Single-component dam material composition and preparation method thereof

A composition, one-component technology, applied in the direction of adhesive types, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of colloid collapse and diffusion, and achieve easy viscosity and high aspect ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

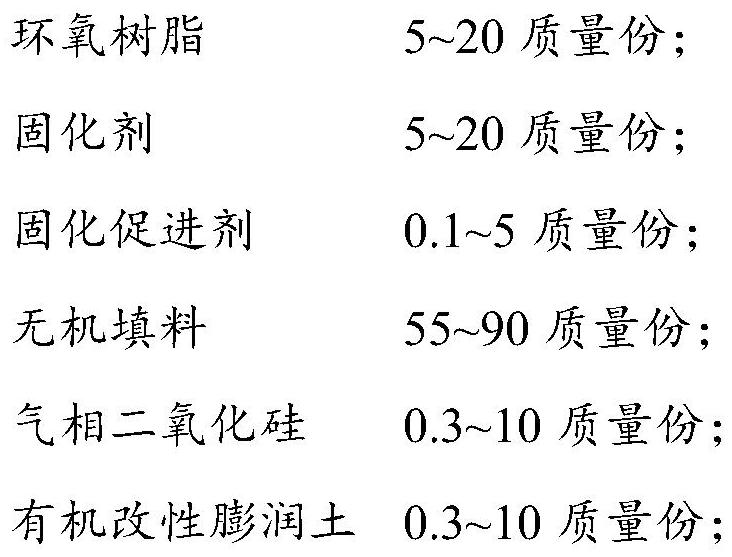

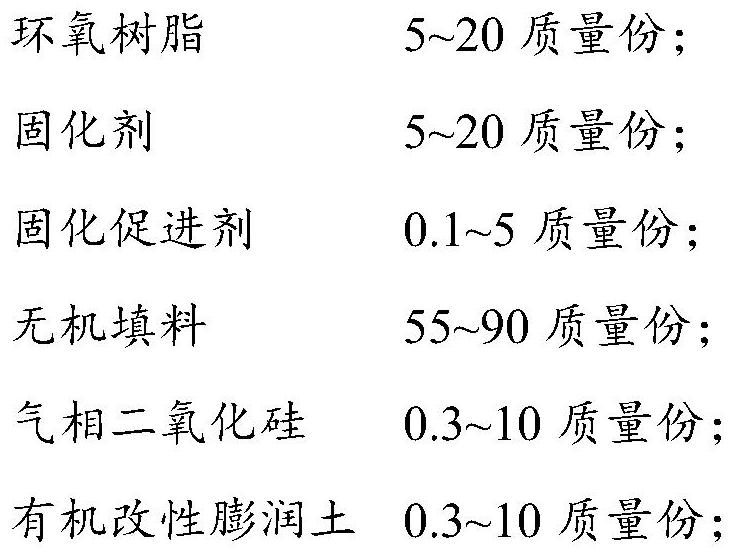

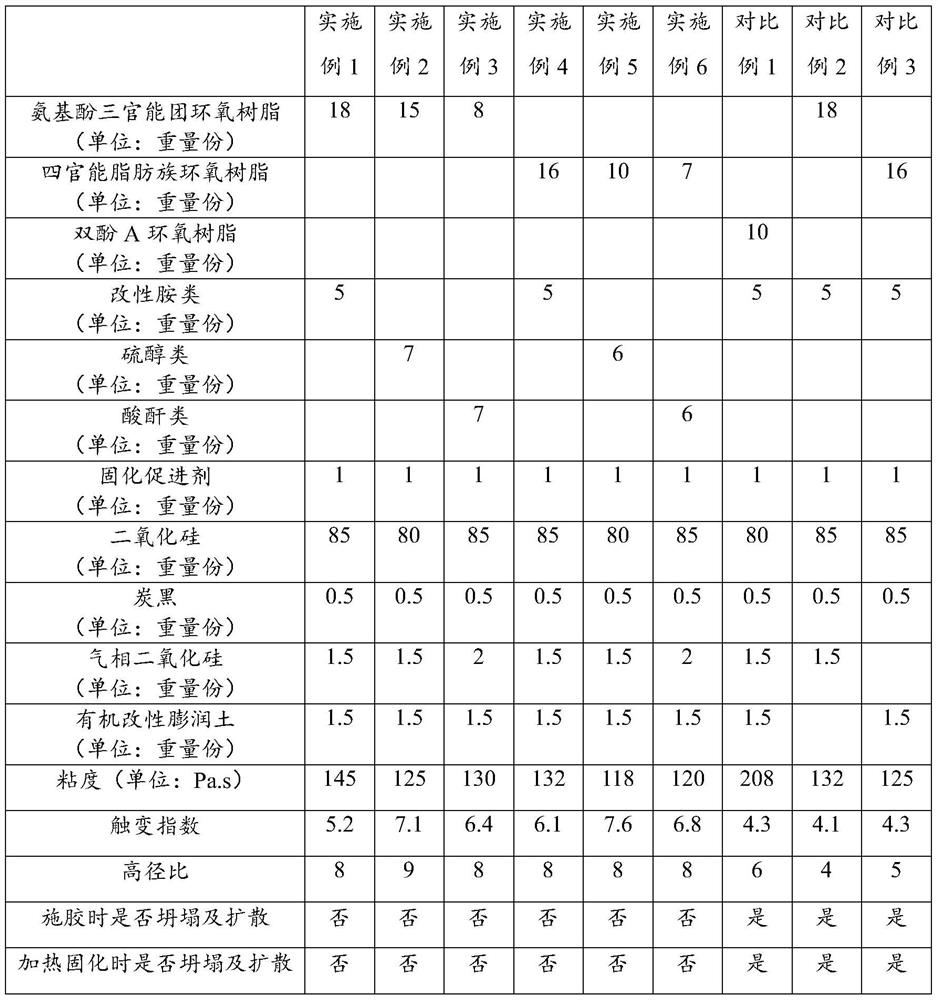

[0020] The one-component dam material composition provided by the present invention includes 5-20 parts by mass of epoxy resin, 5-20 parts by mass of curing agent, 0.1-5 parts by mass of curing accelerator, and 55-90 parts by mass of inorganic filler , 0.3-10 parts by mass of fumed silica, 0.3-10 parts by mass of organically modified bentonite; as required, it may also include colorants such as carbon black. Wherein, the weight part of the curing agent is preferably 5-10, and the weight parts of the fumed silica and the organically modified bentonite are both preferably 0.3-3.

[0021] Epoxy resin is used as the main resin. Generally, one of bisphenol A epoxy resin, bisphenol F epoxy resin, biphenyl epoxy resin, aminophenol trifunctional epoxy resin, and tetrafunctional aliphatic epoxy resin can be selected. or more, preferably one or more of aminophenol trifunctional epoxy resins and tetrafunctional aliphatic epoxy resins. The chemical structural formula of aminophenol trifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com