Manufacturing method and structure of fin field-effect transistor (FinFET) device

A manufacturing method and device technology, which can be used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as the inability of FinFET devices to meet the requirements, and achieve the effects of simple manufacturing process, increased aspect ratio, and improved driving current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The manufacturing method of the FinFET device proposed by the present invention will be further described in detail below with reference to the drawings and specific embodiments.

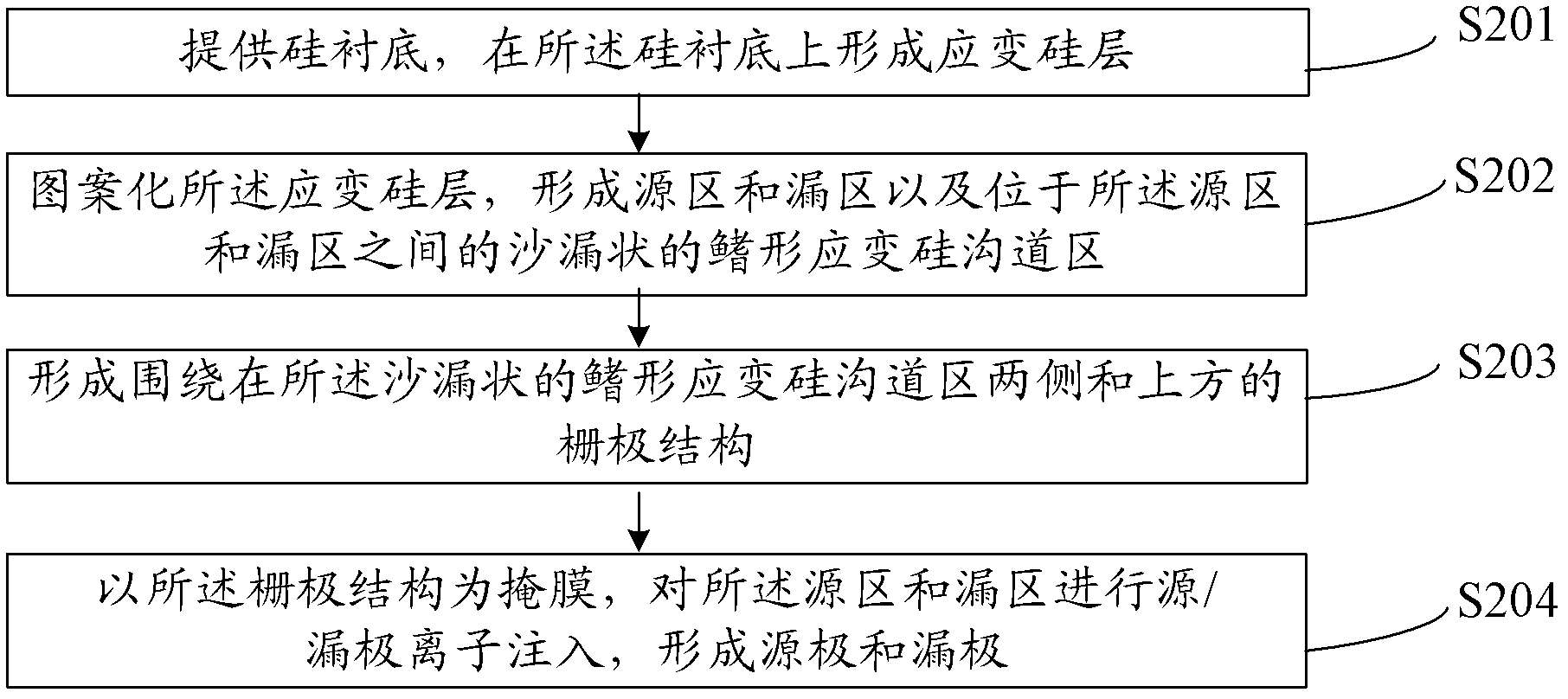

[0024] Such as figure 2 As shown, the present invention proposes a manufacturing method of a FinFET device, comprising:

[0025] S201, providing a silicon substrate, and forming a strained silicon layer on the silicon substrate;

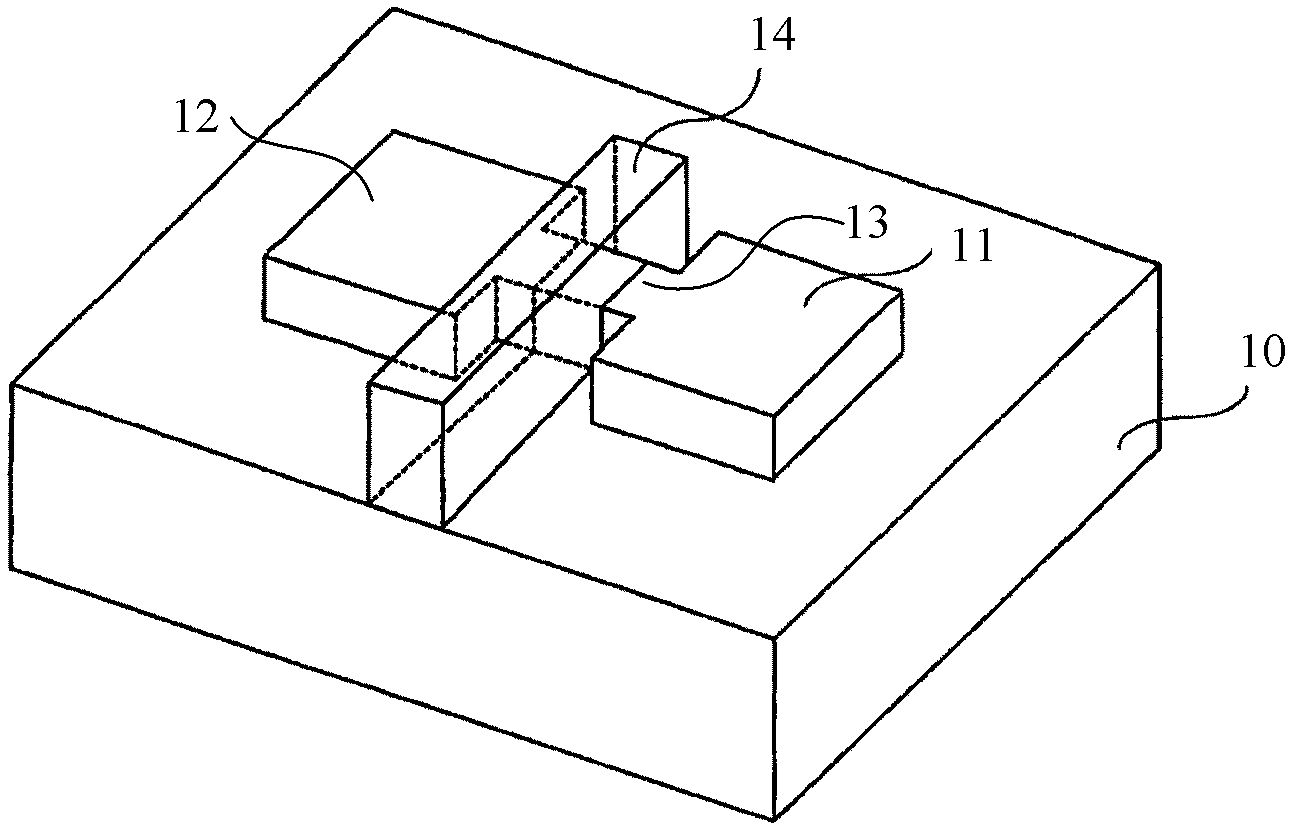

[0026] S202, patterning the strained silicon layer to form a source region and a drain region and an hourglass-shaped fin-shaped strained silicon channel region between the source region and the drain region;

[0027] S203, forming gate structures surrounding and above the hourglass-shaped fin-shaped strained silicon channel region;

[0028] S204. Using the gate structure as a mask, perform source / drain ion implantation on the source region and the drain region to form a source electrode and a drain electrode.

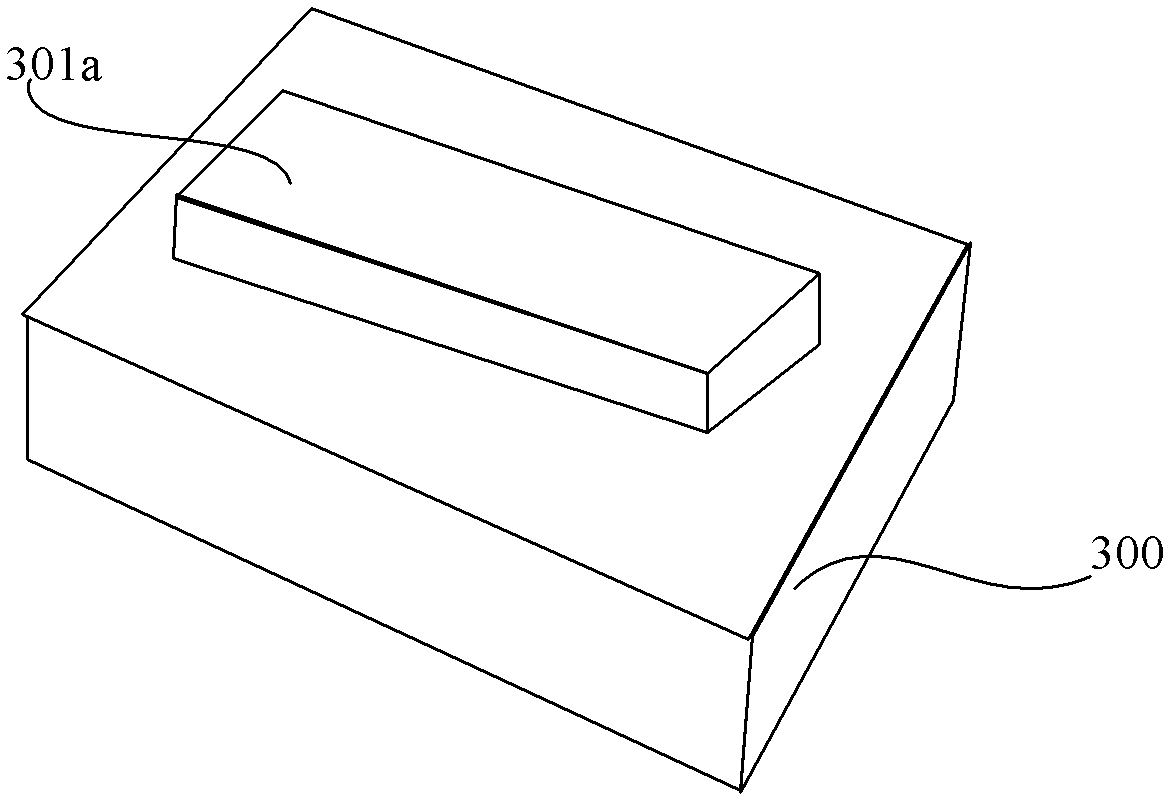

[0029] Attached below Figure 3A-3D right figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com