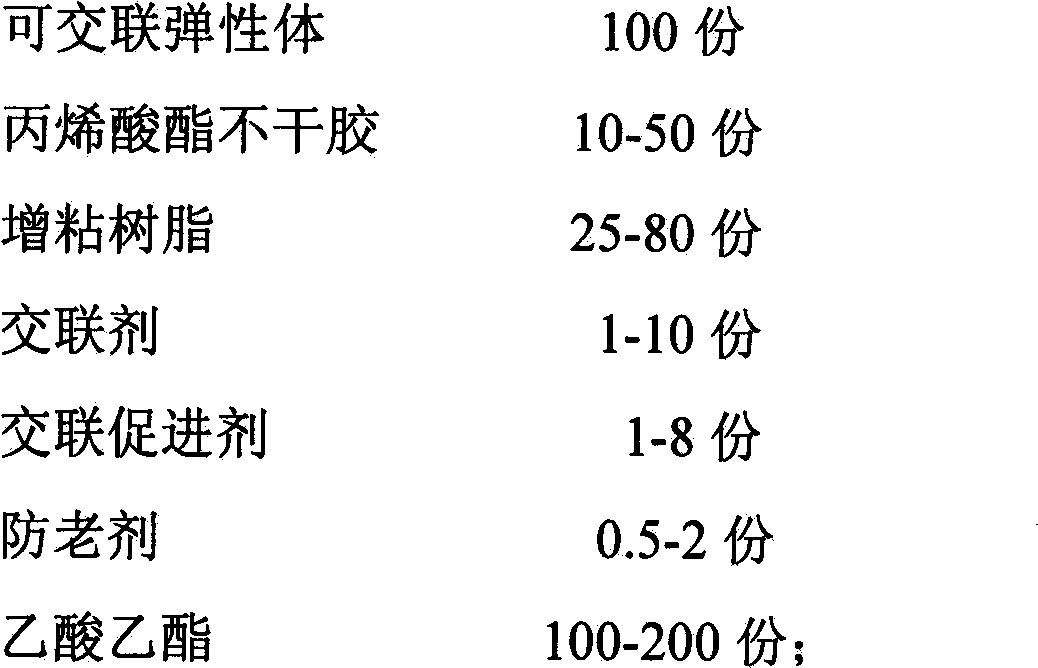

Fiber surface PE protective film pressure sensitive adhesive and preparation method thereof

InactiveCN101575485AGood viscosityReduce the amount of coatingEster polymer adhesivesSolventPressure sensitive

The invention discloses a fiber surface PE protective film pressure sensitive adhesive, which is prepared from the following raw materials by mass portion: 30 to 38 portions of acrylic acid 2-ethylhexyl acrylate, 0 to 4 portions of vinyl acetate, 0.4 to 2 portions of hydroxy-ethyl acrylate, 1.6 to 4 portions of acrylic acid and 55 to 60 portions of solvent. The PE protective film pressure sensitive adhesive prepared by the process is good in viscosity, can achieve a pressure sensitive effect by coating in a small amount during use, avoids PE thin film protruding and winding during drying due to small coated amount and prevents residual adhesive on a protected surface when the protective film is stripped, thereby being widely used for the manufacturing of PE protective films.

Owner:广东华丽宝实业有限公司

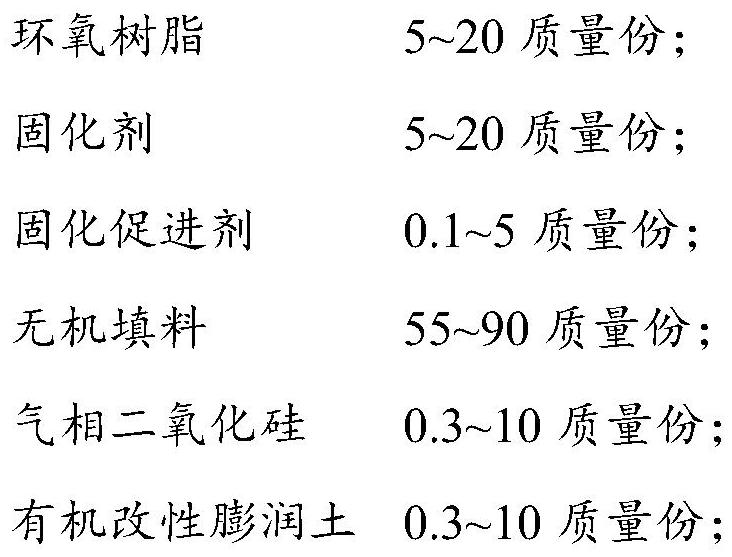

Single-component dam material composition and preparation method thereof

ActiveCN111635723AIncrease aspect ratioGood viscosityNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsFirming agentPolymer chemistry

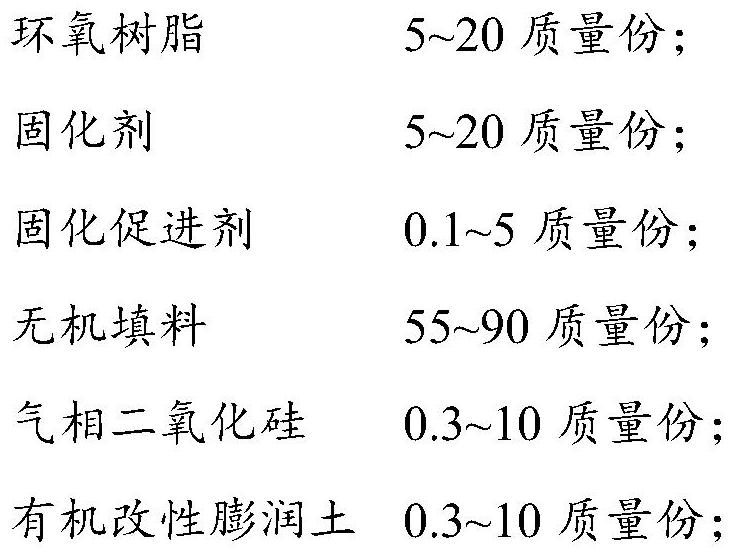

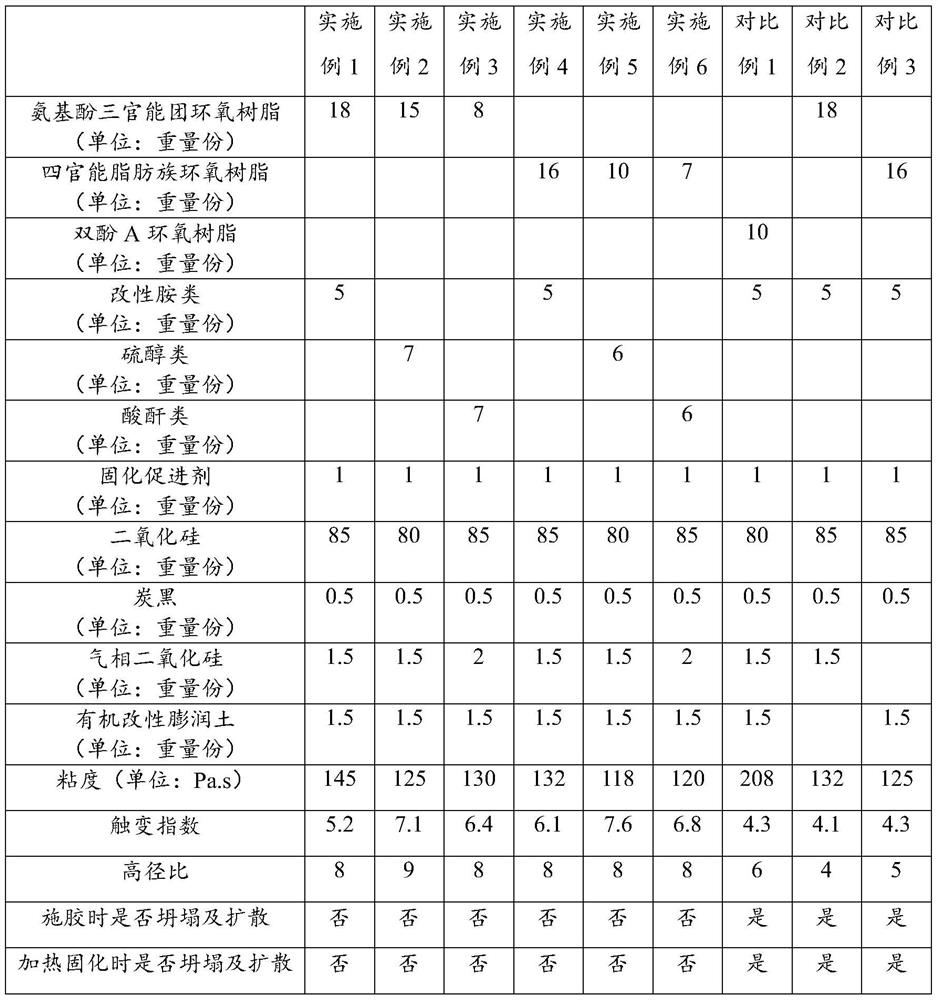

The invention discloses a single-component dam material composition and a preparation method thereof. The single-component dam material composition comprises the following components in parts by mass:5-20 parts of epoxy resin, 5-20 parts of a curing agent, 0.1-5 parts of a curing accelerator, 55-90 parts of an inorganic filler, 0.3-10 parts of fumed silica and 0.3-10 parts of organic modified bentonite, wherein the epoxy resin is one or more of aminophenol trifunctional epoxy resin or tetrafunctional aliphatic epoxy resin. According to the invention, with the combination of aminophenol trifunctional epoxy resin or tetrafunctional aliphatic epoxy resin, fumed silica and organic modified bentonite, the height-diameter ratio and thixotropy are significantly improved, the viscosity under highshearing force is maintained, the sizing is easy, and the dam material does not collapse and diffuse during sizing and heating curing.

Owner:WUHAN CHOICE TECH CO LTD

High-performance concrete and preparation method thereof

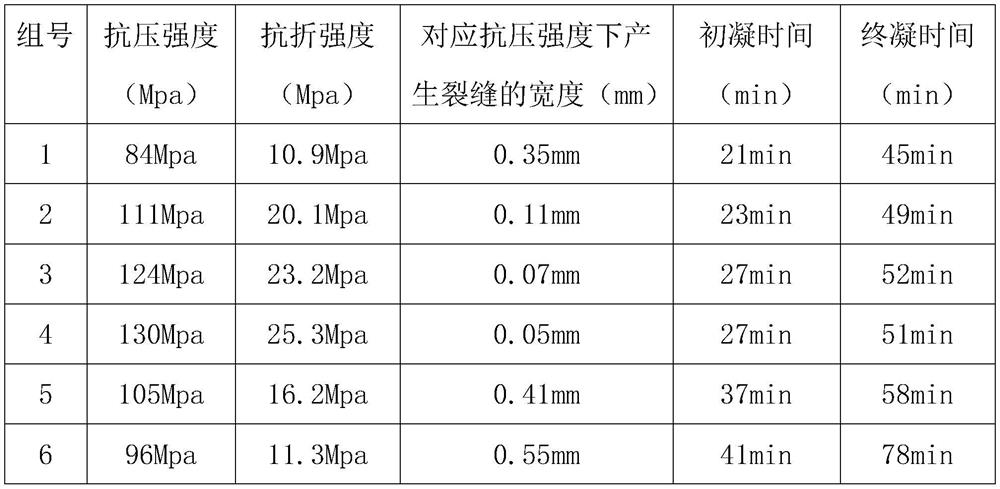

PendingCN111925164ANot easy to toughen fiber agglomerationGood viscosityHydroxypropylmethyl celluloseRiver sand

The invention discloses a high-performance concrete, which comprises a gel material, aggregate, an additive, toughening fibers and mixing water. The gel material comprises Portland cement, fly ash andsilica fume, the aggregate comprises fine river sand, ISO standard sand and quartz sand, and the additive comprises a polycarboxylate water reducer and hydroxypropyl methyl cellulose. The tougheningfibers comprise PVA chopped fibers and PP fibers, and the mass of the toughening fibers does not exceed 3% of the mass of the gel material. The mass ratio of the mixing water to the gel material is less than 0.3. The invention further discloses a preparation method of the high-performance concrete. The adding of the toughening fibers is before the adding of the aggregate so that the toughening fibers are effectively dispersed. The mixing water is added at different stages so that the dispersion and dissipation efficiency of the toughening fibers is improved; and after the toughening fibers areadded, the polycarboxylate water reducer is added, water is added at different stages, more free water can be released, and the workability of the whole stirring process is better.

Owner:GUANGDONG CONSTR VOCATIONAL TECH INST

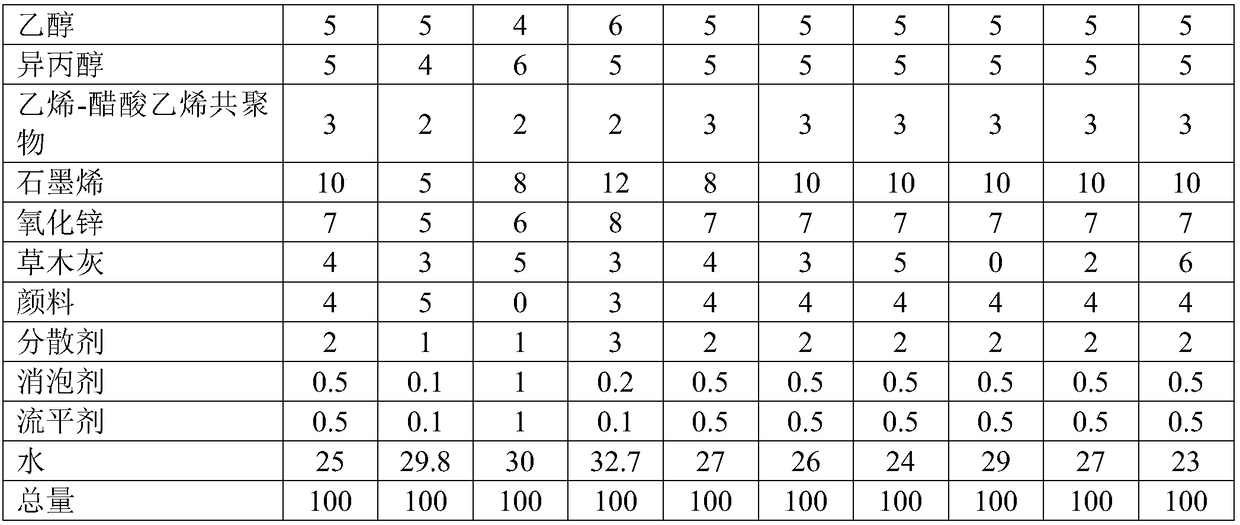

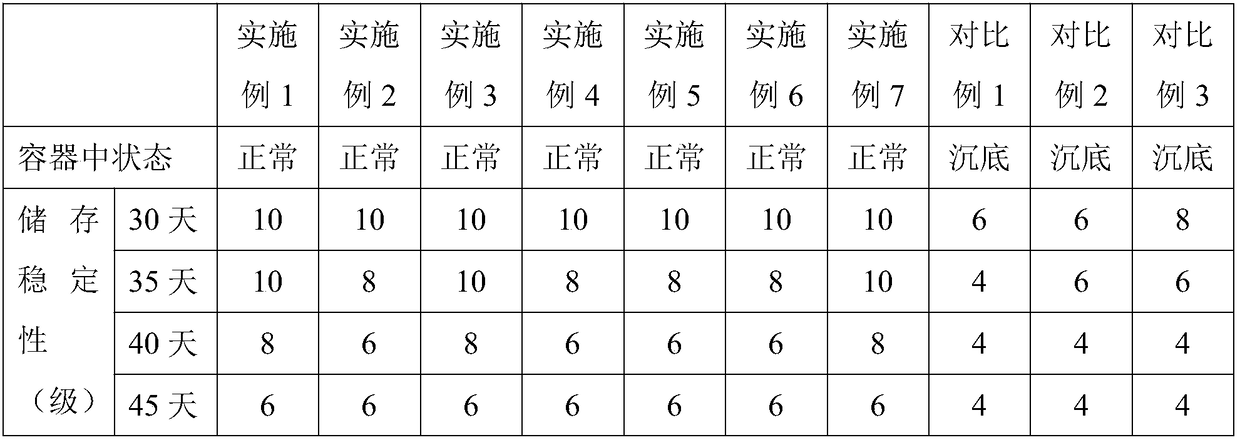

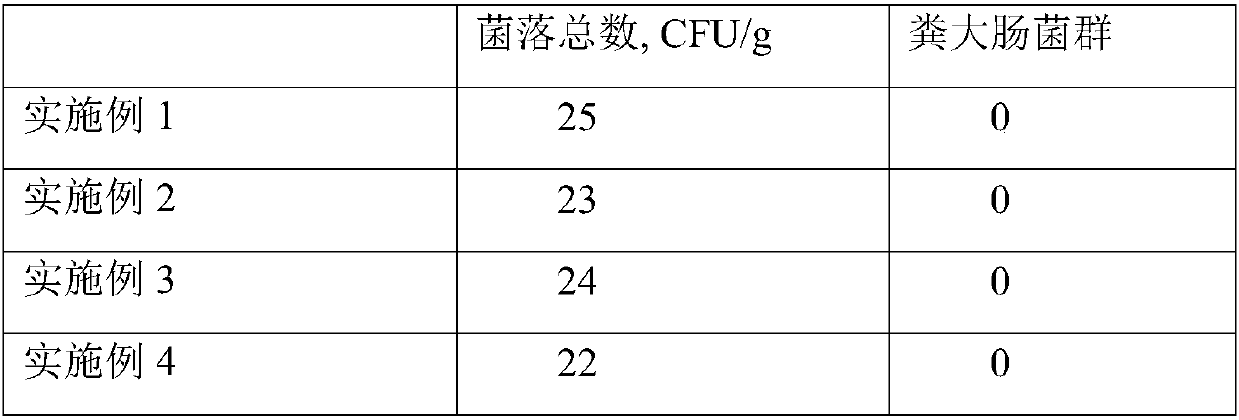

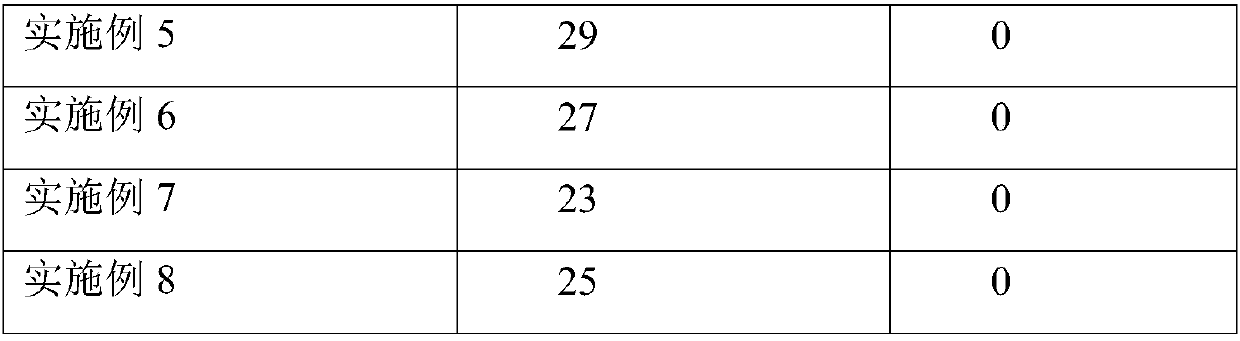

Graphene zinc oxide conductive coating

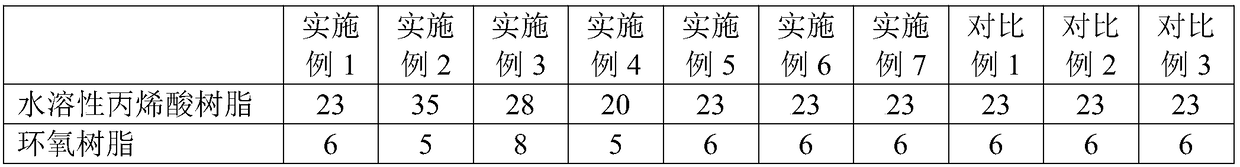

InactiveCN108912787AGood viscosityGuaranteed uniformityEpoxy resin coatingsElectrically-conductive paintsRice strawWater soluble

The invention discloses a graphene zinc oxide conductive coating including the following components by the mass percentage: 20%-35% of water-soluble acrylic resin, 5%-8% of epoxy resin, 4%-6% of ethanol, 4%-6% of isopropanol, 2%-3% of an ethylene-vinyl acetate copolymer, 5%-12% of graphene, 5%-8% of zinc oxide, 3%-5% of rice straw plant ash, 0%-5% of a pigment, 1.0%-3.0% of a dispersant, 0.1%-1.0%of a defoamer, 0.1%-1.0% of leveling agent, and 25%-40% of water. The rice straw plant ash is prepared by completely burning sun-dried rice straw and removing water-soluble salts. A specific contentof rice straw plant ash is added to a graphene zinc oxide conductive coating, and the prepared graphene zinc oxide conductive coating has the advantages of good storage stability and long shelf life and can keep good electrical conductivity.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

Antibacterial and anti-inflammatory hand sanitizer for recycling traditional Chinese medicine dregs

InactiveCN109939036AGood viscosityGood foamingAntibacterial agentsCosmetic preparationsAnti-inflammatoryZanthoxylum dissitum

The invention discloses an antibacterial and anti-inflammatory hand sanitizer for recycling traditional Chinese medicine dregs. The antibacterial and anti-inflammatory hand sanitizer is prepared withthe traditional Chinese medicine dregs, sodium lauryl sulfate, deionized water, sodium lauroyl glutamate, cocamidopropyl betaine, potassium sorbate, citric acid and sacha inchi oil as raw materials and with the assistance of an appropriate quantity of auxiliary materials; the traditional Chinese medicine dregs are remaining dregs obtained after extraction of one or more of radix flemingiae, radixrosa laevigata, caulis spatholobi, zanthoxylum dissitum, leatherleaf mahonia, herba andrographitis, radix angelicae sinensis and radix codcnopsitis pilosulas. The antibacterial and anti-inflammatory hand sanitizer has good viscosity and foamability, high defouling performance, good washability and the antibacterial, anti-inflammatory and skin-care effects; a preparation method of the antibacterialand anti-inflammatory hand sanitizer is convenient to operate, and the hand sanitizer has broad application prospects.

Owner:ZHUZHOU QIANJIN PHARMA

Glue formula

InactiveCN107793962AGood viscosityHigh viscosityNon-macromolecular adhesive additivesChemistryPolyvinyl alcohol

The present invention is a glue formula. The raw materials in the formula are composed by weight percentage: 18-20% formaldehyde, 24-26% polyvinyl alcohol, 28-34% hydrochloric acid, 20-22% sodium hydroxide, 55-55% water 65%, the product prepared by this method is more environmentally friendly and has lower cost.

Owner:徐州市恩矿新材料有限公司

Protective film for electronic screen

InactiveCN110066615AReasonable formulaGood viscosityNon-macromolecular adhesive additivesMacromolecular adhesive additivesACRYLATES COPOLYMEREthyl acetate

The invention discloses a protective film for an electronic screen. The protective film comprises a base material layer, an adhesive layer and a bottom layer; the adhesive layer is prepared from, by weight, 15-20 parts of acrylates copolymer, 10-15 parts of a cross-linking agent, 25-35 parts of ethyl acetate, 12-16 parts of methylbenzene, 6-10 parts of rosin resin, 5-10 parts of glycerin, 4-8 parts of a curing agent, 3-5 parts of sodium silicate and 10-18 parts of a high temperature resistant filler. Accordingly, the formula is reasonable, and the protective film has good viscosity, adhesion force, retention force and initial adhesion of a rolling ball, the product is better used under the occasions at the laminating temperature being 10 DEG C or above, after laminating, an adhesive layercan keep the performance unchanged for a long time under the environment of -20-120 DEG C, deformation such as warping cannot occur, short-term temperature resistance can reach 180 DEG C, and the protective film is widely applied in various baking processes.

Owner:黄德明

Ultrasonic degreasing filming agent used before precision nickel and nickel alloy workpiece spraying coating, and production method thereof

The invention discloses an ultrasonic degreasing filming agent used before precision nickel and nickel alloy workpiece spraying coating. The ultrasonic degreasing filming agent comprises following raw materials, by weight, 6 to 12% of nitric acid, 3 to 6% of nickel nitrate, 3 to 6% of sodium fluoride, 2 to 4% of hexafluorozirconic acid, 1 to 3% of hexafluorotitanic acid, 1 to 2% of phytic acid, 4 to 8% of Y-73 ultrasonic cleaning low-foaming surfactant, 1 to 2% of penetrant JFC, and the balance water. A production method comprises following steps: weighed water is delivered into a reaction vessel; a stirrer is turned on, and rotating speed is controlled to be 120r / min; weighed nitric acid, nickel nitrate, sodium fluoride, hexafluorozirconic acid, hexafluorotitanic acid, phytic acid, Y-73 ultrasonic cleaning low-foaming surfactant, and penetrant JFC are delivered into the reaction vessel successively and slowly, wherein mass concentration of nitric acid is 85%, mass concentration of hexafluorozirconic acid is 50%, mass concentration of hexafluorotitanic acid is 40%, and mass concentration of phytic acid is 50%; stirring is carried out until a transparent solution is obtained; and the transparent solution is collected and packaged.

Owner:DALIAN SANDAAOKE CHEM

Corrugated paper board adhesive

InactiveCN104479589AGood viscosityGood temperature adaptabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesChemistryOrganosilicon

The invention discloses a corrugated paper board adhesive. The corrugated paper board adhesive is prepared from 3-5 parts by weight of diatomite, 2-9 parts by weight of methyl cellulose ether, 6-8 parts by weight of hydrophobic silica, 5-8 parts by weight of sulfated melamine, 2-7 parts by weight of vegetable glue, 4-6 parts by weight of polyurethane, 4-10 parts by weight of organosilicon epoxy resin, 3-6 parts by weight of styrene-butadiene rubber, 1-5 parts by weight of ferrocene, 4-8 parts by weight of nanometer pottery clay, 1-5 parts by weight of an antiager MB, 3-6 parts by mass of alumina silicate, 1-5 parts by weight of fumed silica, 8-11 parts by weight of chloroprene rubber and 4-8 parts by weight of disproportionated rosin. The corrugated paper board adhesive has good viscosity, can well adhere to a paper board and has good temperature adaptability.

Owner:田琳琳

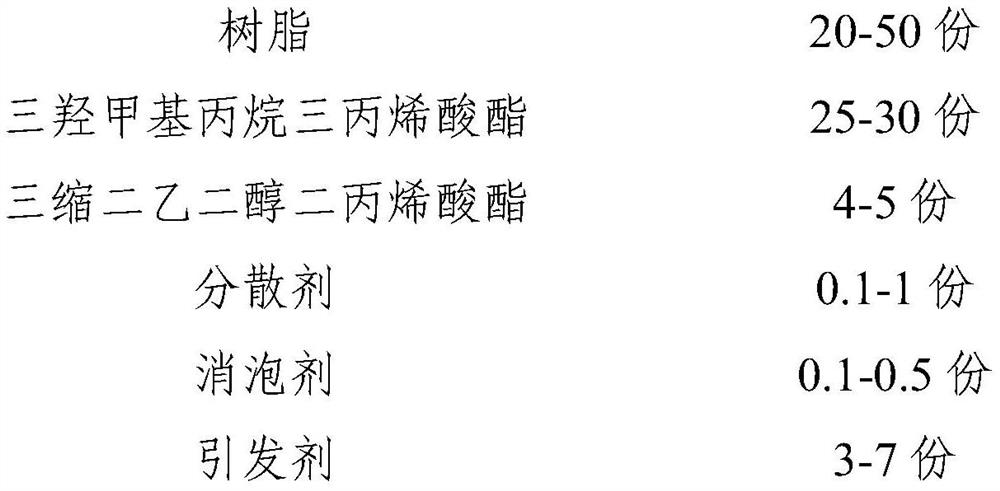

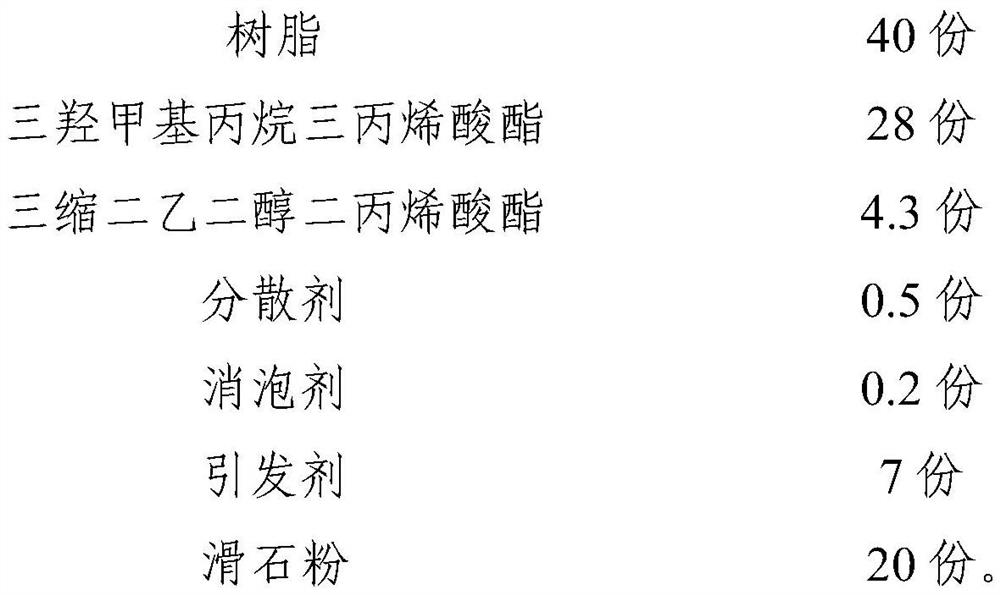

UV light-cured wood coating and preparation method thereof

The invention relates to the field of coatings, in particular to a UV light-cured wood coating and a preparation method thereof. The wood coating comprises the following components in parts by weight: 20-50 parts of resin, 20-40 parts of a monomer and 3-7 parts of an initiator, wherein the resin is epoxy acrylate or modified bisphenol A epoxy acrylate; the monomer is a mixture of trimethylolpropane triacrylate and diethylene glycol diacrylate; the initiator is a mixture of active amine and one or more of TPO, PBZ and OMBB. The wood coating provided by the invention can be cured under UV light, and the wood coating can realize complete odor removal; meanwhile, the wood coating has good viscosity, heat resistance, stability, leveling property and adhesive force, and relatively high curing speed.

Owner:濮阳展辰新材料有限公司

Printing ink for plastic film

The invention discloses printing ink for plastic film. The printing ink is manufactured by the following raw materials in parts by weight: 10-15 parts of waterborne polyurethane resin, 5-6 parts of dimethyl phthalate, 1-2 parts of linseed oil, 2-3 parts of sweet potato powder, 1-2 parts of silicon carbide, 1-2 parts of nanometer bentonite, 1-3 parts of phthalocyanine blue, 1-2 parts of nanometer zinc oxide, 2-5 parts of 2,4-dihydroxy benzoic acid, 2-4 parts of silicone, 3-5 parts of urea, 1-3 parts of terbium nitrate, 2-3 parts of starch sodium ocentyl succinic anhydride, 8-10 parts of sec-butyl acetate, 0.5-1 part of fluorescent powder, 0.5-1 part of microcrystalline wax, 1-2 parts of europium trifluoroacetyl acetone, 1-3 parts of tetrahydrofuran, 10-12 parts of trimethylolpropane triacrylate, 8-10 parts of dipentaerythritol hexaacrylate, 1-1.5 parts of aluminum nitride, 1-2 parts of dibutyltin dilaurate, 1-2 parts of tert-butyl peroxypivalate and 4-5 parts of assistant. Due to the fact that organic substances and inorganic substances are effectively combined, the prepared printing ink is good in fluidity and viscosity, attractive and limpid in color and very good in development prospect.

Owner:ANHUI MEIXIANG PLASTIC

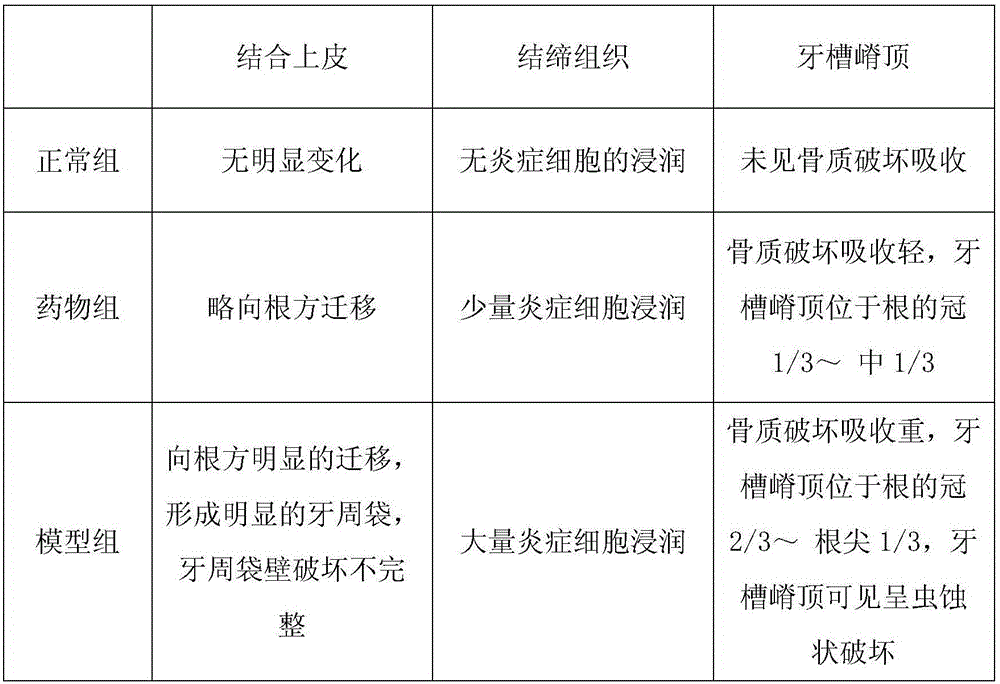

Combined drug for treating periodontitis

InactiveCN105796576AGood viscosityGood liquidityHydroxy compound active ingredientsTetracycline active ingredientsDrugPeriodontitis

The invention discloses a combined drug for treating periodontitis. The combined drug is prepared from, by weight, 1-20 parts of minocycline hydrochloride, 15-100 parts of solanesol and 1,000 parts of glycerol. The combined drug for treating periodontitis is supplemented by an antioxidant drug, so that the curative effect is more remarkable.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

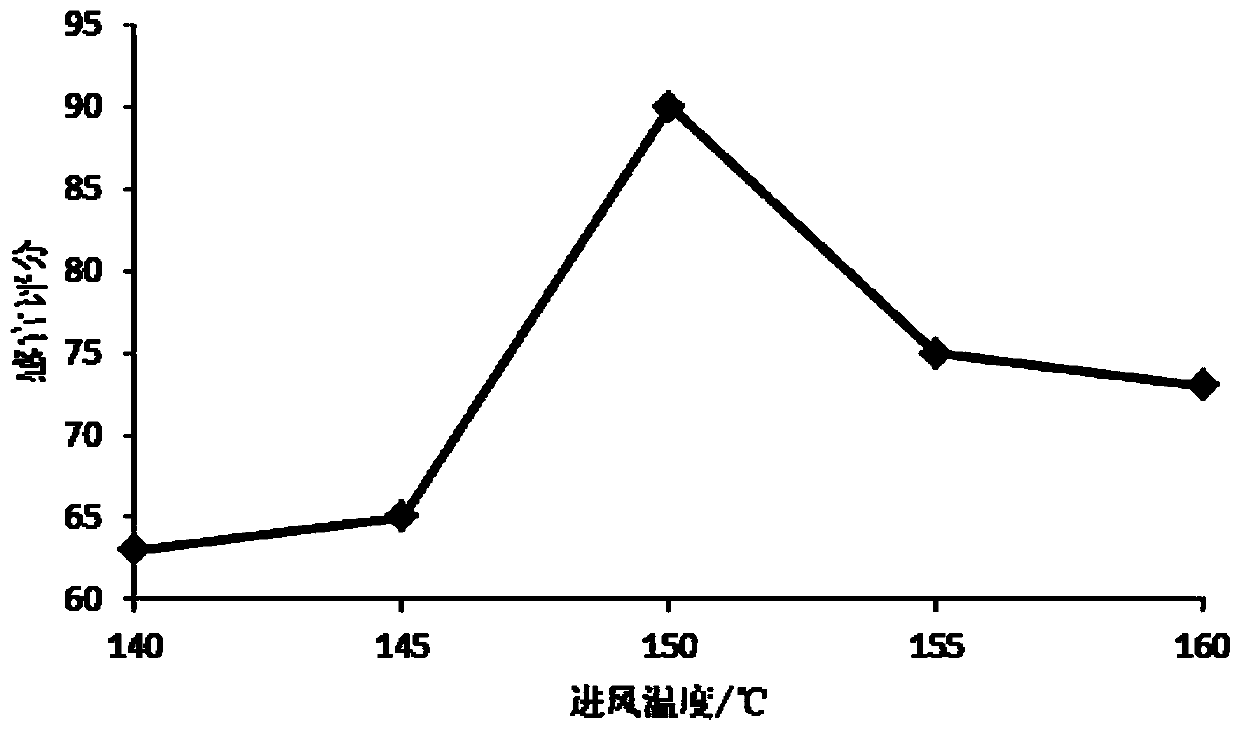

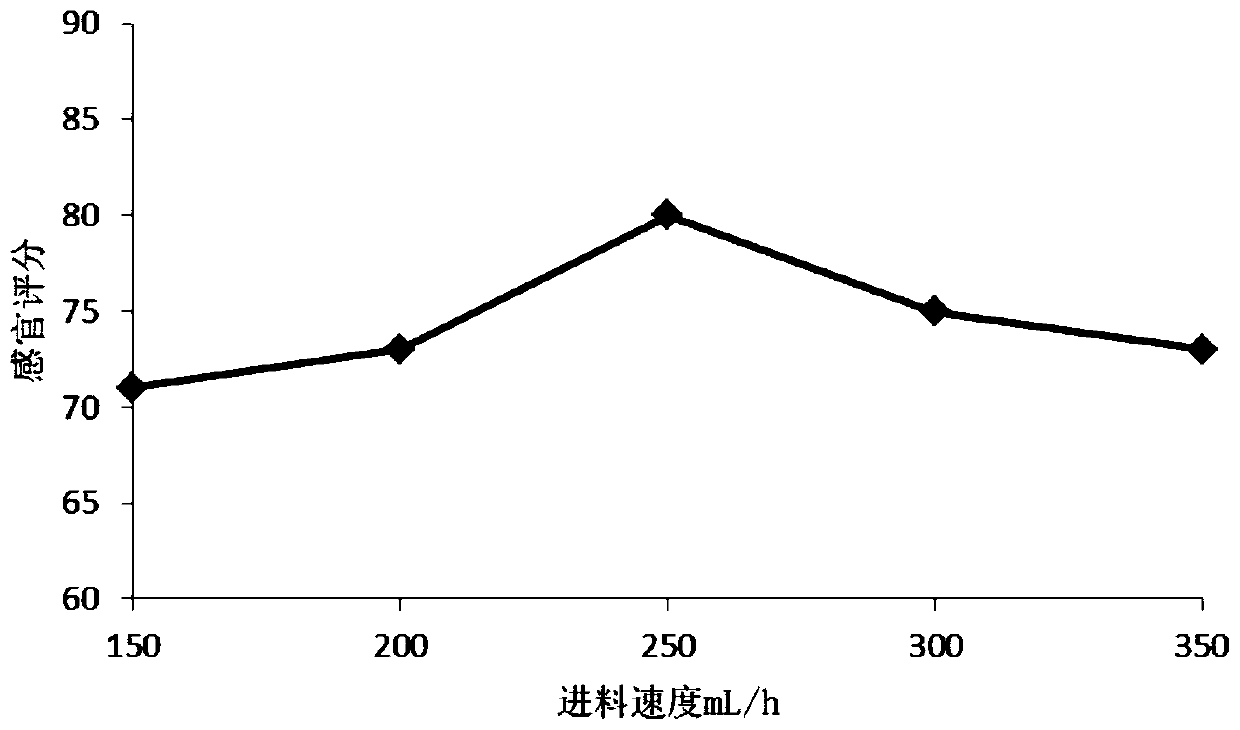

Preparation method for pomegranate flavored yoghurt powder

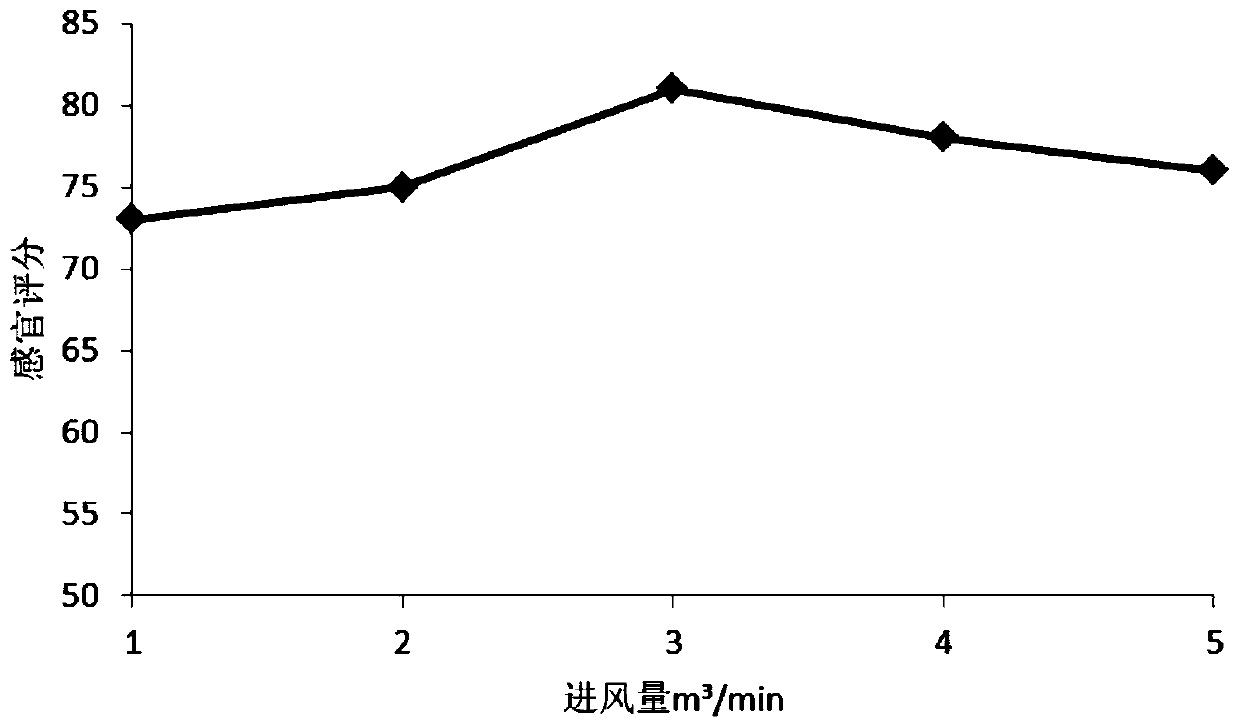

The invention discloses a preparation method for pomegranate flavored yoghurt powder. The preparation method includes the following steps: mixing pomegranate juice and yoghurt with the mass ratio being 1: 5, adding 8.0% of granulated sugar and 0.06% of CMC to uniformly mix so as to obtain pomegranate flavored yoghurt; adding water to dilute the pomegranate flavored yoghurt until solid content is 20%, and then adding 0.02% of carrageenan to uniformly mix so as to form a mixture; putting the mixture into a feeding port of a spray dryer, and performing spray drying to obtain a crude product, wherein the temperature of the air outlet of the spray dryer is set as 70 DEG C, air inlet temperature is 150 DEG C, feeding speed is 250 mL / h and supply air rate is 1-5 m<3> / min; and sieving the crude product with a 300-mesh sieve so as to obtain the pomegranate flavored yoghurt powder. The yoghurt brewed by the pomegranate flavored yoghurt powder prepared by the method is sour and sweet, tasty, anddelicate in taste, and has an appropriate amount of pomegranate fruit fragrance; and the method is simple in preparation.

Owner:BENGBU COLLEGE

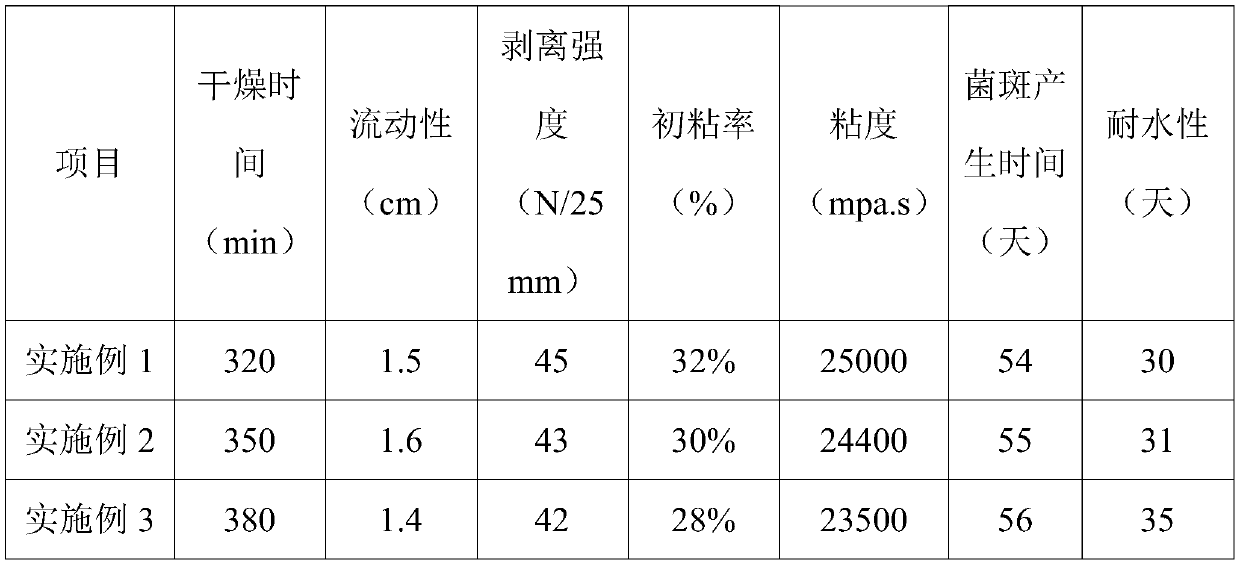

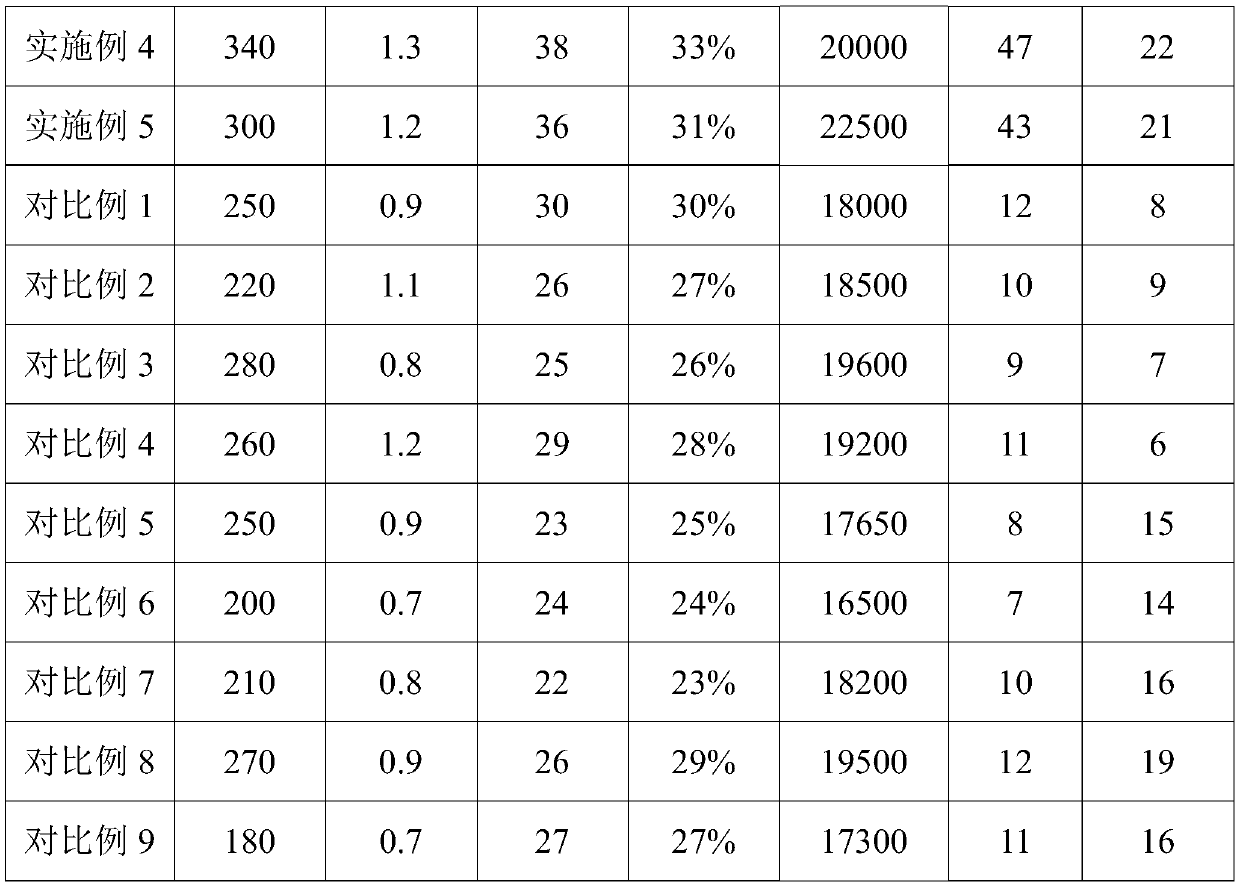

Wall cloth glutinous adhesive powder, and preparation method and application thereof

InactiveCN110527488APromote expansionHigh transparencyMacromolecular adhesive additivesFreeze thawingCross-link

The invention provides a wall cloth glutinous adhesive powder. The wall cloth glutinous adhesive powder is prepared from the following raw materials in parts by weight: 90 to 110 parts of waxy corn starch, 2.5 to 5 parts of an ionic alkali, 0.1 to 0.2 part of a cross-linking agent, 1 to 5 parts of an oxidant, 30 to 40 parts of sodium polyacrylate, 5 to 15 parts of polyvinylamine, 0.01 to 0.05 partof a mildew preventive and 60 to 80 parts of water. The wall cloth glutinous adhesive powder has the advantages of high viscosity, proper initial viscosity, good freeze-thaw property, fluidity and waterproofness, and is convenient for glue applying and wall cloth moving and adjusting.

Owner:江门市环瀛实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com