Conductive paste suitable for high-speed printing

A conductive paste, high-speed printing technology, applied in conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, can solve the problem of affecting the photoelectric conversion efficiency of solar cells, increasing battery series resistance, and poor printing ink permeability and other problems, to achieve the effects of high short-circuit current and conversion efficiency, high surface tension and high temperature viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

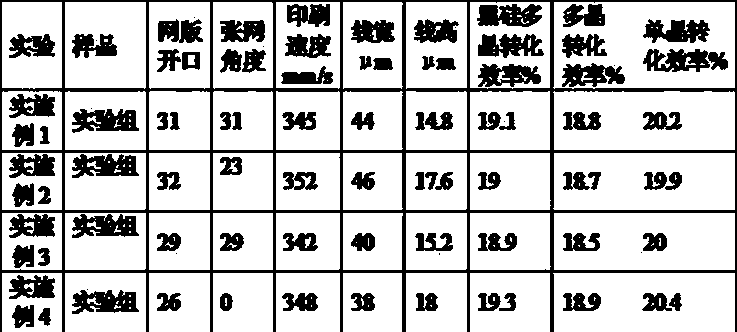

Embodiment 1~4

[0034] Examples 1 to 4: A conductive paste, the conductive paste is composed of the following components by weight:

[0035]

Example 1

Example 2

Example 3

Example 4

75~92 copies of silver powder

78 servings

90 servings

88 servings

82 servings

Organic solvent 5~12 parts

5 servings

8 servings

4.5 servings

6 servings

Organic carrier 2~3 copies

3 copies

2.2 copies

2.6 servings

2.5 servings

Metallic glass-ceramic powder 0.8~5.3 parts

2.8 servings

0.9 copies

3.2 copies

4 parts

0.1~2 parts of thixotropic agent

1.4 copies

0.6 copies

0.9 copies

1.8 servings

[0036] The particle size D50 of the glass microbead powder is 1 to 2 μm;

[0037] Note: Example 1 organic solvent is a mixed solvent formed by terpineol and dimethyl succinate; Example 2 organic solvent is a mixed solvent formed by butyl carbitol and propylene glycol phenyl ether; Example 3 organic solvent is propylene glycol Phenyl ether; Example 4 organic solvent is a mixed solvent formed by terpine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com